Fiber with function of infrared ray absorption, and its preparation method and textile

An infrared and textile technology, applied in the field of fiber materials, can solve the problems of application limitation and expensive textiles, and achieve the effect of obvious color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add gallium-doped zinc oxide powder (the doping amount of gallium is 1.0wt% of the total weight of zinc and gallium) into water for beating and mixing (concentration 25wt%) and add caprolactam (caprolactam) at a temperature of 70°C-80°C ) monomer, wherein the addition amount of gallium-doped zinc oxide powder is 0.5wt% (relative to the total weight of gallium-doped zinc oxide powder and caprolactam monomer). Next, stir at a temperature of 190°C-200°C for 6 hours, then release the pressure (about 30 minutes), then raise the temperature to 230°C-240°C, and keep the temperature under stirring for 18 hours. At this time, the caprolactam monomer Polymerized into polyamide (polyamide). The polyamide compound containing gallium-doped zinc oxide powder is false-twisted into 70d / 24f polyamide by spinning and false-twisting process (spinning temperature 260°C, roll speed 4500m / min, oiling amount 0.5opu) fiber, then woven into a basis weight of 150g / m 2 knitted fabric.

[0027]...

Embodiment 2-4

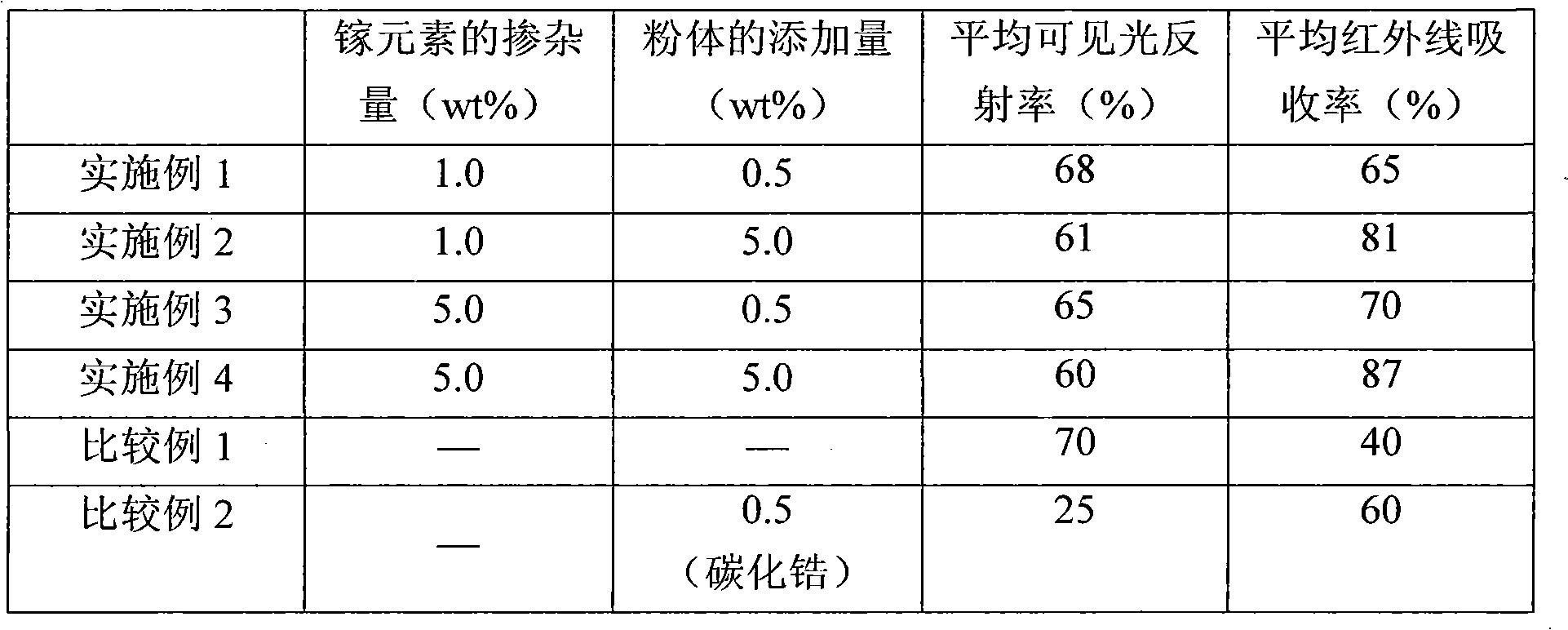

[0029] The preparation method of the knitted fabric of Examples 2-4 is the same as that of Example 1, the difference lies in the doping amount of gallium element and the addition amount of gallium-doped zinc oxide powder, as listed in Table 1.

[0030] Similarly, use the integrating sphere spectrophotometer to test the average reflectance of the knitted fabric of embodiment 2-4 in the visible light wavelength range of 400nm-780nm and the average absorptivity in the infrared wavelength range of 780-2500nm, the results are listed in Table 1 .

Embodiment 5

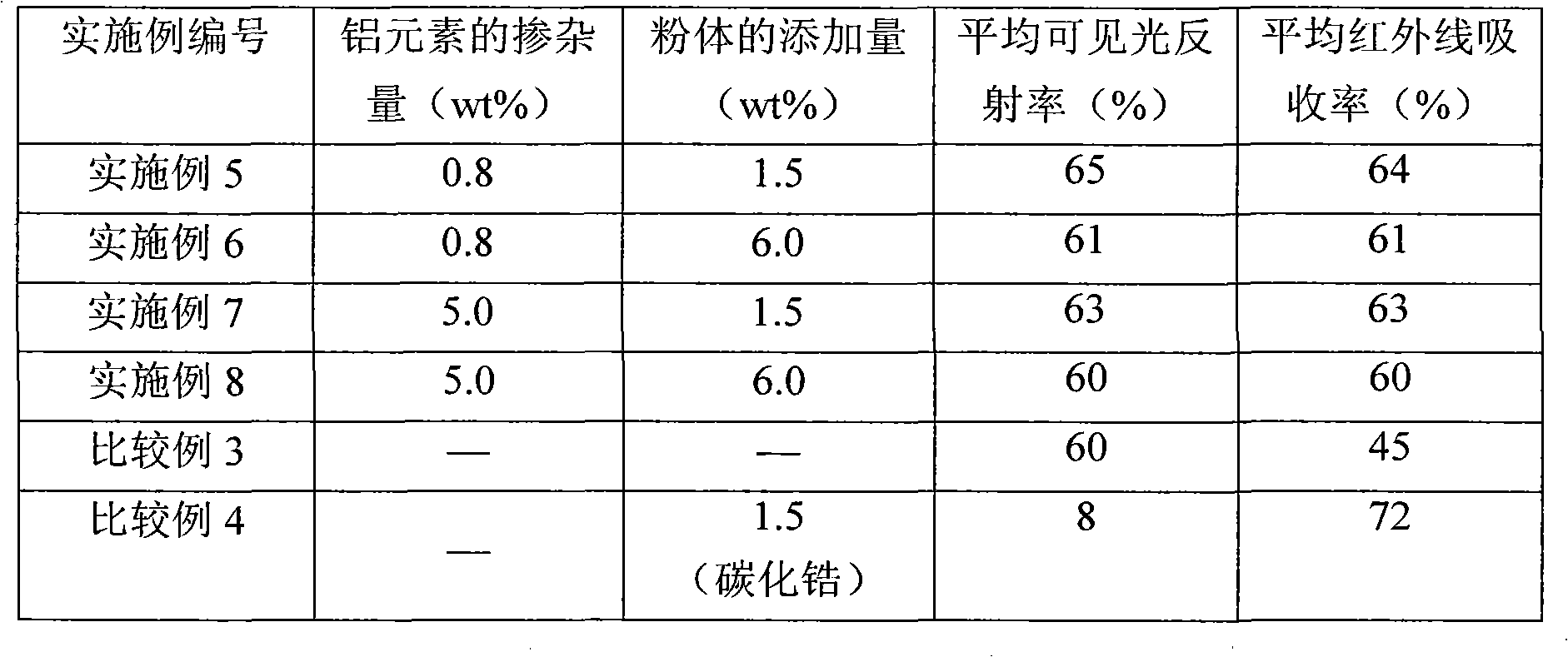

[0040] The zinc oxide powder doped with aluminum element (the doping amount of aluminum is 0.8wt% of the total weight of zinc and aluminum) is first mixed with trimethylolethane (Trimethylolethane) or polyvinyl pyrrolidone (Polyvinyl pyrrolidone) dispersant (the amount is powder 20wt%-100wt% of the body) in a jet mill for pulverization and dispersion treatment, and then directly blended with polypropylene, wherein the blending weight ratio of zinc oxide powder doped with aluminum is 1.5wt% (relative to doped The total weight of aluminum zinc oxide powder and polypropylene), the spinning and false twisting process (spinning temperature 250 ℃, roll speed 2500m / min, oiling amount 1.0opu) will contain aluminum-doped zinc oxide powder The polypropylene compound is false twisted into 60d / 24f polypropylene fiber, and then woven into a basis weight of 120g / m 2 knitted fabric.

[0041] Use the integrating sphere spectrophotometer to test the average reflectance of the knitted fabric o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com