Preparation method of silicon carbide ceramic body for rubber mold

A silicon carbide ceramic and rubber mold technology, applied in the field of ceramic colloidal molding, can solve the problems of carbon inhibition, oxygen inhibition, difficulty in industrial production of SiC ceramics, etc., and achieves simple preparation process, high strength, convenient industrial production and applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

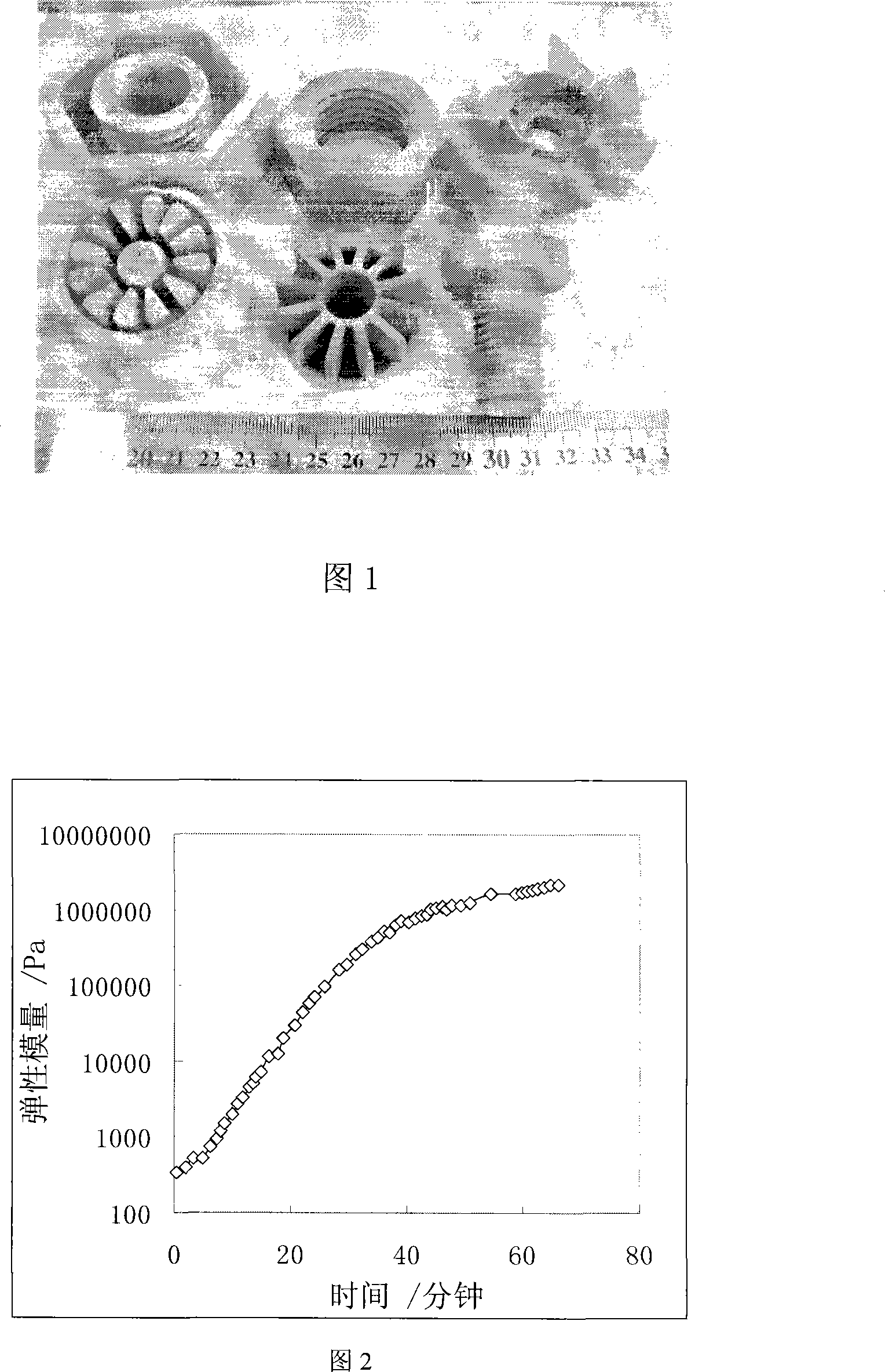

Image

Examples

example 11

[0043] Mix silicone rubber (106 room temperature vulcanized silicone rubber) with catalyst (dibutyltin dilaurate) and transfer agent (tetraethyl orthosilicate) evenly in a ratio of 100:3:3 (by mass). After degassing, it is poured into a container with a pre-replicated object for curing, the curing temperature is room temperature, and the curing time is greater than 24 hours. After curing, properly process the silicone rubber cured body, take out the pre-replicated object, and modify or further process the silicone rubber mold to meet the needs and geometric accuracy of slurry casting.

example 12

[0045] Mix components A and B of epoxy crystal glue (560) uniformly at a ratio of 2:1. After being removed, it is poured into a container with a pre-replicated object and solidified, the curing temperature is room temperature, and the curing time is greater than 24 hours. After curing, properly process the silicone rubber cured body, take out the pre-replicated object, and modify or further process the silicone rubber mold to meet the needs and geometric accuracy of slurry casting.

example 13

[0047] Mix the A and B components of polyurethane (QS-301) crystal glue evenly, and the ratio is 2:1 (mass). After degassing, it is poured into a container with a pre-replicated object for curing, the curing temperature is room temperature, and the curing time is greater than 24 hours. After curing, properly process the cured body of polyurethane crystal glue, take out the pre-replicated object, and modify or further process the mold of polyurethane crystal glue to meet the needs of slurry casting and geometric accuracy.

[0048] Epoxy resin is used as a gel system for SiC gel casting molding to prepare SiC ceramic body examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com