Preparation method of silicon carbide/zirconium carbide composite ceramic

A technology of composite phase ceramics and zirconium carbide, which is applied in the field of preparation of silicon carbide/zirconium carbide composite ceramics, can solve the problems of the mechanical properties and high temperature resistance of the final composite ceramics, and achieve high density ceramics, simple operation, Effects that are easy to engineer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Under an inert atmosphere, dissolve zirconocene dichloride with dimethyl sulfoxide, stir, then add liquid hyperbranched polycarbosilane, the mass ratio of zirconocene dichloride and liquid hyperbranched polycarbosilane is 1: 1.

[0025] (2) Under the protection of an inert atmosphere, the mixture obtained in step (1) was distilled off under reduced pressure in vacuum to remove the solvent.

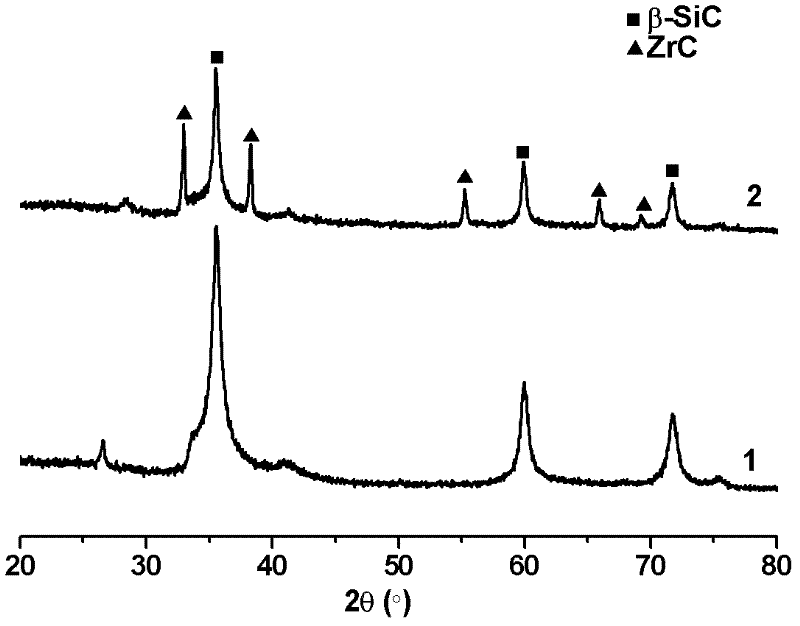

[0026] (3) The mixture obtained in step (2) was cracked at 1400° C. for 120 min under the protection of an inert atmosphere to prepare silicon carbide / zirconium carbide composite ceramics.

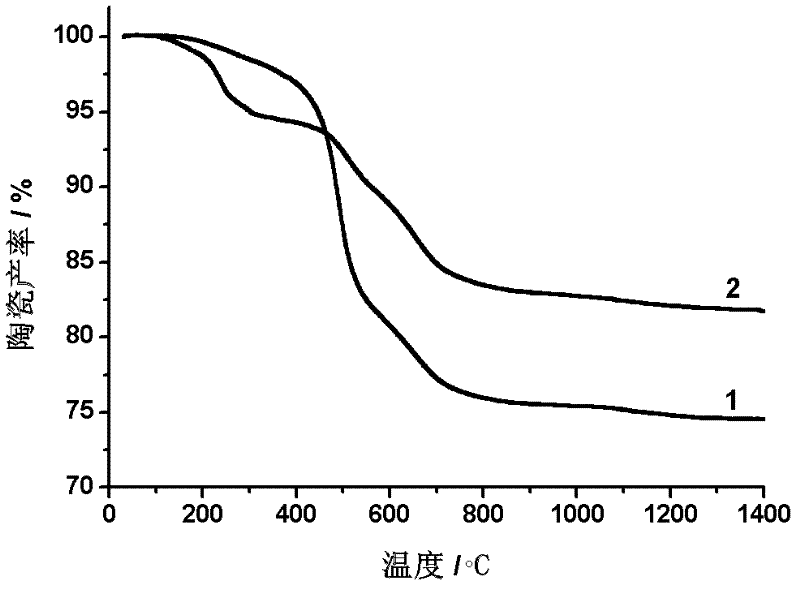

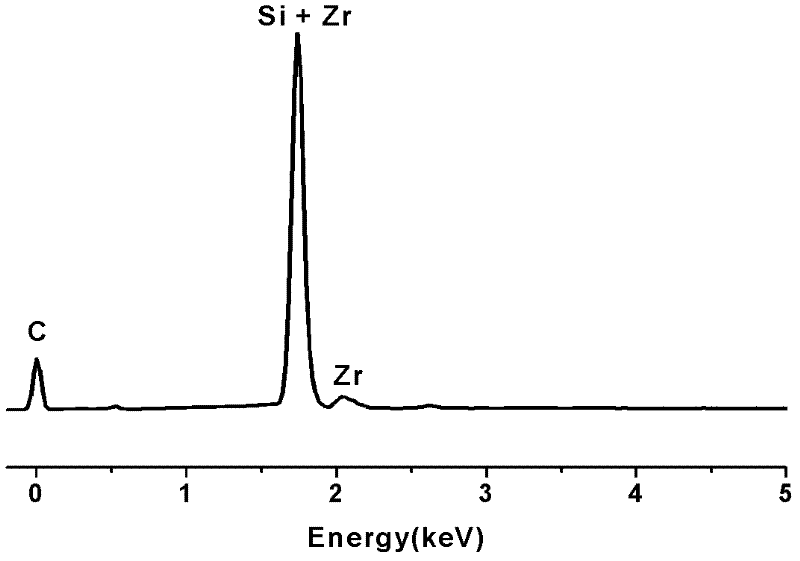

[0027] The average molecular formula of the used raw material liquid hyperbranched polycarbosilane is-[SiH 1.26 (CH 3 ) 0.60 (CH 2 CH=CH 2 ) 0.14 CH2 ] n -, as measured by thermogravimetric analysis (TGA), the ceramic yield of liquid hyperbranched polycarbosilane / dichlorozirconocene hybrid precursor at 1400°C is 84.7%, while the raw material liquid hyperbranched polycarbosilane at 140...

Embodiment 2

[0032] (1) Under an inert atmosphere, dissolve zirconocene dichloride with dimethylformamide, stir, then add liquid hyperbranched polycarbosilane, the mass ratio of zirconocene dichloride and liquid hyperbranched polycarbosilane is 1: 2.

[0033] (2) Under the protection of an inert atmosphere, the mixture obtained in step (1) was distilled off under reduced pressure in vacuum to remove the solvent.

[0034] (3) The mixture obtained in step (2) was cracked at 1600° C. for 60 min under the protection of an inert atmosphere to prepare silicon carbide / zirconium carbide composite ceramics.

[0035] The average molecular formula of the used raw material liquid hyperbranched polycarbosilane is-[SiH 1.36 (CH 2 CH 3 ) 0.40 (CH 2 C≡CH) 0.24 CH 2 ] n -, as determined by thermogravimetric analysis (TGA), the ceramic yield of liquid hyperbranched polycarbosilane / dichlorozirconocene hybrid precursor at 1600°C is 76.7%, while the raw material liquid hyperbranched polycarbosilane at ...

Embodiment 3

[0037] (1) Under an inert atmosphere, dissolve zirconocene dichloride with chloroform, stir, then add liquid hyperbranched polycarbosilane, the mass ratio of zirconocene dichloride and liquid hyperbranched polycarbosilane is 1:3.

[0038] (2) Under the protection of an inert atmosphere, the mixture obtained in step (1) was distilled off under reduced pressure in vacuum to remove the solvent.

[0039] (3) The mixture obtained in step (2) was cracked at 1200° C. for 60 minutes under the protection of an inert atmosphere to prepare silicon carbide / zirconium carbide composite ceramics.

[0040] The average molecular formula of the used raw material liquid hyperbranched polycarbosilane is-[SiH(CH 3 )CH 2 ] n -, as determined by thermogravimetric analysis (TGA), the ceramic yield of liquid hyperbranched polycarbosilane / dichlorozirconocene hybrid precursor at 1200°C is 85.2%, while the raw material liquid hyperbranched polycarbosilane at 1200°C The ceramic yield rate is 76.4%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com