Nano zirconium carbide induction type heat-storage heat-preservation polyester fiber and preparation method thereof

A nano-zirconium carbide and polyester fiber technology, which is applied in the fields of fiber chemical characteristics, single-component polyester artificial filament, melt spinning, etc., can solve problems such as unseen introductions and data reports, and achieve technical content and added value High quality, good quality, and obvious cost-effective advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

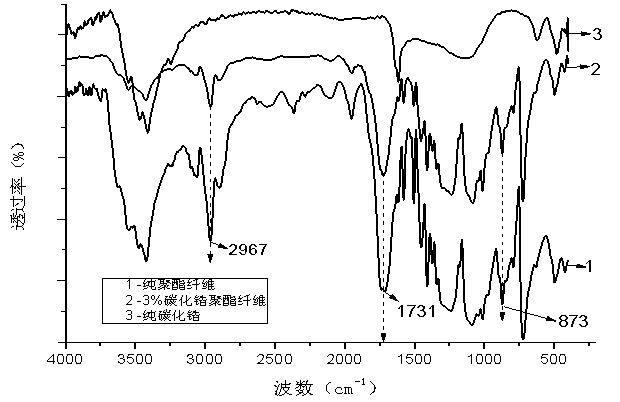

Image

Examples

Embodiment 1

[0021] This example provides a method for preparing nano zirconium carbide induction heat storage and heat preservation polyester fiber by spinning and drawing deformation of 111dtex / 36f. Its production process and conditions are as follows:

[0022] The intrinsic viscosity of polyester chips is 0.648dl / g, the amount of nano-zirconium carbide additive added online in melt spinning is 3.0% of the mass fraction of polyester raw materials, and the particle size distribution of nano-zirconium carbide is 40nm; 5-stage screw melting The extrusion process obtains the blended melt; on the basis of the original polyester fiber production equipment, this embodiment increases the mixing, mixing Improve the refining effect and improve the rheology and spinnability of the melt; the temperature of the 5-stage screw is 270±2°C, 280±2°C, 284±2°C, 285±2°C and 283±2°C respectively.

[0023] The spinning temperature is 285°C, the slow cooling zone temperature is 296°C, the side blowing speed is...

Embodiment 2

[0028] This example provides a method for preparing nano zirconium carbide induction heat storage and heat preservation polyester fiber by spinning and stretching 76dtex / 24f. Its production process and conditions are as follows:

[0029]The intrinsic viscosity of polyester chips is 0.648dl / g, the amount of nano-zirconium carbide additive added online in melt spinning is 5.0% of the mass fraction of polyester raw materials, and the particle size of nano-zirconium carbide is 40nm; 5-stage screw melt extrusion The blended melt is obtained by pressing process; this embodiment is based on the original polyester fiber production equipment, by adding ZrC additive injection device and blended melt cross-split homogenization device in the spinning assembly to increase mixing and kneading The effect is to improve the rheology and spinnability of the melt; the temperature of the five-stage screw is 270±2°C, 280±2°C, 283±2°C, 284±2°C and 283±2°C respectively.

[0030] The spinning temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com