Nano zirconium carbide induction type heat-storage heat-preservation polyester fiber and preparation method thereof

A nano-zirconium carbide, polyester fiber technology, applied in the direction of single-component polyester rayon, melt spinning, stretch spinning, etc. The effect of high value, good quality and obvious cost performance advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

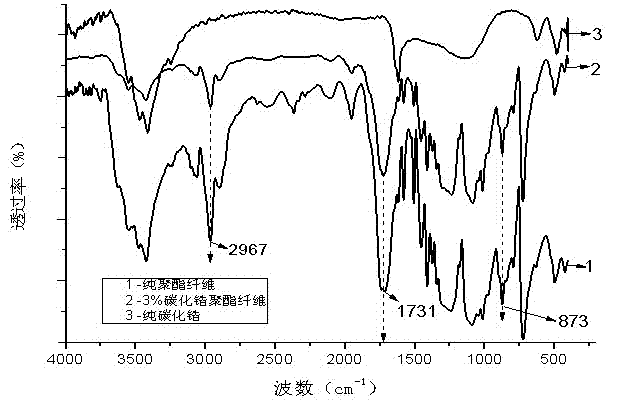

Image

Examples

Embodiment 1

[0021] This example provides a method for preparing nano zirconium carbide induction heat storage and heat preservation polyester fiber by spinning and drawing deformation of 111dtex / 36f. Its production process and conditions are as follows:

[0022] The intrinsic viscosity of polyester chips is 0.648dl / g, the amount of nano-zirconium carbide additive added online in melt spinning is 3.0% of the mass fraction of polyester raw materials, and the particle size distribution of nano-zirconium carbide is 40nm; 5-stage screw melting The extrusion process obtains the blended melt; on the basis of the original polyester fiber production equipment, this embodiment increases the mixing, mixing Improve the refining effect and improve the rheology and spinnability of the melt; the temperature of the 5-stage screw is 270±2°C, 280±2°C, 284±2°C, 285±2°C and 283±2°C respectively.

[0023] The spinning temperature is 285°C, the slow cooling zone temperature is 296°C, the side blowing speed is...

Embodiment 2

[0028] This example provides a method for preparing nano zirconium carbide induction heat storage and heat preservation polyester fiber by spinning and stretching 76dtex / 24f. Its production process and conditions are as follows:

[0029]The intrinsic viscosity of polyester chips is 0.648dl / g, the amount of nano-zirconium carbide additive added online in melt spinning is 5.0% of the mass fraction of polyester raw materials, and the particle size of nano-zirconium carbide is 40nm; 5-stage screw melt extrusion The blended melt is obtained by pressing process; this embodiment is based on the original polyester fiber production equipment, by adding ZrC additive injection device and blended melt cross-split homogenization device in the spinning assembly to increase mixing and kneading The effect is to improve the rheology and spinnability of the melt; the temperature of the five-stage screw is 270±2°C, 280±2°C, 283±2°C, 284±2°C and 283±2°C respectively.

[0030] The spinning temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com