PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and preparation method thereof

An anti-ultraviolet and infrared technology, which is applied in the field of dynamically blocking infrared and anti-ultraviolet PVB film and its preparation field, can solve the problems of single function of PVB functional film and poor blocking effect, and achieve the effect of increasing the blocking effect of infrared and ultraviolet rays and stable performance , Improve the effect of infrared shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without departing from the concept of the present invention, some simple deduction or replacement can be made, which should be regarded as belonging to the protection scope of the present invention. "Parts" used in the following examples mean parts by weight.

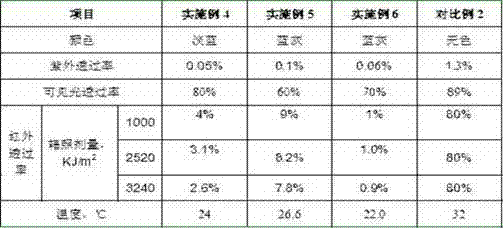

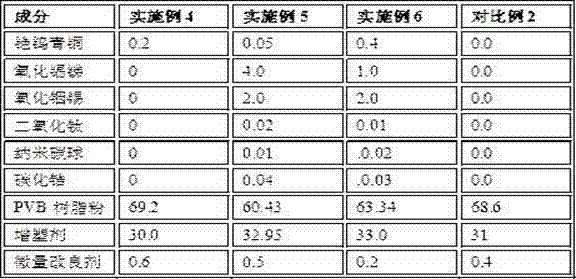

[0028] One, table 1 is that a kind of thickness is 0.38mm dynamic cut-off infrared ray and the embodiment 1-3 of the PVB film of anti-ultraviolet and the composition ratio of the PVB film of comparative example 1 and preparation method thereof:

[0029]

[0030] (1) Dispersing cesium tungsten bronze composite nanoparticles through a solvent in parts by weight to obtain a cesium tungsten br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com