Spraying powder, hot-sprayed in-situ synthesized zirconium boride-zirconium carbide base ceramic coating and preparation method thereof

A ceramic coating and zirconium carbide-based technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of poor density and many pores of ceramic-based coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a method for preparing a zirconium boride-zirconium carbide based ceramic coating in situ by thermal spraying, comprising:

[0044] Plasma spraying is carried out on the spraying powder to obtain thermal spraying in-situ synthesis of zirconium boride-zirconium carbide based ceramic coating, and the spraying powder is the spraying powder described in the above technical solution.

[0045] In the invention, the sprayed powder is subjected to plasma spraying to obtain thermal spraying in-situ synthesis of zirconium boride-zirconium carbide based ceramic coating. In the present invention, the spraying powder is consistent with the spraying powder described in the above technical solution, and will not be repeated here.

[0046] In an embodiment of the present invention, the current during the plasma spraying process is 550A-650A; in other embodiments, the current during the plasma spraying process is 580A-620A; in another embodiment, the The current ...

Embodiment 1

[0061] 3 microns of aluminum powder (purity > 98%), 10 microns of zirconium hydride powder and 15 microns of boron carbide powder are fully mechanically mixed according to the mass ratio of 30:58.5:11.5 to obtain a mixture;

[0062] The mixture is granulated by spray-drying granulation to obtain a spray powder with a particle size of -140 to +325 mesh.

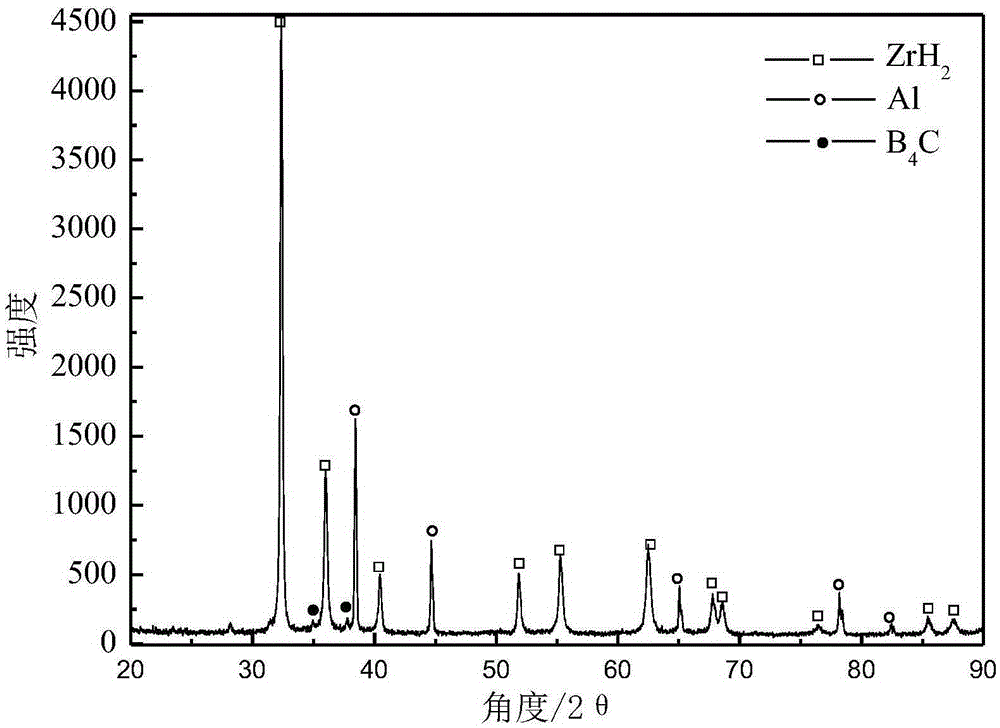

[0063] Carry out XRD detection to the spraying powder that the embodiment of the present invention 1 prepares, detection result is as follows figure 1 as shown, figure 1 For the XRD spectrum of the spray powder prepared in Example 1 of the present invention, by figure 1 It can be seen that the spray powder prepared in Example 1 of the present invention contains zirconium hydride, aluminum and boron carbide.

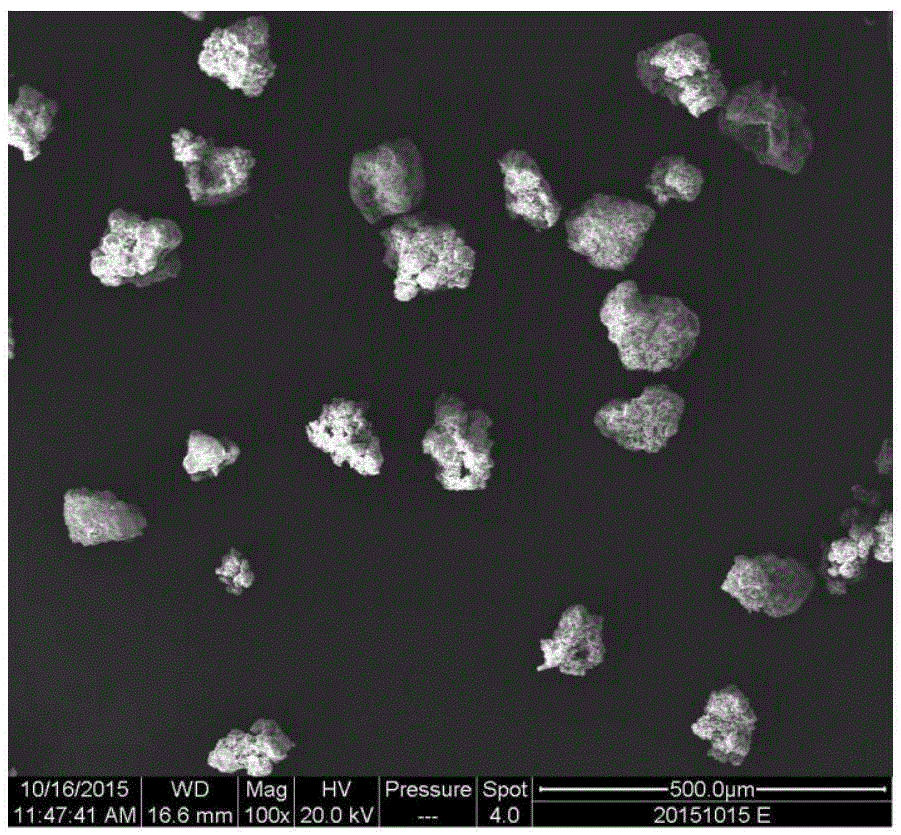

[0064] Carry out SEM detection to the spraying powder that the embodiment of the present invention 1 prepares, detection result is as follows figure 2 as shown, figure 2 For the SEM figure of the spray powder prepar...

Embodiment 2

[0066] 2 microns of aluminum powder (purity > 98%), 5 microns of zirconium hydride powder and 5 microns of boron carbide powder are fully mechanically mixed according to the mass ratio of 25:62.6:12.4 to obtain a mixture;

[0067] The mixture is granulated by spray-drying granulation to obtain a spray powder with a particle size of -180 to +280 mesh.

[0068] According to the method described in Example 1, the spray powder prepared in Example 2 of the present invention was tested. The test result was that the spray powder prepared in Example 2 of the present invention contained zirconium hydride, aluminum and boron carbide, and the spray powder Uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com