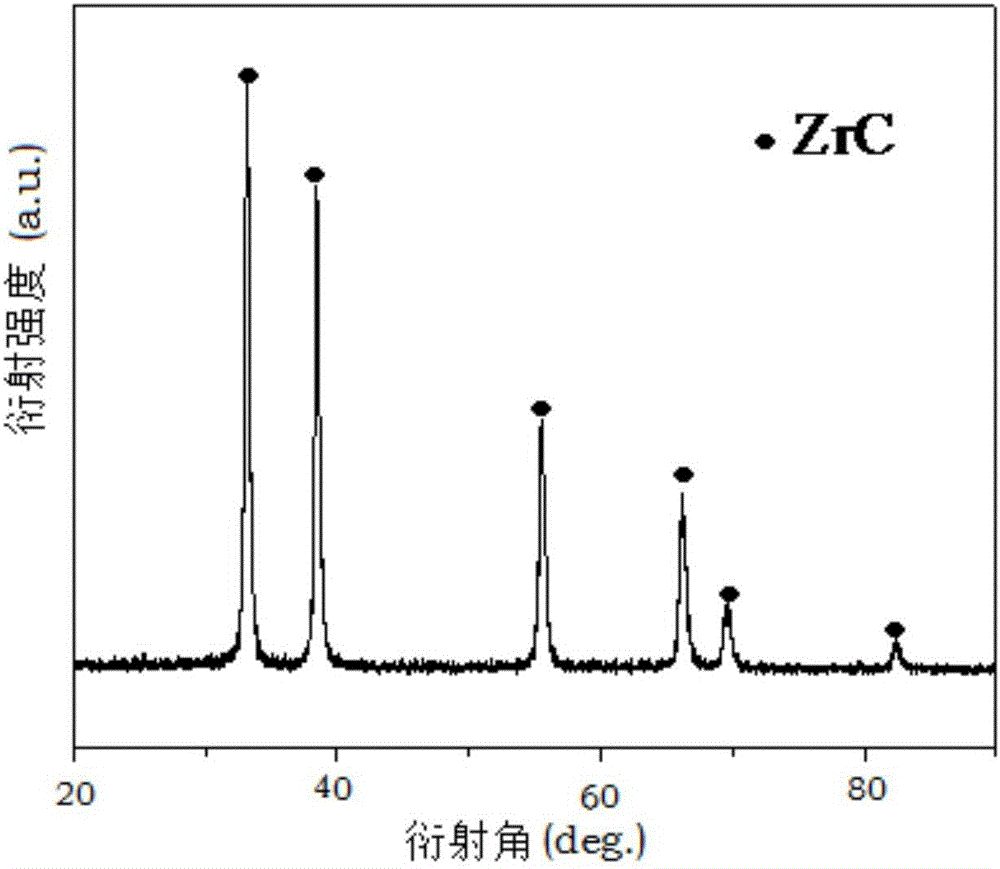

Preparation method of zirconium carbide micro-nanofibers

A technology of micro-nano fiber and zirconium carbide, which is applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of complicated steps and long preparation cycle, and achieve the effect of low cost, simple preparation process and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

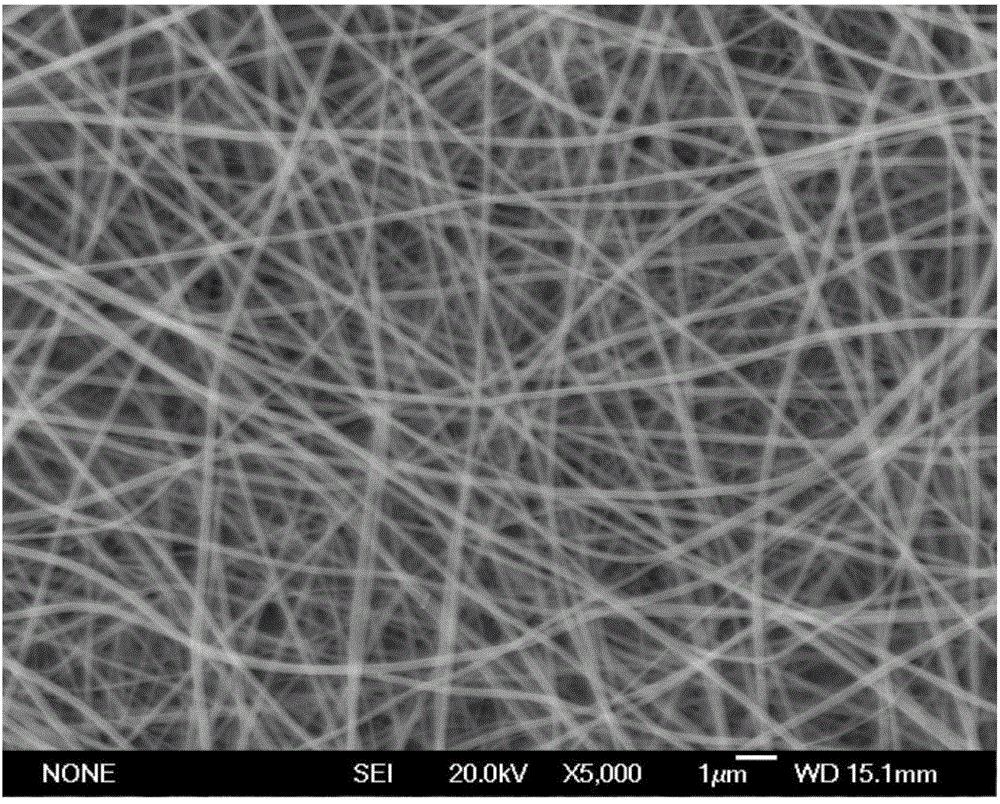

Embodiment 1

[0025] A kind of preparation method of zirconium carbide micro-nano fiber provided by the present invention, the specific operation steps are as follows:

[0026] Step 1, select raw materials

[0027] Take by weighing 1.17g sucrose and 4ml n-propoxide zirconium as carbon source and zirconium source respectively, 10ml of N,N-dimethylformamide (abbreviated as DMF) and 4ml absolute ethanol as solvent, 2.5ml glacial acetic acid as chelating agent, 1.008g polyvinylpyrrolidone (PVP for short) is used as spinning aid.

[0028] Step 2, configure the spinning solution

[0029] Add 1.17g of sucrose weighed in step 1 to 10ml of DMF solution, heat in a water bath at 80°C for 20min to obtain solution A; add 4ml of zirconium n-propoxide to 4ml of absolute ethanol, and add 2.5ml of glacial acetic acid to obtain solution B, then Mix solution A and solution B, finally add 1.008g of PVP and stir evenly to obtain spinning solution.

[0030] Step 3, Electrospinning

[0031] The spinning solut...

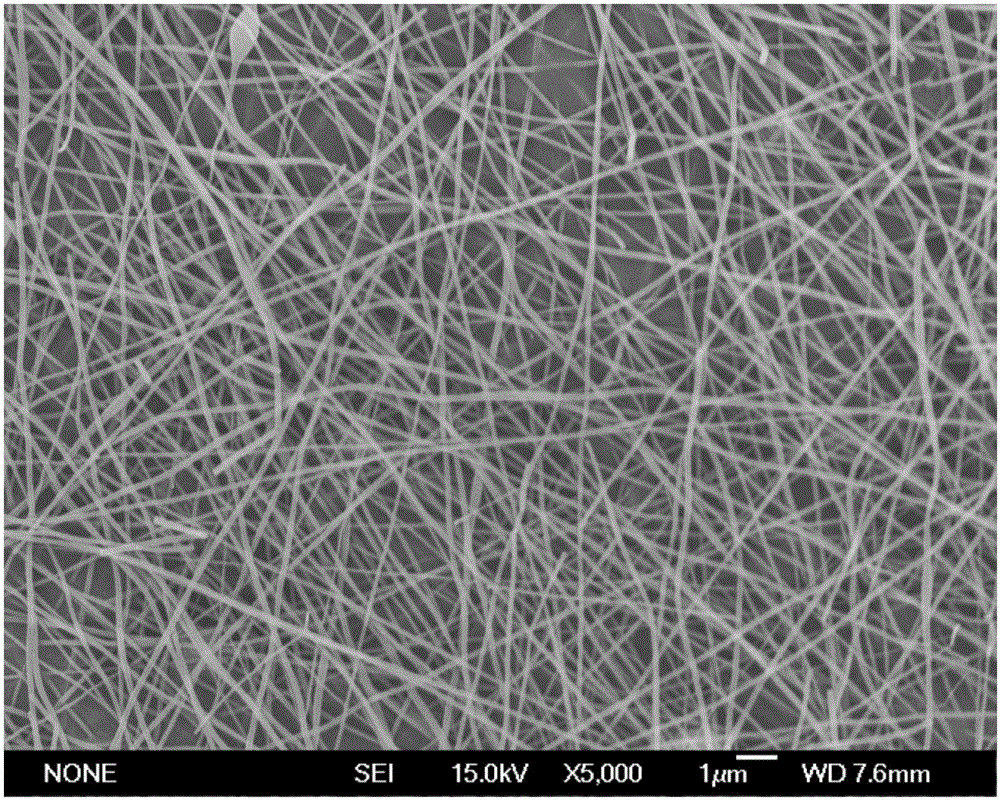

Embodiment 2

[0035] The preparation method of another zirconium carbide micro-nano fiber provided by the present invention, the specific operation steps are as follows:

[0036] Step 1, select raw materials

[0037] Weigh 1.18g of glucose and 4ml of zirconium n-propoxide as carbon source and zirconium source respectively, 10ml of DMF and 4ml of absolute ethanol as solvent, 2.5ml of glacial acetic acid as chelating agent, and 1.261g of PVP as spinning aid.

[0038] Step 2, configure the spinning solution

[0039] Add 1.18g of glucose weighed in step 1 to 10ml of DMF solution, heat in a water bath at 70°C for 30min to obtain solution A; add 4ml of zirconium n-propoxide to 4ml of absolute ethanol, and add 2.5ml of glacial acetic acid to obtain solution B, and dissolve solution A Mix with melt B, finally add 1.261g of PVP and stir evenly to obtain spinning solution.

[0040] Step 3, Electrospinning

[0041] The spinning solution obtained in step 2 is electrospun using standard electrospinni...

Embodiment 3

[0045] The preparation method of another zirconium carbide micro-nano fiber provided by the present invention, the specific operation steps are as follows:

[0046] Step 1, select raw materials

[0047] Weigh 0.814g of sucrose and 2.0g of zirconium oxychloride as carbon source and zirconium source respectively, 10ml of DMF and 4ml of absolute ethanol as solvent, 2.0ml of glacial acetic acid as chelating agent, and 1.261g of PVP as spinning aid.

[0048] Step 2, configure the spinning solution

[0049] Add 0.814g of sucrose weighed in step 1 into 10ml of DMF solution, heat in a water bath at 70°C for 30min to obtain solution A; dissolve 2.0g of zirconium oxychloride in 4ml of absolute ethanol, and add 2.0ml of glacial acetic acid to obtain solution B, and After solution A and melt B are mixed, 1.261g of PVP is finally added and stirred evenly to obtain a spinning solution.

[0050] Step 3, Electrospinning

[0051]The spinning solution obtained in step 2 is electrospun using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com