Method for reducing COD (chemical oxygen demand) of permanent violet process wastewater and application of method

A permanent violet and waste water technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high total nitrogen concentration and poor biodegradability, improve treatment efficiency, save usage, The effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

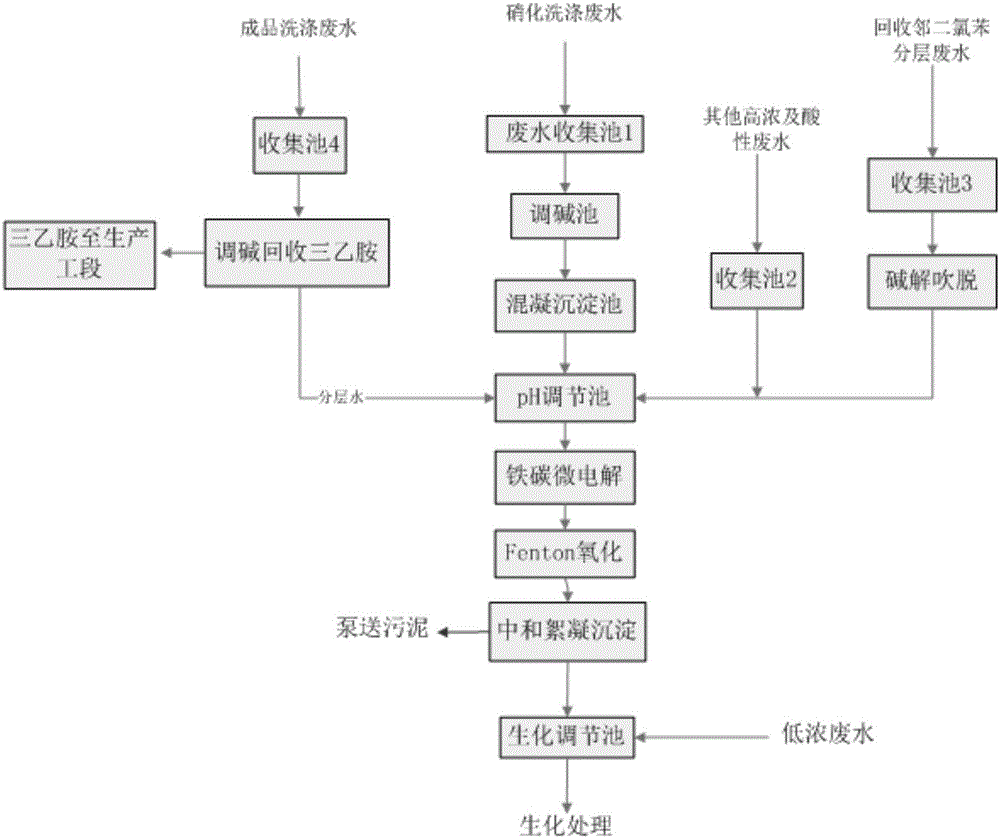

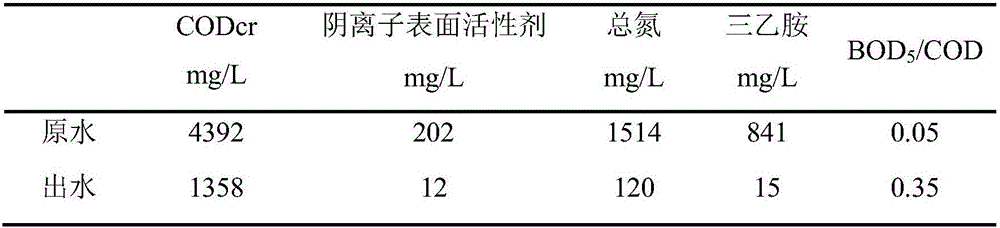

[0041] The comprehensive wastewater quality parameters of a process wastewater producing permanent violet in Yinchuan are as follows: CODcr 4392mg / L, anionic surfactant 202mg / L, total nitrogen 1514mg / L, triethylamine 841mg / L, combined with figure 1 , the present embodiment proposes a method for reducing the COD of permanent violet wastewater, the steps are as follows:

[0042] A. The workshop nitrification and washing wastewater is discharged to the collection pool 1 after secondary sedimentation, and the pH of the nitrification and washing wastewater is adjusted to 12 with an emulsion with a mass fraction of 25% calcium oxide, and 700mg / L of aluminum sulfate is added, and 5mg / L of PAM, after static precipitation in the coagulation sedimentation tank, the supernatant enters the subsequent pH adjustment tank; the COD of the nitrification washing wastewater is reduced from 4800mg / L to 2780mg / L, and the anionic surfactant is reduced from 802mg / L to 371mg / L. Concentration 6645mg / L...

Embodiment 2

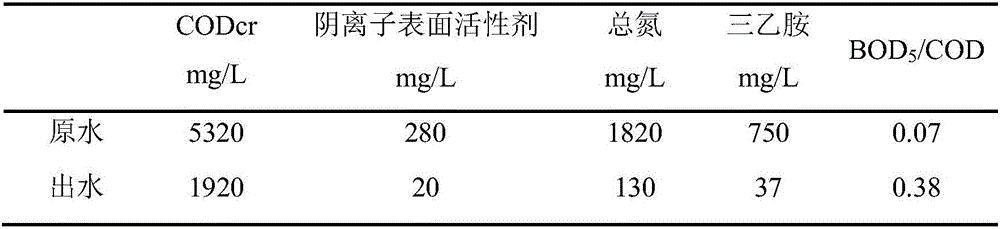

[0052] In order to ensure that the permanent violet wastewater produced by a chemical company in Lianyungang, Jiangsu Province meets the requirements of biochemical influent water, and further ensure that the wastewater discharge meets the takeover standard, this example proposes a method for reducing the COD of the permanent violet wastewater. The steps are the same as in Example 1. Among them, in step A, the pH of nitrification and washing wastewater is adjusted to 11 with an emulsion of 33% calcium hydroxide calcium, and 250 mg / L PAC and 2.5 mg / L PAM are added for flocculation and precipitation; in step B, the wastewater is first concentrated and then added The caustic soda adjusts the pH to 13, distills and recovers triethylamine at a constant temperature of 88°C, concentrates the effluent and stratified water into the pH adjustment pool; step C will distill the mother liquor to recover the stratified wastewater produced by the solvent o-dichlorobenzene, Adjust the pH of th...

Embodiment 3

[0057] In order to ensure that the permanent violet wastewater produced by a chemical company in Binhai, Jiangsu meets the biochemical influent requirements, and further ensures that the wastewater discharge meets the takeover standard, this example proposes a method for reducing the COD of the permanent violet wastewater. The steps are the same as in Example 1. Among them, in step A, adjust the pH of nitrification and washing wastewater to 11.5 with an emulsion with a mass fraction of 30% calcium oxide, and add 500 mg / LPAS and 3 mg / L PAM for flocculation and precipitation; in step B, the finished product containing triethylamine is pulled apart The washing wastewater is distilled at a constant temperature of 90°C to adjust the pH to 12 with lye to recover triethylamine; in step C, the stratified wastewater produced by distilling and recovering the solvent o-dichlorobenzene from the mother liquor is distilled with the concentrated lye obtained by drying the triethylamine. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com