Recovery method of triethylamine in glyphosate mother liquid

The technology of a glyphosate mother liquor and a recovery method is applied in the field of recovering triethylamine in the glyphosate mother liquor produced by the dialkyl phosphite method, which can solve the problems of large loss of triethylamine and the like, so as to improve the recovery rate and recover the The effect of high rate and strong economic value

Active Publication Date: 2008-11-19

SHANDONG WEIFANG RAINBOW CHEM

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the loss of triethylamine in this process is relatively large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

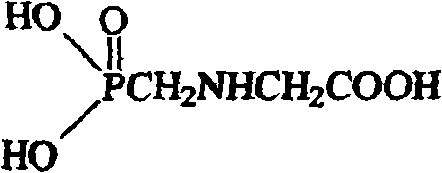

The invention relates to a novel method for reclaiming triethylamine in glyphosate mother liquid produced by a method of dialkyl phosphite. The reclaiming method is realized by the following steps that: (1) in the process for preparing the glyphosate by the method of dialkyl phosphite, liquid caustic soda is added into the crystallized mother liquid to make the triethylamine layered, the lower layer is the glyphosate mother liquid; (2) an extracting agent prepared by an organic solvent and an acid phosphorus oxide extracting agent is added into the glyphosate mother liquid, the mixture is stirred and is kept stand to layer and separate; (3) the glyphosate waste water in the lower layer is concentrated to prepare glyphosate; the organic phase in the upper layer is added with hydrochloric acid to generate triethylamine hydrochloride and is kept stand to layer; a regenerating extracting agent in the upper layer returns to the production process and is used to extract continuously; and the triethylamine hydrochloride in the lower layer is added with liquid caustic soda and is adjusted to be basic so that the triethylamine hydrochloride is converted into the triethylamine which is layered and is used to synthesize after dewatered. The novel method effectively improves the coefficient of reclaiming of the triethylamine and has simple process, easy operation and high economical benefits.

Description

Recovery method of triethylamine in glyphosate mother liquor (1) Technical field The invention relates to a method for recovering triethylamine in glyphosate mother liquor, in particular to a new method for recovering triethylamine in glyphosate mother liquor produced by a dialkyl phosphite method. (2) Technical background Glyphosate, as a high-efficiency, broad-spectrum, low-toxicity, and safe organic phosphine post-emergence herbicide, is very effective in the control of perennial deep-rooted weeds, and has important roles in agriculture, forestry, animal husbandry, and horticulture. It is one of the most widely used herbicides at present. Its application path has been continuously broadened by means of cultivating various glyphosate-resistant transgenic crop varieties. In recent years, glyphosate has maintained a high growth rate of use. It is currently the most widely used herbicide in the world. At present, the treatment process of glyphosate mother liquor produce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C211/05C07C209/84C07F9/38

Inventor 孙国庆陈琦侯永生牛月利夏立花王喜朝曲凡旭

Owner SHANDONG WEIFANG RAINBOW CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com