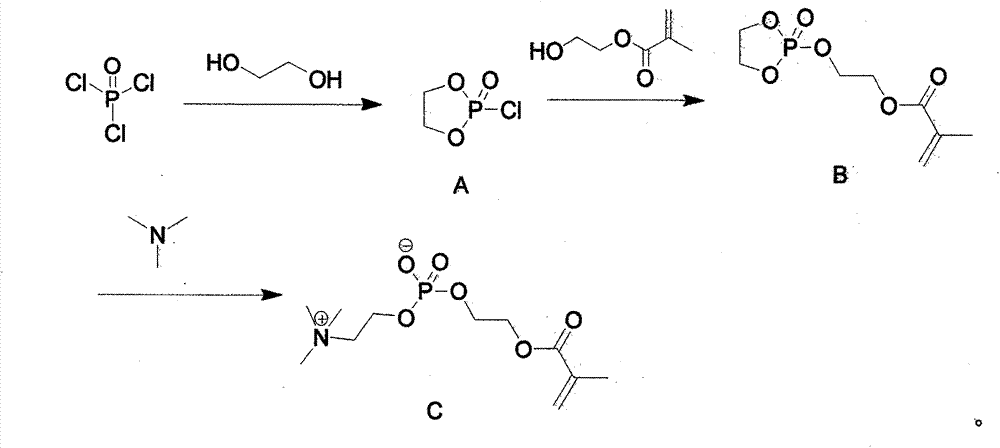

Method for synthesizing MPC using one-pot method

A technology of mixing solution and acetonitrile, applied in the direction of phosphorus organic compounds, etc., can solve problems such as difficulty and difficulty in obtaining pure MPC, and achieve the effects of simple operation, saving input of raw materials and auxiliary materials, and saving equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with embodiments.

[0020] The method for one-pot synthetic MPC, comprises the following steps:

[0021] Step 1) Dissolve 168g of phosphorus oxychloride (1.1eq) in 2500ml of acetonitrile, mix 62g of ethylene glycol (1.0eq) with 110g of triethylamine (1.1eq), and slowly add it dropwise to the above-mentioned acetonitrile at -10°C , then keep stirring at this temperature for 30 minutes, and stir at room temperature for one hour, then cool the reaction solution to -10°C;

[0022] Step 2) Slowly add a mixed solution of 117g HEMA (0.9eq) and 110g triethylamine (1.1eq) dropwise at -10°C, then stir at this temperature for three hours, cool to -20°C, and dissolve triethylamine under nitrogen protection. Filter out the amine hydrochloride, feed 180g trimethylamine (3.0eq) into the mother liquor, close the reactor, raise the temperature to 60°C and keep stirring at this temperature for 26 hours, spin dry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com