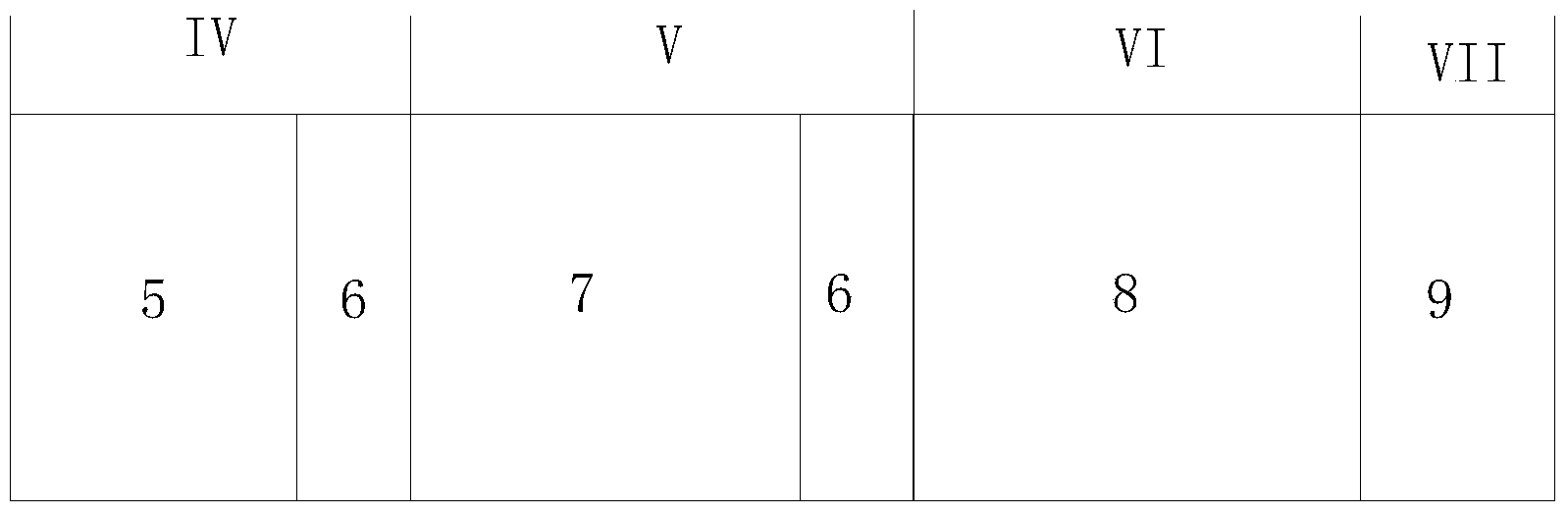

Patents

Literature

56 results about "Hybrid reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hybrid biological reactor (HBR) was developed which involved the introduction of a new phase of attached-biomass into a regular suspended-growth system (activated sludge process) by addition of carriers to...

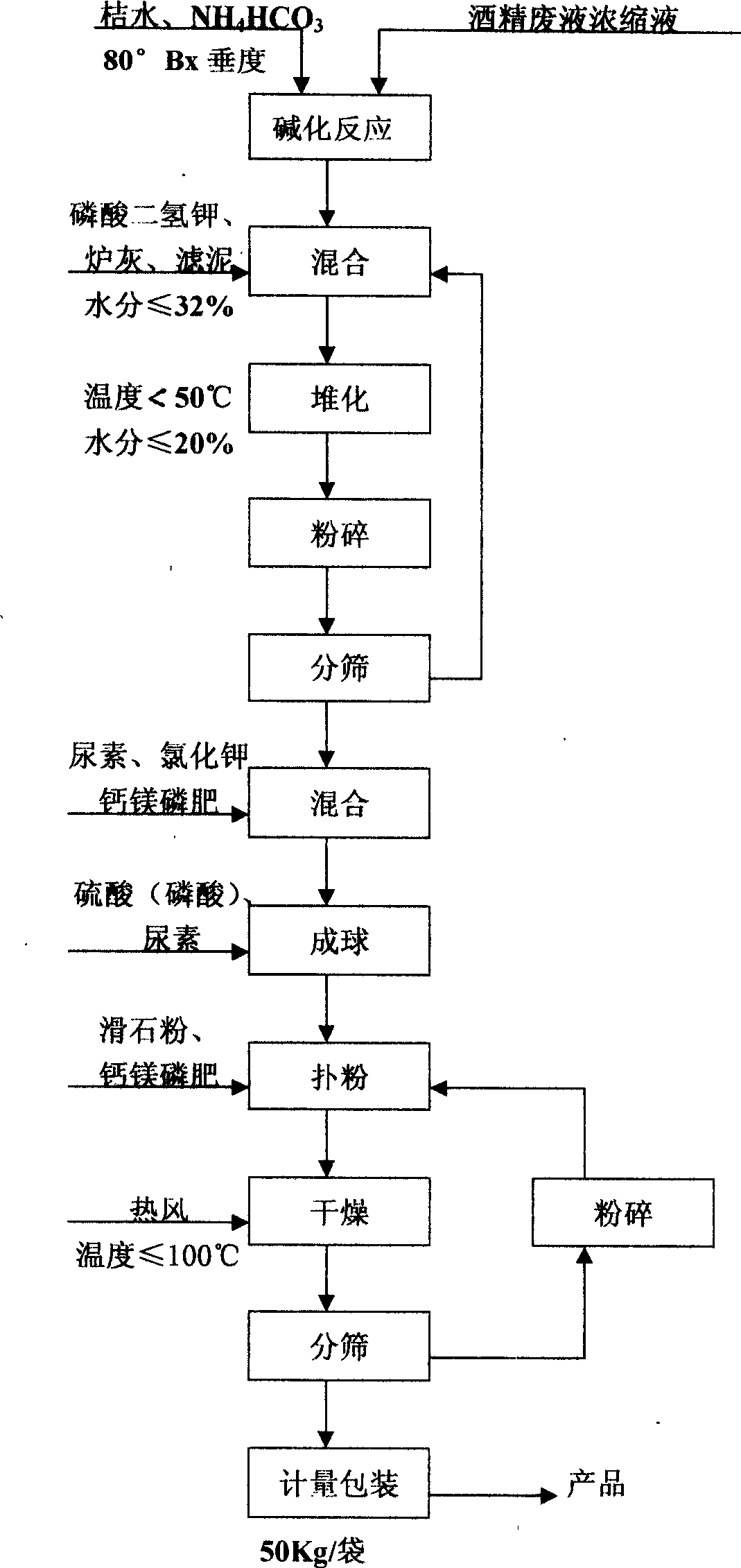

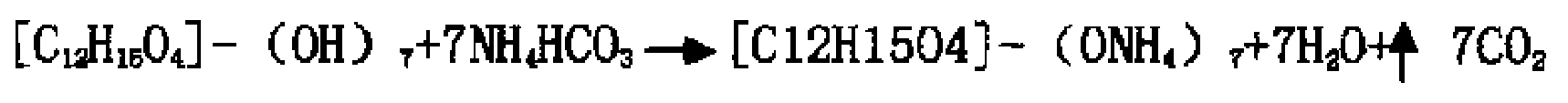

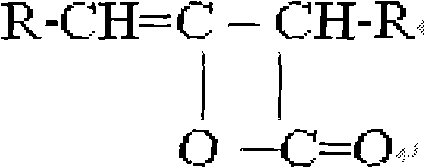

Technique for producing humic acid organic compound fertilizer from sugar refinery waste slag and wastewater

ActiveCN101462899ASolve pollutionHigh thermal efficiencyBio-organic fraction processingClimate change adaptationSocial benefitsEcological environment

The invention discloses a process for producing an organic humic complex fertilizer by the waste residue and waste water of sugar mills. The process comprises the following steps: condensing waste alcohol liquid; performing an alkalization reaction; mixing, reacting and composting for fermentation; crushing, screening, mixing, and disk balling; powdering, drying, screening and packaging. The process for producing the organic humic complex fertilizer by the waste residue and the waste water of the sugar mills helps thoroughly recovers and utilizes the waste residue and the waste water of the sugar mills, solve the problem of environmental pollution caused by waste discharge and increase the economic benefit and social benefit of enterprises. The novel organic humic complex fertilizer integrates yield increase benefit, quality benefit and ecological environment benefit, has stronger market competitiveness as a substitute product of imported complex fertilizers and represents the radical direction of fertilizer development in the future.

Owner:湛江中研科技开发有限公司

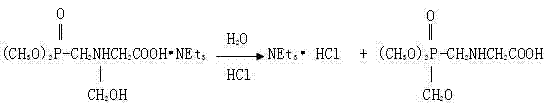

Method for preparing AKD by serialization

The invention provides a method for preparing AKD by serialization. The method includes the following steps: reaction of acyl chloride and tertiary amine is carried out, acyl chloride in formula ratio is divided into two or three parts, each part is 10-90% of the formula ratio, the rest part of acyl chloride is added in times after 30-300 seconds, triethylamine in formula ratio and first part of acyl chloride are simultaneously, respectively and continuously added at the front end of a reactor; material is continuously fed into a hybrid reactor from different feeding holes by virtue of a plurality of metering pumps, the material is subject to hybrid reaction in the hybrid reactor by stirring, cutting and malposition moving, and the temperature of material is controlled; the material is remained in the reactor, discharged from the outlet of the reactor and enters into a continuous extractor, and meanwhile diluted hydrochloric acid is continuously added into the extractor, is dispersed with reaction product to form uniform mixed solution and then enters into a slope precipitator, separation of oil phase and water phase is carried out, the oil phase is discharged from the upper outlet, and the water phase is discharged from the lower outlet; and the oil phase is namely the AKD, and the water phase is triethylamine hydrochloride solution.

Owner:SUZHOU TIANMA SPECIALTY CHEM

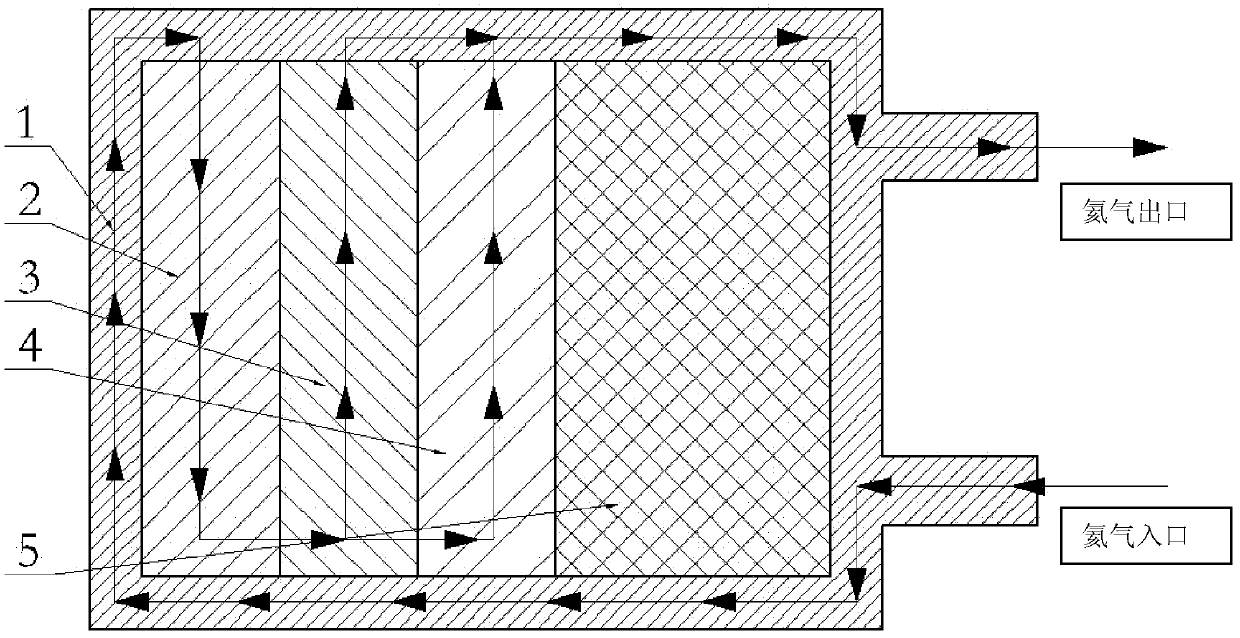

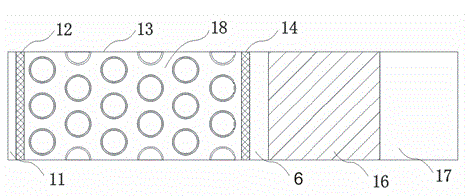

Hybrid reactor cladding for realizing long-term energy amplification by using fast-thermal coupling mixed energy spectrum

InactiveCN102610284AIncrease temperatureRaise the outlet temperatureNuclear energy generationThermonuclear fusion reactorFission neutronLiquid lithium

The invention relates to a hybrid reactor cladding for realizing long-term energy amplification by using a fast-thermal coupling mixed energy spectrum, which comprises a first wall, a fast fission region, a non fission neutron multiplication area, a thermal fissile area and a tritium breeding area. The structure of the hybrid reactor cladding is the first wall, the fast fission area, the non fission neutron multiplication area, the thermal fission area and the tritium breeding area in sequence from inside to outside. The cladding adopts the way that helium flows circumferentially and is cooled step by step. Helium enters into the cladding from a side pipeline of the first wall, enters into a fast neutron fission area transversely through the cladding after cooling the first wall, enters into the non fission neutron multiplication area and the thermal fission area from the other side of the cladding after cooling the fast neutron fission area and then enters the side pipeline of the first wall and flows out. Liquid lithium lead in the tritium breeding area enters into the cladding from the upper part of the cladding and flows out from the lower part and brings out heat and tritium relying on the flow. According to the hybrid reactor cladding, the long-term energy amplification, higher power generation efficiency and better safety can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

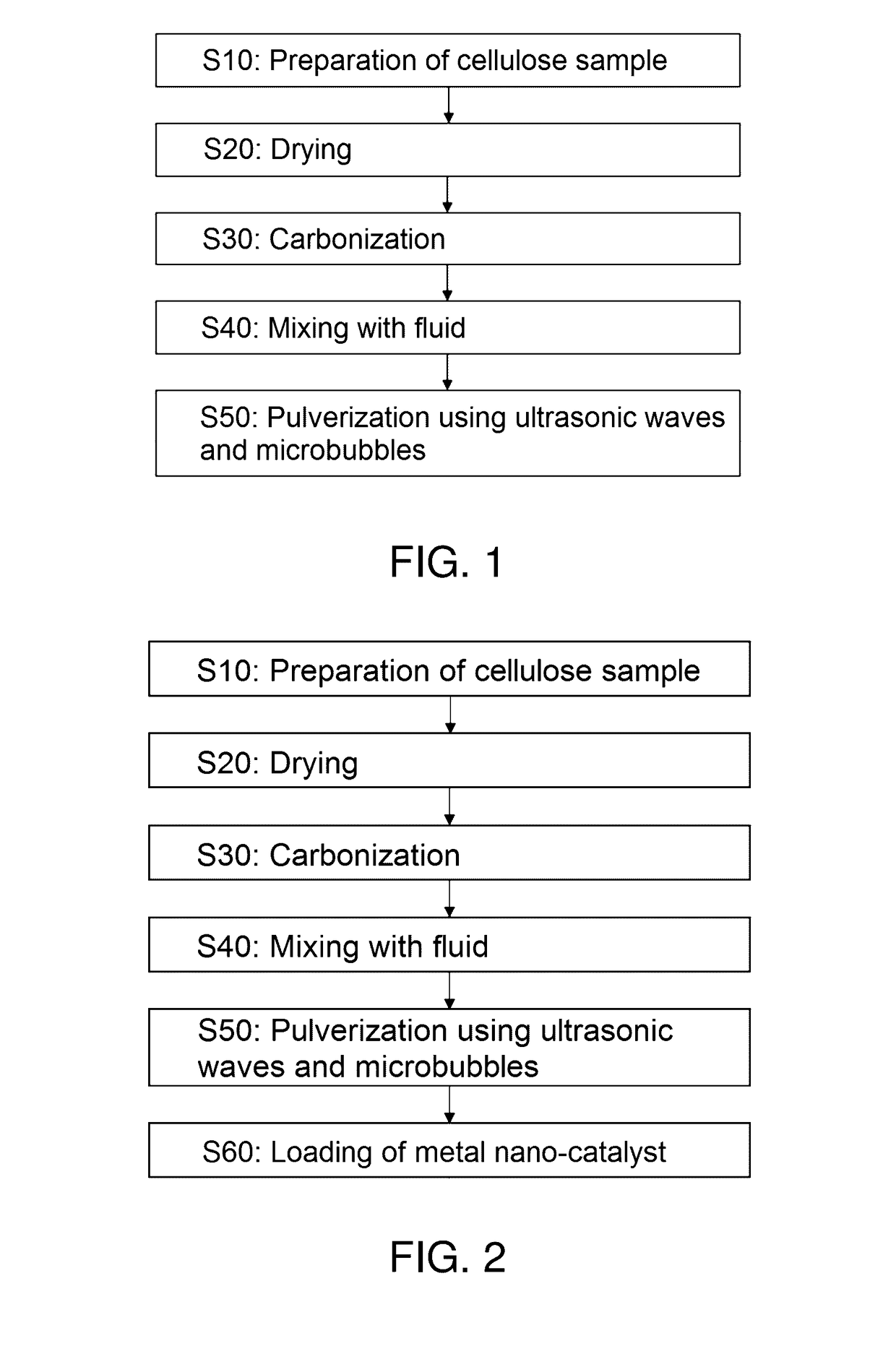

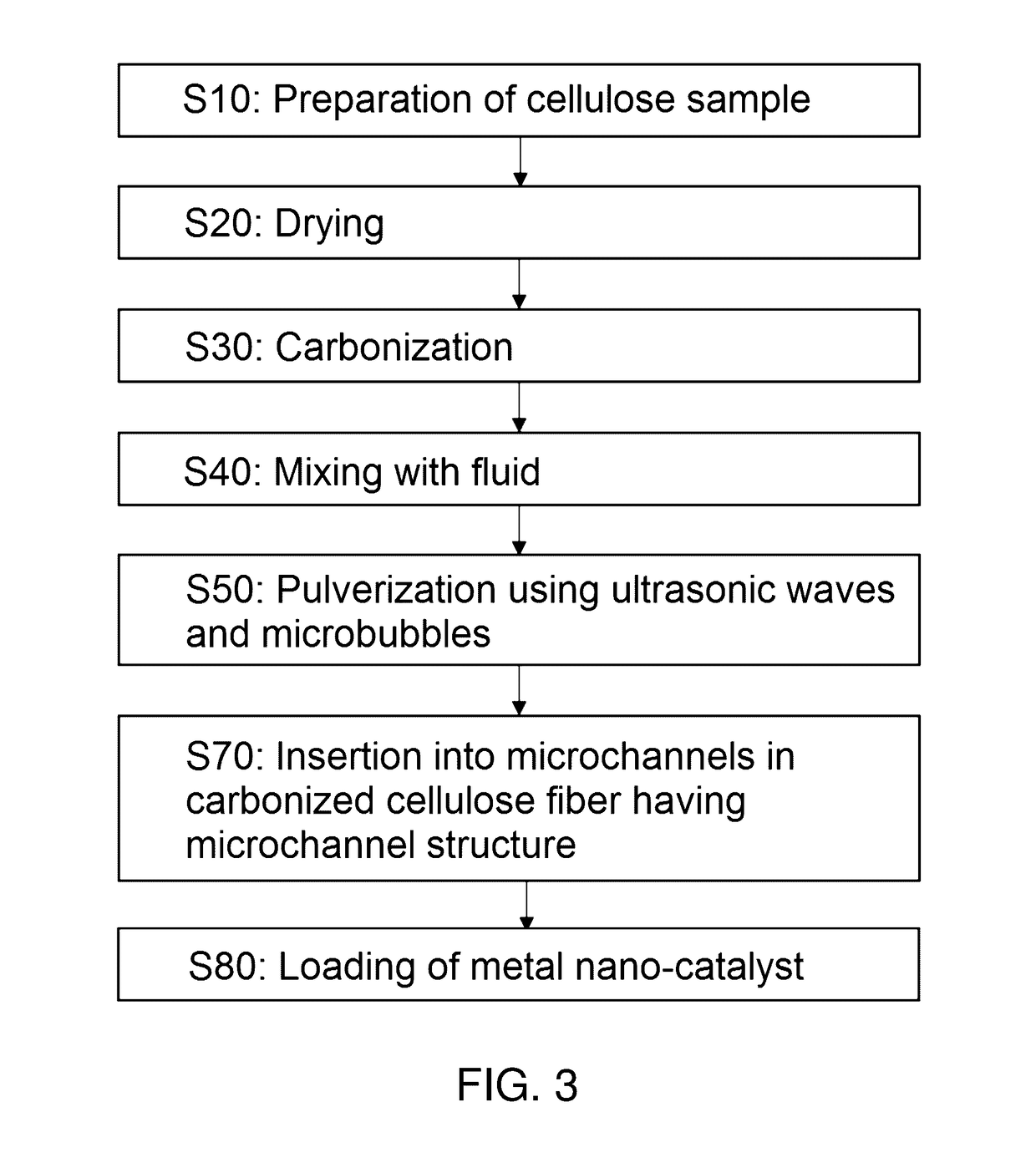

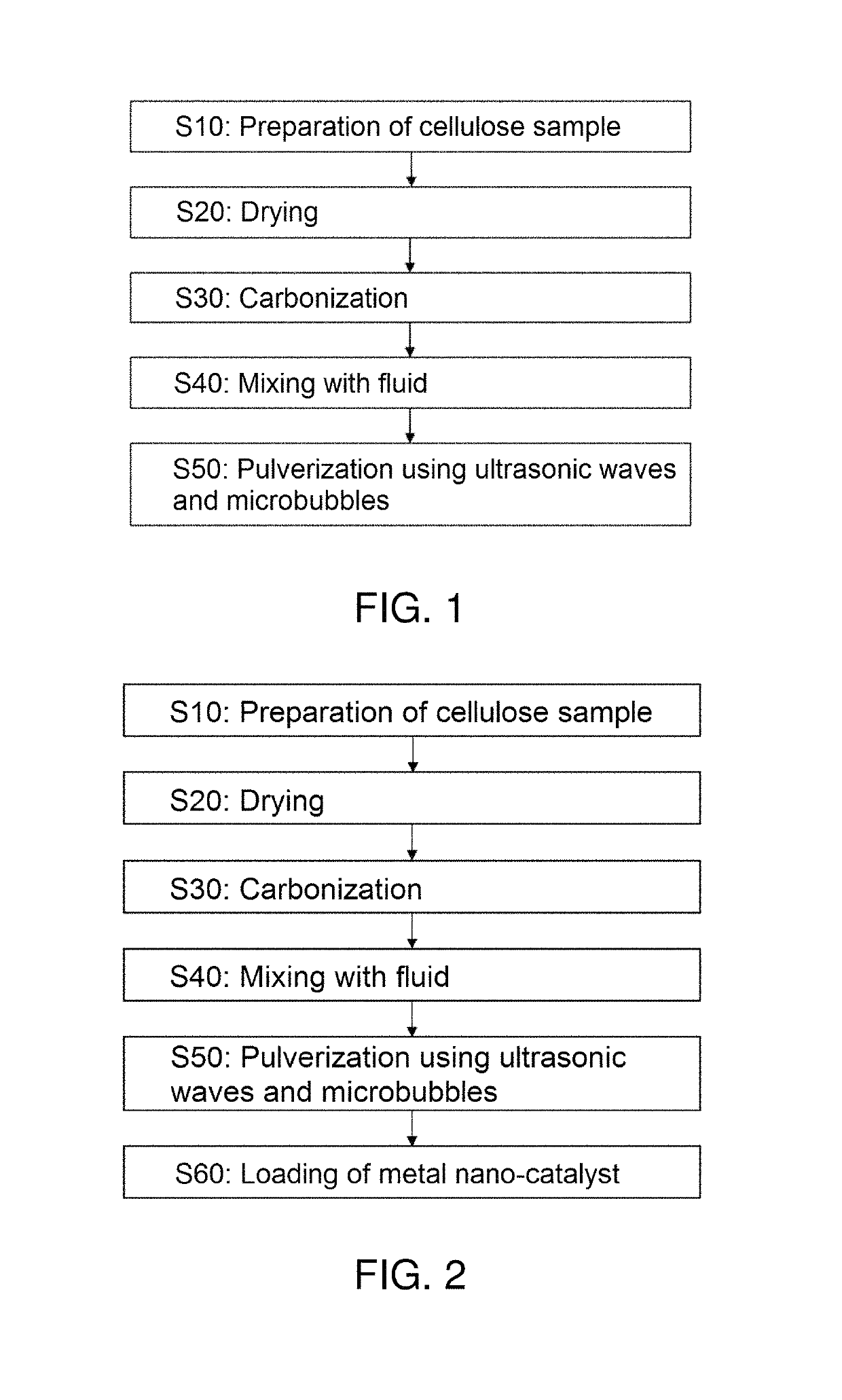

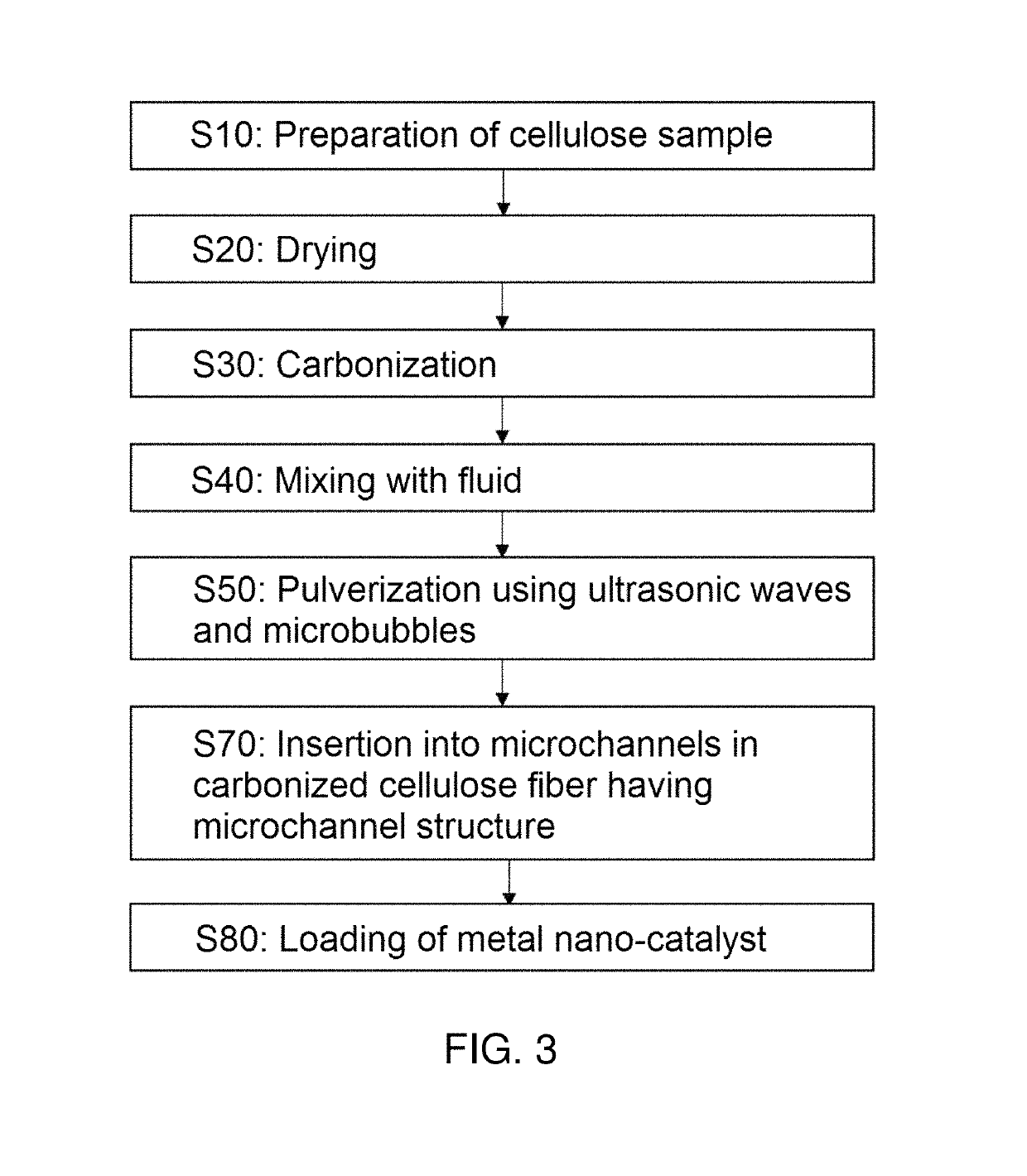

Method of preparing minute carbonized cellulose and method of preparing catalyst support using the same

ActiveUS20170098827A1Increase surface areaReduce manufacturing costCell electrodesBiofuelsManufacturing cost reductionMicro nano

Disclosed is a method of manufacturing carbonized fine cellulose, which enables the formation of carbonized nano-sized cellulose by subjecting cellulose to drying, carbonization, and pulverization by means of shock waves using ultrasonic waves and microbubbles, thus realizing mass producibility, making it possible to fabricate a carbonized nano-sized material having uniform quality, and reducing the manufacturing costs. The carbonized fine cellulose is in the form of a nano-sized uniform carbon powder, and can thus be utilized as a catalyst support in various forms, such as fuel cell electrodes, electrodes of energy storage devices such as supercapacitors or secondary batteries, catalyst supports for micro-nano hybrid reactors, etc.

Owner:KOREA INST OF ENERGY RES

Th-U self-sustaining circulating full fused salt fuel hybrid reactor system and operation method thereof

ActiveCN103886921APromote proliferationEfficient use ofNuclear energy generationFast fission reactorsBreeder reactorHigh energy

The invention belongs to the field of cladding designs of a fusion and fission hybrid reactor, and particularly relates to a Th-U self-sustaining circulating full fused salt fuel hybrid reactor system and an operation method thereof. The Th-U self-sustaining circulating full fused salt fuel hybrid reactor system is characterized in that a fast fission breeder reactor provides an initial easily fission fuel required by starting of a thermal fission reactor, a cladding design of the thermal fission reactor utilizes an arrangement strategy of a seed-cladding to improve the entirety neutron economy of the system, and the purposes of a high energy enlargement factor of the system, tritium breeding and thorium-uranium self-sustaining circulating of the system are realized; <233>U is loaded in an energy generating region, so that the energy generating region has a good neutronics property and is mainly used for realizing the purposes of energy amplification of the system, neutron multiplication and most <233>U breeding of the system; superfluous neutrons enter a tritium producing region and are used for tritium breeding and part of <233>U breeding of the system. According to the hybrid reactor, due to self-sustaining circulating of thorium and uranium, a thorium fuel is converted into <233>U and is gradually burn up in an operation process, and the Th-U self-sustaining circulating full fused salt fuel hybrid reactor system can effectively and stably operate for a long time just by gradually adding the thorium fuel and removing the generated fission product.

Owner:TSINGHUA UNIV

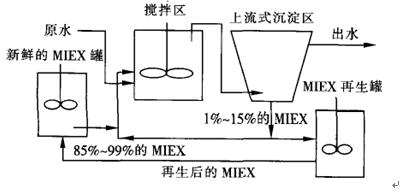

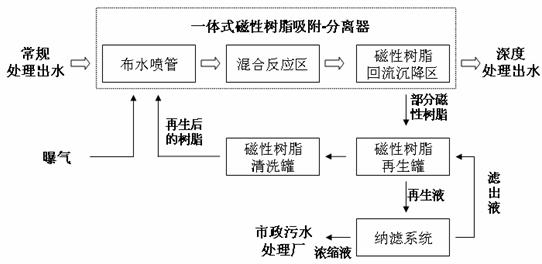

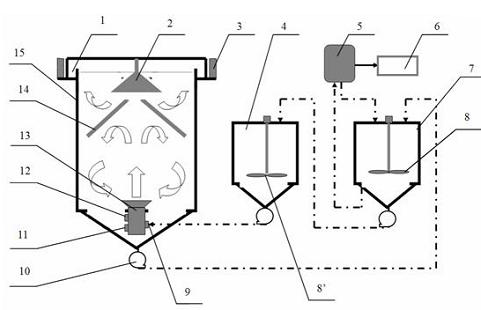

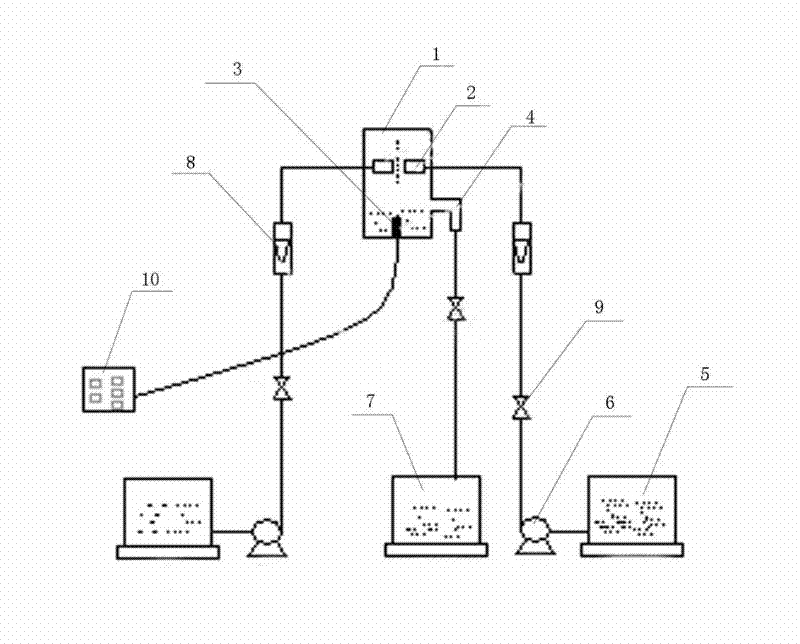

System and method for advanced treatment of drinking water based on vertical flow type three-phase hybrid reactor

InactiveCN102205995AImprove water qualityLow investment costWater/sewage treatment by ion-exchangeWater basedSulfate radicals

The invention discloses a system and a method for advanced treatment of drinking water based on a vertical flow type three-phase hybrid reactor, which belong to the field of water treatment. The system comprises a vertical flow type three-phase hybrid reactor, a magnetic resin regeneration tank, a magnetic resin washing tank and a nanofiltration system and is characterized in that: the vertical flow type three-phase hybrid reactor is connected with the magnetic resin regeneration tank; the magnetic resin regeneration tank is connected with the magnetic resin washing tank and the nanofiltration system respectively; and the magnetic resin washing tank is connected with the vertical flow type three-phase hybrid reactor. The method comprises the following steps of: performing three-phase hybrid; adsorbing; separating solid, liquid and gas; regenerating magnetic resin; cleaning; and reusing desorption liquid. By the system and the method, over 50 percent of CODMn, over 70 percent of ammonia nitrogen, over 40 percent of nitrate radical and over 50 percent of sulfate radical in the conventional outflow water of the drinking water can be removed, and the quality of the outflow water is stable.

Owner:NANJING UNIV

Anaerobic reactor

InactiveCN102939369AIncrease in sizeIncrease the number ofBio-organic fraction processingGas production bioreactorsFluidized bedProcess engineering

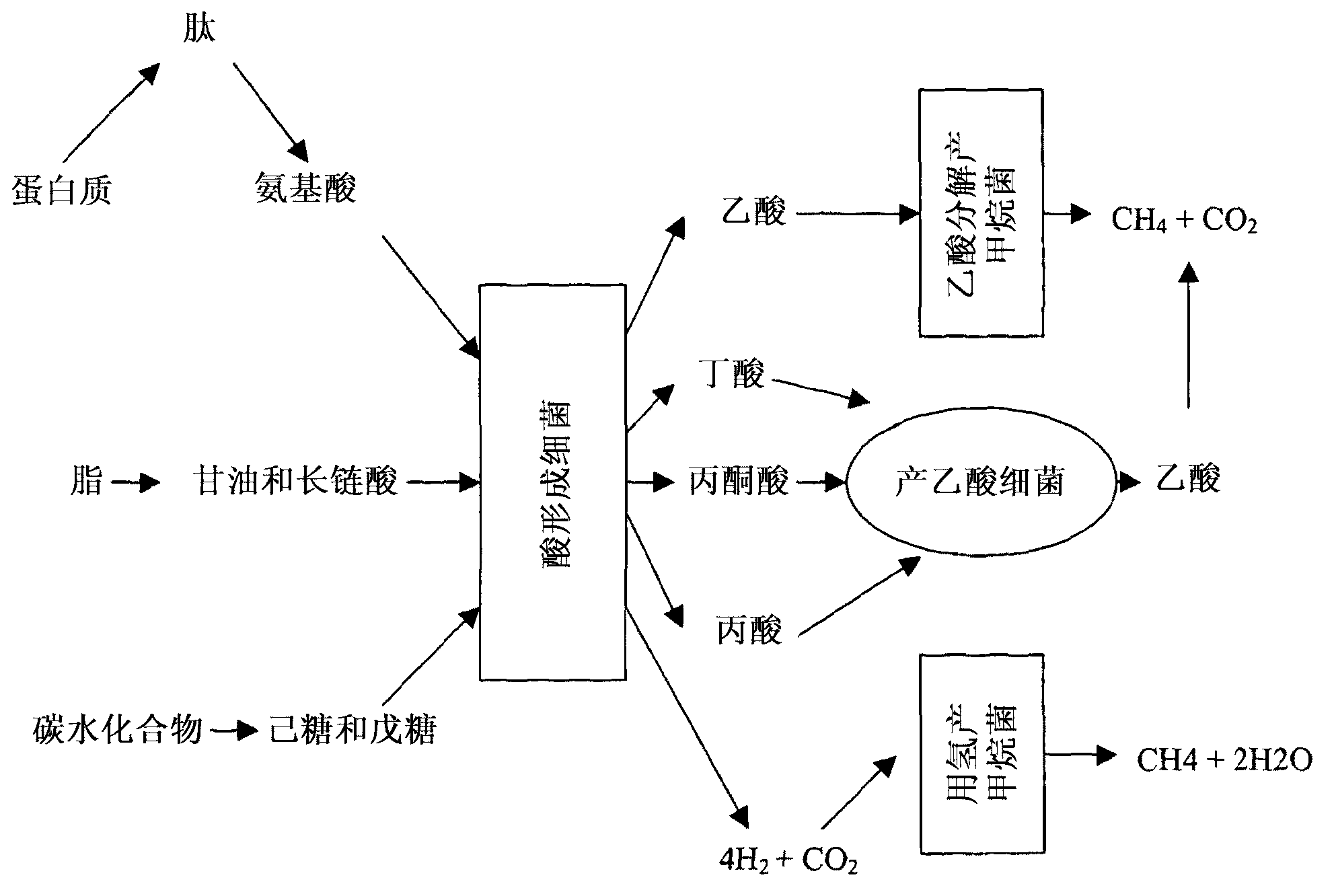

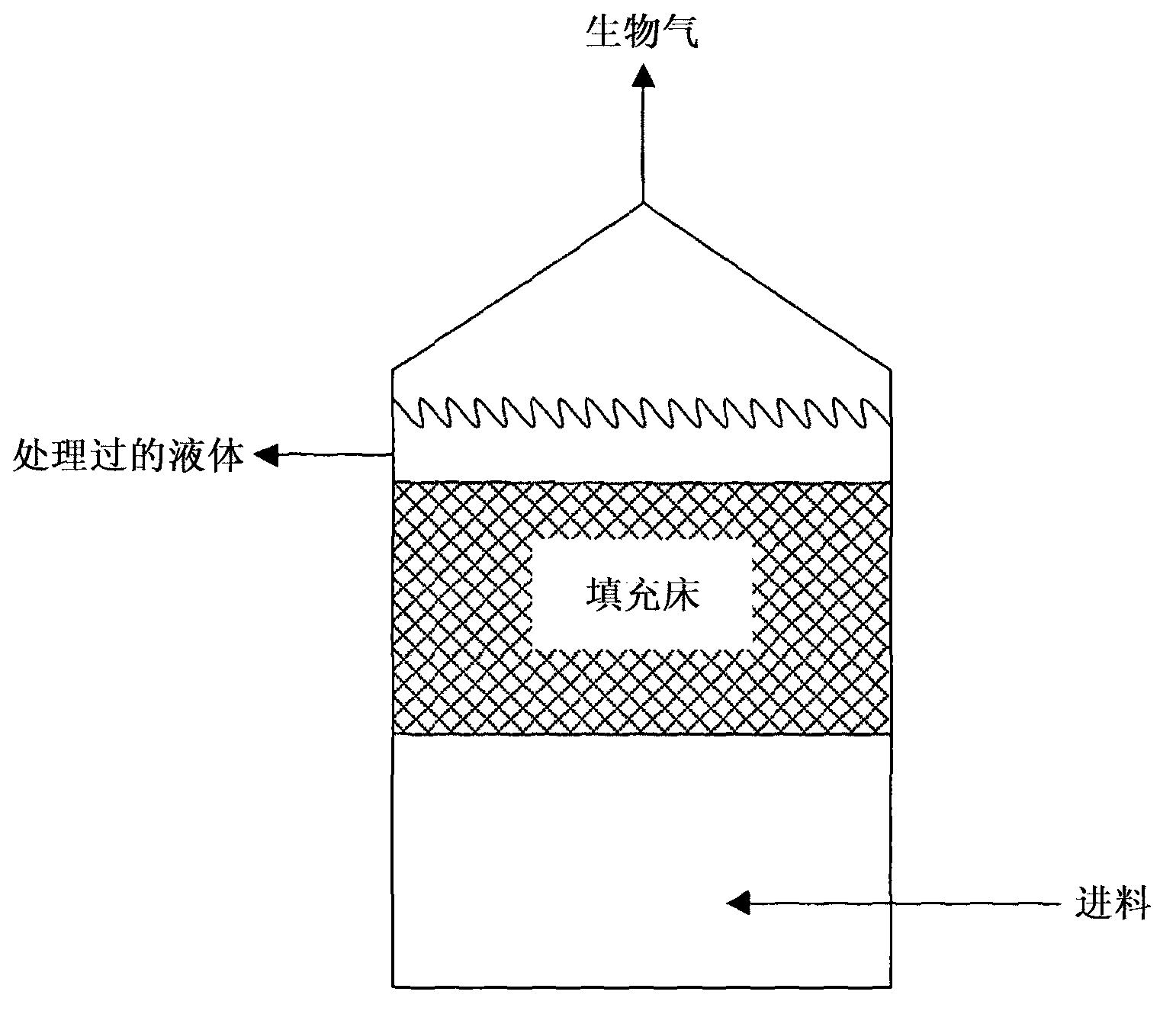

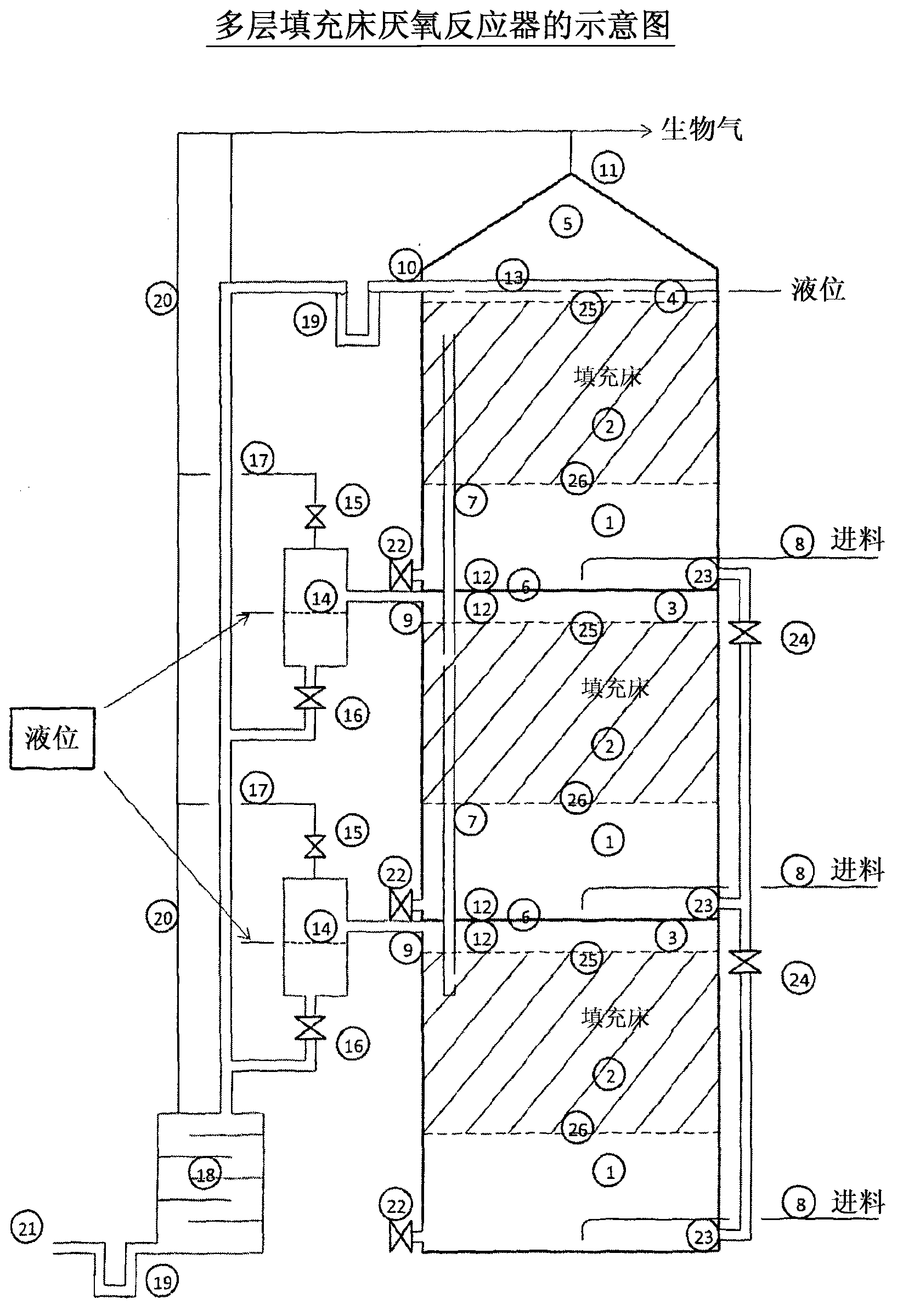

An anaerobic reactor comprising two or more discrete reaction chambers arranged one above the other is disclosed. The reactor may be in the form of a tank separated into discrete chambers by means of solid members, or the reactor may be in the form of separate and stackable chambers. Additionally, the reactor may be a packed bed reactor, a fluidised bed reactor, or a hybrid reactor comprising at least one packed bed reaction chamber and at least one fluidised bed reaction chamber. Use of an anaerobic reactor according to the invention enables an increase in the yield of biogas that can be produced per unit area of land occupied by an anaerobic reactor. A method of producing biogas is also disclosed, the method comprising providing an anaerobic reactor according to the invention, providing input biomass, carrying out anaerobic digestion of the biomass in the reactor, and collecting the biogas produced.

Owner:ADVANCED BIOGAS TECH

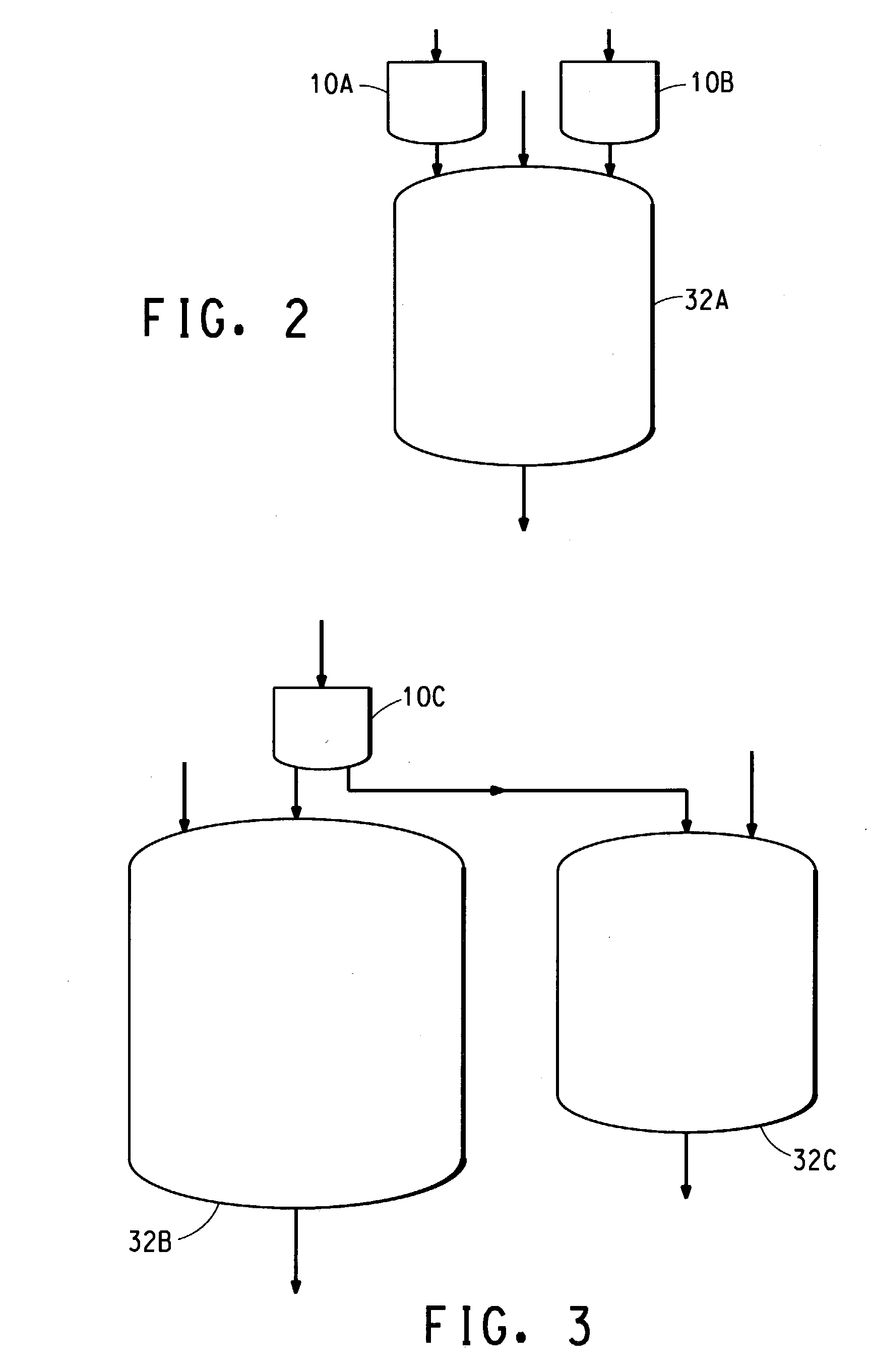

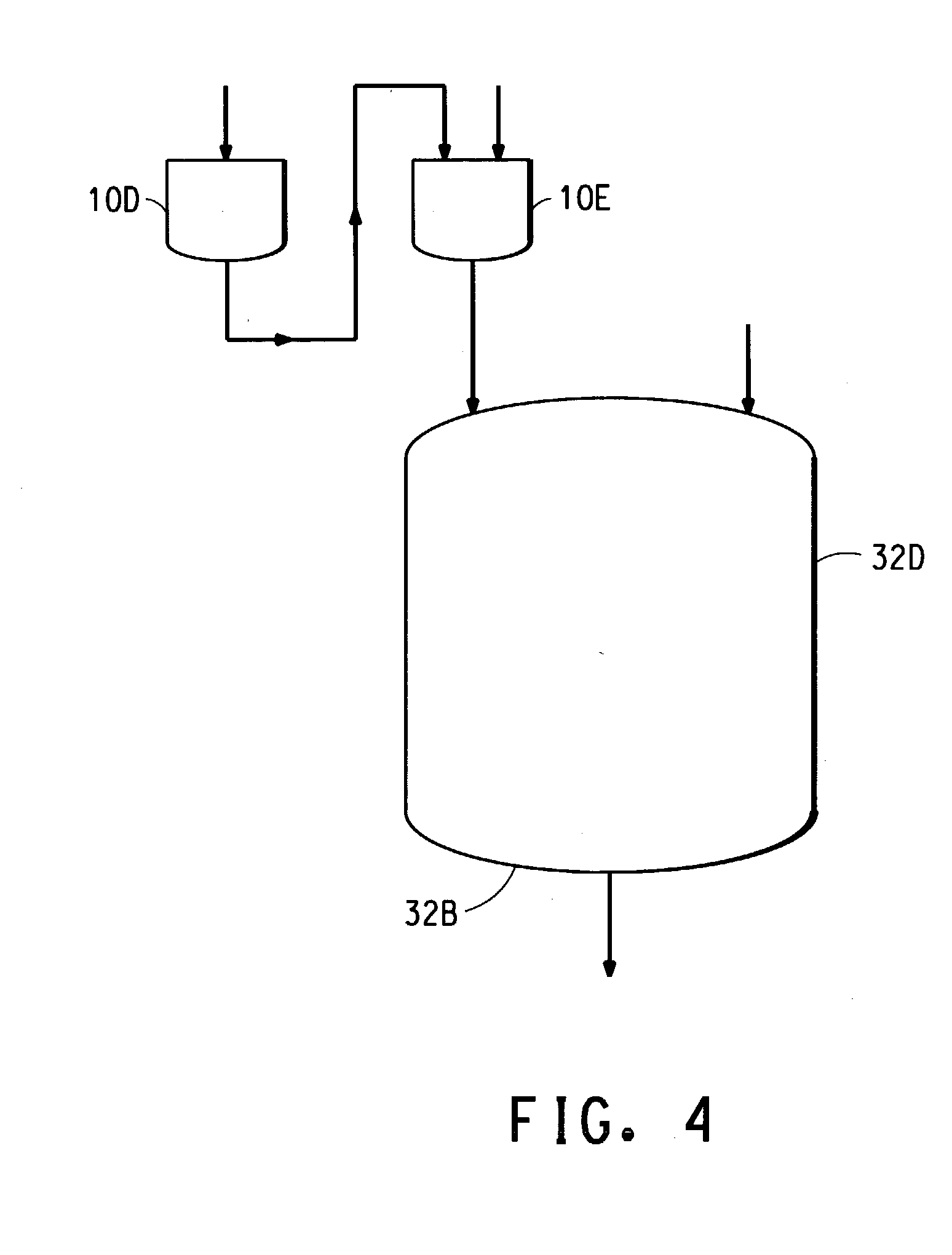

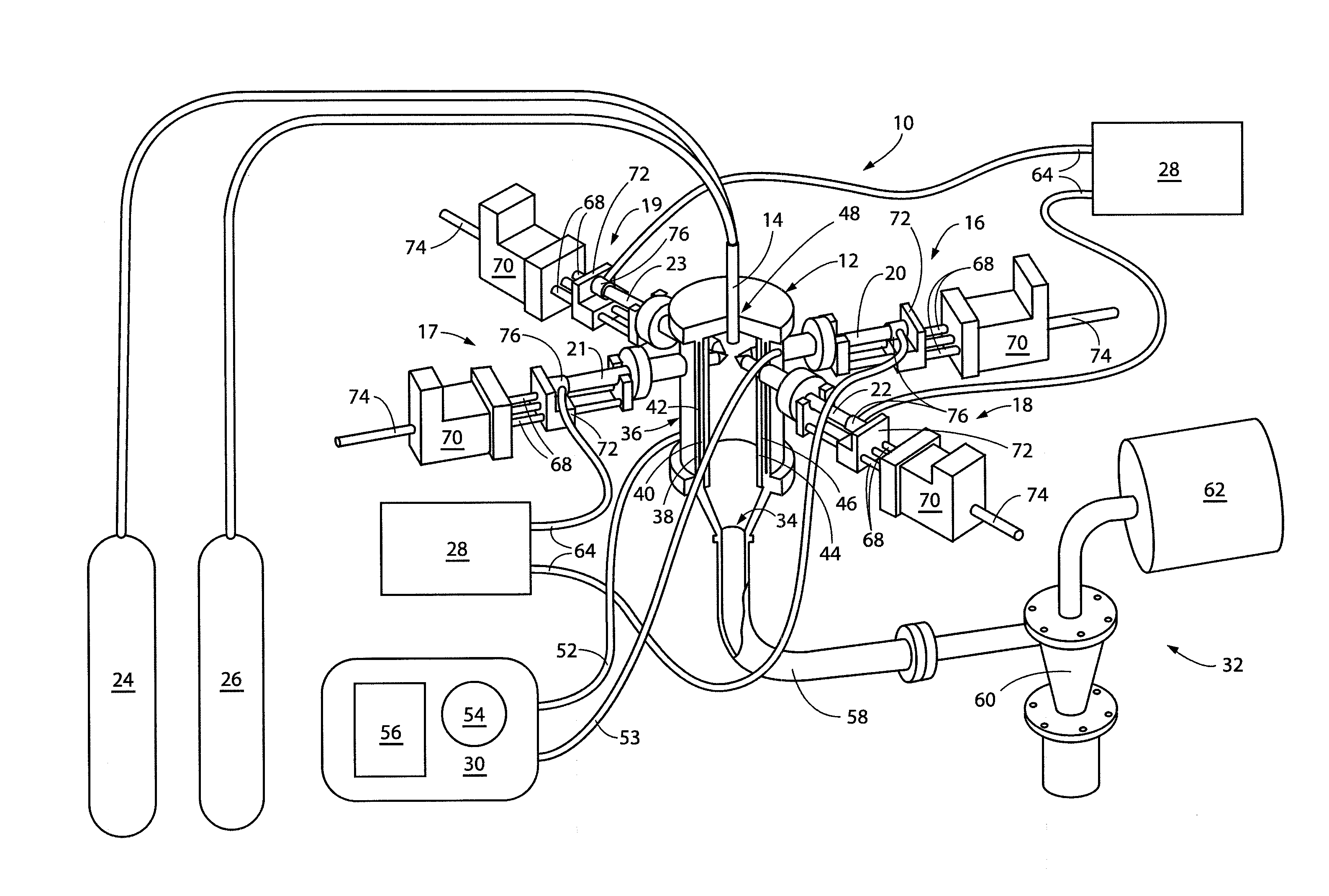

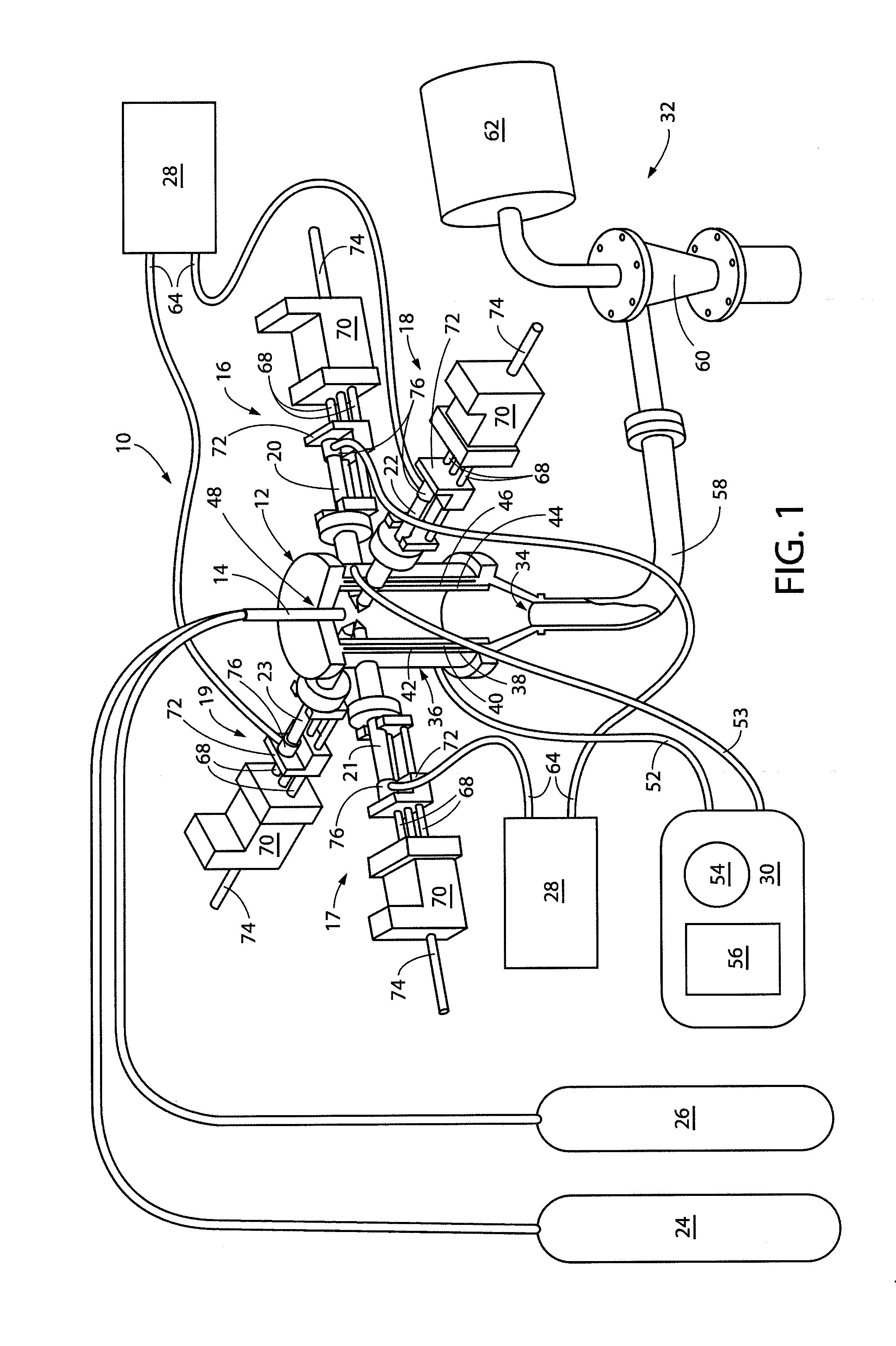

Pressurized high temperature polymerization process and polymerization system used therein

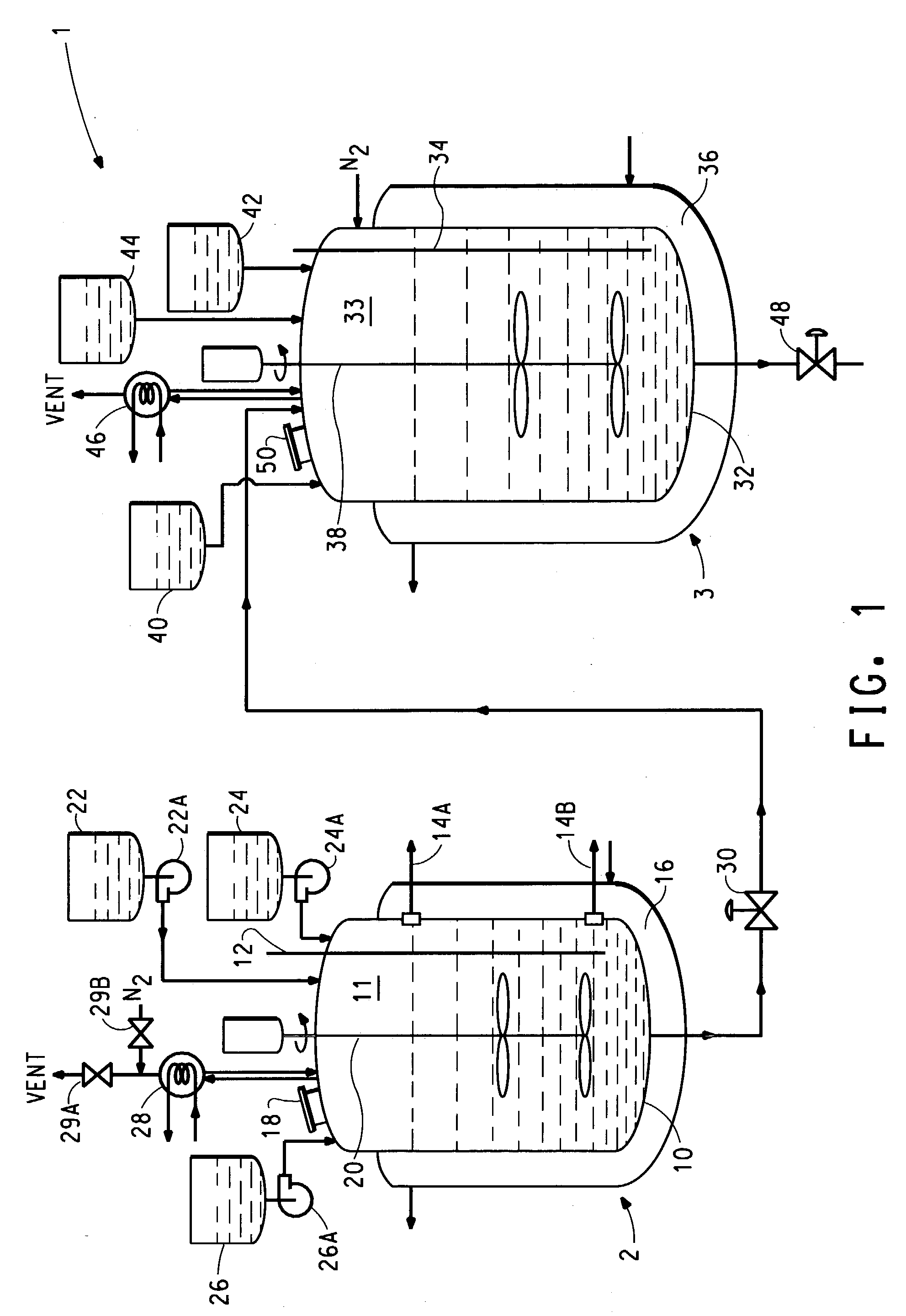

The present invention is directed to a novel high temperature polymerization process operating at high pressures for producing a polymer. The process includes conveying hybrid reactor mixtures, which include one or more hybrid reactor monomers and one or more hybrid reactor initiators to one or more hybrid reactors. The hybrid reactors are maintained at effective hybrid polymerization temperatures and sub-reflux polymerization gage pressures to cause polymerization of a portion of the hybrid reactor monomers into the polymer. The process further includes conveying hybrid reactor contents from. the hybrid reactors to one or more batch reactors maintained at effective batch polymerization temperatures and reflux polymerization pressures to cause polymerization of a remaining portion of the hybrid reactor monomers into the polymer. The hybrid reactors are smaller in volume than the batch reactors. By utilizing the hybrid / batch reactor combination, the process of the present invention can be operated under safe working conditions. The process of the present invention also allows control of the polydispersity and molecular weight of the resulting polymers. As a result, the polymers made therefrom can be used as binders in compositions, such as coating compositions used in the automotive refinish and OEM applications having desired coating properties. The present invention is also directed to a polymerization system used in the process of the present invention.

Owner:AXALTA COATING SYST IP CO LLC

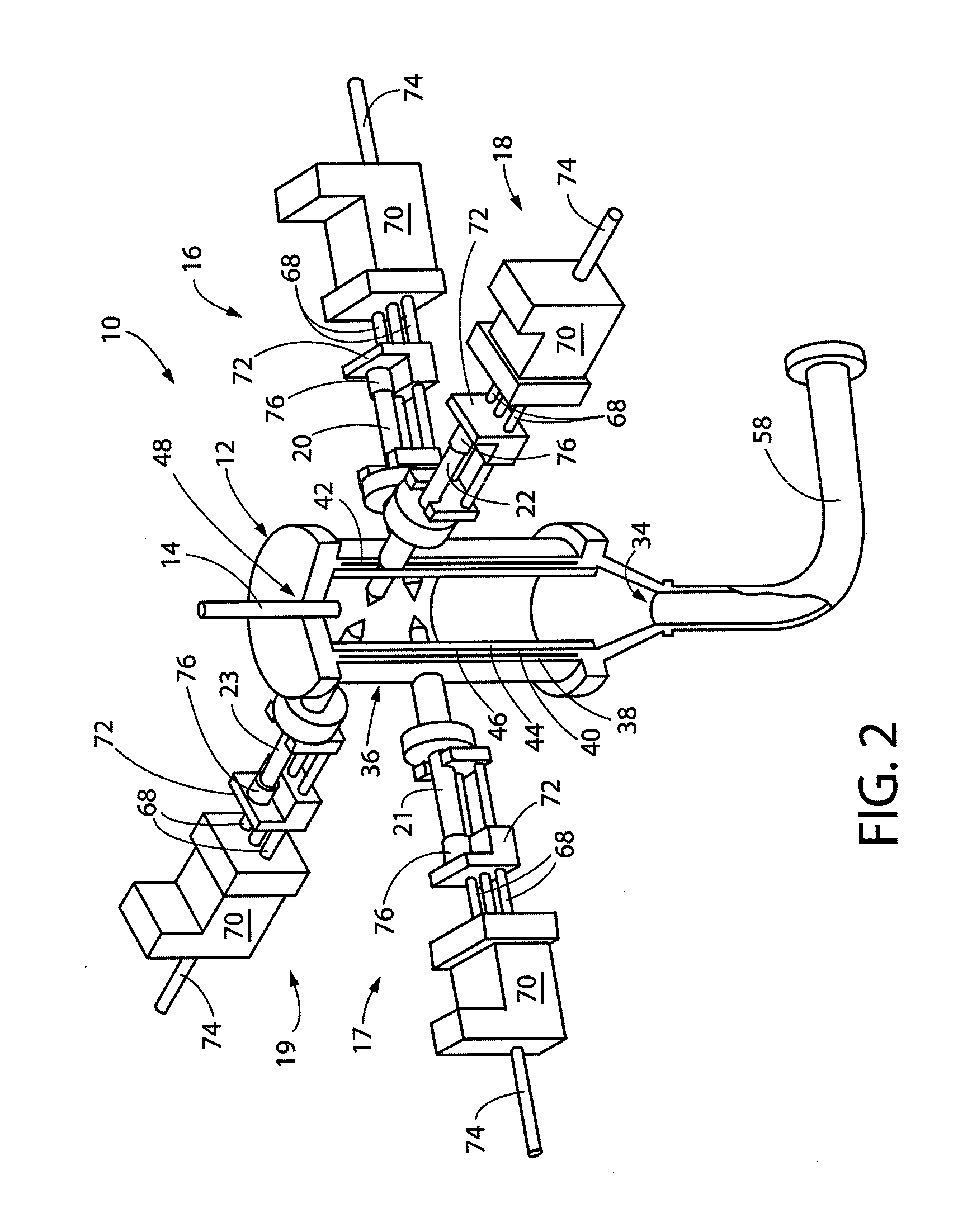

Combustion flame plasma hybrid reactor systems, chemical reactant sources and related methods

Combustion flame-plasma hybrid reactor systems, chemical reactant sources, and related methods are disclosed. In one embodiment, a combustion flame-plasma hybrid reactor system comprising a reaction chamber, a combustion torch positioned to direct a flame into the reaction chamber, and one or more reactant feed assemblies configured to electrically energize at least one electrically conductive solid reactant structure to form a plasma and feed each electrically conductive solid reactant structure into the plasma to form at least one product is disclosed. In an additional embodiment, a chemical reactant source for a combustion flame-plasma hybrid reactor comprising an elongated electrically conductive reactant structure consisting essentially of at least one chemical reactant is disclosed. In further embodiments, methods of forming a chemical reactant source and methods of chemically converting at least one reactant into at least one product are disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

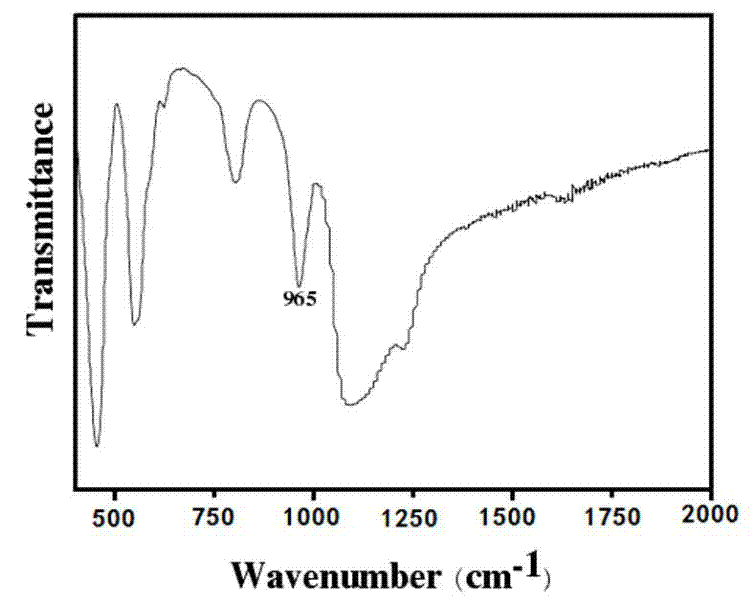

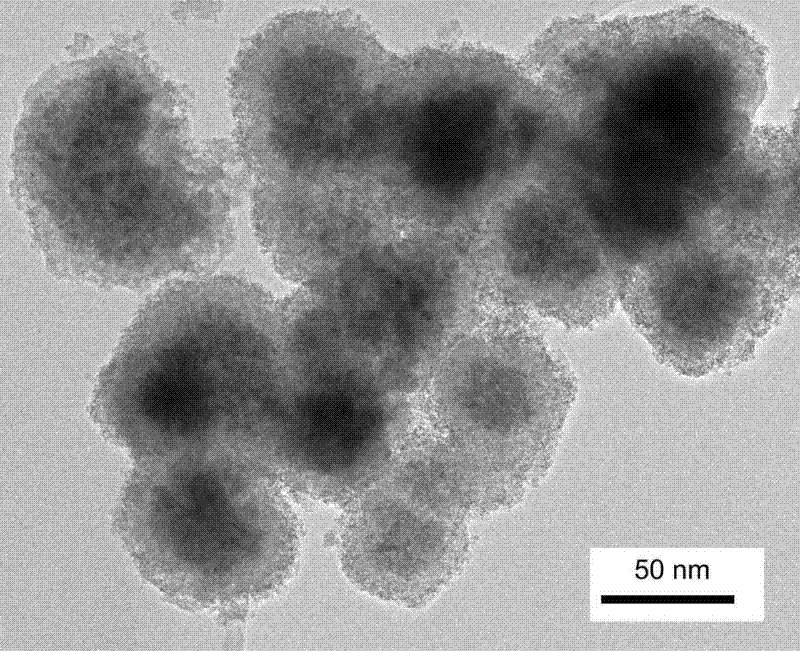

Preparation method of magnetically supported titanium-silicon molecular sieve catalyst and special impact ultrasonic micro-mixing reactor

InactiveCN102266794AHigh catalytic activityEfficient recyclingOrganic chemistryMolecular sieve catalystsNickel saltPtru catalyst

The invention relates to a method for producing a magnetic-loaded titanium silicon molecular sieve catalyst and special equipment of the method. The method for producing the magnetic-loaded titanium silicon molecular sieve catalyst comprises the following steps: colliding a mixture solution of soluble ferric salt and soluble nickel salt with ammonia spirit and then completely mixing under condition of sonic oscillation; obtaining ferrous acid nickel powder through a hydro-thermal reaction, and then mixing titanate hydrolysate with estersil hydrolystate to produce tianium silicon sol, and thenadding ferrous acid nickel powder into the tianium silicon sol, finally producing the magnetic-loaded titanium silicon molecular sieve catalyst through steps of hydro-thermal reaction, filtering, washing, drying and annealing. The colliding ultrasonic micro hybrid reactor used by the method is to install two nuzzles capable of colliding and mixing mixture solution mixed by soluble ferric salt andsoluble nickel salt with ammonia spirit in the reactor. in the invention, the magnetic is used nanoparticle as carrier; surface of the magnetic nanoparticle is cladded with a titanium silicon compound; high catalytic activity of the titanium silicon molecular sieve catalyst is maintained relatively, and solid-liquid separation is preformed under additional condition of magnetic field and a purpose of efficiently reclaiming the catalyst is achieved.

Owner:ZHONGBEI UNIV

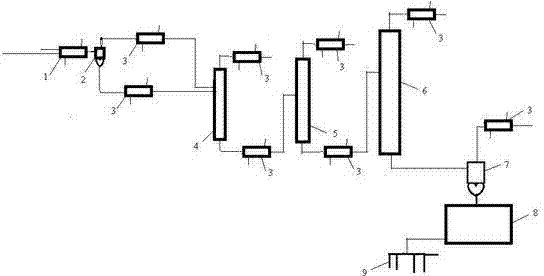

Continuous hydrolysis system for preparing glyphosate by glycine method

ActiveCN103788127AAvoid rushingGuaranteed hydrolysis effectGroup 5/15 element organic compoundsGlycineVapor–liquid separator

The invention provides a continuous hydrolysis system for preparing glyphosate by a glycine method. The continuous hydrolysis system is characterized by comprising a hybrid reactor, a gas-liquid separator, a heat exchanger, a methylal recovery tower, a methyl alcohol recovery tower, a hydrolysis tower, a flash evaporator, a heat insulation storage tank and a crystallization kettle, wherein the hybrid reactor is connected with the gas-liquid separator; a liquid discharge hole and a liquid outlet of the gas-liquid separator are respectively connected with the heat exchanger; the heat exchanger is connected with the methylal recovery tower; the methylal recovery tower, the methyl alcohol recovery tower, the hydrolysis tower, the flash evaporator, the heat insulation storage tank and the crystallization kettle are sequentially connected. After the continuous hydrolysis system is adopted, the problem of low efficiency of single-kettle intermittent operation of the traditional multi-hydrolysis kettle can be solved, so that the production efficiency is greatly improved; the product quality and the reaction yield of the continuous hydrolysis system are superior to those of the traditional technology; compared with the traditional technology, the continuous hydrolysis system saves the energy consumption by more than 20%.

Owner:福华通达化学股份公司

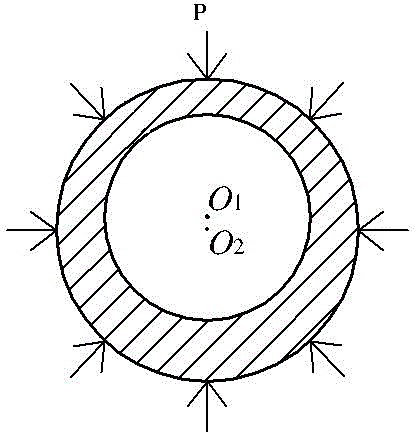

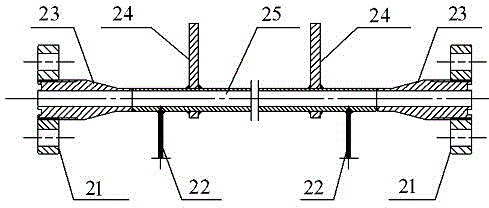

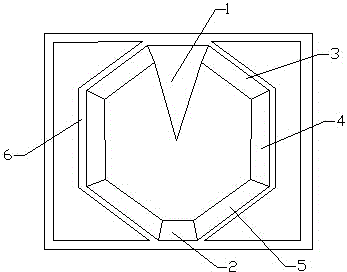

Eccentric pipe for simulating hybrid reactor subcritical energy cladding passage in heating, and experimental device

InactiveCN104568377ATypical runner structureMaterial heat developmentHydrodynamic testingEngineeringCopper

The invention discloses an eccentric pipe for simulating a hybrid reactor subcritical energy cladding passage in heating, and an experimental device. The center of the inner diameter circle of the eccentric pipe is represented by O1, the center of the outer diameter circle of the eccentric pipe is represented by O2, the distance from O1 to O2 is greater than zero, the line segment between O1 and O2 is represented by O1O2, a plurality of thermoelectric couples are welded on the outer diameter wall of the eccentric pipe, the welding points of the thermoelectric couples and the eccentric pipe are symmetrically distributed by taking the line segment as a symmetric axis, the outer wall of the eccentric pipe is provided with a pressure guiding pipe communicated to the interior of the eccentric pipe, and a heat insulation protecting structure is arranged on the outer wall of the eccentric pipe. The experimental device comprises the eccentric pipe, the two ends of the eccentric pipe are connected with screwed nipples, one end of each screwed nipple, far away from the eccentric pipe, is connected with a threaded flange, and an electrified copper bar is further welded on the outer wall of the eccentric pipe. By using the experimental device, single-phase flow and heat-transfer characteristic experiment can be carried out under a full circumferential inhomogeneous heating condition, and the thermal-hydraulic characteristics of a hybrid reactor subcritical energy cladding cooling passage are simulated.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

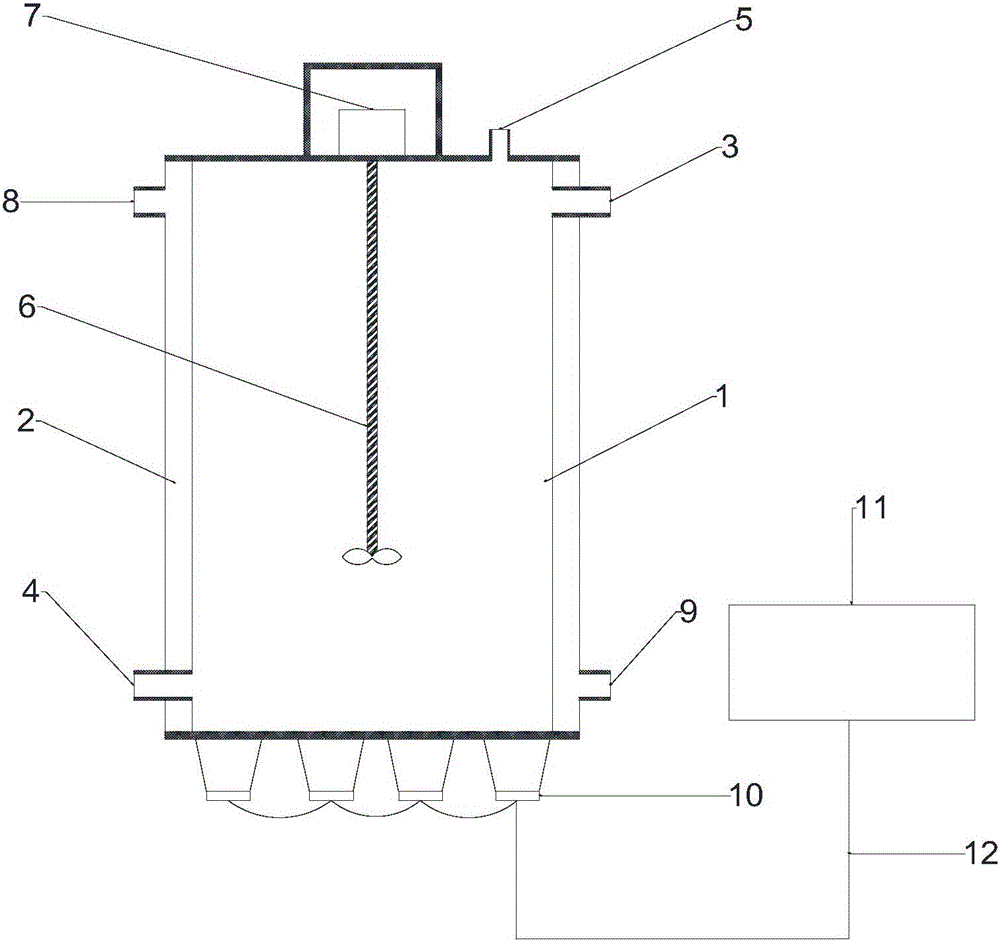

System for processing fossil fuel combustion waste gas by biology method

InactiveCN101732983AImprove efficacyChemical freeDispersed particle separationAir quality improvementElectricityOperating instruction

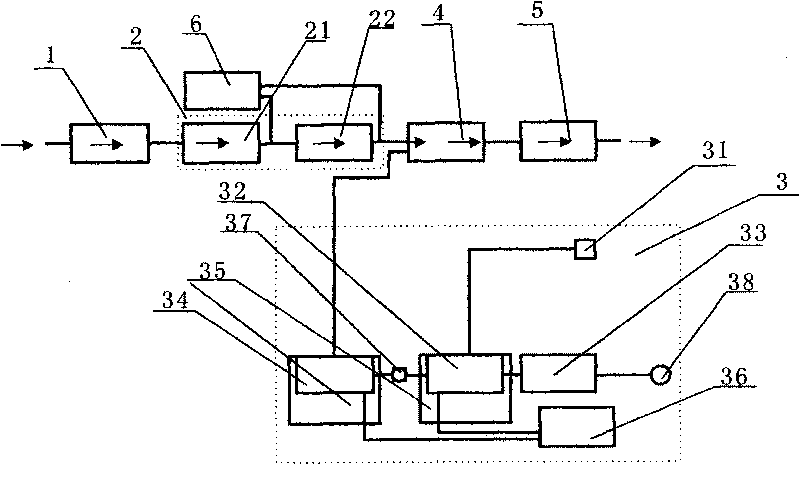

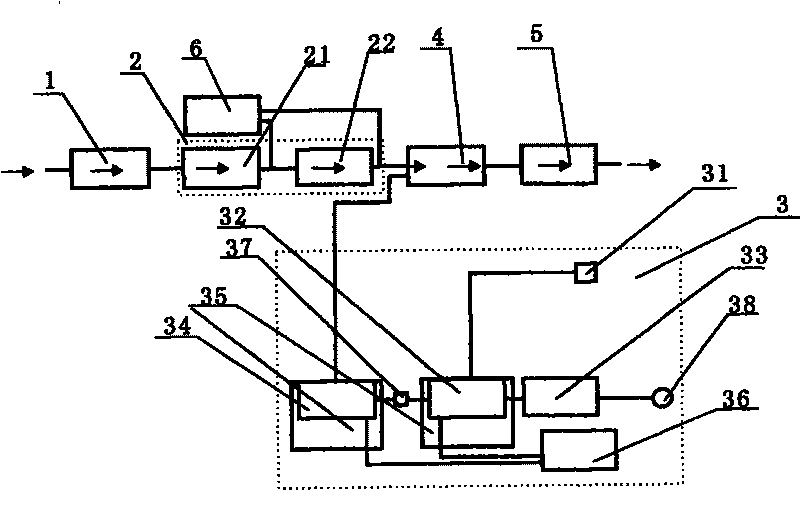

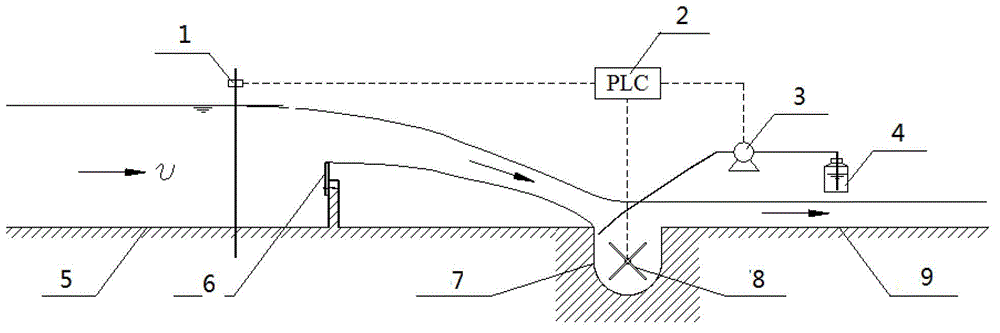

The invention relates to a system for processing fossil fuel combustion waste gas by a biology method, mainly consisting of an intake end waste gas detector (1), a cooler (2), an ultrasonic atomization device (3), a hybrid reactor (4), an air discharge end waste gas detector (5), a system power source and a CPU control centre. The system is characterized in that a pipeline is sequentially communicated to the intake end waste gas detector (1), the cooler (2), the hybrid reactor (4) and the air discharge end waste gas detector (5); a discharge hole pipe of the ultrasonic atomization device (3) is communicated to the intake end of the hybrid reactor (4); and a waste gas temperature sensor (6) is arranged at the air outlet end of the cooler (2). The system power source provides electricity support for components and receives control from the CPU control centre which receives and analyzes data from a detection device and a sensor of the components; besides, an operating instruction is issued to an executing mechanism of the component, thereby achieving the purpose of design.

Owner:左曦

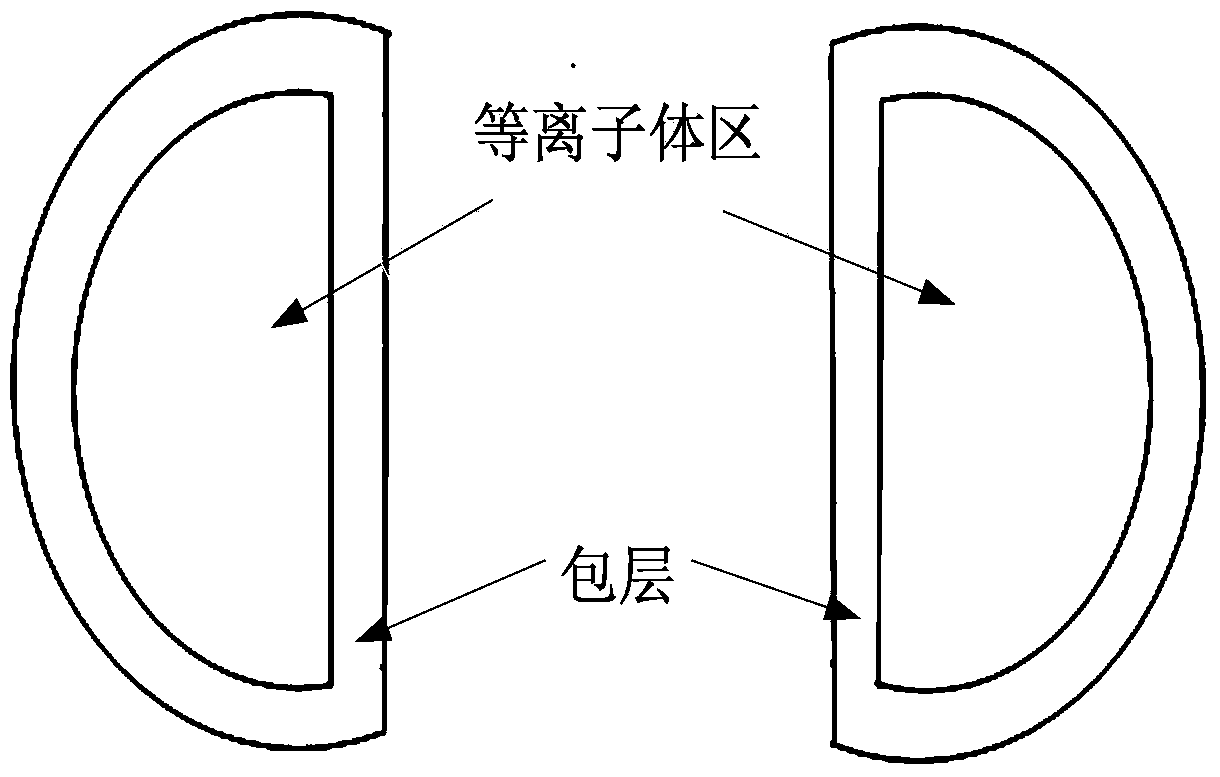

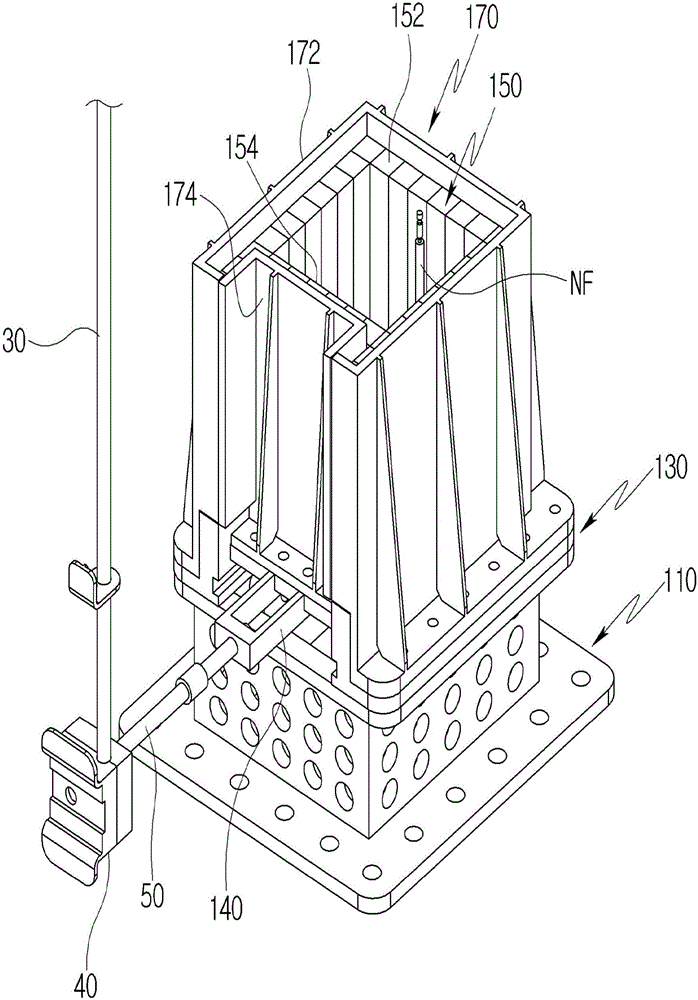

Hybrid reactor in-core detector assembly for core monitoring and protection

InactiveCN105247620ASimultaneous execution of functionsExecutive functionPower plant safety arrangementNuclear energy generationHybrid typeNuclear engineering

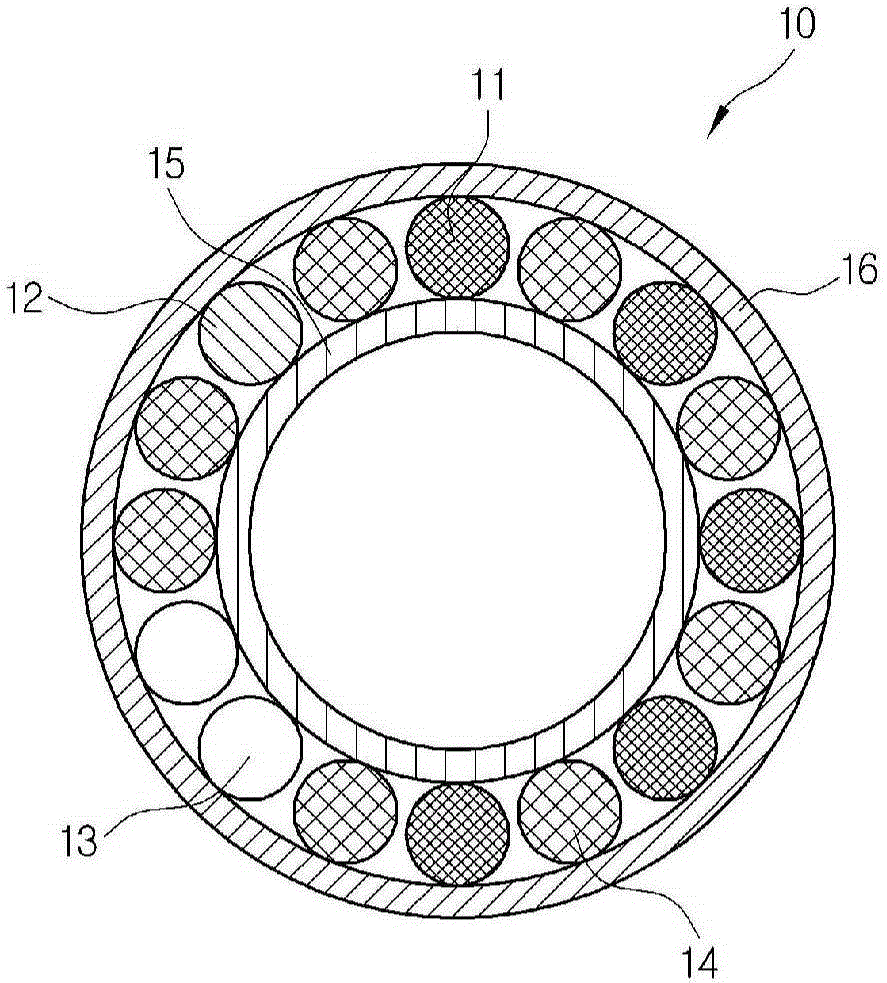

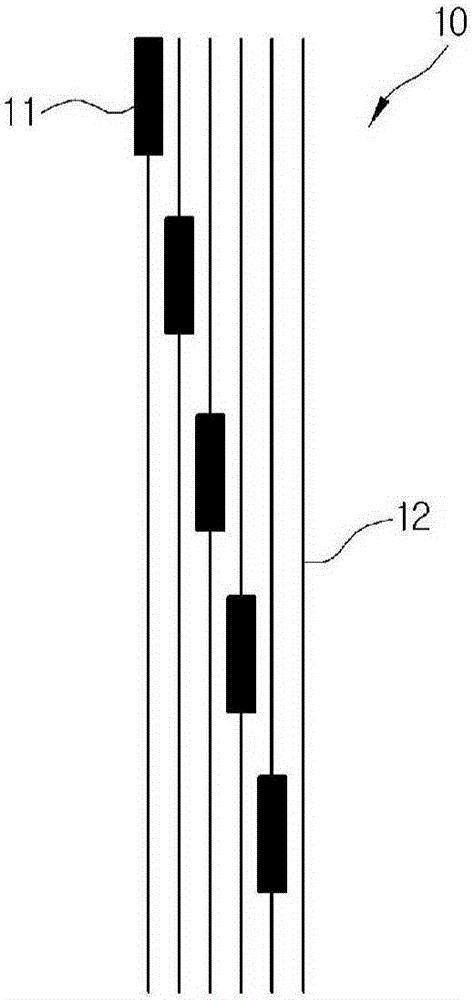

The present invention relates to a hybrid reactor in-core detector assembly for core monitoring and protection and, specifically, a hybrid reactor in-core detector assembly for simultaneously carrying out a reactor core monitoring function and a reactor core protection function, comprising: vanadium detectors and a background detector for carrying out the reactor core monitoring function; platinum detectors for carrying out the reactor core protection function; and one integrated core exit thermocouple. According to the present invention, since the reactor in-core detector assembly using the vanadium detectors and the platinum detectors is a hybrid type, the reactor core monitoring function and the reactor core protection function can be simultaneously carried out.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

Replaceable fusion neutron source

InactiveUS20100119025A1Increase nuclear fission reactionImprove power densityNuclear energy generationReactor fuel elementsNuclear fusionNuclear fission

Disclosed are a replaceable fusion core that can be inserted and removed from the core of a nuclear fission reactor, thereby enabling the replacement of materials exposed to neutron flux and reducing outage times and “hybrid reactor, method, and device for improved nuclear fusion reactors to provide sufficient flux of fast neutrons with sufficient energy to transmutate transuranic wastes from nuclear fission and to be used in improved nuclear fuel cycles so as to effectively reduce the amount radio-toxicity, and the risks and costs of the disposal of nuclear waste, thereby reducing the cost of nuclear energy and increasing its acceptability as an energy source. This abstract is intended for use as a scanning tool only and is not intended to be limiting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method of preparing minute carbonized cellulose and method of preparing catalyst support using the same

ActiveUS10276876B2Efficiently formedSuitable for processingCell electrodesBiofuelsCelluloseManufacturing cost reduction

Disclosed is a method of manufacturing carbonized fine cellulose, which enables the formation of carbonized nano-sized cellulose by subjecting cellulose to drying, carbonization, and pulverization by means of shock waves using ultrasonic waves and microbubbles, thus realizing mass producibility, making it possible to fabricate a carbonized nano-sized material having uniform quality, and reducing the manufacturing costs. The carbonized fine cellulose is in the form of a nano-sized uniform carbon powder, and can thus be utilized as a catalyst support in various forms, such as fuel cell electrodes, electrodes of energy storage devices such as supercapacitors or secondary batteries, catalyst supports for micro-nano hybrid reactors, etc.

Owner:KOREA INST OF ENERGY RES

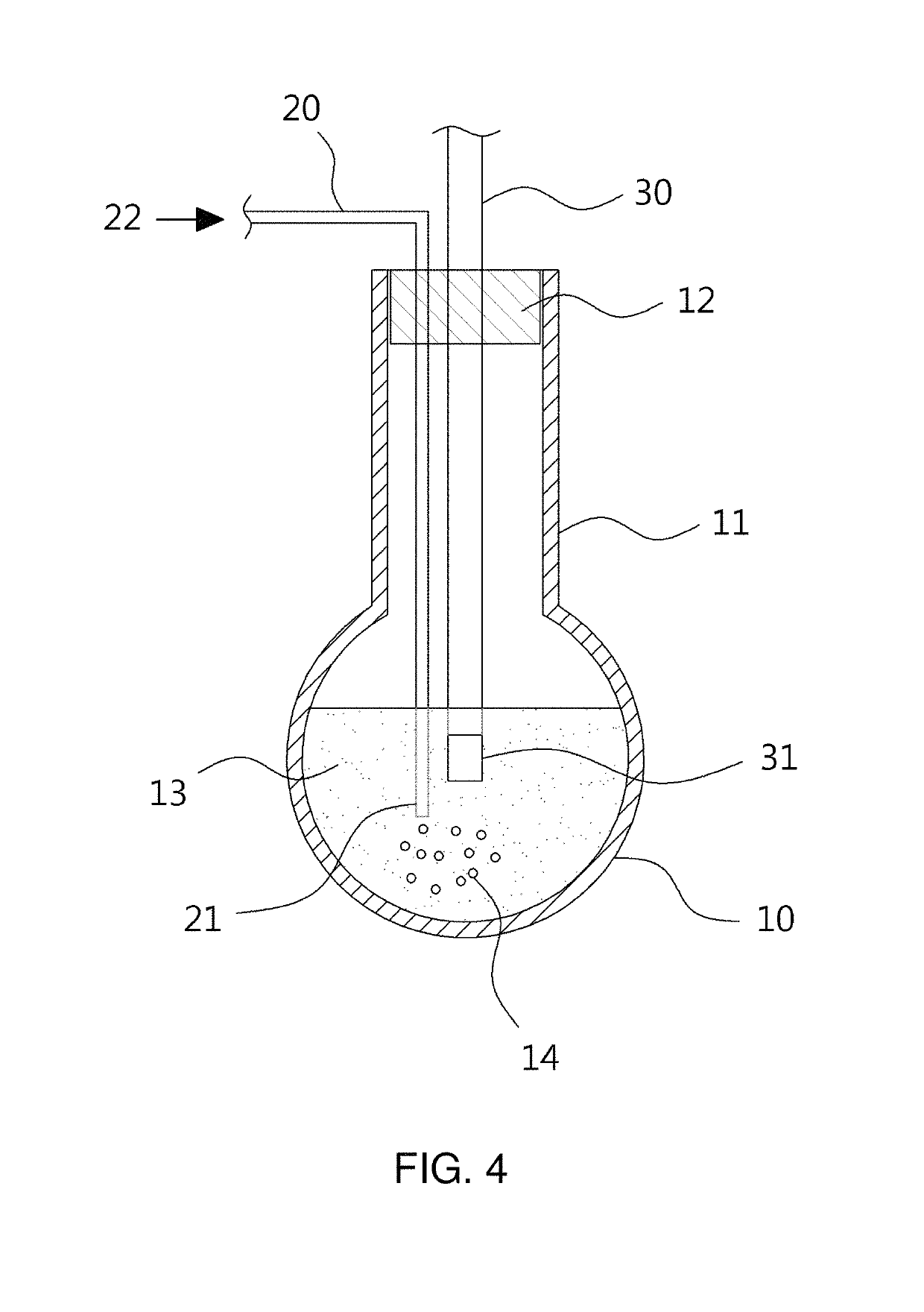

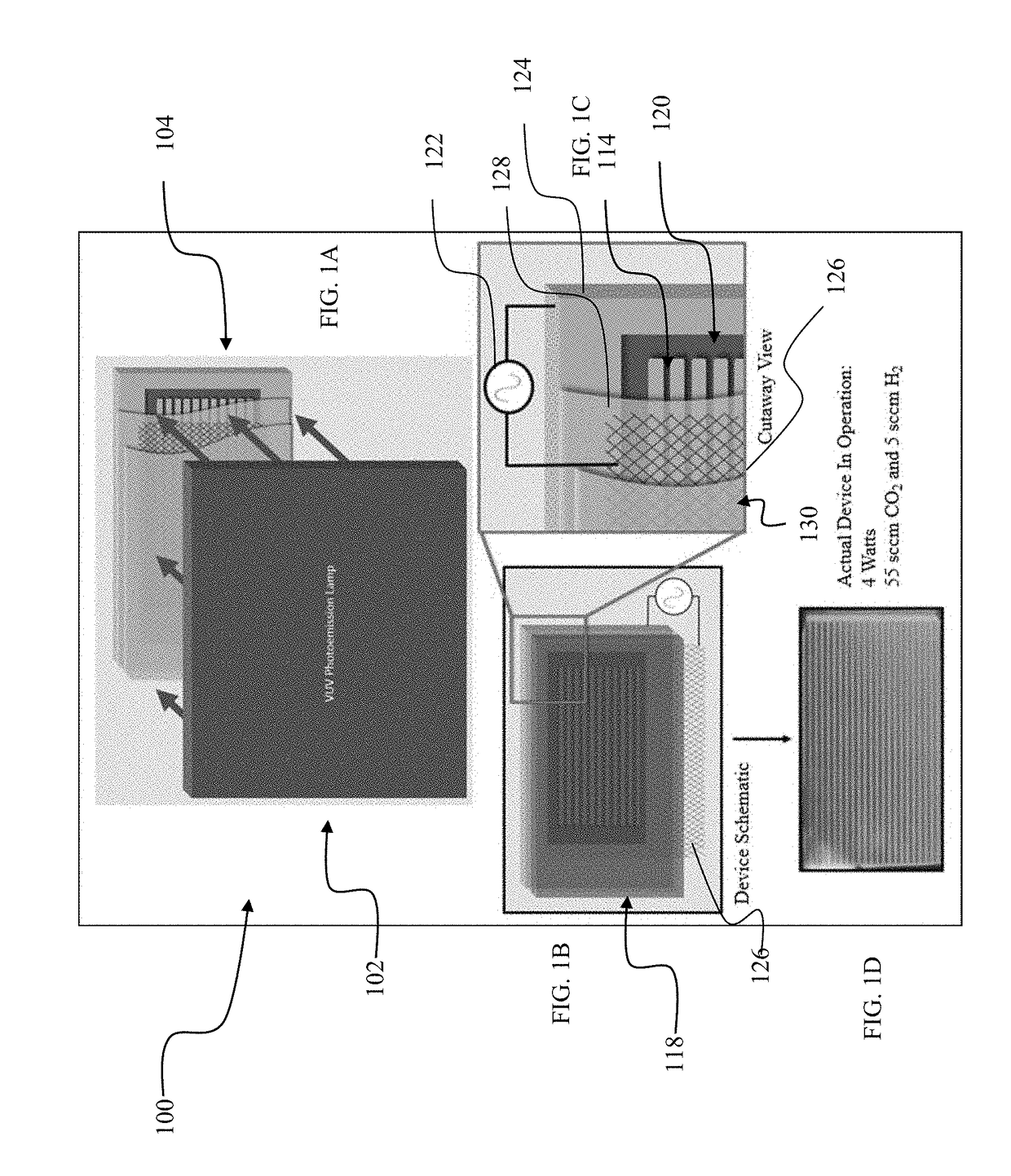

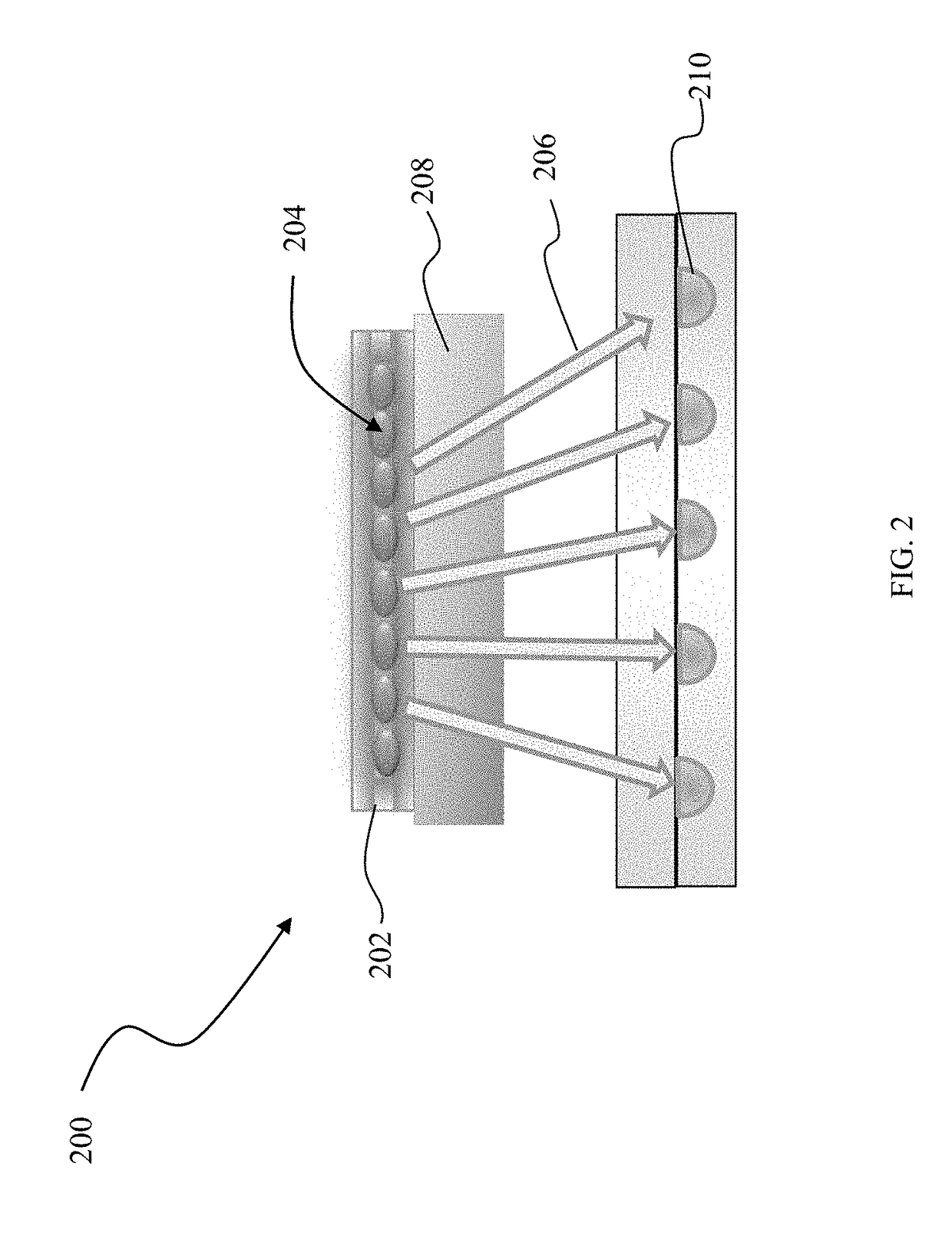

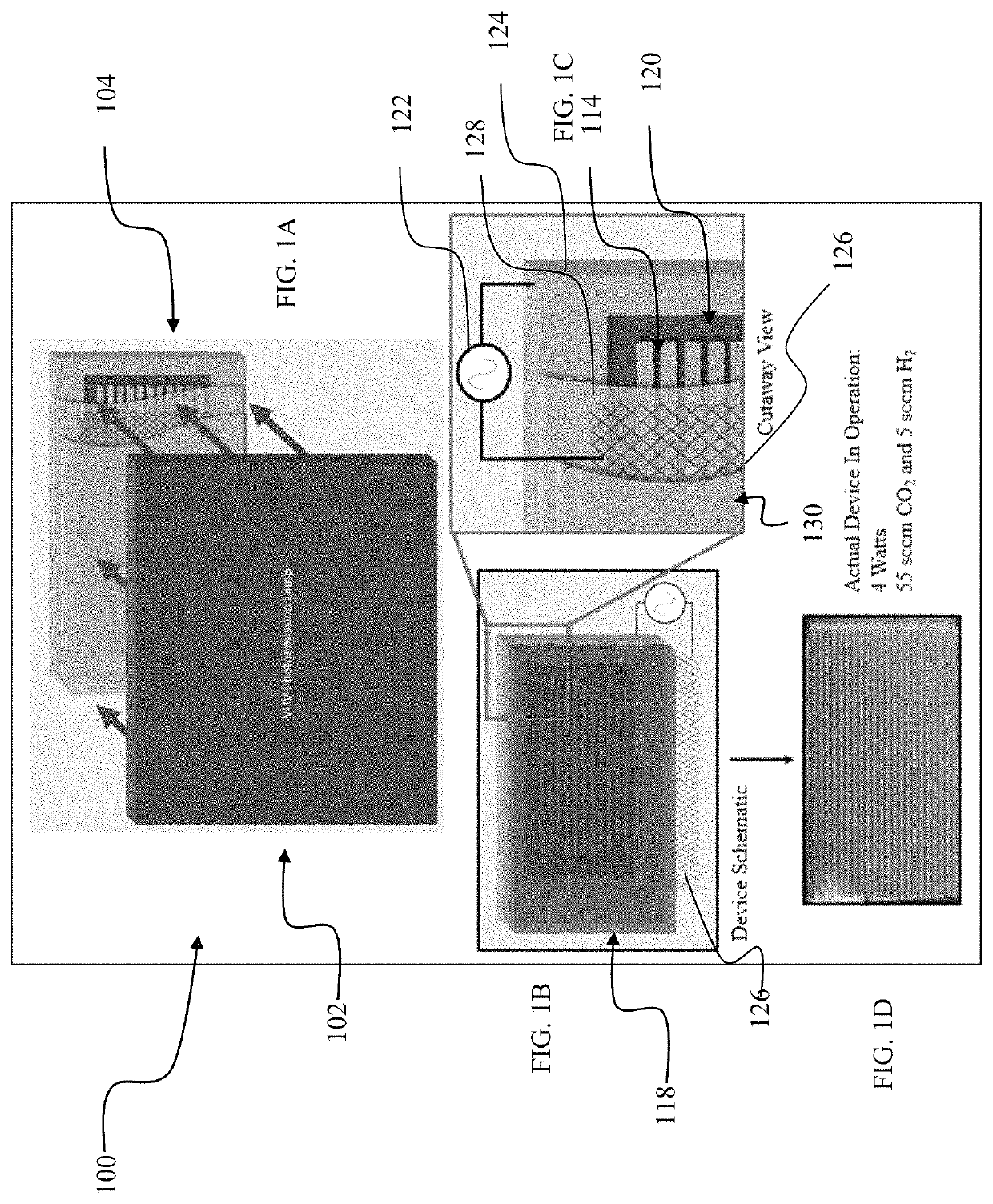

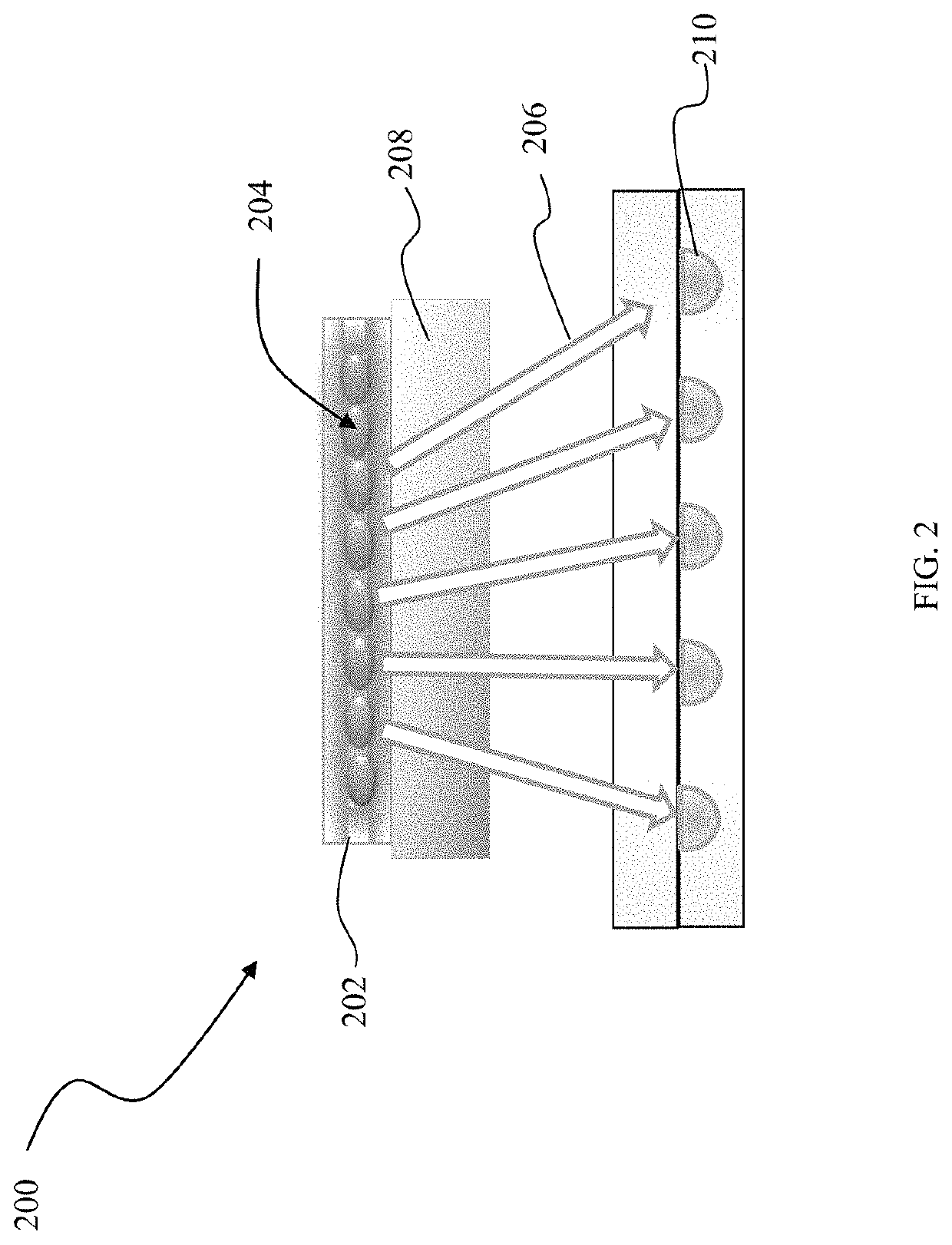

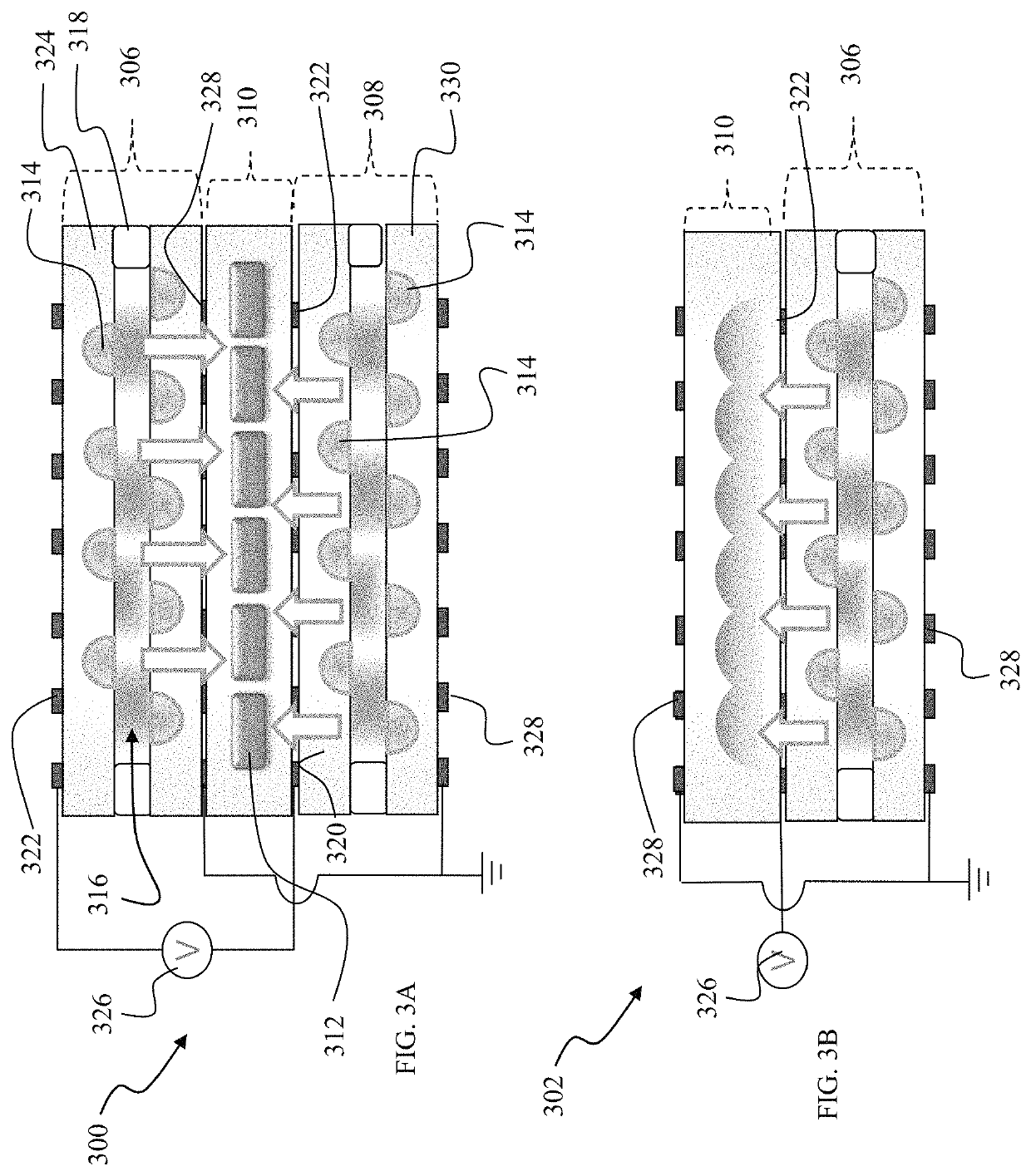

Hybrid photochemical/plasma reactor devices

ActiveUS20180099257A1Chemical/physical/physico-chemical microreactorsElectrical discharge ozone preparationPhase timeProduct gas

A method for generating a hybrid reaction flows feedstock gas that is also a plasma medium through microchannels. Plasma is generated with the plasma medium via excitation with a time-varying voltage. UV or VUV emissions are generated at a wavelength selected to break a chemical bond in the feedstock gas. The UV or VUV emissions are directed into the microchannels to interact with the plasma medium and generate a reaction product from the plasma medium. A hybrid reactor device includes a microchannel plasma array having inlets and outlets for respectively flowing gas feedstock into and reaction product out of the microchannel plasma array. A UV or VUV emission lamp has its emissions directed into microchannels of the microchannel plasma array. Electrodes ignite plasma in the microchannels and stimulating the UV or VUV emission lamp to generate UV or VUV emissions. One common or plural phased time-varying voltage sources drive the plasma array and the UV or VUV emission lamp.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

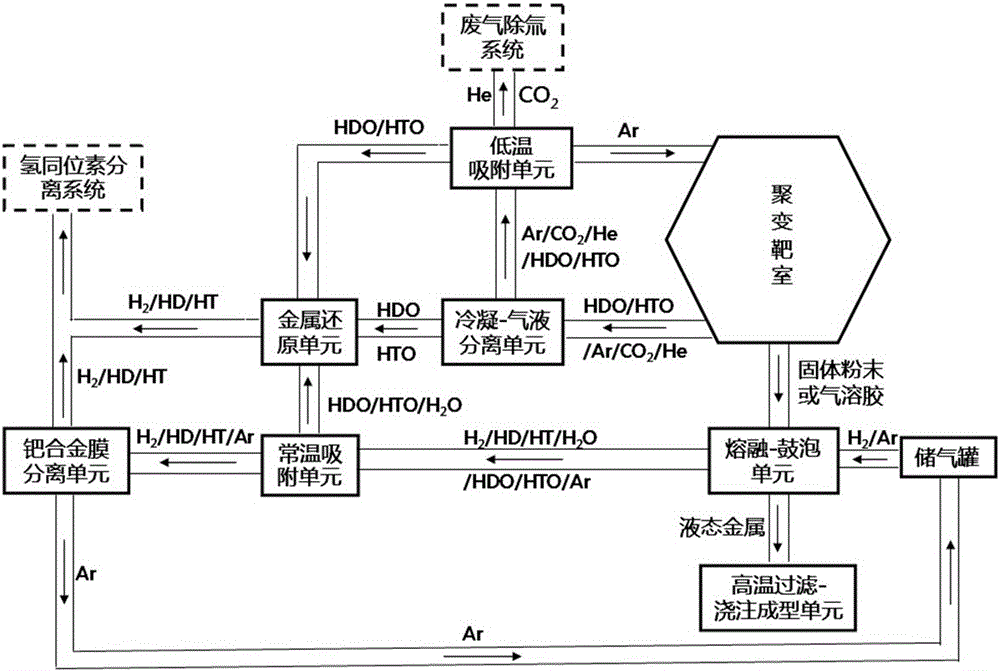

Device for processing products of fusion-fission hybrid reactor fusion target chamber

InactiveCN105976872AAvoid complexityAvoid questions with ambiguous compositionNuclear energy generationThermonuclear fusion reactorNuclear engineeringFusion fission

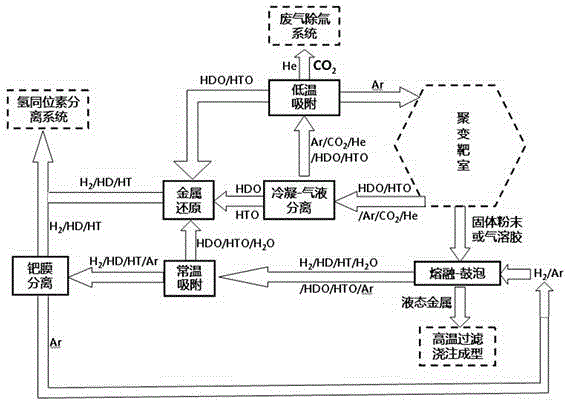

The invention provides a device for processing products of a fusion-fission hybrid reactor fusion target chamber, comprising units of a fusion target chamber, condensation-gas-liquid separation, low temperature adsorption, fusion-bubbling, normal temperature adsorption, metal reduction, palladium-membrane separation, a gas storage tank and high temperature filtering and casting molding, etc. The device of the invention avoids that constituents in the products of the fusion-fission hybrid reactor fusion target chamber are complex and unclear by oxidizing residual deuterium and tritium into water through introducing oxygen elements in the fusion target chamber, simplifies the processing source item and deuterium and tritium recycling technology, and adopts various processing technologies for gas state products and solid state products and guarantees relatively high recycling efficiency of the deuterium and tritium fuels. Besides, in the device for processing products of the fusion-fission hybrid reactor fusion target chamber, substantial Ar gas can be recycled, which saves cost. The device for processing products of the fusion-fission hybrid reactor fusion target chamber can recycle the residual deuterium and tritium fuels with recycling rate over 95%, which satisfies deuterium self-sustaining of the fusion-fission hybrid reactor and requirements for safety, economy and environment protections.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

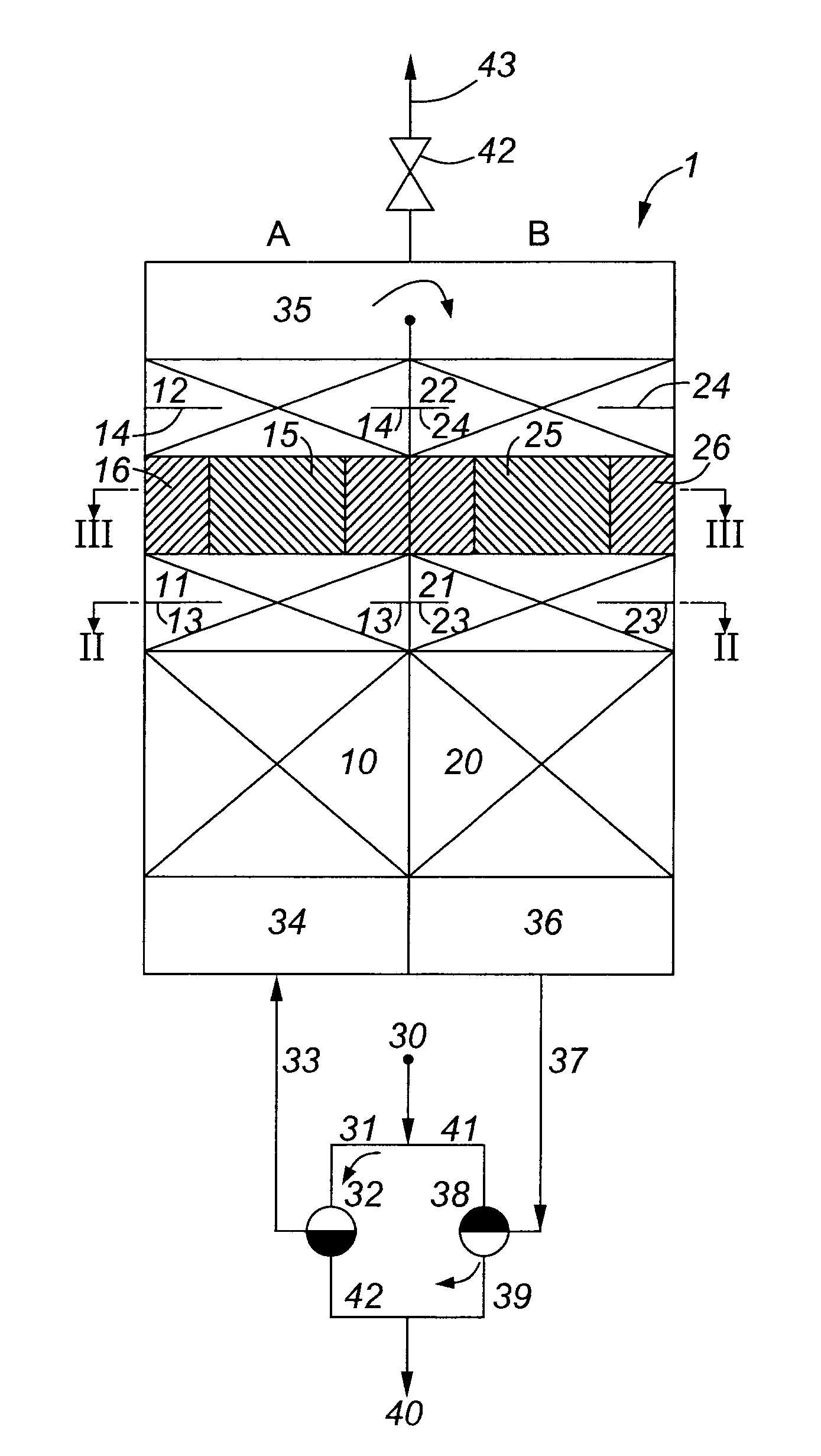

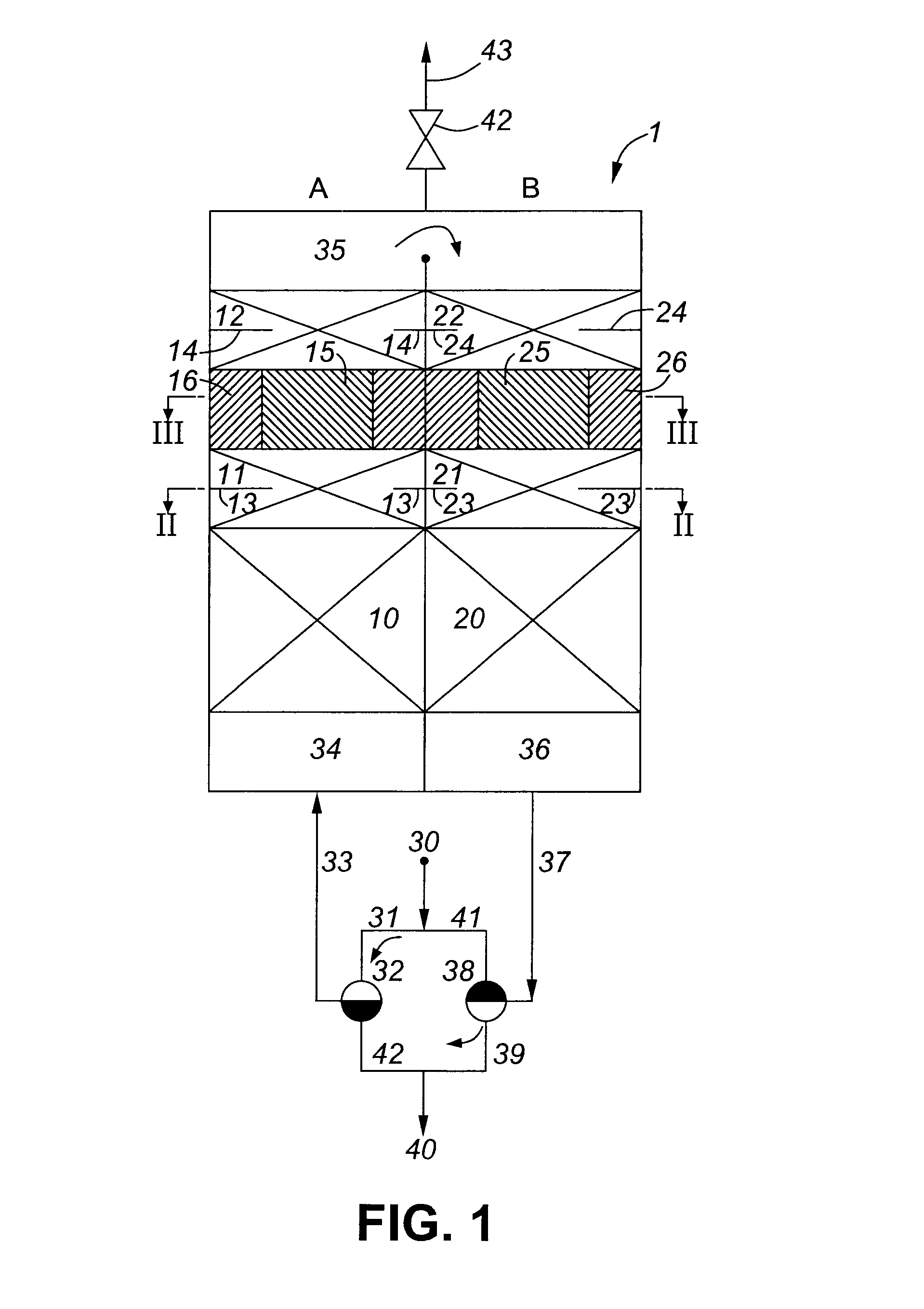

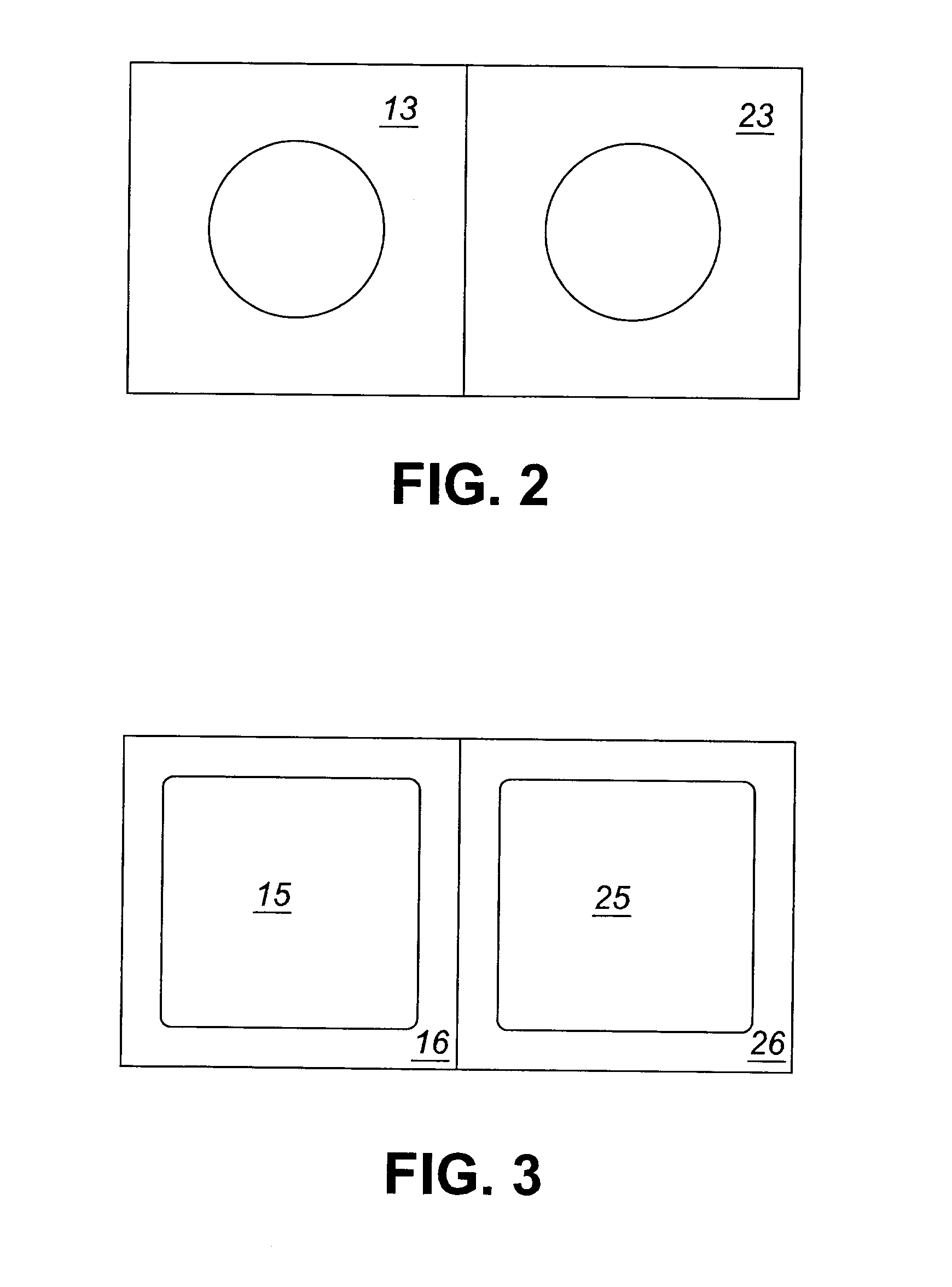

Hybrid reactor with two reaction zones

ActiveUS8609052B2Improve efficiencyReaction rate were also differentCombination devicesGas treatmentLow activityChemical reaction

The invention relates to a hybrid reverse flow catalytic apparatus having two reaction zones: a homogeneous reaction zone in porous ceramic and a heterogeneous reaction zone with catalyst, arranged in two different catalyst beds. A first catalytic bed located in a central region of the reactor is provided with a low activity catalyst and a second catalyst bed located in a peripheral region of the reactor is provided with a high activity catalyst. The provision of two catalyst beds containing different catalysts reduces the effect of radial temperature gradients in the reactor and improves the overall efficiency of the reactor. The invention also relates to method of performing catalytic and thermochemical reactions in said apparatus.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

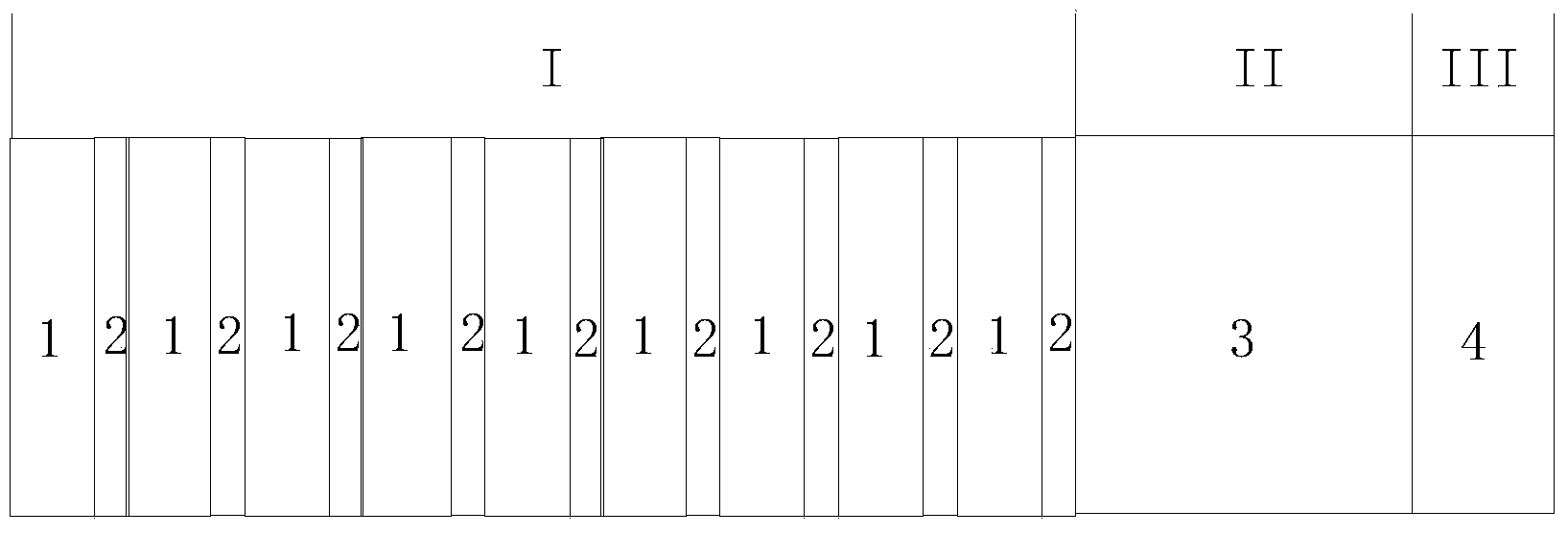

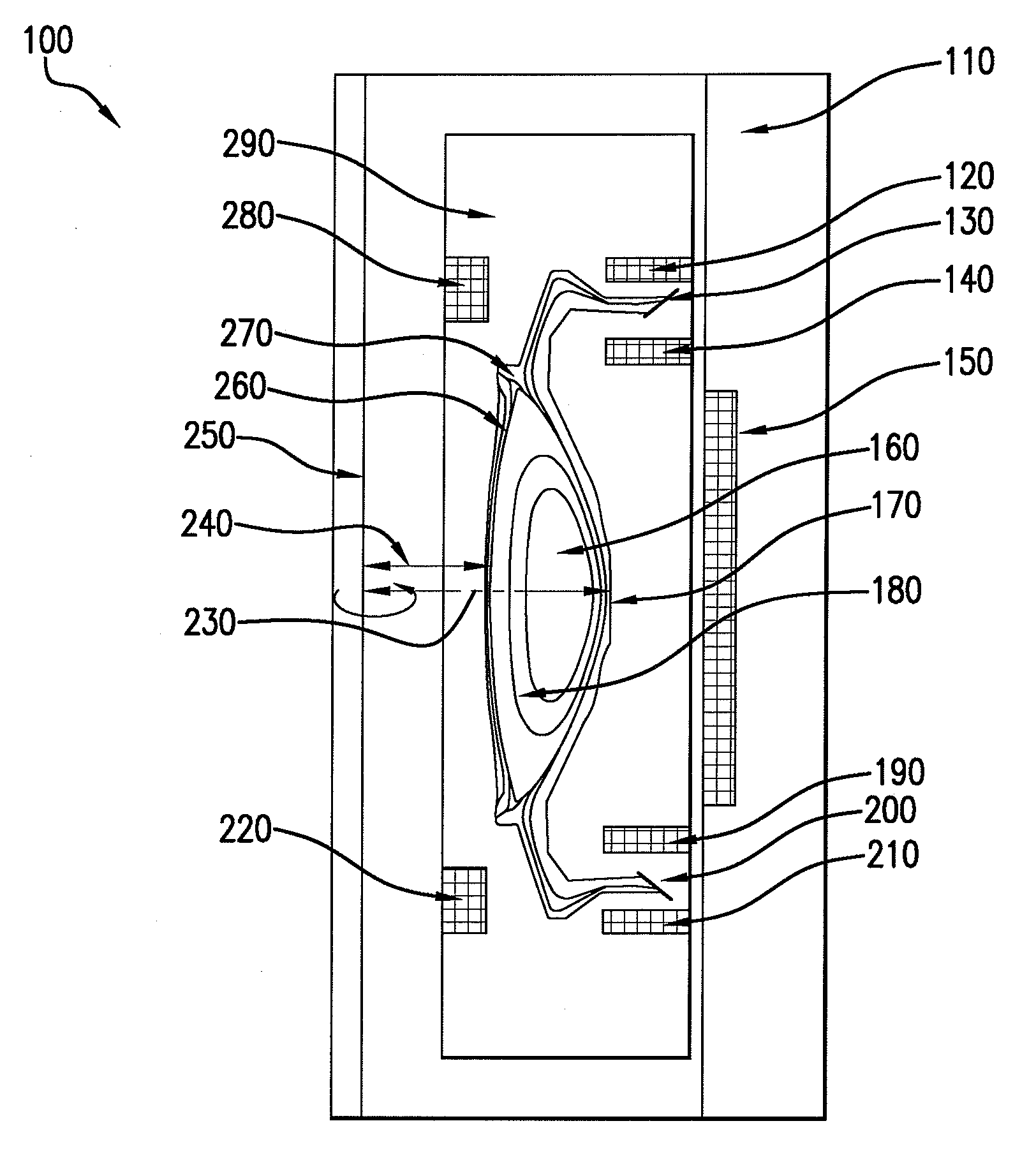

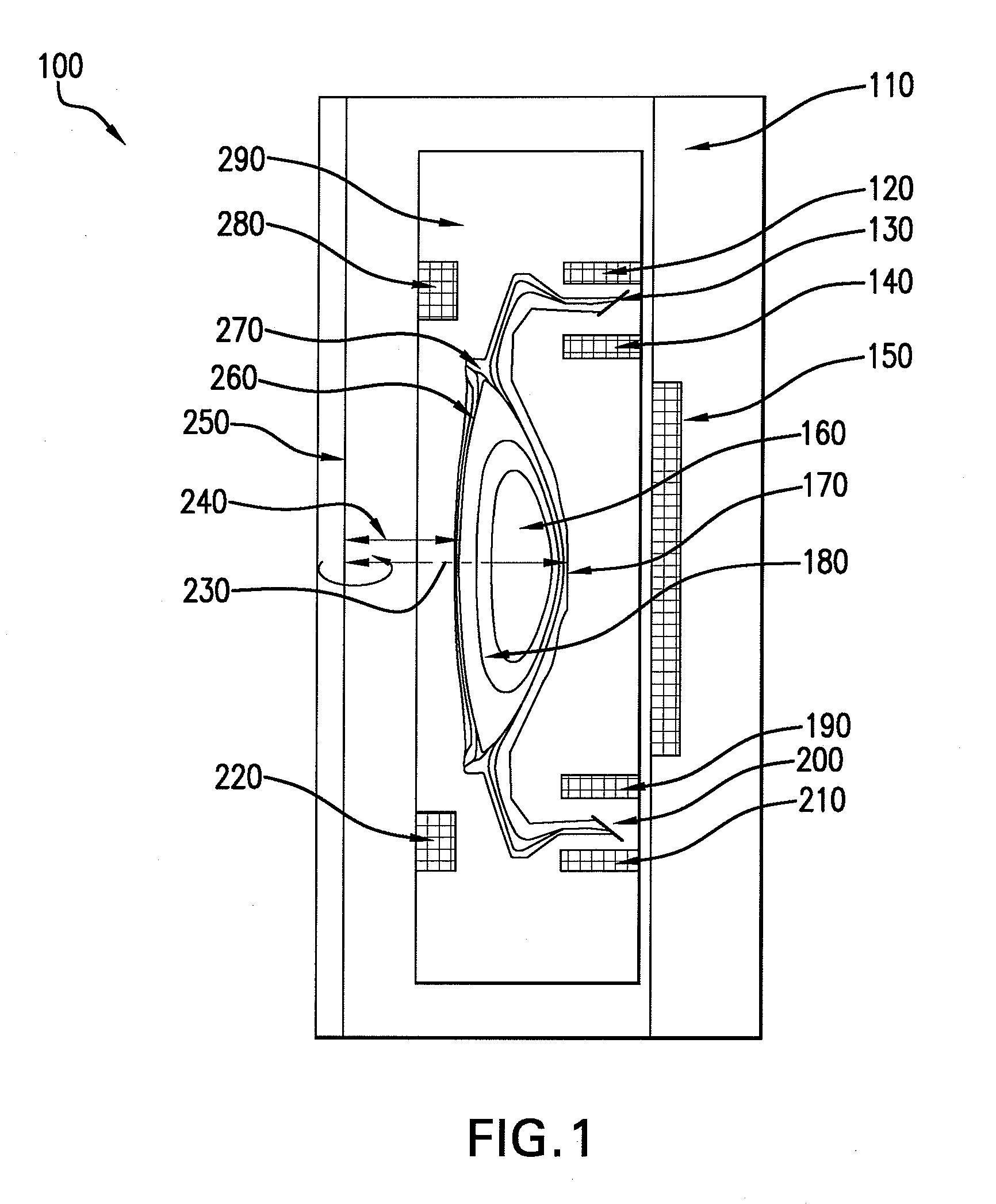

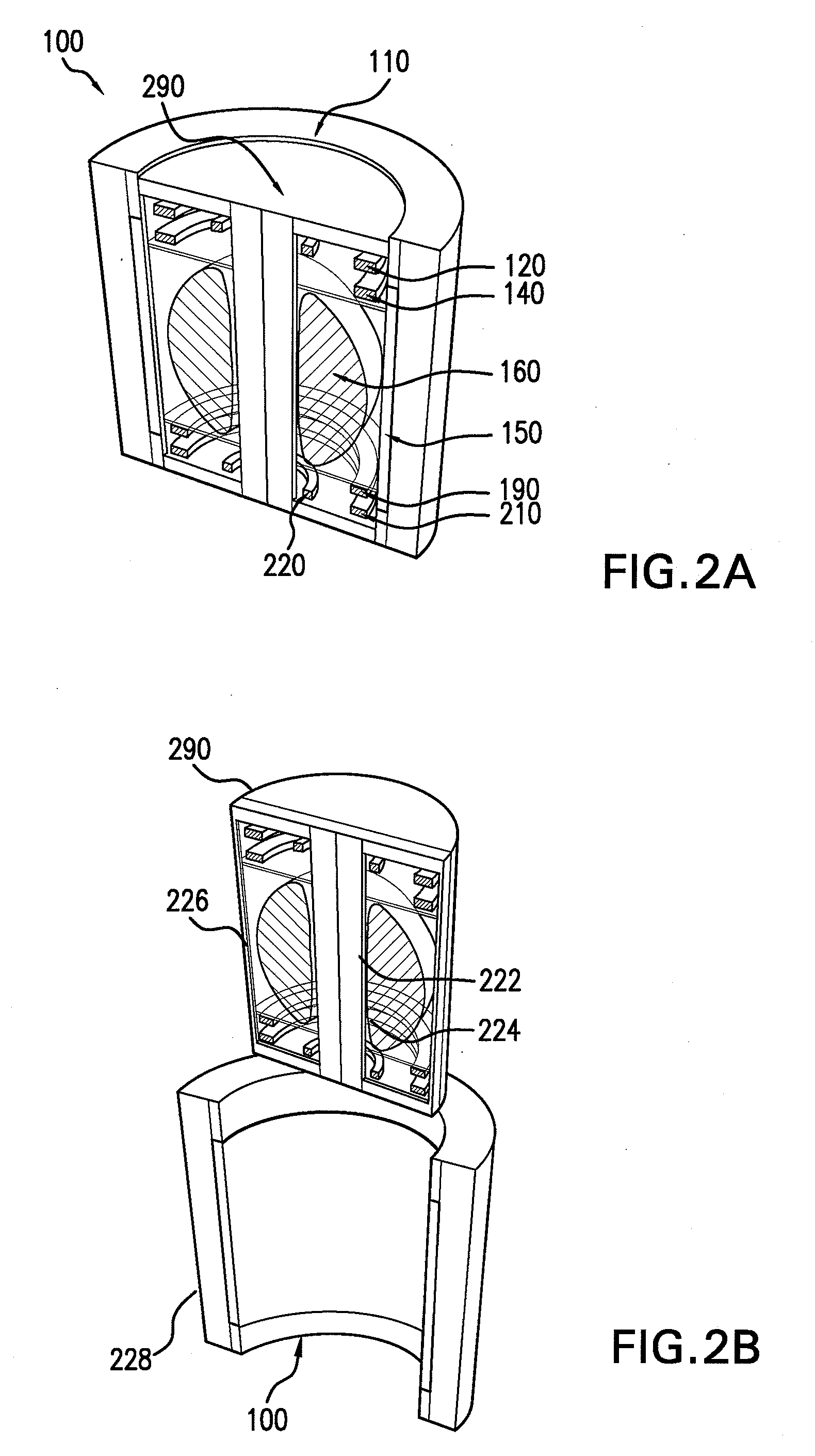

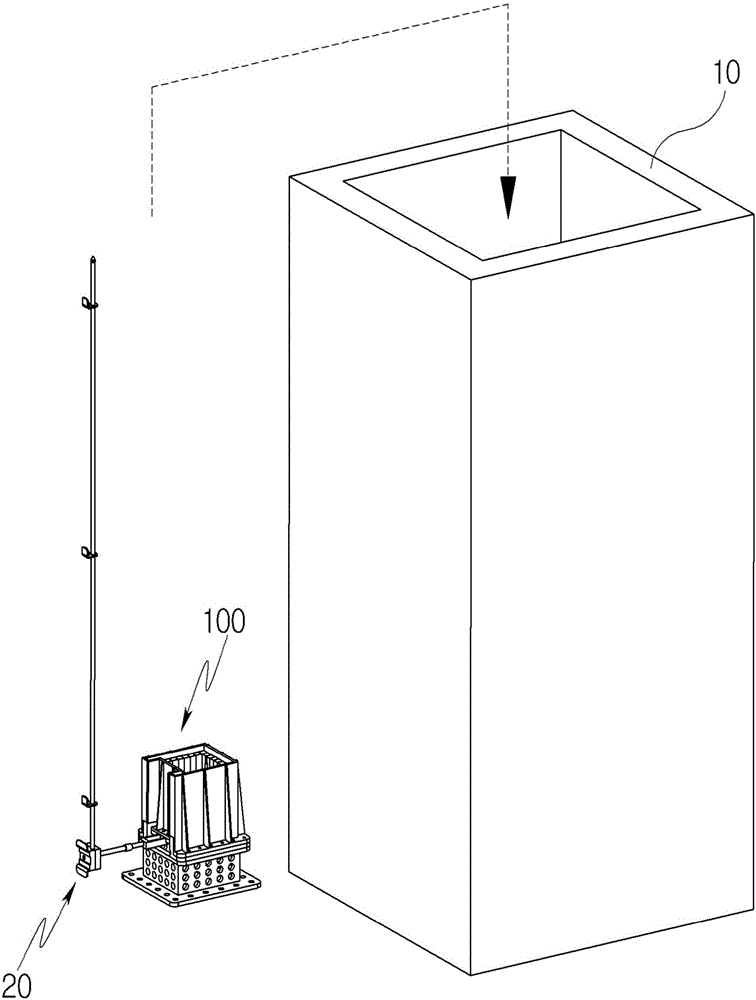

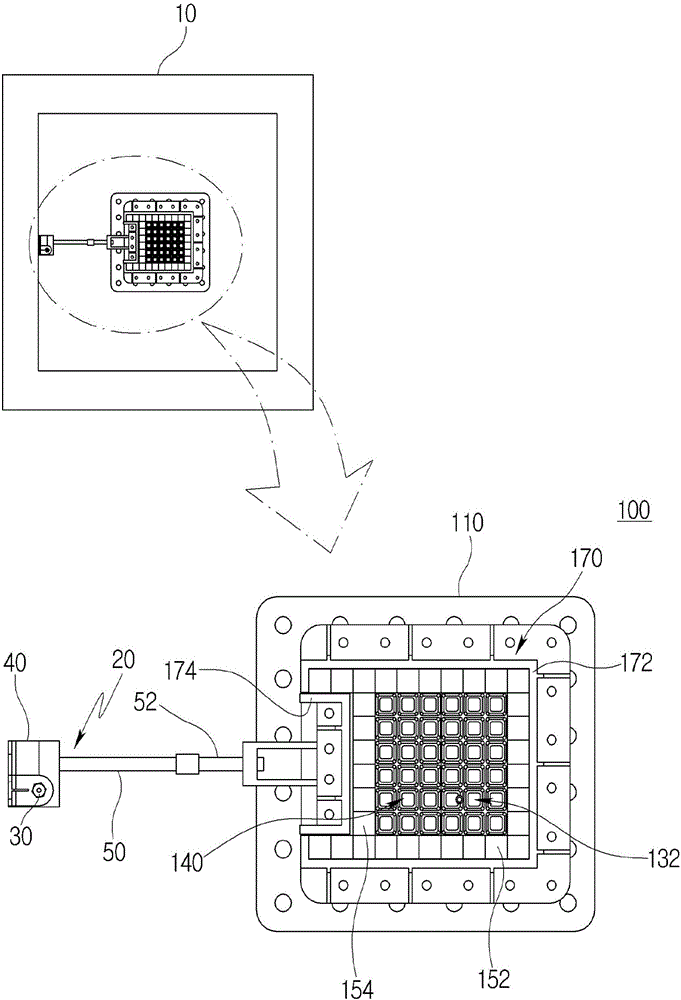

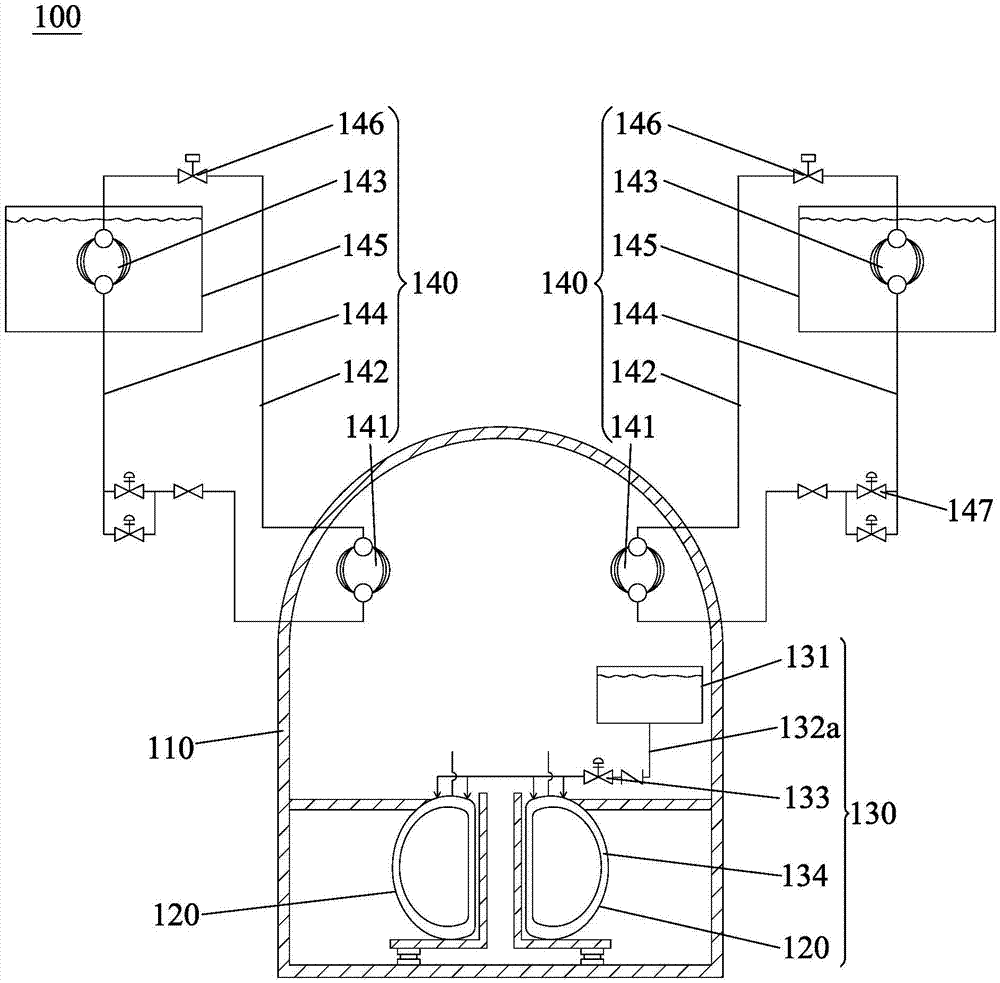

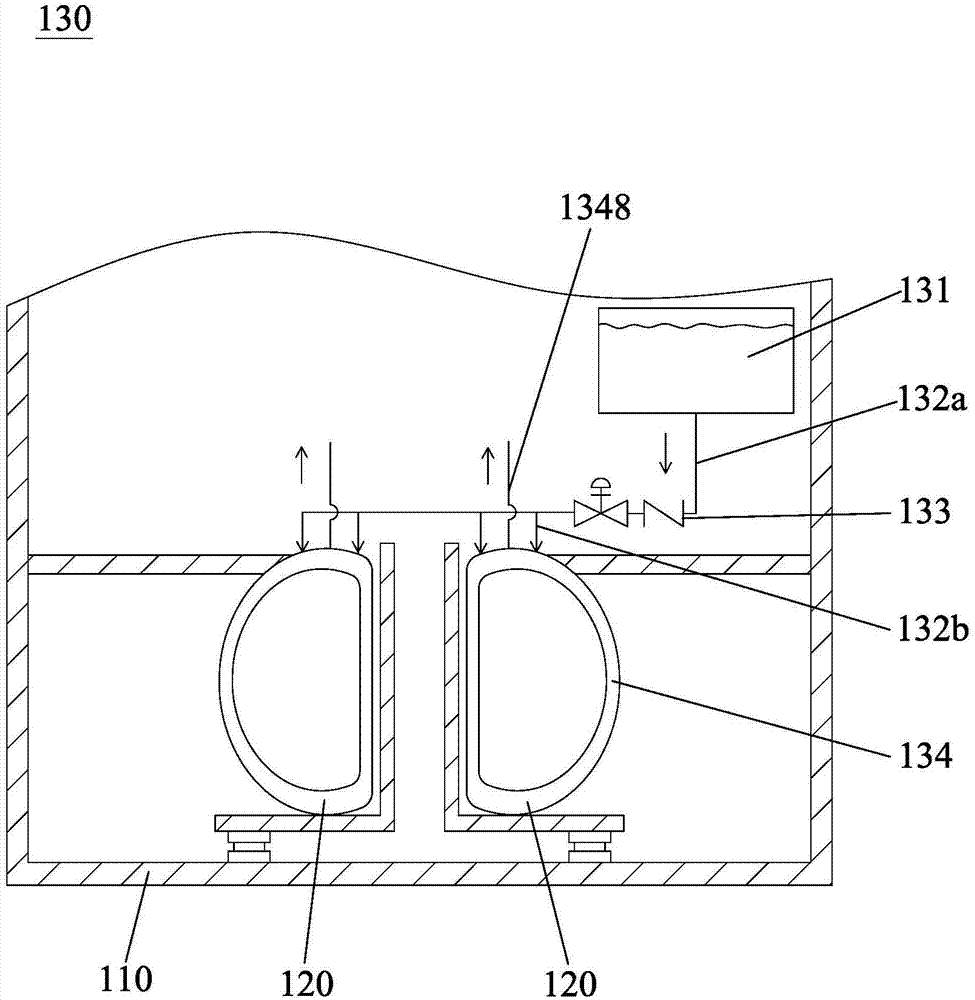

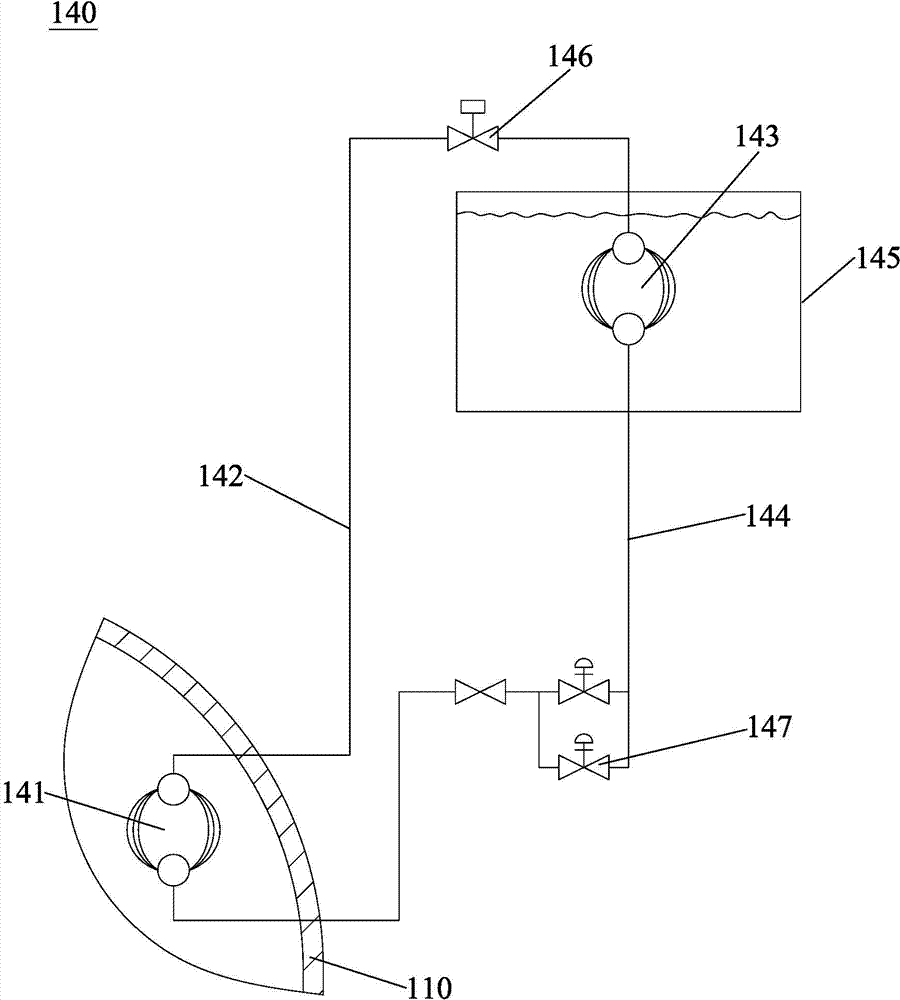

Hybrid nuclear reactor with separable core

InactiveCN106531228ASecuring Space for Critical ExperimentsReduced number of unit gridsNuclear energy generationFuel element assembliesNuclear reactorOperation mode

The present invention provides a core separation type hybrid reactor capable of realizing the same output operation as a conventional reactor with a single reactor or as a critical facility. When used as a critical facility, a grid of the reactor constituent material is loaded in a space for a portion of the separation core that is laterally moved to form a critical test space therebetween, thereby performing a grid characteristic experiment. The reactor includes a core separation type mixed reactor 100 provided inside the concrete water tank 10, and a mode switching driving section 20 for adjusting the operation mode of the hybrid reactor 100, and the core separation type mixed reactor 100, comprising: a lattice structure 130 of a separate structure disposed on a bottom surface portion of the concrete water tank 10; a reflector structure 150 of a separate type structure disposed at an edge portion of the grid structure 130; and a type partition wall structure 170 in which the reflector structure 150 is surrounded by an upper portion of the grid structure 130.

Owner:KOREA ATOMIC ENERGY RES INST

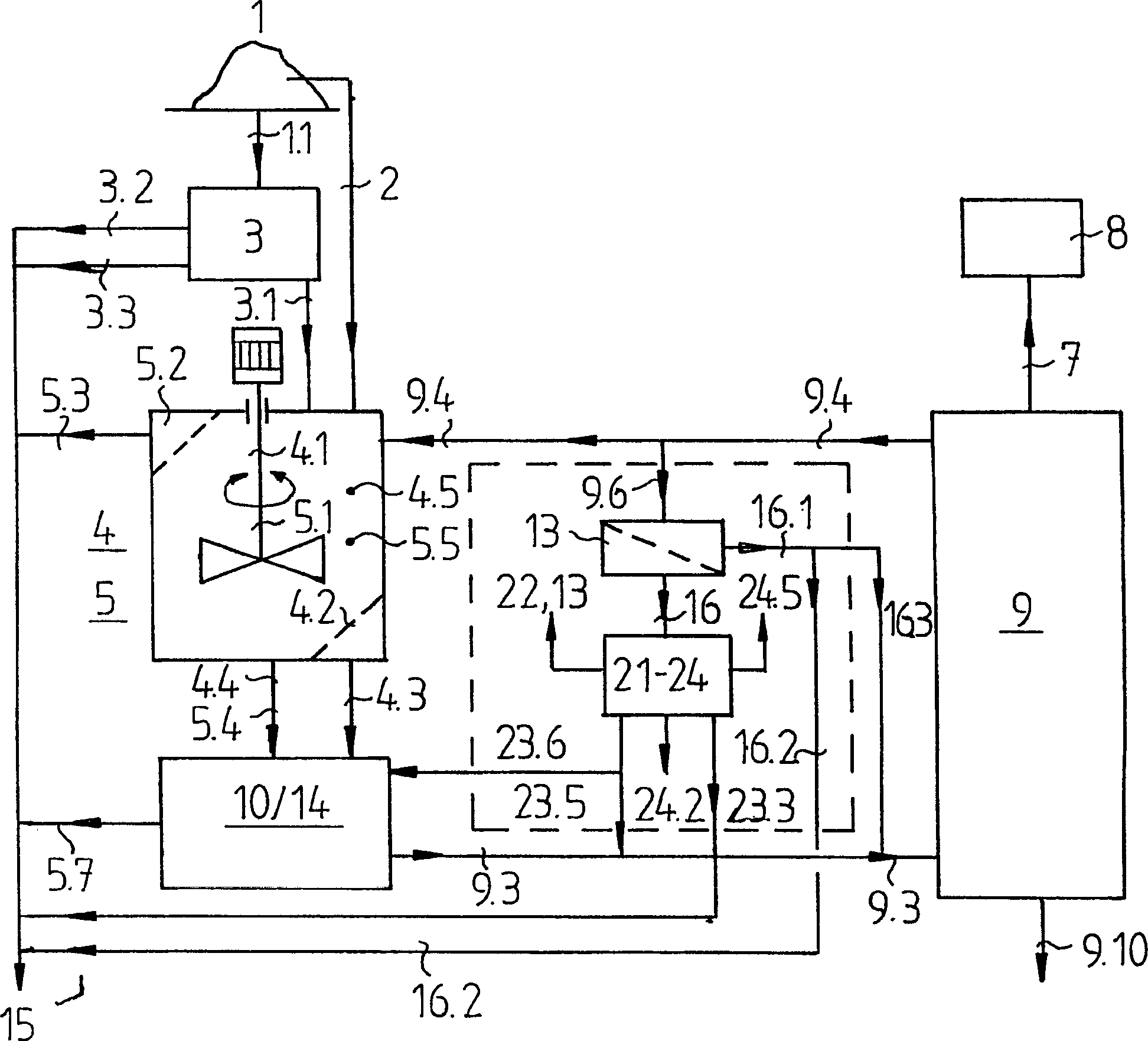

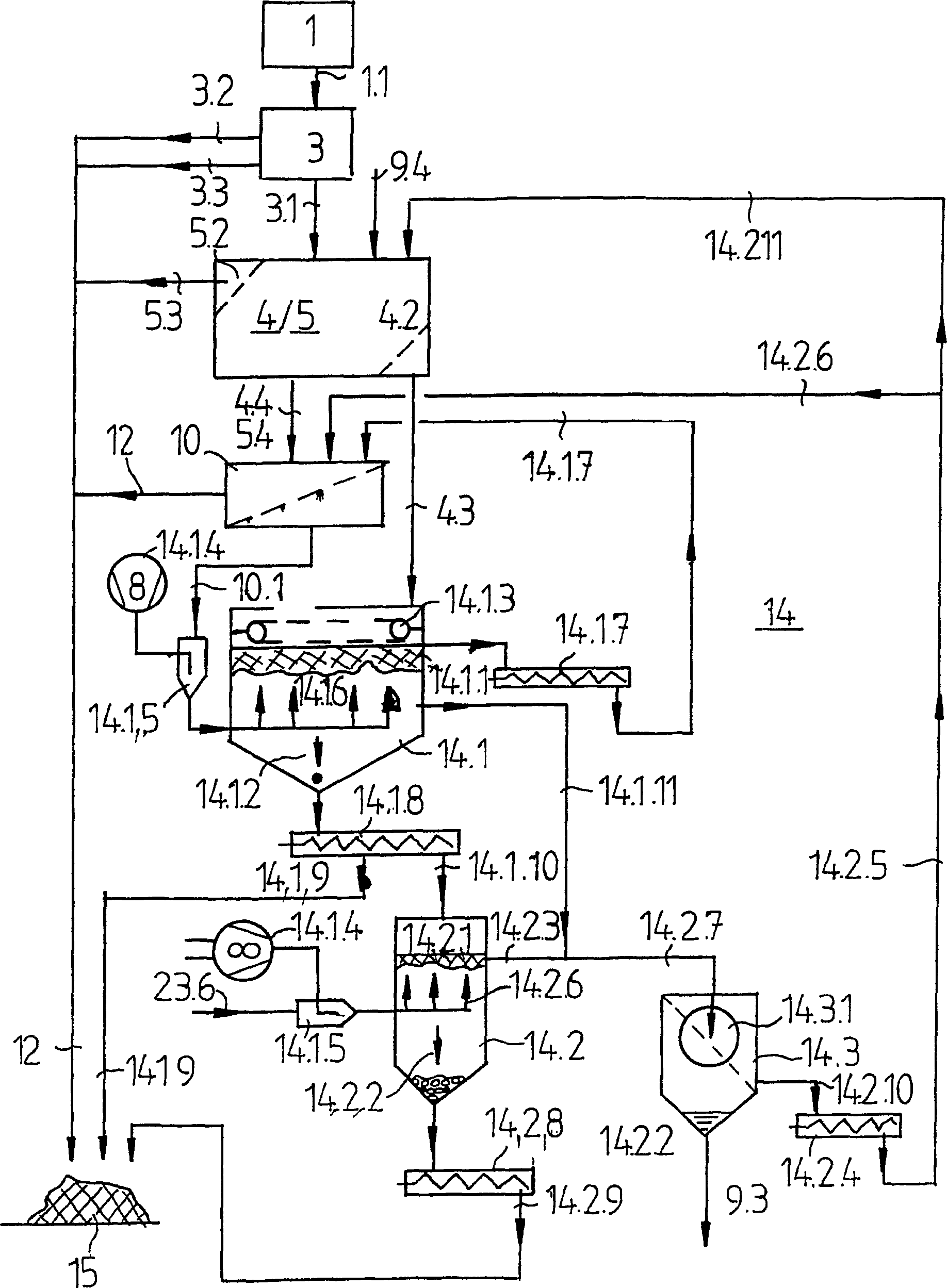

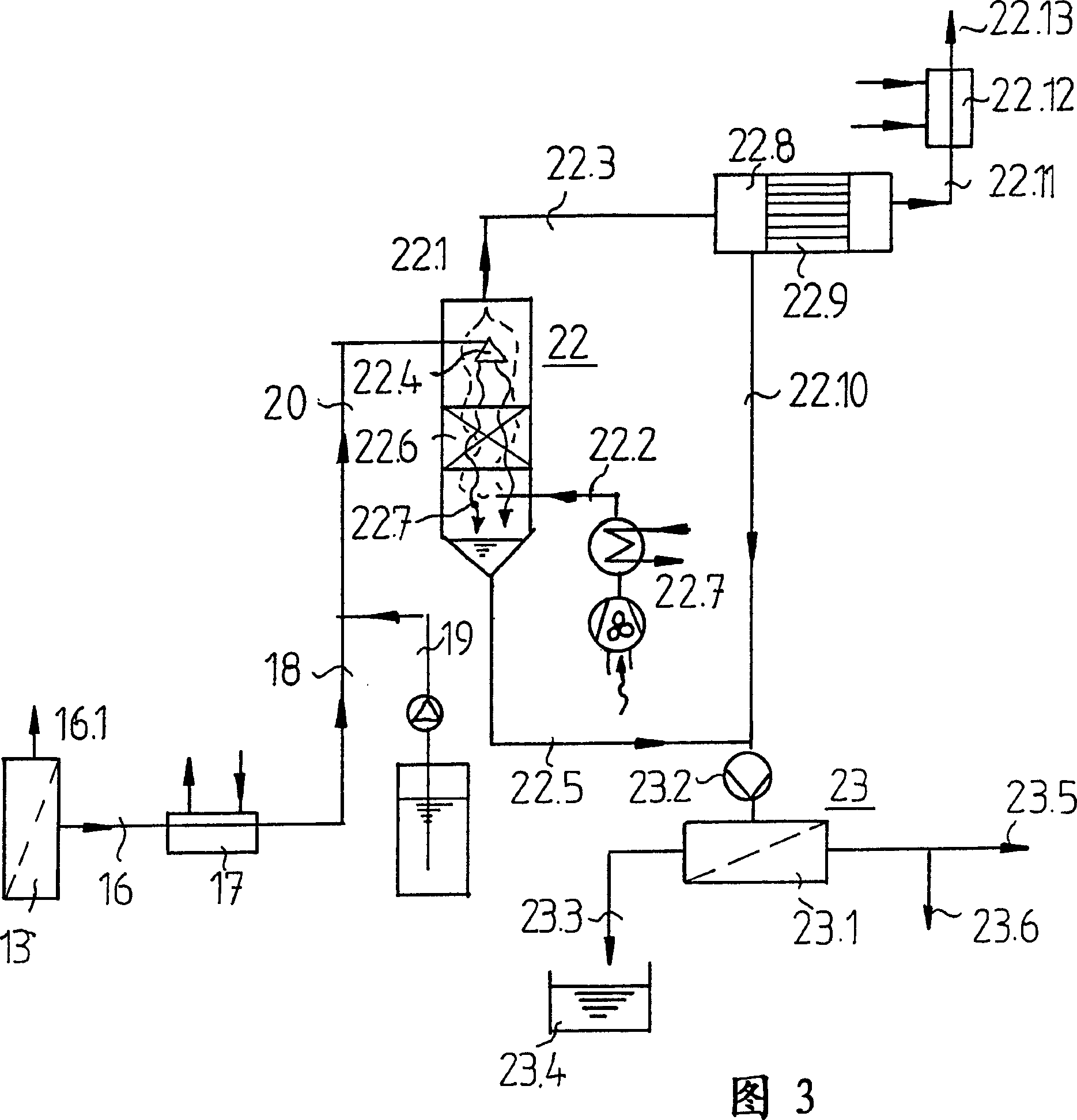

Method and hybrid reactor for processing residual wastes

The invention relates to a method for mechanical and biological processing of wastes, in particular residual wastes consisting of physico-chemical processing (PCA) for removing nitric acid from processed water which is exempt of organic components. Said invention also relates to a hybrid reactor consisting of a fixed bed, a sludge extraction device and a device for supernatant destruction.

Owner:埃斯卡公司

Method and device for environment-friendly dredging remained water metering coagulation treatment

InactiveCN102718300AImprove water qualityReduce contentWater/sewage treatment by flocculation/precipitationWater flowEngineering

The invention relates to a method and a device for environment-friendly dredging remained water metering coagulation treatment, and belongs to the technical field of water treatment. The method comprises the following steps: (1) dredging remained water enters a mechanical stirring hybrid reactor while the flow rate is metered by a thin-walled weir; (2) coagulant is added into the hybrid reactor continuously; (3) the coagulant and pollutants in the dredging remained water are in contact with and react with each other while being stirred; and (4), the dredging remained water flows along a straight channel to form flocculating constituents which are removed through precipitation. The device adopts the structure that the thin-walled weir and an ultrasonic wave liquid level meter is arranged in a water inflow channel; a mechanical stirrer is mounted in the hybrid reactor; the hybrid reactor is communicated with a coagulant adding device; the lower side of the hybrid reactor is communicated with a water outflow channel; and a controller is connected with and used for controlling the ultrasonic wave liquid level meter, the mechanical agitator and the coagulant adding device. According to the invention, the structure is simple; the operation is convenient; the degree of automation is high; the operating cost is low; the device can be disassembled, mounted and transplanted to a site at any time; and the application prospect is wide.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

Insulating encapsulation material used for photoelectric transformer

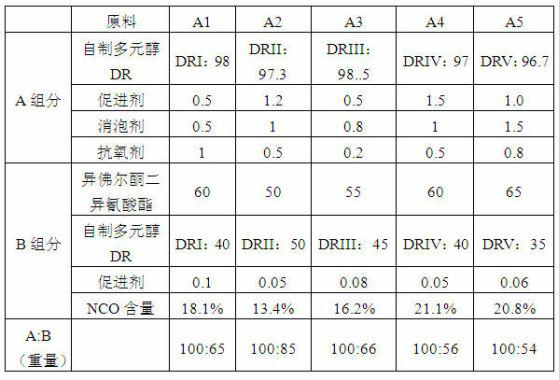

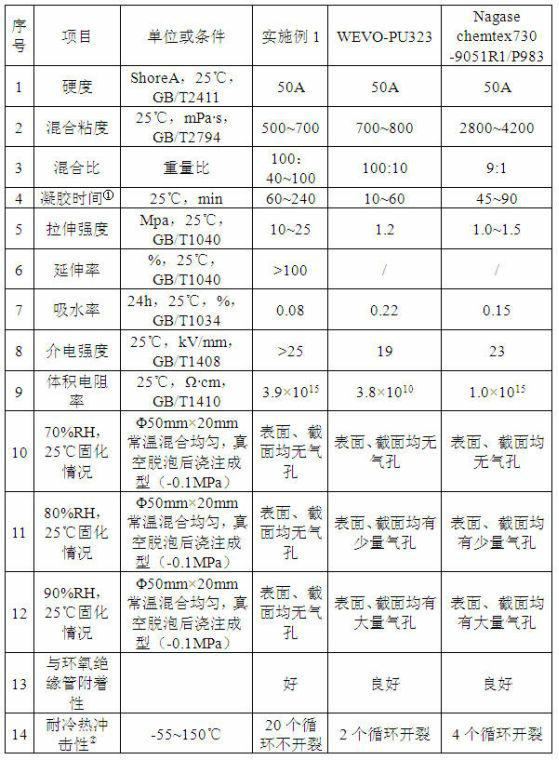

ActiveCN102558493AOvercoming sensitivityNot easy to produceOther chemical processesAlcoholAntioxidant

The present invention relates to an insulating encapsulation material used for a photoelectric transformer, which is composed by mixing a component A and a component B, the preparation method comprises the following steps: (1) preparing self-made polyol: putting castor oil, hydrogenated bisphenol A, plant oil, C3-C6 dihydric alcohol and a catalyst into a reactor, introducing nitrogen and heating for reflux, cooling and discharging when no reflux is generated; (2) preparing the component A: putting the self-made polyol, an accelerator, an antifoaming agent and an antioxidant in a hybrid reactor, heating and stirring, vacuum dehydrating, cooling to the room temperature and then filtering; (3) preparing the component B: absorbing isophorone diisocyanate into the reactor, introducing nitrogen, heating and stirring, slowly adding the accelerator and the self-made polyol, insulating and then discharging; (4) mixing the component A and the component B and then uniformly stirring, curing at room temperature after vacuum deaeration is carried out. The insulating encapsulation material used for the photoelectric transformer has the advantages of no sensitivity to moisture during the packaging process, low curing shrinking stress, perfect electrical insulation performance after curing, and good cold and heat shock resistance.

Owner:无锡东润电子材料科技有限公司

Method for processing products of fusion-fission hybrid reactor fusion target chamber

InactiveCN105976871AAvoid complexityAvoid questions with ambiguous compositionNuclear energy generationThermonuclear fusion reactorFusion fissionProcess engineering

The invention provides a method for processing products of a fusion-fission hybrid reactor fusion target chamber, comprising steps of oxidation, condensation-gas-liquid separation, low temperature adsorption, fusion-bubbling, normal temperature adsorption, metal reduction, palladium-membrane separation, etc. The method of the invention avoids that constituents in the products of the fusion-fission hybrid reactor fusion target chamber are complex and unclear by oxidizing residual deuterium and tritium into water through introducing oxygen elements in the fusion target chamber, simplifies the processing source item and deuterium and tritium recycling technology, and adopts various processing technologies for gas state products and solid state products and guarantees relatively high recycling efficiency of the deuterium and tritium fuels. Besides, in the method for processing products of the fusion-fission hybrid reactor fusion target chamber, substantial Ar gas can be recycled, which saves cost. The method for processing products of the fusion-fission hybrid reactor fusion target chamber can recycle the residual deuterium and tritium fuels with recycling rate over 95%, which satisfies deuterium self-sustaining of the fusion-fission hybrid reactor and requirements for safety, economy and environment protections.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

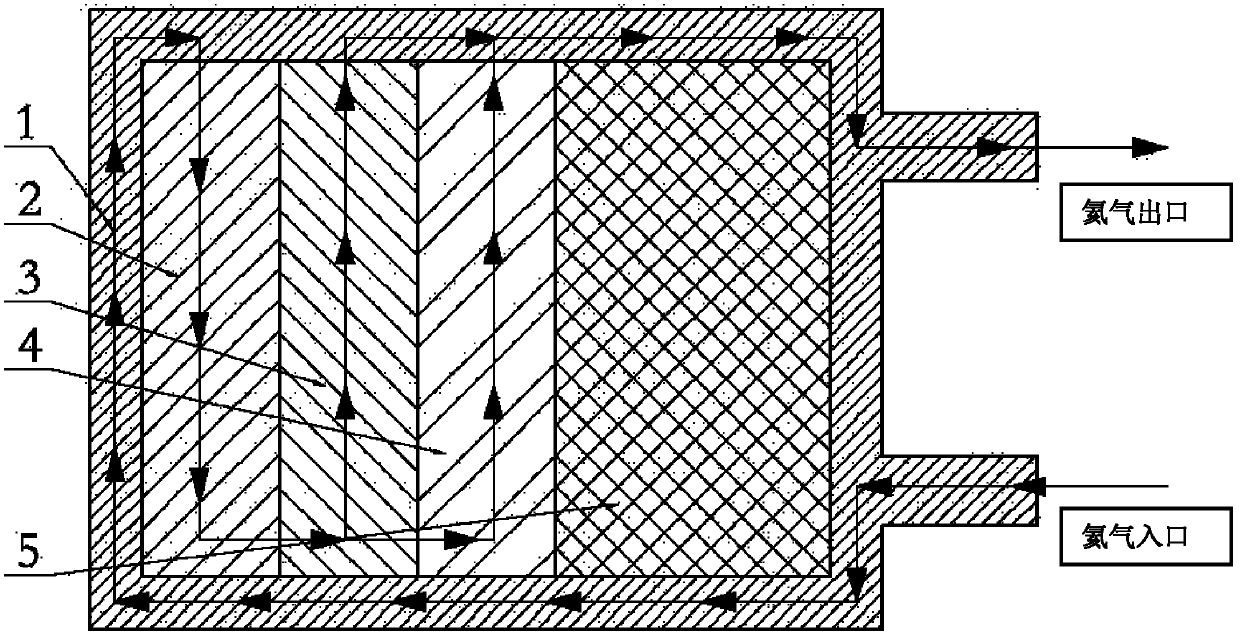

Method and device for producing hydrogen through pulsed power ultrasonic enhanced anaerobic biological fermentation

InactiveCN105861566AImprove mass transfer efficiencyIncrease mass transfer rateBioreactor/fermenter combinationsBiological substance pretreatmentsHybrid reactorUltrasonic generator

The invention relates to a method and a device for producing hydrogen through pulsed power ultrasonic enhanced anaerobic biological fermentation and belongs to a biological hydrogen production technology. The method comprises the following steps: performing pulsed power ultrasonic enhanced treatment on fermentation liquor in an anaerobic biological fermentation hydrogen production system by adopting pulsed power ultrasonic waves at a constant temperature of 35 DEG C, wherein the frequency of the pulsed power ultrasonic waves is 20-100 KHz, the power density is 50-250 W / L, and the action time of the pulsed power ultrasonic waves is 1-2 S, and the interval time is 58-59 S; the device adopts a structure that an ultrasonic transducer is assembled at the bottom of the lower end of a reaction tank body, and an ultrasonic generator is communicated with the ultrasonic transducer through a lead. According to the method and the device provided by the invention, a full hybrid reactor is combined with the ultrasonic transducer, so that the mass transfer efficiency of the hydrogen inside the anaerobic biological fermentation system, the yield of the hydrogen and the utilization rate of the device are improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Subcritical energy cladding accident mitigation system

ActiveCN104269193AIntegrity guaranteedNuclear energy generationEmergency protection arrangementsHydrogenNuclear engineering

The invention discloses a subcritical energy cladding accident mitigation system. The subcritical energy cladding accident mitigation system comprises a passive water injection system and at least one group of passive cooling systems, wherein the passive water injection system is arranged in a containment shell and is used for injecting water into a subcritical energy cladding arranged in the containment shell, so that heat of the subcritical energy cladding is conducted into the containment shell; the passive cooling system penetrates through the containment shell in a sealing manner, so as to conduct the heat in the containment shell out of the containment shell; the passive water injection system can automatically conduct the heat of the subcritical energy cladding into the containment shell, cooling mediums are circulated in the passive cooling system, so as to conduct the heat in the containment shell into atmospheric environment; heat can be conducted passively from a hybrid reactor core to the containment shell and from the inside of the containment shell to the outside of the containment shell under an accident, all waste heat of the subcritical energy cladding during running can be completely covered and exhausted, serious accidents such as hybrid reactor core melting, high-pressure molten reactor, and hydrogen gas explosion can be effectively prevented, and the integrity of the subcritical energy cladding is ensured.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

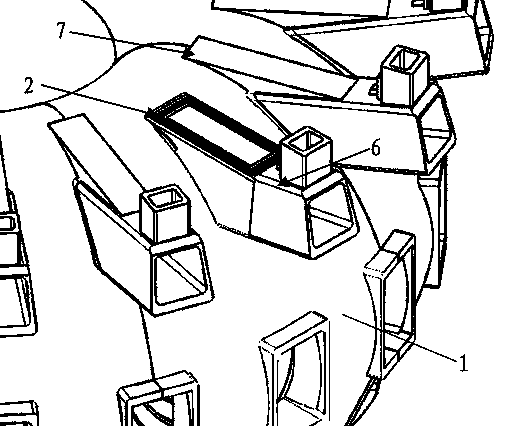

Subcritical blanket refuelling system and refuelling method thereof

ActiveCN104134476ARealize remote controlEnsure safetyNuclear energy generationReactor fuel elementsFission fusionEngineering

The invention discloses a subcritical blanket refuelling system and a refuelling method thereof and belongs to the technical field of equipment of fission-fusion hybrid reactors. The subcritical blanket refuelling system is characterized in that a vacuum shell is provided with 18 connecting plates; each connecting plate is composed of two symmetrical connecting plate modules which are connected by a bolt; a TF upper connecting plate is additionally arranged between the two connecting plate modules of one of the connecting plates, is positioned between two TF coils and is connected with the connecting plates at the two sides by bolts; the TF upper connecting plate is provided with a charging and discharging opening communicating the inner part with the outside. The subcritical blanket refuelling system and the refuelling method disclosed by the invention have the beneficial effects that the resistance of fluid in pipes is reduced, the flow of a single blanket module is increased, the heat exchange capability of a subcritical blanket of ITER fission-fusion hybrid reactors is improved; and the installation difficulty of the blanket module is reduced, which is beneficial to subsequent inspection, maintenance and replacement.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

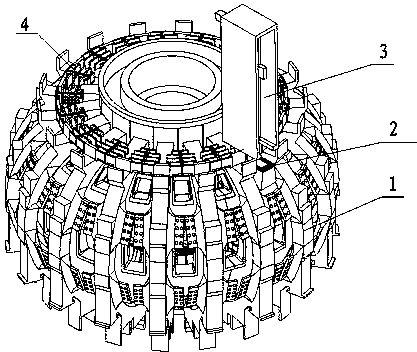

Modular type fusion-and-fission hybrid reactor cladding fuel section based on Z pinch driving

InactiveCN104157312AGood neutron multiplication performanceMeet self-sustaining requirementsNuclear energy generationThermonuclear fusion reactorEngineeringZ-pinch

The invention discloses a modular type fusion-and-fission hybrid reactor cladding fuel section based on Z pinch driving. A fusion target driving mechanism is arranged at the top end of each fuel section body, a target recycling area is arranged at the bottom end of each fuel section body, the fuel section is divided into the multiple fuel section bodies in the annular direction, and each fuel section body is axially provided with three independent modules which include the trapezoid-table upper-end module located at the upper portion, the cuboid middle module located in the middle and the trapezoid-table lower-end module located at the lower portion. Cooling water pipes of the upper-end modules are arranged to be in transverse-S shapes, cooling water pipes of the lower-end modules are arranged to be in transverse-S shapes, cooling water pipes of the middle modules are axially arranged, an engineering passage is arranged at the outer end of the fuel section and is in a vertically-through type, and the upper end and the lower end of the engineering passage are communicated with the middle section of a double-layer safe shell. Based on Z pinch inertial confinement fusion driving, the defects of the complex structure, the limited available space and the poor hybrid reactor cladding engineering reliability caused by a Tokamak magnetic confinement device are overcome, and long-time stable energy output is achieved.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Hybrid photochemical/plasma reactor devices

ActiveUS10625235B2Chemical/physical/physico-chemical microreactorsElectrical discharge ozone preparationChemical physicsHybrid reactor

A method for generating a hybrid reaction flows feedstock gas that is also a plasma medium through microchannels. Plasma is generated with the plasma medium via excitation with a time-varying voltage. UV or VUV emissions are generated at a wavelength selected to break a chemical bond in the feedstock gas. The UV or VUV emissions are directed into the microchannels to interact with the plasma medium and generate a reaction product from the plasma medium. A hybrid reactor device includes a microchannel plasma array having inlets and outlets for respectively flowing gas feedstock into and reaction product out of the microchannel plasma array. A UV or VUV emission lamp has its emissions directed into microchannels of the microchannel plasma array. Electrodes ignite plasma in the microchannels and stimulating the UV or VUV emission lamp to generate UV or VUV emissions. One common or plural phased time-varying voltage sources drive the plasma array and the UV or VUV emission lamp.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Preparation method for zinc gel of alkaline zinc-manganese dioxide battery

InactiveCN103695714AImprove discharge performanceExtended service lifePrimary cell electrodesMethacrylatePowder mixture

The invention discloses a preparation method for zinc gel of an alkaline zinc-manganese dioxide battery. The preparation method comprises the following steps: (1) putting aluminum, bismuth and rare earth metals into a pressure fuse, heating to be molten, pressing galvanizing zinc to produce a zinc alloy, and crushing to produce zinc alloy particles; (2) mixing the zinc alloy particles with polyacrylic acid, or methacrylic acid, polyacrylic ester or methyl propiolate, polyacrylate or methyacrylate, and indium oxide powder, and grinding into a zinc powder mixture with particle size of 50-100 micrometers; (3) putting the zinc powder mixture and electrolyte prepared in advance into a hybrid reactor according to the volume ratio of 1:1, heating to 50-70 DEG C, agitating and mixing for 30-60 minutes at the agitation speed of 1000 revolutions / minute-2000 revolutions / minute, thus preparing zinc gel. According to the zinc gel of the alkaline zinc-manganese dioxide battery, prepared by adopting the preparation method, the discharge capability is greatly improved, the service life is effectively prolonged, and the zinc gel of the alkaline zinc-manganese dioxide battery is lead-free and mercury-free, thus being more environment-friendly.

Owner:高建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com