Insulating encapsulation material used for photoelectric transformer

A technology for optoelectronic transformers and packaging materials, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as small curing shrinkage stress, achieve excellent insulation performance, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

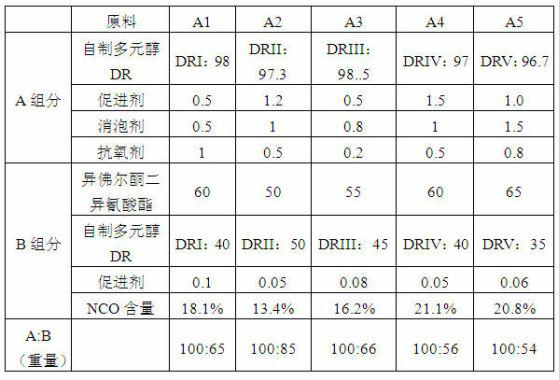

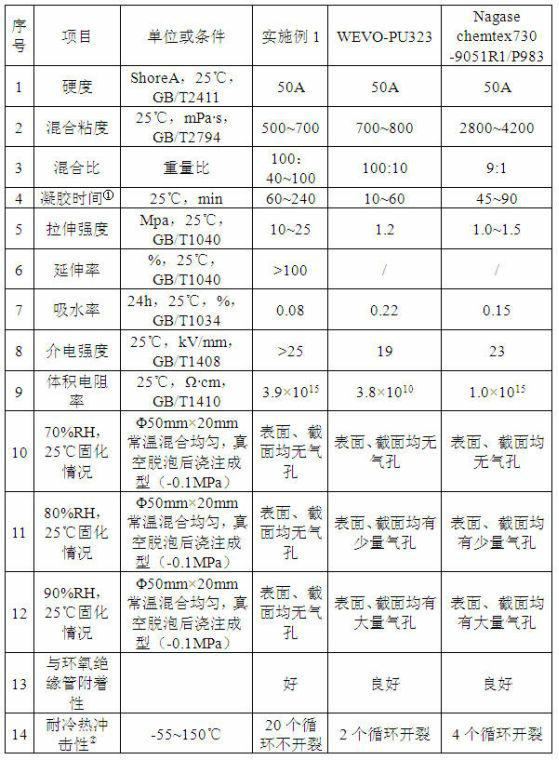

Embodiment 1

[0019] (1) First prepare self-made polyols: add castor oil, hydrogenated bisphenol A, vegetable oil, C3~C6 dihydric alcohols, and catalyst solid CaO into the reactor, protect it with nitrogen, and keep the temperature at 200°C in the reactor after heating up Reflux until there is no reflux, lower the temperature to 40°C, and discharge to obtain self-made polyol;

[0020] (2) Preparation of component A: self-made polyol, accelerator dibutyltin dilaurate, defoamer BYK070, antioxidant tetrakis(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester ( 1010) Mix according to the mass percentage, add to the mixing kettle, heat up and stir to 110°C, evacuate to below -0.1Mpa, dehydrate for 15min, then cool to room temperature, filter and discharge to obtain A component;

[0021] (3) Preparation of component B: Inhale isophorone diisocyanate into the reaction kettle, fill with dry nitrogen, raise the temperature to 60°C, stir, add the accelerator dibutyltin dilaurate and s...

Embodiment 2

[0024] (1) First prepare self-made polyols: add castor oil, hydrogenated bisphenol A, vegetable oil, C3~C6 dihydric alcohols, and catalyst solid CaO into the reactor, protect it with nitrogen, and keep the temperature in the reactor at 180°C after heating up Reflux until there is no reflux, lower the temperature to 40°C, and discharge to obtain self-made polyol;

[0025] (2) Preparation of component A: Mix self-made polyol, accelerator dibutyltin dilaurate, defoamer BYK070, antioxidant 2,6-di-tert-butyl-4-methylphenol according to mass percentage, add and mix In the kettle, heat up and stir to 110°C, evacuate to below -0.1Mpa, dehydrate for 20min, then cool to room temperature, filter and discharge to obtain component A;

[0026] (3) Preparation of component B: Inhale isophorone diisocyanate into the reaction kettle, fill with dry nitrogen, raise the temperature to 65°C, stir, add the accelerator dibutyltin dilaurate and self-made polyol dropwise within 2 hours, Insulated for...

Embodiment 3

[0029] (1) First prepare self-made polyols: castor oil, hydrogenated bisphenol A, vegetable oil, C3~C6 glycol, catalyst solid Li(OH) 2 Put it into the reaction kettle, protect it with nitrogen, keep the temperature of 240°C in the reaction kettle to reflux after heating up, until there is no reflux, cool down to 50°C, and discharge to obtain self-made polyol;

[0030] (2) Preparation of component A: self-made polyol, accelerator stannous octoate, defoamer BYK070, antioxidant tetrakis (4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester (1010) Mix according to the mass percentage, add to the mixing kettle, raise the temperature and stir to 100°C, evacuate to below -0.1Mpa, dehydrate for 30min, then cool to room temperature, filter and discharge to obtain component A;

[0031] (3) Preparation of component B: Inhale isophorone diisocyanate into the reaction kettle, fill with dry nitrogen, raise the temperature to 50°C, stir, add the accelerator stannous octoate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com