Ultrasonic-acoustic emission detection method for composite material

A technology of acoustic emission detection and composite materials, which is applied in the field of ultrasonic-acoustic emission of composite materials, can solve problems such as the decline of defect detection ability, the difficulty of non-destructive testing, and severe sound wave attenuation, so as to reduce the propagation distance and energy loss, Improved detection capability, frequency characteristics and effects of improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

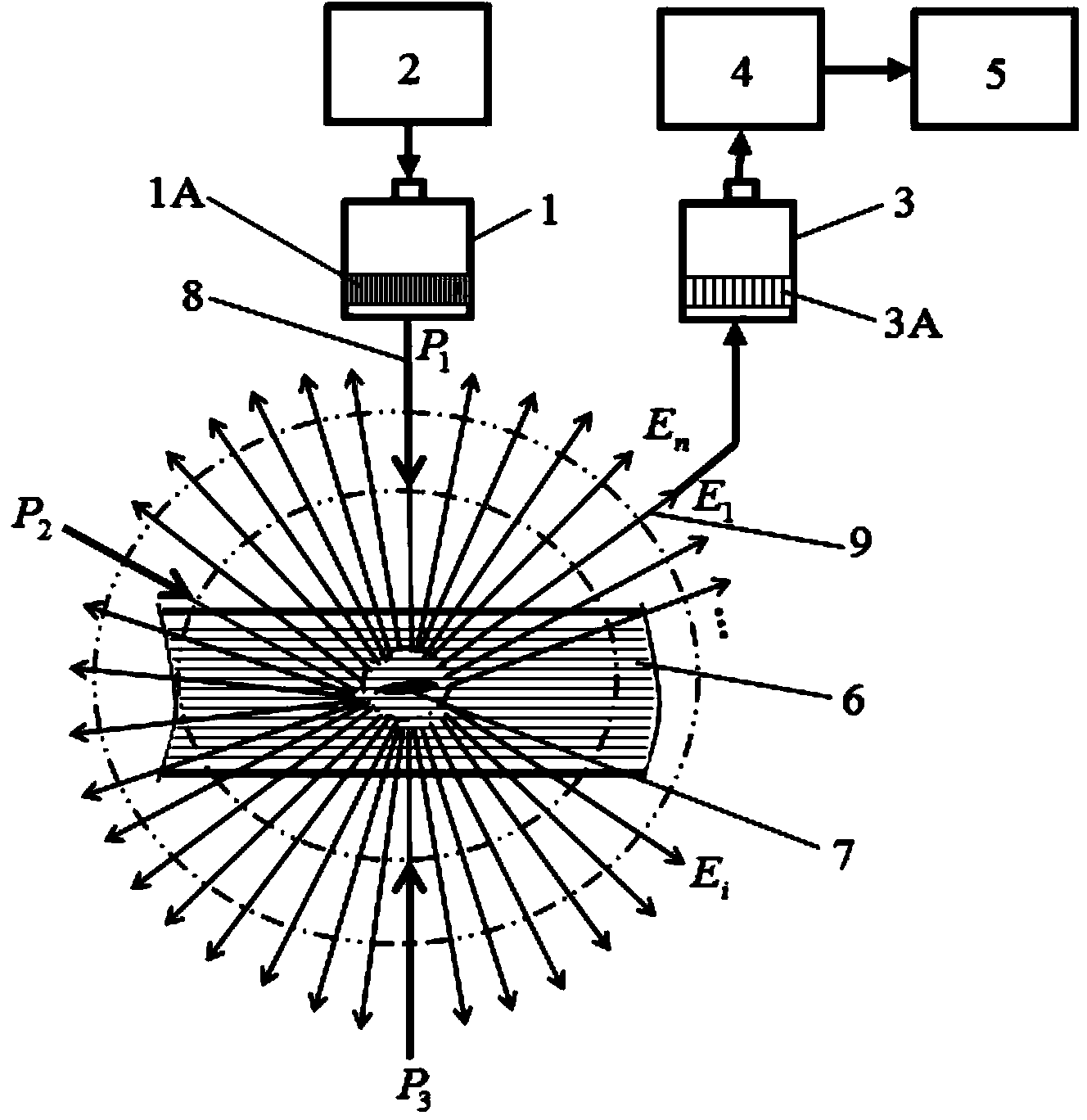

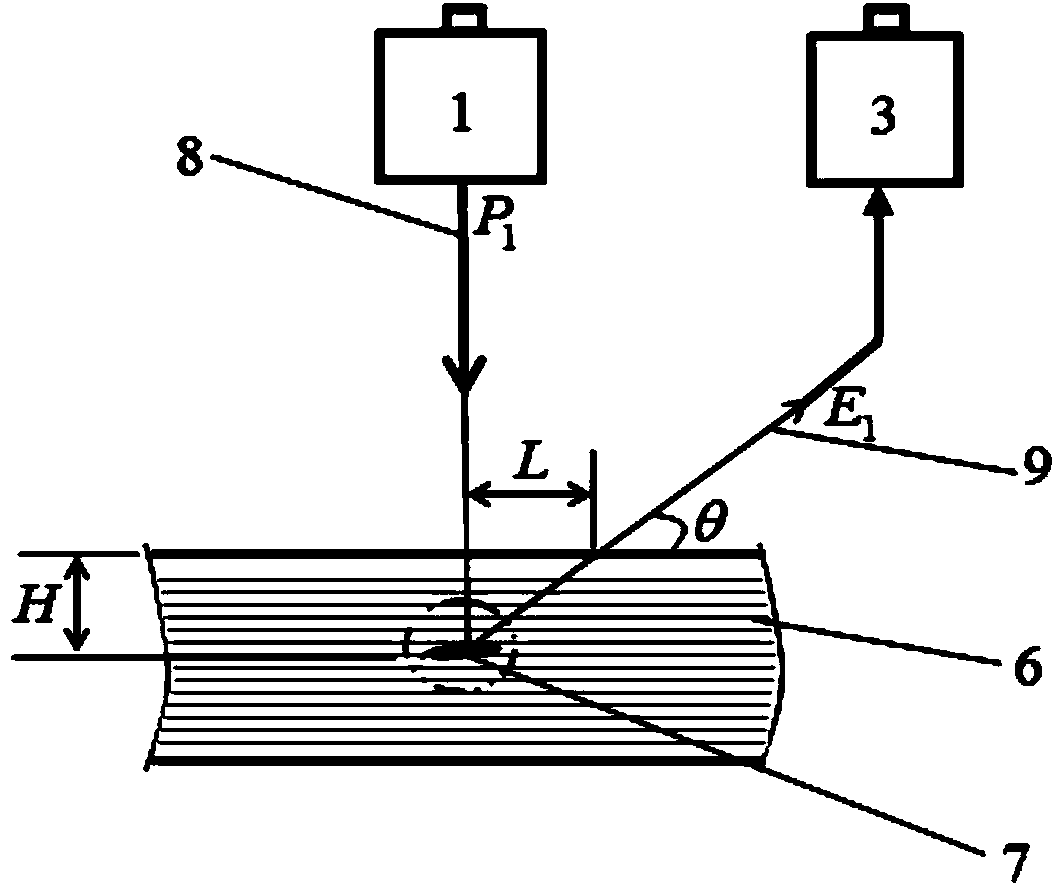

Embodiment 1

[0041] Adopt the ultrasonic-acoustic emission detection method and detection steps of the composite material in the present invention, select the single-shot-single-receive detection mode, select the manual scanning mode, and the transmitting transducer 1 and the receiving transducer 3 adopt integrated layout transduction The two have a zero approach distance and are located on the same side of the composite material part. The frequency of the transmitting transducer 1 is selected as 2MHz, and the frequency of the receiving transducer 3 is selected as 5MHz. A series of 5mm and 10mm carbon fiber composite parts are respectively carried out. The actual detection application, the actual detection application effect shows that the detection resolution and surface detection blind area can reach the thickness of a single composite material layup, and can detect Ф3mm, 0.13mm deep and 9.8mm deep defects in the composite material structure, which is very good. the actual detection effec...

Embodiment 2

[0043] Adopt the ultrasonic-acoustic emission detection method and detection steps of the composite material in the present invention, select the single-shot-double-receive detection mode, select the automatic scanning mode, the transmitting transducer 1 and the receiving transducer 3 adopt a separate layout, and the installation is automatic On the scanning detection equipment, the distance between the transmitting transducer 1 and the receiving transducer 3 is 10mm, and they are located on both sides of the composite material part. The frequency of the transmitting transducer 1 is selected as 1MHz, and the frequency of the receiving transducer 3 is selected as 2MHz. , respectively carried out a series of actual detection applications on 20mm and 50mm carbon fiber composite parts. The actual detection application results show that the detection resolution and surface detection blind area can reach the thickness of a single composite layer, and can detect Ф3mm, 0.13 mm deep, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com