Method for processing products of fusion-fission hybrid reactor fusion target chamber

A processing method and fusion target technology, applied in the field of hybrid energy reactors, can solve problems such as unclear forms, and achieve the effects of cost saving, high recovery efficiency, and simplified processing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

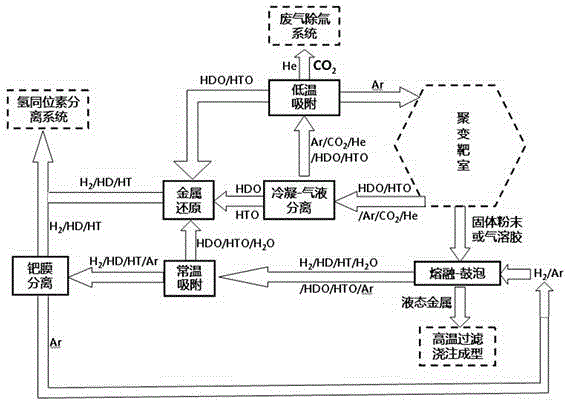

Embodiment 1

[0058] In Example 1, CuO / Cu (where the mole fraction of CuO is 1%) is selected as the oxide-containing metal material of the recyclable transfer line (RTL), and the high energy generated by the fusion reaction will vaporize or ionize part of the RTL, and the oxygen element in it Oxidizes remaining deuterium-tritium fuel to water. Fusion target room products are mainly divided into two routes, one is gas, mainly including HDO (steam), HTO (steam), Ar, CO 2 , He, etc.; the other way is an aerosol or solid powder formed by RTL material vaporization or ionization and cooling. The gas enters the low-temperature condensation-gas-liquid separation unit. At 0°C~5°C, the HDO (steam) and HTO (steam) in it are condensed into a liquid state to obtain liquid I, which enters the metal reduction unit; Ar, CO in the gas 2 , He and a small amount of uncondensed HDO (steam), HTO (steam) become tail gas Ⅰ. Tail gas I enters the low-temperature adsorption unit, and the adsorbent uses 4A molecul...

Embodiment 2

[0068] In Example 2, the recyclable transmission line (RTL) material is Fe 2 o 3 / Fe (where Fe 2 o 3 The mole fraction is 1%), the high energy generated by the fusion reaction will vaporize or ionize part of the RTL, and the oxygen element in it will oxidize the remaining deuterium-tritium fuel into water. Fusion target room products are mainly divided into two routes, one is gas, mainly including HDO (steam), HTO (steam), Ar, CO 2 , He, etc.; the other way is an aerosol or solid powder formed by RTL material vaporization or ionization and cooling. The gas enters the low-temperature condensation-gas-liquid separation unit. At 0°C~5°C, the HDO (steam) and HTO (steam) in it are condensed into a liquid state to obtain liquid I, which enters the metal reduction unit; Ar, CO in the gas 2 , He and a small amount of uncondensed HDO (steam), HTO (steam) become tail gas Ⅰ. Tail gas Ⅰ enters the low-temperature adsorption unit. Activated carbon is used as the adsorbent. At -196°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com