Method for preparing AKD by serialization

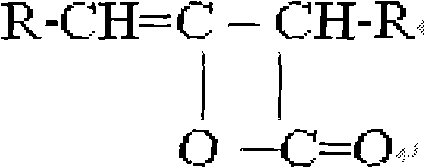

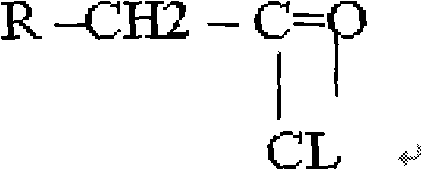

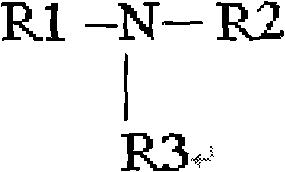

A formula and acyl chloride technology, applied in the field of continuous preparation of AKD, can solve the problems of complicated equipment structure, inability to obtain high-quality products, etc., and achieve the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The mixing reactor has a diameter of 100 mm, an effective length of 840 mm, and a rotation speed of 50 to 70 rpm. The feeding amount is: 10.8~27.0 kg / hour of stearyl chloride (octadecyl carbon contains 35%, 16 carbon contains 65%), 4.2~12.6 kg / hour of triethylamine. The feeding method is to add all the triethylamine and 1 / 3 to 2 / 3 of the acid chloride at the first feeding position at the two feeding ports, and the second feeding position is about 80-120 mm away from the first feeding position. , add the remaining amount of acid chloride. When the material is added to the first feeding position, the reaction will release heat immediately, and the temperature will rise sharply. The heat of reaction must be removed quickly by means of a cooling system. The temperature of the reactant is controlled at 65-110°C. After about 7-15 minutes, the reactor is discharged. The mouth begins to discharge the reaction product in the form of paste, which enters the continuous extractor,...

Embodiment 2

[0046]The mixing reactor has a diameter of 219 mm, an effective length of 1400 mm, and a rotation speed of 50 to 70 rpm. Feeding amount is: stearyl chloride (octadecane contains 35%, sixteen carbon contains 65%) 132 kilograms~108 / hour, triethylamine 51.8~42.4+ kilograms / hour. The feeding method is to add all the triethylamine and 20-80% of the acid chloride in the two feeding ports respectively at the first feeding position, and the second feeding position is about 1-3 minutes away from the first feeding position, and add remaining amount of acid chloride. When the material is added to the first feeding position, the reaction exotherms and the temperature rises sharply. The heat of reaction must be removed quickly with the help of the cooling system (hollow shaft and external jacket), and the temperature of the reactant should be controlled below 115°C, about 9-15°C. Minutes later, the reactor discharge port began to discharge a paste-like reaction product, which entered the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com