Method and device for producing hydrogen through pulsed power ultrasonic enhanced anaerobic biological fermentation

An anaerobic biological and ultrasonic technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of high hydrogen partial pressure and low mass transfer efficiency, and improve the utilization rate. , Improve the mass transfer rate and avoid the effect of gas purification problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

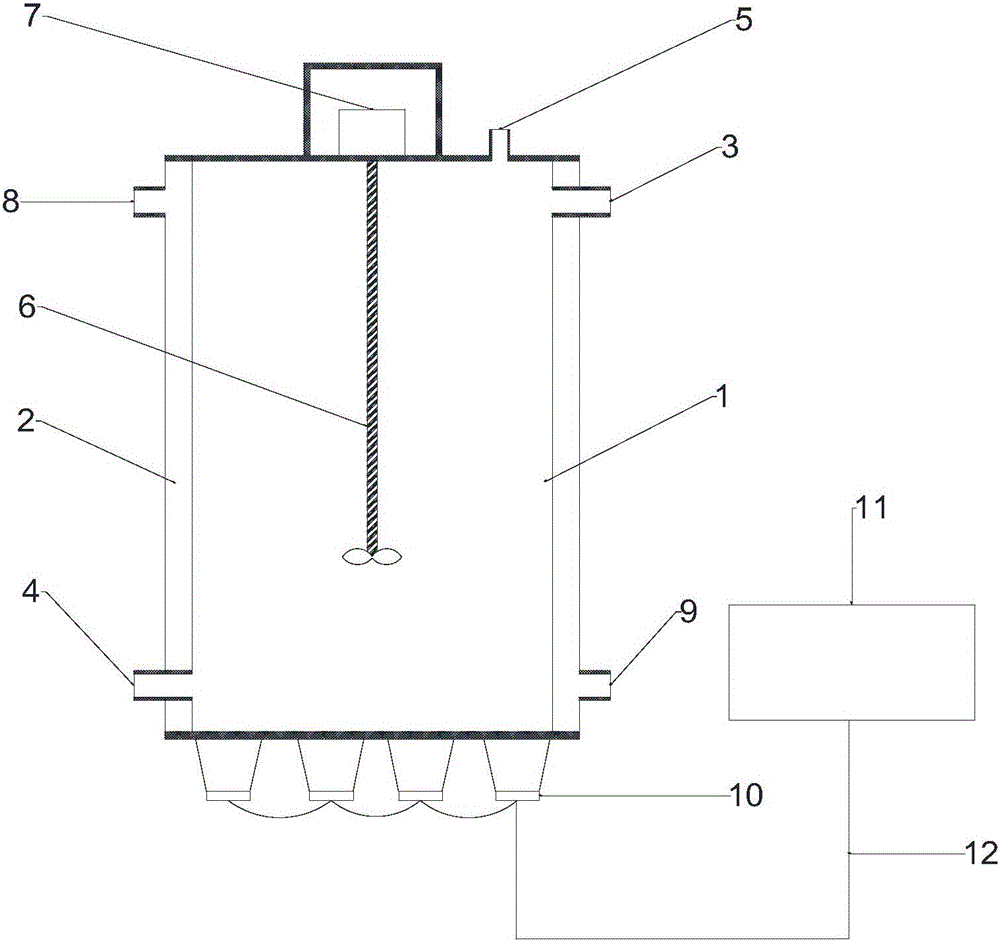

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] A method for intensifying anaerobic biological fermentation hydrogen production with pulsed power ultrasonic waves, which uses pulsed power ultrasonic waves to perform pulsed power ultrasonic intensified treatment on the fermentation broth in an anaerobic biological fermentation hydrogen production system at a constant temperature of 35°C. The ultrasonic frequency is 20-100KHz, the power density is 50-250W / L, the pulse power ultrasonic action time is 1-2S, and the interval time is 58-59S.

[0014] A pulsed power ultrasonic enhanced anaerobic biological fermentation hydrogen production device, a constant temperature water jacket 2 is covered and contained on the outside of the cylinder of the reaction tank 1, and the upper and lower sides of the constant temperature water jacket 2 are respectively provided with A water port 8 and a water outlet 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com