Technique for producing humic acid organic compound fertilizer from sugar refinery waste slag and wastewater

A sugar factory waste residue and production process technology, applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment, etc., can solve the problems of waste of natural resources, pollution of the natural environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

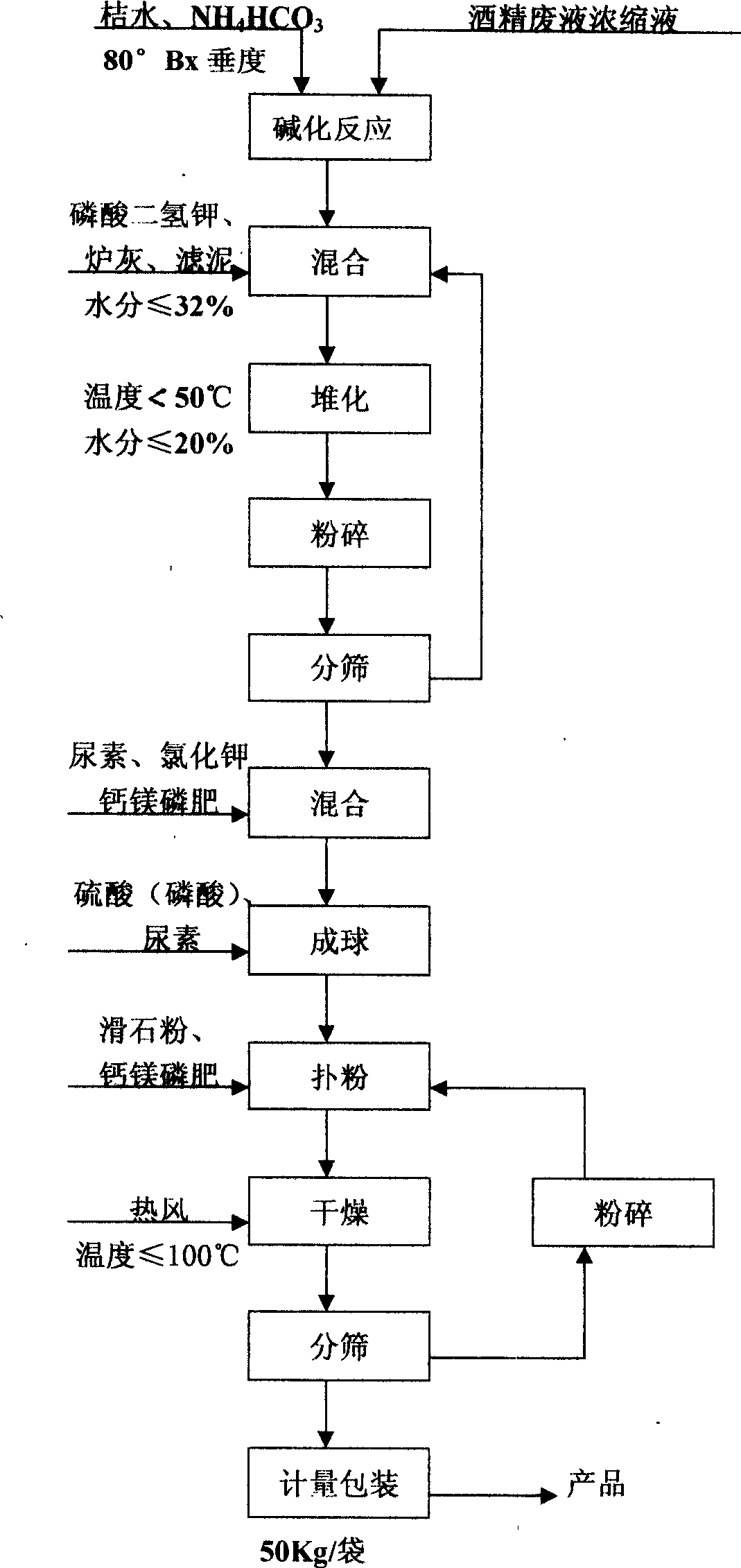

Image

Examples

Embodiment 1

[0024] Example 1: Sulfurous acid process filter mud as raw material

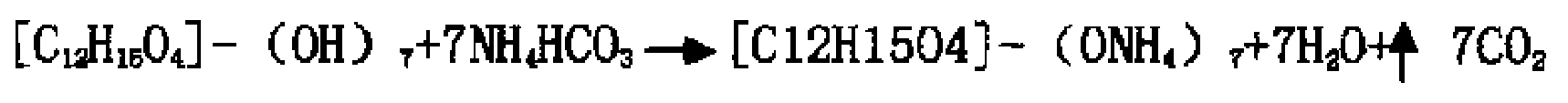

[0025] The process for producing humic acid organic compound fertilizer using sugar factory waste residue and wastewater of the present invention follows the following process steps:

[0026] 1. Concentration of alcohol waste liquid

[0027] The PH value of the alcohol waste liquid is 4.2-4.9, slightly acidic, the main components: sugar 1.7%, ash, organic matter and native humic acid 6.5%, N is 0.06%, PO 2 O 5 Is 0.01%, K 2 It is 0.23% and the moisture content is 91.5%. Because of its high water content and low utilization rate, it must be concentrated before use. The concentration of 80°Bx is similar to that of orange water.

[0028] Using the working principle of the electric heat pump, with the refrigerant as the carrier, the vaporized 30℃ refrigerant gas is compressed by the electric heat pump, the pressure is 1.2-1.8Mpa, the temperature is ≥108℃, and the alcohol waste liquid is heated in the condensing evap...

Embodiment 2

[0045] Example 2: Carbonic acid filter mud as raw material

[0046] The process steps are the same as in Example 1, except that in step (3), the ratio of the alkalization reaction liquid to the filter mud, furnace ash and cane pith is 1:1.3 to 1.5.

[0047] The main equipment used in the present invention is common equipment for producing compound fertilizers, such as belt conveyors, screw conveyors, bucket elevators, disc ball machines, rotary dryers, vibrating screens, mixers, alkalization reaction tanks, fans, Water pump and so on.

[0048] Product quality standard of the present invention

[0049] 1. Humic acid organic compound fertilizer produced by sulphurous acid method filter mud

[0050] 1. Product quality standards

[0051] Humic acid ≥ 18%, organic matter ≥ 45%, N ≤ 9%, P ≤ 5%, K ≤ 6%, moisture ≤ 12%, inorganic calcium, magnesium, and sulfur 3%, particle size 1-4 mm.

[0052] 2. Raw materials and costs

[0053] Orange water and alcohol concentrate 280Kg 150 yuan, sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com