System and method for advanced treatment of drinking water based on vertical flow type three-phase hybrid reactor

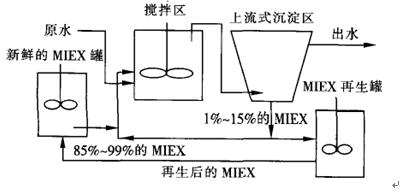

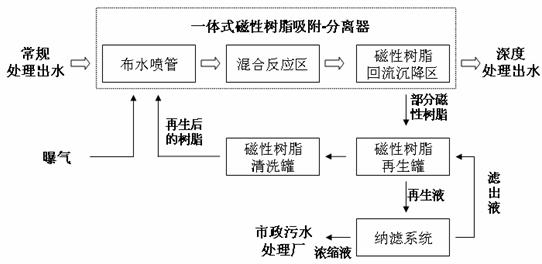

A technology for mixing reactors and drinking water treatment, applied in ion-exchange water/sewage treatment, etc., can solve the problems of large floor space, high equipment investment, and adequate mixing of water and resin, saving floor space and reducing investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

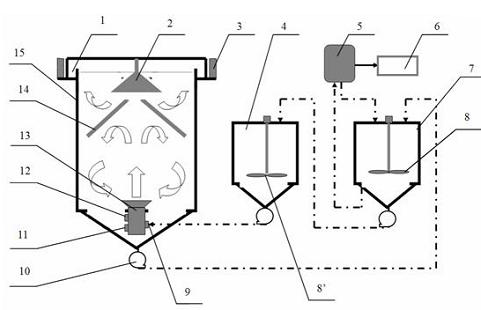

[0036] Step 1.1 Three-phase mixing: Put 150mL of magnetic resin MD201 into a vertical flow three-phase mixing reactor (the diameter of the reactor is 0.2 meters, the height is 0.4 meters, and the height of the conical bottom is 0.1 meters). After gas and regenerated magnetic resin is mixed in the water distribution nozzle, it is sprayed out at a flow rate of 2 m / s, of which the water inlet flow rate is 40 liters / hour, the aeration rate is 40 liters / hour, and the water is continuously inflow / outlet;

[0037] Step 1.2 Adsorption: The sprayed three-phase mixed fluid of water, solid and gas is affected by the blocking partition, forming a mixed reaction reflux zone above the nozzle, and the magnetic resin is fully mixed with the incoming water to absorb and remove trace pollutants in the water. The reflux flow and the blocked partition sink into the bottom of the reactor, and part of the magnetic resin at the bottom will also enter the mixed reaction zone under the action of the re...

Embodiment 2

[0045] The operating conditions are the same as in Example 1, but the water inlet flow rate of step 1.1 is adjusted to 3 m / s, 80% of the magnetic resin sinks into the bottom of the reactor with the reflux flow in step 1.3, and step 1.4 is regenerated with 150mL of 30% NaCl solution, and the water outlet See Table 3 for water quality:

[0046] Table 3 Water quality of advanced treatment effluent

[0047] water quality index

Embodiment 3

[0049] The steps are the same as in Example 1, but the MD-201 resin in step 1.1 is changed to MIEX resin, and the magnetic resin is mixed in the water distribution nozzle after the conventional treatment of effluent, aeration and regeneration, and then sprayed at a flow rate of 1 m / s. The other operating conditions remain unchanged, and the water quality of the effluent is shown in Table 4:

[0050] Table 4 Water quality of advanced treatment effluent

[0051] water quality index

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com