System for processing fossil fuel combustion waste gas by biology method

A technology for fossil fuels and waste gas combustion, applied in separation methods, chemical instruments and methods, and air quality improvement, can solve problems such as harmful by-products, secondary pollution, and incomplete treatment, and achieve convenient, reliable, and intelligent operation. High, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

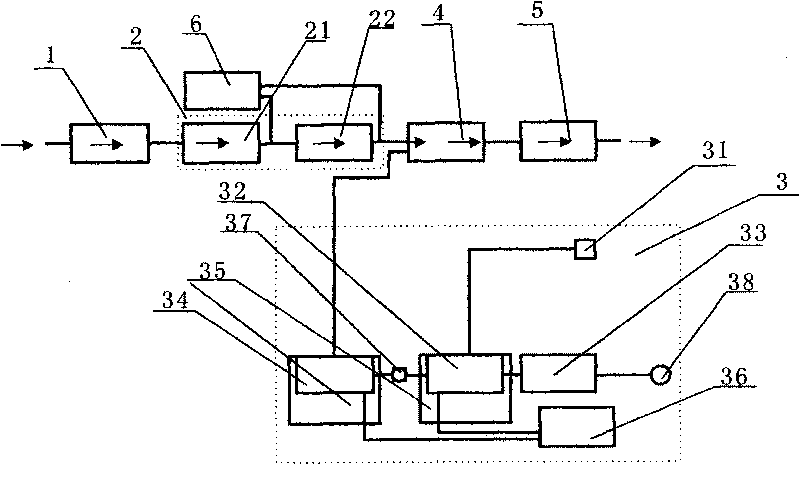

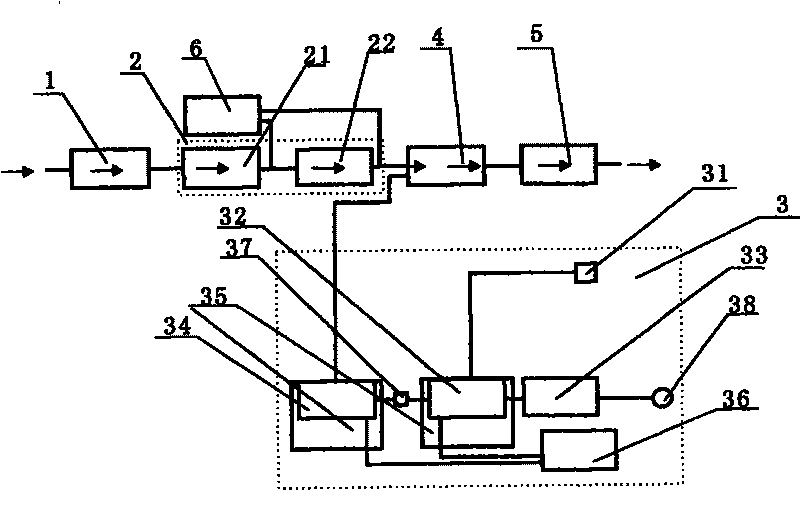

[0022] figure 1Shown in the present invention mainly is by inlet end exhaust gas detector (1), cooler (2), ultrasonic atomization device (3), mixing reactor (4), outlet end exhaust gas detector (5), system power supply and CPU control center, characterized in that the pipelines are sequentially connected to the exhaust gas detector (1) at the inlet end, the cooler (2), the mixing reactor (4) and the exhaust gas detector (5) at the outlet end, and the ultrasonic atomization device ( 3) the outlet pipe of the mixing reactor (4) is connected to the inlet end of the mixing reactor (4), the exhaust gas temperature sensor (6) is arranged at the air outlet end of the cooler (2), and the system power supply provides power support for each component, and Accepting the control of the CPU control center, the CPU control center receives the data of the detection devices and sensors of each component, analyzes and processes these data, and at the same time, issues work instructions to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com