Preparation method of magnetically supported titanium-silicon molecular sieve catalyst and special impact ultrasonic micro-mixing reactor

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of preparation of magnetically supported titanium-silicon molecular sieve catalyst, can solve the problems of reducing the catalytic activity and selectivity of the titanium-silicon molecular sieve catalyst, losing the specific surface area and effective active site of the catalyst, and achieving easy solid-liquid The effect of separation, good catalytic performance, and efficient recovery and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

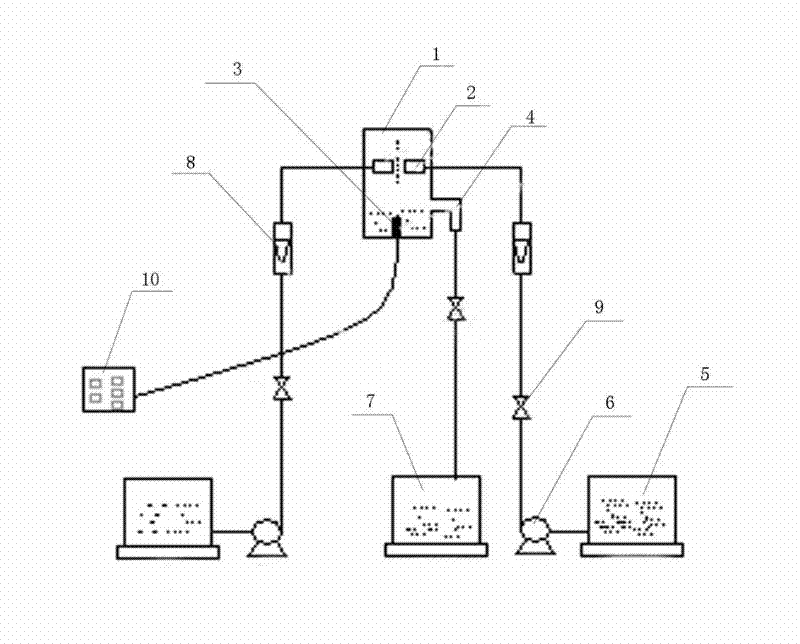

[0034] The impingement ultrasonic micro-mixing reactor used in the preparation method of the magnetic-supported titanium-silicon molecular sieve catalyst of the present invention includes a reactor 1, the upper part of the inner cavity of the reactor 1 is provided with two nozzles 2, and the lower part is equipped with an ultrasonic oscillator 3. The shell of the reactor 1 is higher than the ultrasonic oscillator 3 and lower than the nozzle 2. There is an overflow port 4. The nozzle 2 is connected to the two liquid storage tanks 5 through the pipeline. The pipeline is equipped with a delivery pump 6 and the overflow port 4 communicates with the liquid storage tank 7 through pipelines. A flow meter 8 and a control valve 9 are installed on the pipeline. The ultrasonic oscillator 3 is connected to the control board 10 .

[0035] In step (1), the mixed solution of soluble ferrous salt and soluble nickel salt is placed in one of the liquid storage tanks 5, and the ammonia solution...

Embodiment 1

[0038] Prepare a mixed solution with a concentration of 2.0 mol / L ferric nitrate and 1.0 mol / L nickel nitrate, and then prepare a solution with a concentration of 4.0 mol / L ammonia solution, put the two liquids in the liquid storage tank respectively, and pump them into the In reactor 1, the impact velocity of the liquid is 10m / s, and the pH of the reaction liquid is controlled to be 10 by adjusting the flow rate. Then move the reaction solution into a closed kettle for hydrothermal reaction. The hydrothermal temperature is 180°C and the hydrothermal time is 6 hours. After the reaction is completed, it is filtered, washed, and vacuum-dried at 120°C to obtain nickel ferrite powder.

[0039] Mix 208g (1.0mol) tetraethyl ammonium hydroxide (TAPOH) (20%wt) and 180g (10mol) deionized water, and stir at 18°C After 60 minutes, a silicon ester hydrolyzate was obtained. Then 3.4g (0.01mol) tetrabutyl titanate (TBOT), without adding isopropanol (IPA) solvent, 101.5g (0.05mol) tetraprop...

Embodiment 2

[0044] Prepare a mixed solution with a concentration of 1.0 mol / L ferric chloride and 0.5 mol / L nickel chloride, and then prepare a solution with a concentration of 2.0 mol / L ammonia solution, place the two liquids in the liquid storage tank respectively, and transport them by the delivery pump 6 Entering reactor 1, the impact velocity of the liquid is 3m / s, and the pH of the reaction liquid is controlled to be 12 by adjusting the flow rate. Then move the reaction liquid into a closed kettle for hydrothermal reaction. The hydrothermal temperature is 120°C and the hydrothermal time is 12 hours. After the reaction is completed, it is filtered, washed, and vacuum-dried at 150°C to obtain nickel ferrite powder.

[0045] Mix 208g (1.0mol) Tetraethyl Tetrasilicate (TEOS), 304.5g (0.3mol) Tetrapropylammonium Hydroxide (TAPOH) (20%wt) and 720g (40mol) deionized water, stir at 5°C After 30 minutes, a silicon ester hydrolyzate was obtained. Then 13.6g (0.04mol) tetrabutyl titanate (TBO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com