Anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of anaerobic reactors, can solve the problems of biogas volume limitation, provide satisfactory solutions, etc., and achieve the effect of reducing capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

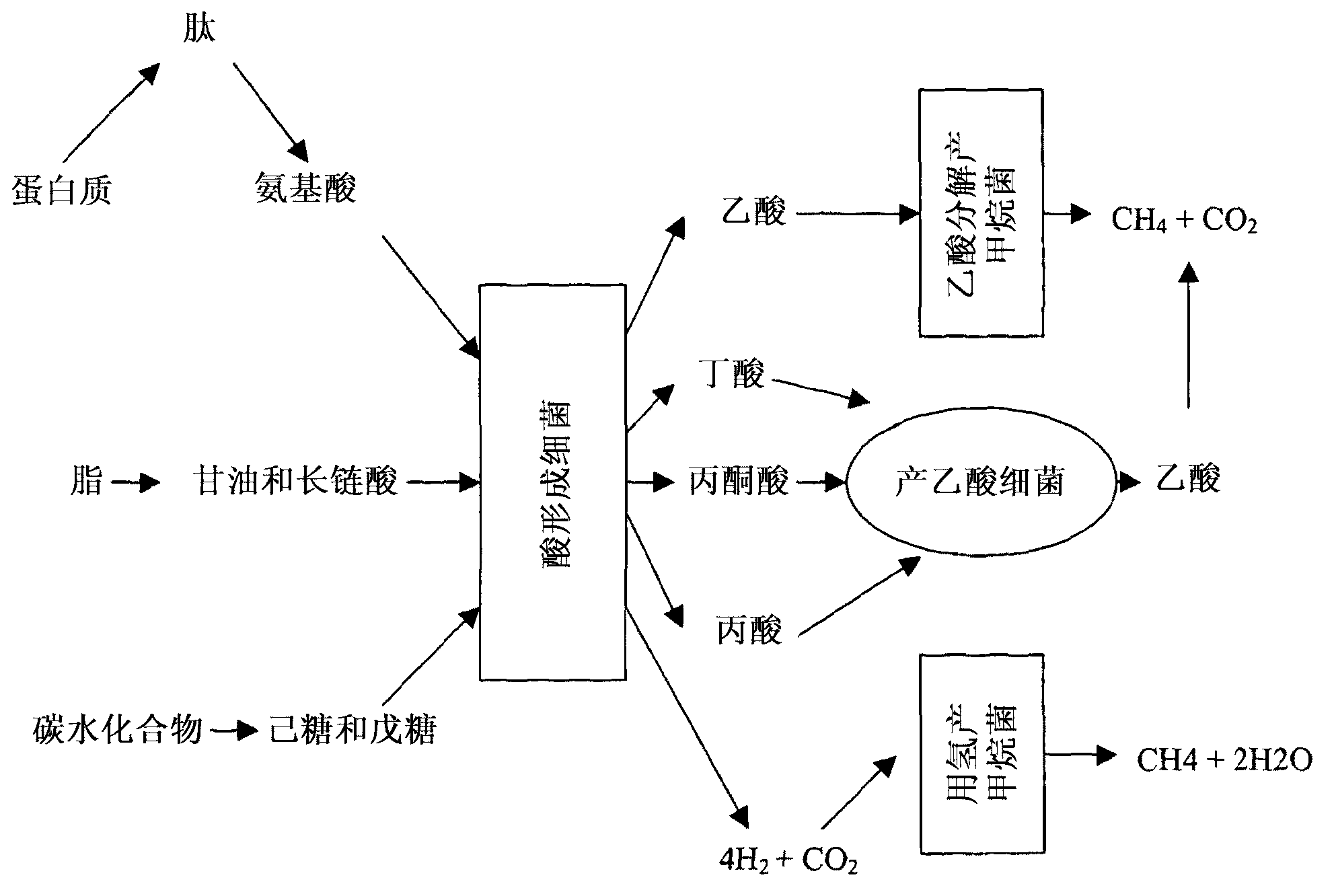

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

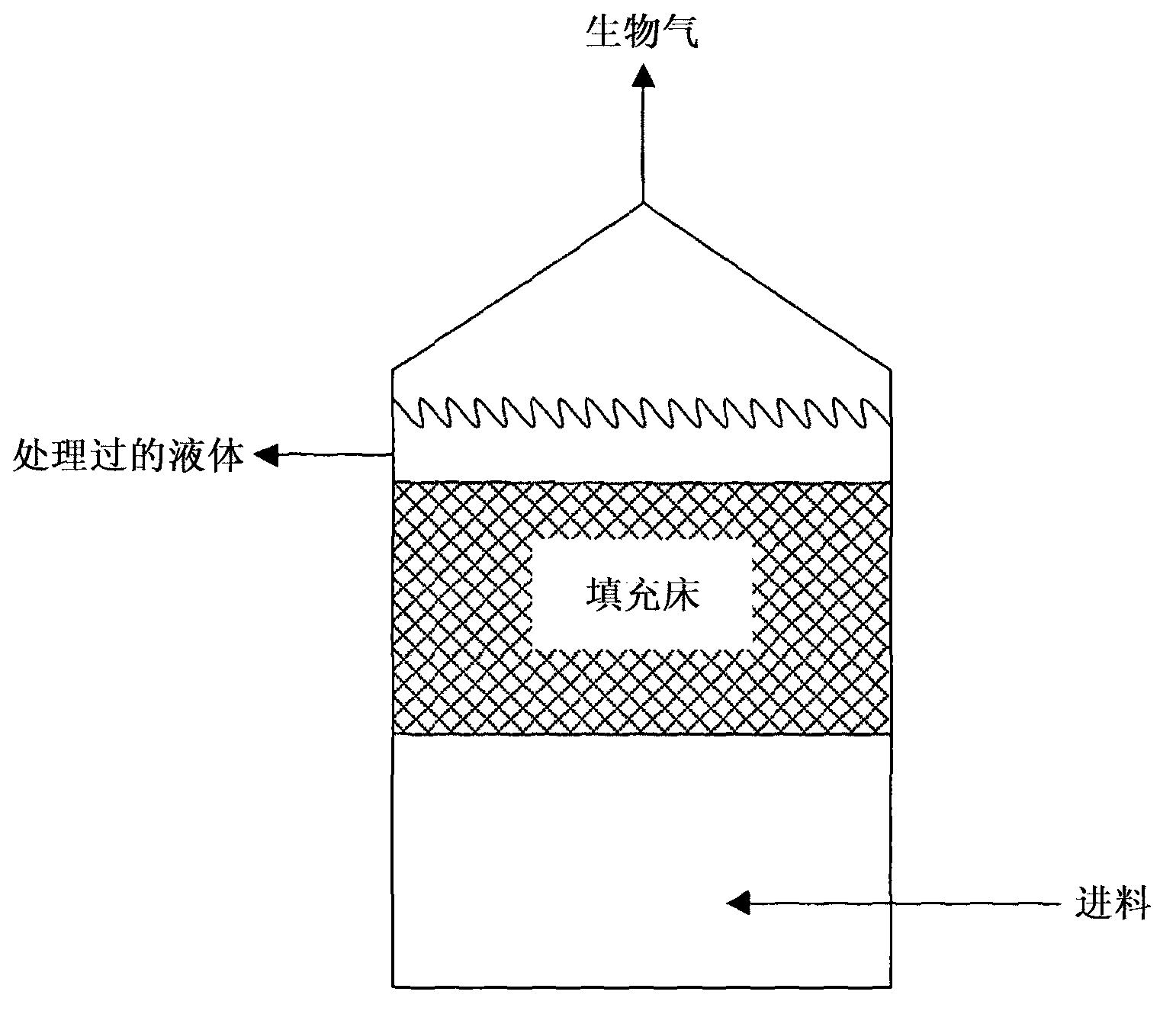

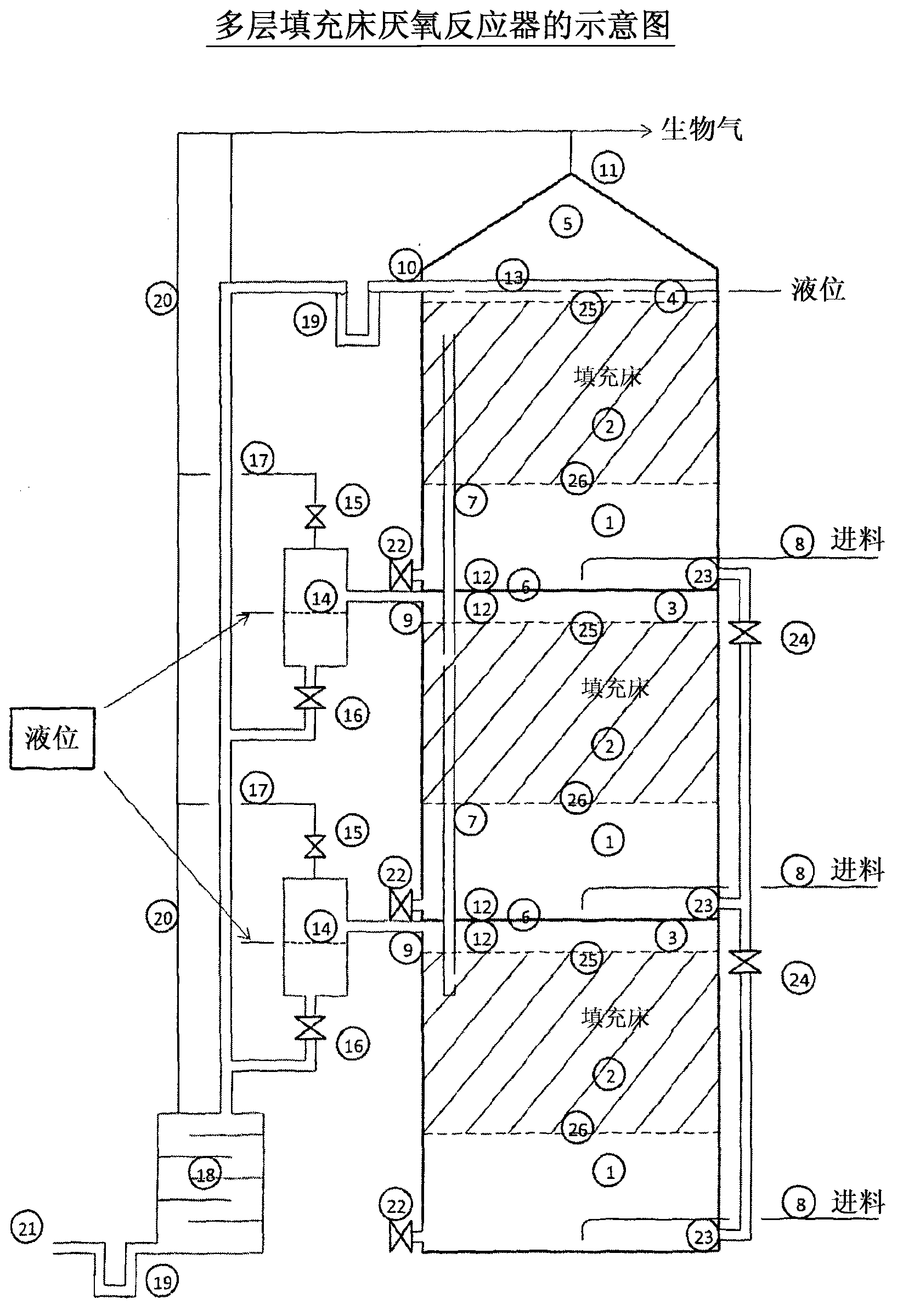

[0041] The reactor of the present invention comprises two or more reaction chambers arranged one above the other. Preferably, the chamber is arranged in a substantially vertical (preferably vertical) configuration. Thus, in one embodiment, the reactor of the present invention comprises one or more stacks of reaction chambers, or one or more substantially vertical stacks.

[0042] The reaction chambers of the reactor are separated from each other. In particular, there should be no flow of bacteria, biomass or anaerobic digestion products between the chambers. Each chamber operates independently to produce biogas by anaerobic digestion of biomass. Each chamber is separated from adjacent chambers by, for example, a solid plate. As noted above, although the chambers may be considered to be separate chambers operating independently, it is common to provide pressure equalization means between each chamber in the reactor and the chambers above and below it. Pressure equalization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com