Process for producing asarin

A technology of Asarum and Lewis acid, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of high-temperature distillation, high anhydrous requirements, and inconvenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

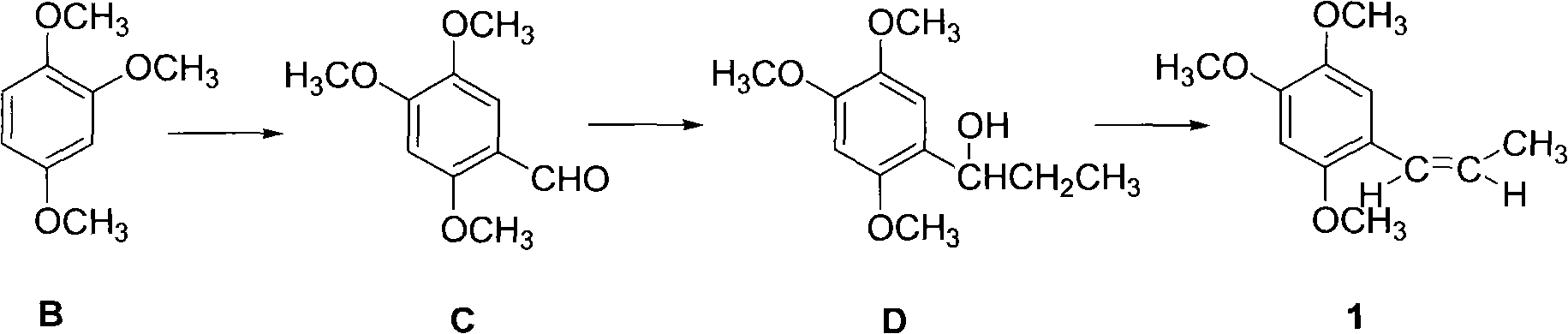

Method used

Image

Examples

Embodiment 1

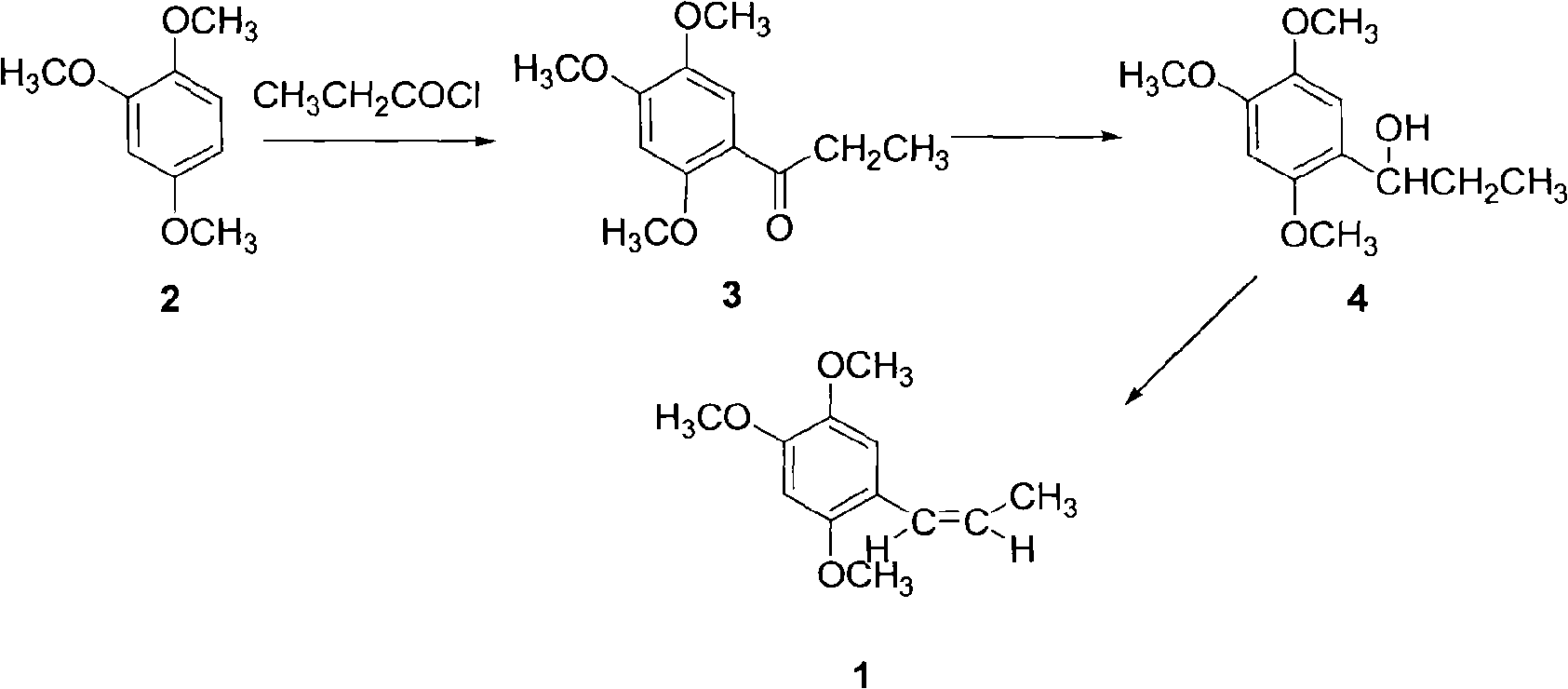

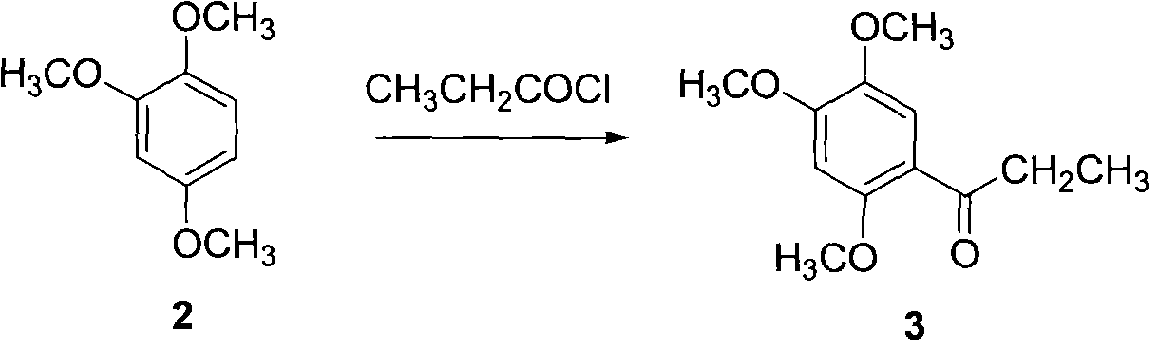

[0031] One, the preparation of 2,4,5-trimethoxypropiophenone

[0032] Put 15 kg of 1,2,4-trimethoxybenzene, 15 kg of propionic anhydride, and 300 kg of dichloromethane into the kettle, lower the temperature to 15°C, add 26 kg of aluminum trichloride, and keep the temperature below 30°C. After the addition, the temperature was raised to 40-70°C, and the heat preservation reaction was carried out for 2-5 hours. The material was discharged into 400 kg of water, extracted with dichloromethane (100 liters × 3), the organic layers were combined, washed with water until neutral, and dichloromethane was distilled under normal pressure. methane, placed at room temperature for crystallization, filtered, and dried under normal pressure. 15 kg of solid was obtained, the yield was 75%. The melting point is 107-109°C.

[0033] Two, the preparation of 2,4,5-trimethoxyphenylpropanol

[0034] Dissolve 15 kg of the reaction product of the previous step in 100 liters of tetrahydrofuran, cool ...

Embodiment 2

[0038] One, the preparation of 2,4,5-trimethoxypropiophenone

[0039] Put 15 kg of 1,2,4-trimethoxybenzene, 15 kg of propionyl chloride, and 300 kg of dichloroethane into the kettle, lower the temperature to 15°C, add 26 kg of aluminum trichloride, and keep the temperature below 30°C. After the addition, the temperature is raised to 40-70°C, the reaction is kept for 2-5 hours, and the material is discharged into 400 kg of water. Extract with dichloroethane (100 liters x 3), combine organic layers, wash with water until neutral, evaporate dichloroethane under normal pressure, place at room temperature for crystallization, filter, and dry under normal pressure. 14.4 kg of solid was obtained with a yield of 72%. The melting point is 107-109°C.

[0040] Two, the preparation of 2,4,5-trimethoxyphenylpropanol

[0041] Dissolve 15 kg of the reaction product of the previous step in 100 kg of ethyl acetate, cool in an ice-salt bath to -5°C, start adding sodium borohydride, after the...

Embodiment 3

[0045] One, the preparation of 2,4,5-trimethoxypropiophenone

[0046] Put 15 kg of 1,2,4-trimethoxybenzene, 26 kg of anhydrous zinc chloride, and 300 kg of dichloroethane into the kettle, lower the temperature to 20°C, add 15 kg of propionic anhydride dropwise, and keep the temperature below 30°C. After the addition, the temperature is raised to 60°C, and the reaction is kept for 2-5 hours, and the material is discharged into 400 kg of water. The layers were separated, the aqueous layer was extracted with dichloromethane (100 liters × 3), the organic layers were combined, washed with water until neutral, dichloromethane was evaporated under normal pressure, crystallized, filtered, and dried under normal pressure. 16 kg of solid was obtained with a yield of 78%. The melting point is 107-109°C.

[0047] Two, the preparation of 2,4,5-trimethoxyphenylpropanol

[0048]Dissolve 15 kg of the reaction product of the previous step in 100 kg of ethyl acetate, cool in an ice-salt bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com