Method for preparing combustion inhibitor bisphenol A bis(diphenyl phosphate)

A technology of diphenyl phosphate and flame retardant, which is applied in the field of preparation of polycondensation type phosphate, can solve the problems of difficult control, mold pollution, and large energy consumption in recycling, and achieves the steps of reducing vacuum removal of phenol, reducing The effect of processing difficulty and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

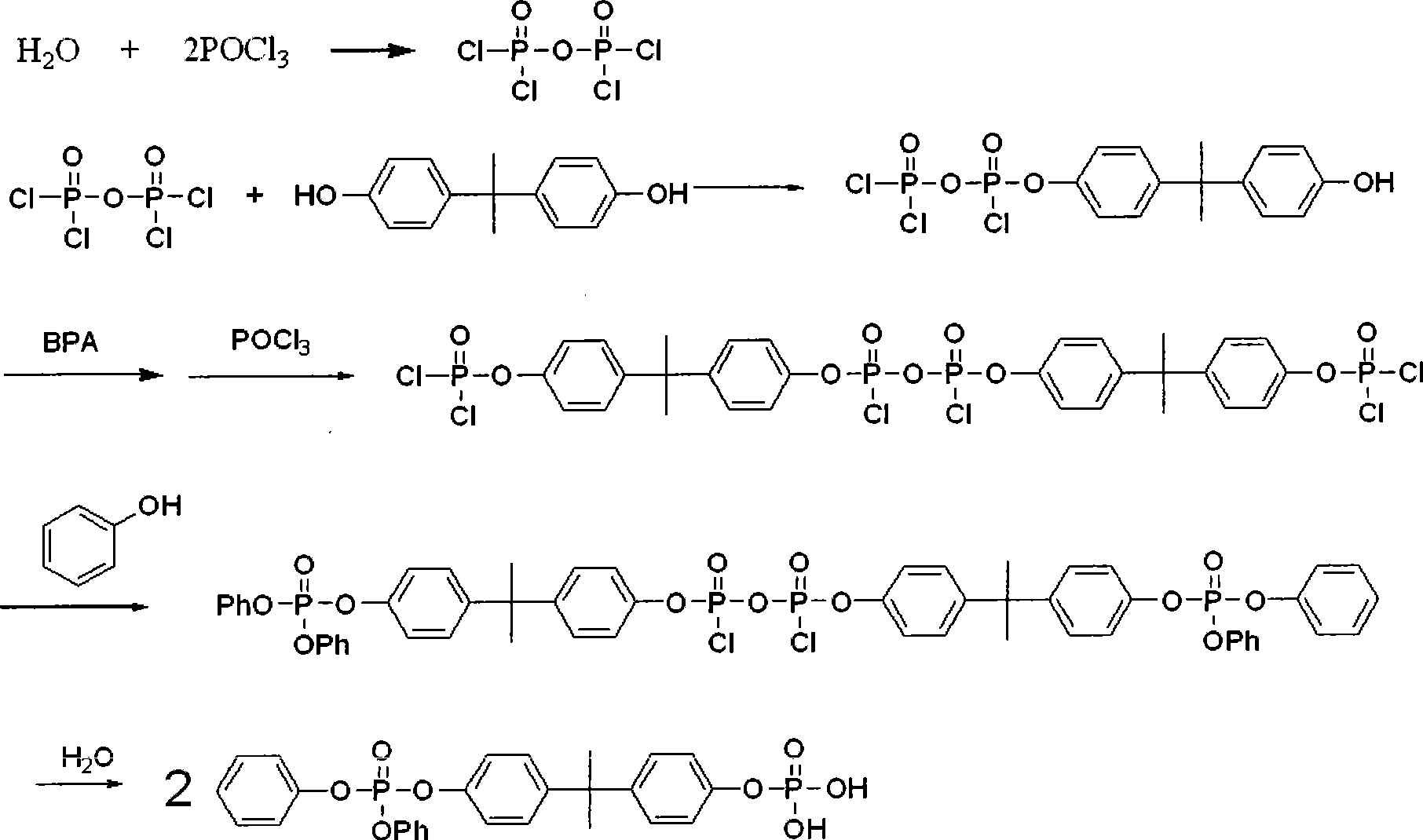

Method used

Image

Examples

Embodiment 1

[0022] Add 12240Kg of phosphorus oxychloride, 25Kg of catalyst anhydrous zinc chloride and 4.56Kg of cocatalyst calcium chloride into the 20L reaction equipment equipped with stirrer, thermometer, condenser, solid feeder and hydrogen chloride absorption device, and start the stirrer , control the stirring speed to 200 rpm, turn on the condensed water, and heat to 73-78°C, add 4560Kg of bisphenol A continuously, after adding bisphenol A dropwise within 2-2.5 hours, raise the temperature to 110-115°C , reacted for 1.5 to 2 hours, and the hydrogen chloride produced was recovered by a hydrochloric acid recovery device. Then, the excess phosphorus oxychloride is removed under normal and reduced pressure at 110-140° C., and the content of phosphorus oxychloride in the intermediate is analyzed to be about 1.0%, and a colorless intermediate product is obtained.

[0023] Next, the temperature of the intermediate is lowered to about 100°C, and 7144Kg of phenol is continuously added drop...

Embodiment 2

[0026] Add 13770Kg of phosphorus oxychloride, 136Kg of catalyst anhydrous zinc chloride and 22.8Kg of cocatalyst calcium chloride into the 20L reaction equipment equipped with stirrer, thermometer, condenser, solid feeder and hydrogen chloride absorption device, and start the stirrer , control the stirring speed to 250 rpm, turn on the condensed water, and heat to 73-78°C, add 4560Kg of bisphenol A continuously, after adding bisphenol A dropwise within 2-2.5 hours, raise the temperature to 110-115°C , reacted for 1.5 to 2 hours, and the hydrogen chloride produced was recovered by a hydrochloric acid recovery device. Then, excess phosphorus oxychloride is removed under normal and reduced pressure at 110-140° C., and the content of phosphorus oxychloride in the intermediate is analyzed to be less than 0.8%, and a colorless intermediate product is obtained.

[0027] Next, the temperature of the intermediate is lowered to about 100°C, and 7144Kg of phenol is continuously added dro...

Embodiment 3

[0030] In the 20L reaction equipment equipped with stirrer, thermometer, condenser, solid feeder and hydrogen chloride absorption device, add phosphorus oxychloride 12852Kg, catalyst anhydrous zinc chloride 50Kg and promoter calcium chloride 20Kg, start the stirrer, Control the stirring speed to 320 rpm, turn on the condensed water, and heat to 73-78°C, add 4560Kg of bisphenol A continuously, after adding bisphenol A dropwise within 2-2.5 hours, raise the temperature to 110-115°C, React for 1.5 to 2 hours, and the produced hydrogen chloride is recovered by a hydrochloric acid recovery device. Then, excess phosphorus oxychloride was removed under normal and reduced pressure at 110-140° C., and the content of phosphorus oxychloride in the intermediate was analyzed to be about 1.0%, and a colorless intermediate product was obtained.

[0031] Next, the temperature of the intermediate is lowered to about 100°C, and 7144Kg of phenol is continuously added dropwise to the intermediate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com