Method for producing metal aluminium by high-alumina fly ash chlorination electrolysis

A technology of high-alumina fly ash and electrolysis, which is applied in the field of producing metal aluminum by chlorination and electrolysis of high-alumina fly ash, which can solve the problems of high corrosion resistance of equipment and materials, large amount of red mud, and concentration of sodium aluminate solution Low-level problems, to achieve the effect of solving the shortage of bauxite resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

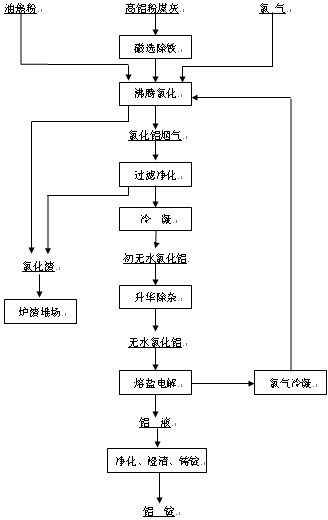

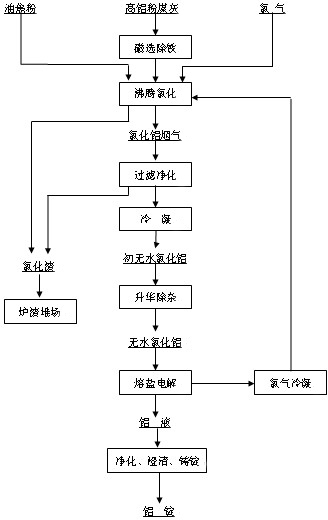

[0030] Embodiment of the present invention: technological process of the present invention sees attached figure 1 shown. The present invention mainly contains following technological process:

[0031] The alumina content of high-alumina fly ash is 45%, and the iron oxide content is 2%. After magnetic separation and iron removal, the iron oxide content in the ash is 0.9%. Chlorine gas with a concentration of 40% is introduced inside, and the chlorination temperature of the boiling chlorination furnace is 850°C. The alumina in the fly ash fully reacts with the chlorine gas introduced under the condition that the carbon in the oil coke powder is used as the reducing agent. Aluminum chloride bimolecular smoke is obtained. The aluminum chloride flue gas is purified by a filter and sent to the condenser to cool down to 250°C, so that other chloride impurities are condensed and discharged from the process in the form of ash. The flue gas then enters the trap and cools down to 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com