Rechargeable aluminum ion cell and preparation method thereof

An aluminum-ion battery and ion technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of limited lithium resources, restrictions on the large-scale application of lithium-ion batteries, expensive costs and potential safety hazards, and achieve reserves Rich, good chemical stability and electrochemical stability, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

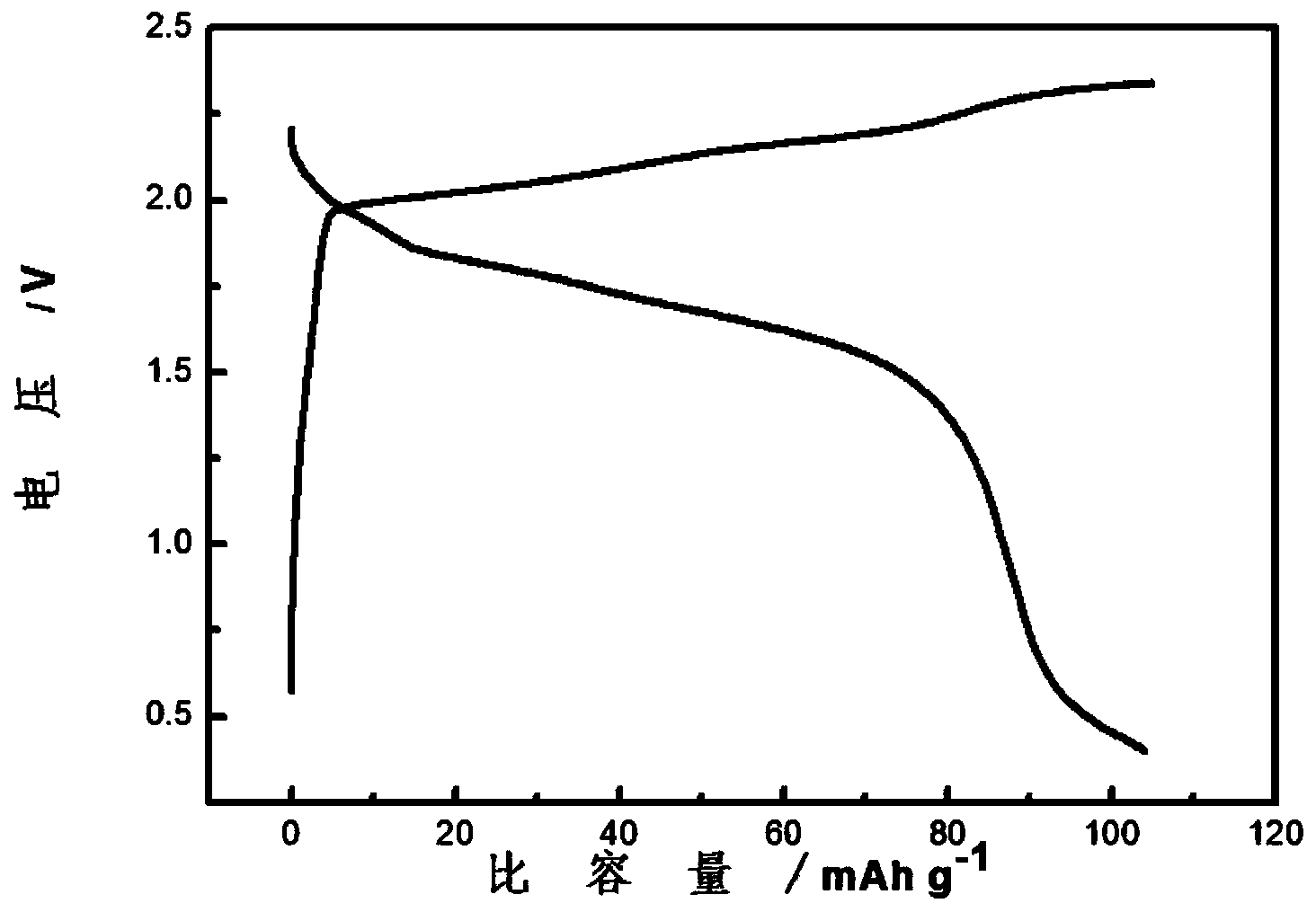

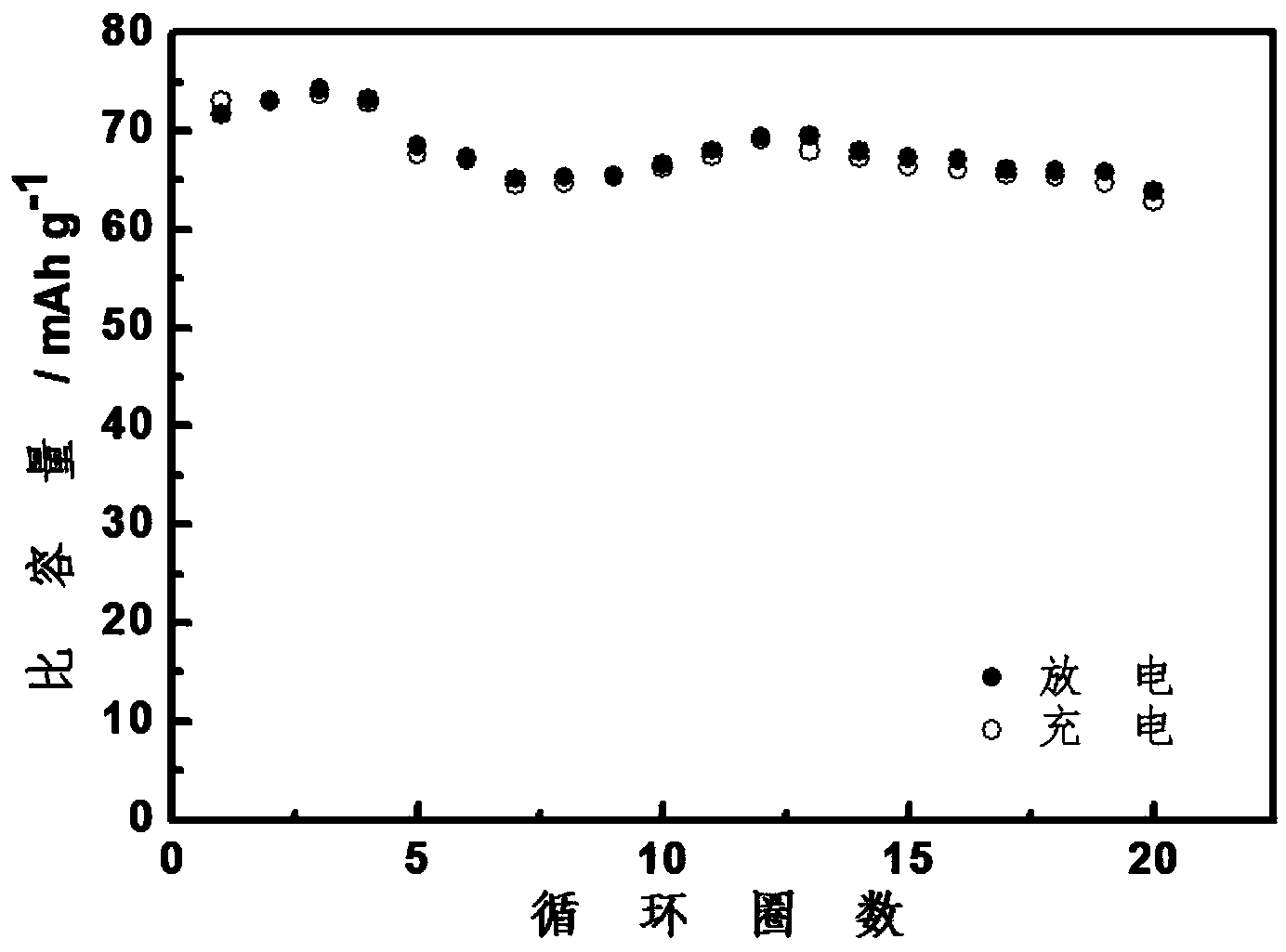

Embodiment 1

[0026] Carbon paper is used as the cathode material. Flatten the carbon paper on a manual rolling machine, cut it into discs with a diameter of 16mm, scrub it with absolute ethanol, and dry it in an oven at 60°C for 2 hours. Take molybdenum foil with a thickness of 0.5mm, and cut out two molybdenum sheets with a size of 4mm×7mm. Drill holes with a diameter of 1 mm on the two molybdenum sheets. Place the carbon paper in the middle of the molybdenum sheet, and drill a hole with a diameter of 1mm thick according to the position of the hole on the molybdenum sheet. Carbon paper and molybdenum sheets are bound together with current collector wire to form the positive electrode. The positive electrode composed of carbon paper and molybdenum sheet was wrapped with glass fiber filter paper (GF / D, Whatman). Soak the high-purity aluminum sheet in absolute ethanol for 3 hours, and ultrasonically vibrate it, and use it as the negative electrode after drying. The ionic liquid was prepa...

Embodiment 2

[0028] Carbon black is used as the cathode material. Add a little ethanol to the carbon black to wet it, put it into a mold with a diameter of 20mm, press it with a pressure of 15MPa, bake it in an oven at 60°C for 1 hour, and then heat it to 800°C under vacuum for 2 hours and cool naturally. Then take a molybdenum foil with a thickness of 0.5mm, and cut out two molybdenum sheets with a size of 4mm×7mm. Drill holes with a diameter of 1 mm on the two molybdenum sheets. Place the carbon black electrode sheet in the middle of the molybdenum sheet, and drill a hole with a diameter of 1mm thick according to the position of the hole on the molybdenum sheet. Carbon paper and molybdenum sheets are bound together with current collector wire to form the positive electrode. The positive electrode composed of carbon paper and molybdenum sheet was wrapped with glass fiber filter paper (GF / D, Whatman). Soak the high-purity aluminum sheet in absolute ethanol for 3 hours, and ultrasonicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com