Citral with low color number and preparation method thereof

A technology of citral and color number, which is used in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (preparation of thick citral)

[0046] Add 774g prenol (about 9mol), 84g prenaldehyde (about 1mol) and 1.15g phosphoric acid (mass content 85%, about 0.01mol) into the bottom of the rectification column, the number of theoretical plates of the rectification column is 9 , the temperature at the bottom of the tower is 110°C, the vacuum at the top of the tower is 5KPa, and the reflux ratio is 1:10. Prenyl alcohol and water are extracted at the top of the tower. After heating the tower kettle for 5 hours, when there is almost no reflux at the top of the tower, stop heating. The product obtained in the tower kettle is isopentenyl prenyl aldehyde, and the acetal content is 99% as detected by the gas phase. Add 0.79g of pyridine (about 0.01mol) into the still of the rectification tower, raise the temperature of the still to 150°C, the vacuum at the top of the tower is 2KPa, the reflux ratio is 1:3, and the cis / trans-iso Pentenyl-3-methylbutadiene ether and prenol...

Embodiment 2

[0048] Embodiment 2 (the reduction of citral color number)

[0049] The thick citral that makes among the embodiment 1 first uses diameter 50mm, high 1m, the CO that theoretical plate number is 30 plates2 Stripping tower for stripping treatment. CO 2 The stripping tower is operated under the condition of normal pressure and 20°C, the crude citral is added from the upper part of the tower, and the CO2 added in the lower part of the tower 2 Countercurrent contact in column, CO 2 The ratio of volume flow rate to citral is 20:1, the residence time of the liquid phase in the tower is 10min, and the crude citral product after air stripping is continuously extracted from the bottom of the tower.

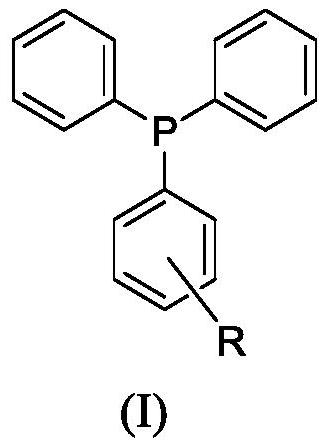

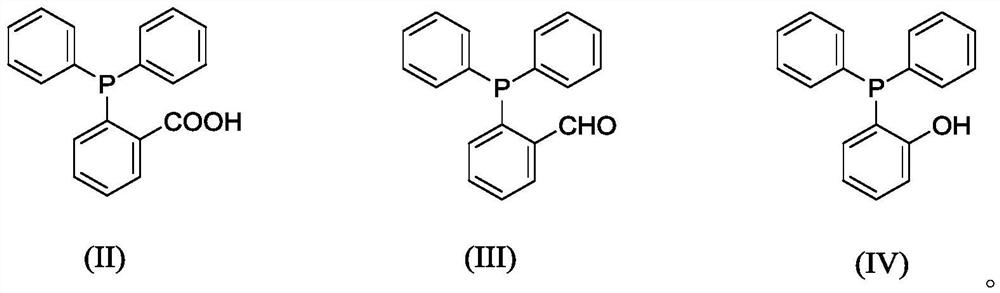

[0050] The triarylphosphine compound (II) Added to the above-mentioned crude citral product after air stripping, the addition amount of triarylphosphine compound (II) is 0.02wt% of the crude citral product quality through air stripping, after mixing uniformly, enter the rectification to...

Embodiment 3

[0051] Embodiment 3 (the reduction of citral color number)

[0052] The thick citral that makes among the embodiment 1 first uses diameter 50mm, high 1m, the CO that theoretical plate number is 20 plates 2 Stripping tower for stripping treatment. CO 2 The stripping tower is operated under the condition of normal pressure and 25°C, the crude citral is added from the upper part of the tower, and the CO2 added in the lower part of the tower 2 Countercurrent contact in column, CO 2 The ratio of volume flow rate to citral is 50:1, the residence time of the liquid phase in the tower is 30min, and the crude citral product after air stripping is continuously extracted from the bottom of the tower.

[0053] The triarylphosphine compound (III) Added to the above-mentioned crude citral product after air stripping, the addition amount of triarylphosphine compound (III) is 0.04wt% of the crude citral product quality through air stripping, after mixing uniformly, enter the rectificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chemical purity | aaaaa | aaaaa |

| Chemical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com