Production equipment and process of high-quality low-sulfur biodiesel

A biodiesel and production equipment technology, applied in the preparation of liquid hydrocarbon mixtures, biofuels, petroleum industry, etc., can solve the problems that the biodiesel production process cannot meet the requirements of the National V standard, cannot use biodiesel for desulfurization, and has low sulfur content , to achieve the effect of low sulfur content, small total equipment investment and small color number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

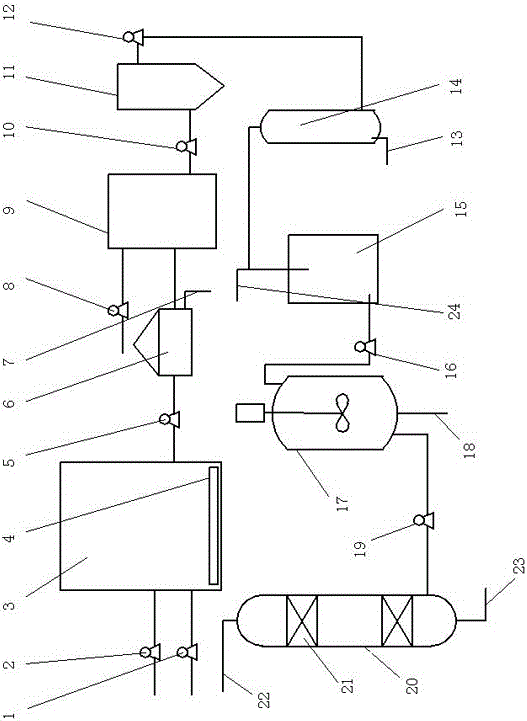

Embodiment 1

[0050] Waste oil (sulfur content is 350mg / Kg) 10 tons, pumped into the aeration reaction tank 3, the oil-water ratio is 1:1, the concentration of salt water is 0.5%, the aeration plate 4 is opened, the air-water ratio is 5:1, the waste oil Stay in the aeration reaction tank 3 for 20 minutes, centrifuge after the aeration reaction, remove a large amount of sulfur-containing impurities, proteins, colloids, etc. in the waste oil, the centrifuge discharge directly enters the ultrasonic tank 9, and open the clear water feed pump 8 at the same time, The oil-water ratio is 1:1, and the ultrasonic frequency is turned on to 10MHz. The oil-water mixture generates free radicals and annihilates bubbles under the action of ultrasonic cavitation. Remove it into the waste water, stand still and separate the water to obtain the secondary desulfurization raw material oil, the raw material oil pump 12 continuously pumps the secondary desulfurization raw material oil into the atmospheric distilla...

Embodiment 2

[0052] 10 tons of swill oil (sulfur content is 300mg / Kg), pumped into the aeration reaction tank 3, the oil-water ratio is 1:2, the concentration of salt water is 0.3%, the aeration plate 4 is opened, the air-water ratio is 3:1, and the swill oil Stay in the aeration reaction tank 3 for 40 minutes, centrifuge after the aeration reaction, remove a large amount of sulfur-containing impurities, proteins, colloids, etc. in the waste oil, and the centrifuge discharge directly enters the ultrasonic tank 9, and simultaneously turns on the clear water feed pump 8, The oil-water ratio is 2:1, and the ultrasonic frequency is turned on to 6MHz. Under the action of ultrasonic cavitation, the oil-water mixture generates free radicals and annihilates bubbles. Remove it into the waste water, stand still and separate the water to obtain the secondary desulfurization raw material oil, the raw material oil pump 12 continuously pumps the secondary desulfurization raw material oil into the atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com