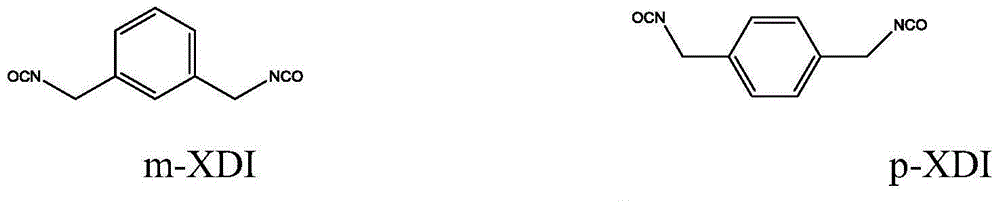

Preparation method of isocyanate

A technology of isocyanate and amine hydrochloride, applied in the direction of organic chemistry, can solve the problems of uneven dispersion, shorten the time of thermophotochemical reaction, etc., and achieve the effect of increasing solubility and improving uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

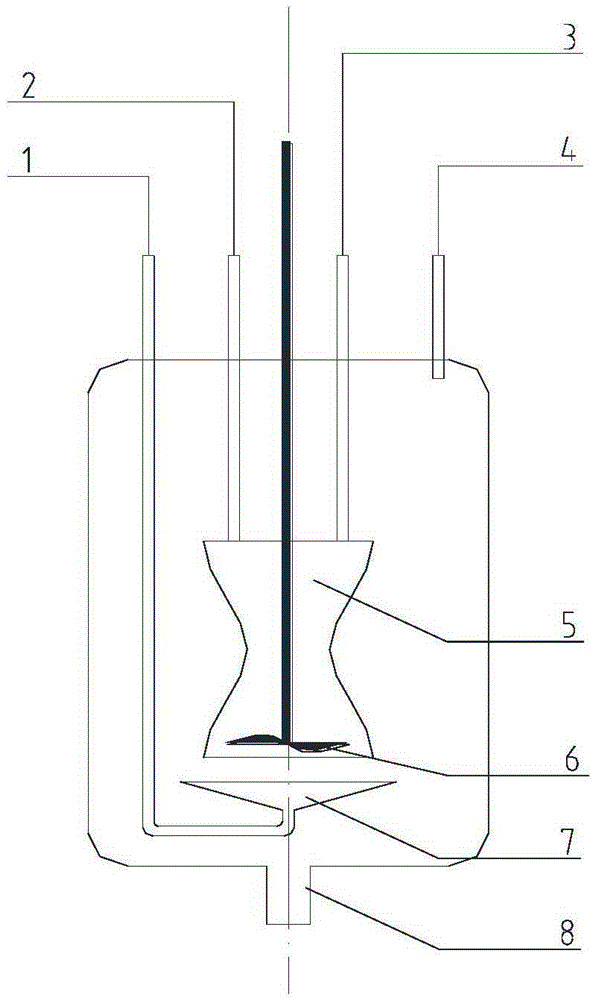

[0106] An autoclave with a jet reactor, a phosgene blowing tube and agitation was used as reaction equipment for step a, with a volume of 10 liters. Put 817g (6mol) of m-xylylenediamine and 7354g of o-dichlorobenzene (total amine concentration of feed is 10wt%) into the raw material tank to form m-xylylenediamine solution (or called reaction solution). The temperature of the reaction solution was kept at 20°C by means of external cooling. Hydrogen chloride gas is passed in the nozzle of jet reactor by high-pressure pump, and the feed rate of hydrogen chloride is 8L / min, starts to inject m-xylylene dimethoxane by the nozzle of jet reactor with the speed of 158g / min at the same time Amine solution, and at the same time, the stirring of the reactor was started to carry out the preliminary salt-forming reaction.

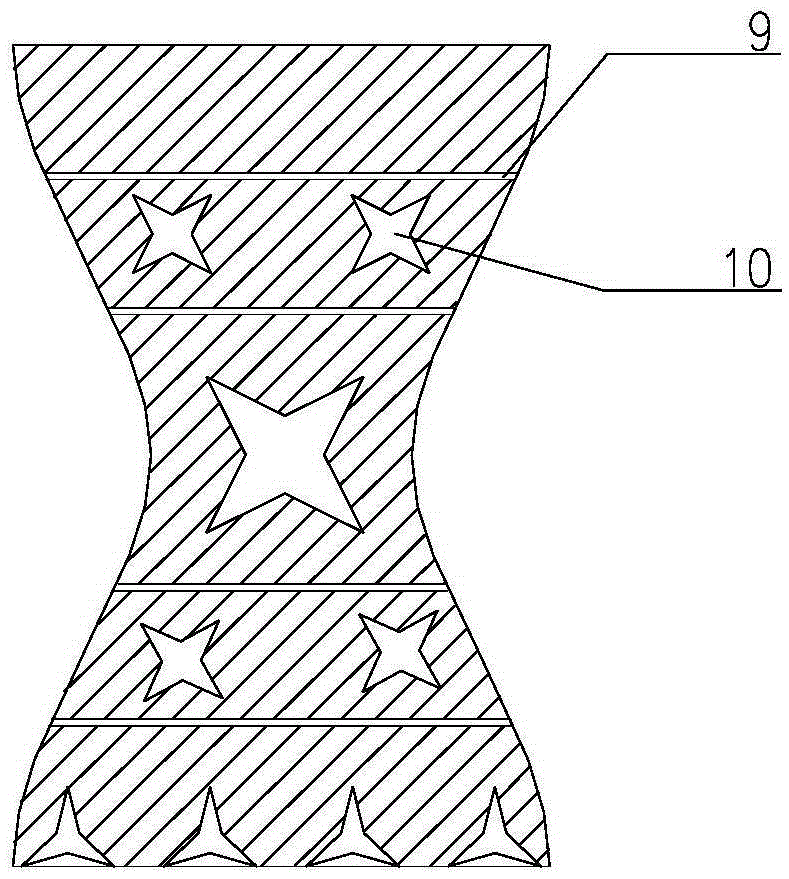

[0107] The salt-forming and aging reaction kettle used in this example adopts an hourglass-shaped liquid slurry disperser with equal upper and lower end surface areas. ...

Embodiment 2

[0111] The same tank reactor as in Example 1 was used. Put 817g (6mol) of m-xylylenediamine and 7354g of o-dichlorobenzene (total amine concentration of feed is 10wt%) into the raw material tank to form m-xylylenediamine solution (or called reaction solution). The temperature of the reaction solution was kept at 20°C by means of external cooling. Hydrogen chloride gas is passed in the nozzle of jet reactor by high-pressure pump, and the feed rate of hydrogen chloride is 8L / min, starts to inject m-xylylene dimethoxane by the nozzle of jet reactor with the speed of 158g / min at the same time Amine solution, and at the same time, the stirring of the reactor was started to carry out the preliminary salt-forming reaction.

[0112] The salt-forming and aging reaction kettle used in this example adopts an hourglass-shaped liquid slurry disperser with equal upper and lower end surface areas. The height of the hourglass-shaped liquid slurry disperser is 1 / 3 of the height of the tank re...

Embodiment 3

[0116] The same tank reactor as in Example 1 was used. Put 1225g (9mol) of m-xylylenediamine and 6946g of o-dichlorobenzene (total amine concentration of feed is 15wt%) into the raw material tank to form m-xylylenediamine solution (or called reaction solution). The temperature of the reaction solution was kept at 20°C by means of external cooling. Hydrogen chloride gas is passed into the nozzle of jet reactor by high-pressure pump, and the feeding speed of hydrogen chloride is 12L / min, starts to inject m-xylylene dimethyl dimethacrylate by the nozzle of jet reactor with the speed of 158g / min simultaneously with material pump. Amine solution, and at the same time, the stirring of the reactor was started to carry out the preliminary salt-forming reaction.

[0117] The salt-forming and aging reaction kettle used in this example adopts an hourglass-shaped liquid slurry disperser with unequal upper and lower end surface areas. The height of the hourglass-shaped liquid slurry dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com