Modified isocyanate and preparation method thereof

A technology of isocyanate and diisocyanate, which is applied in the field of modified isocyanate and its preparation, can solve problems such as increased viscosity, storage stability and safety problems, and achieve improved low-temperature storage stability, long-term storage stability, Good low temperature storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

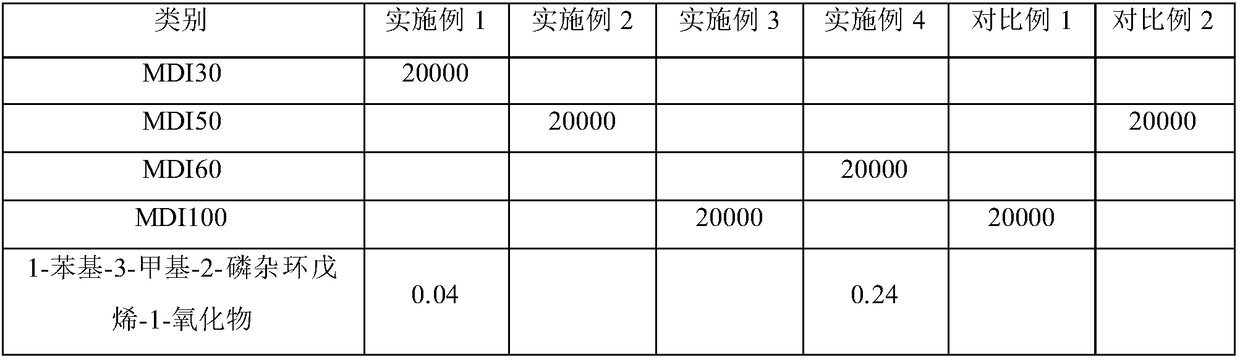

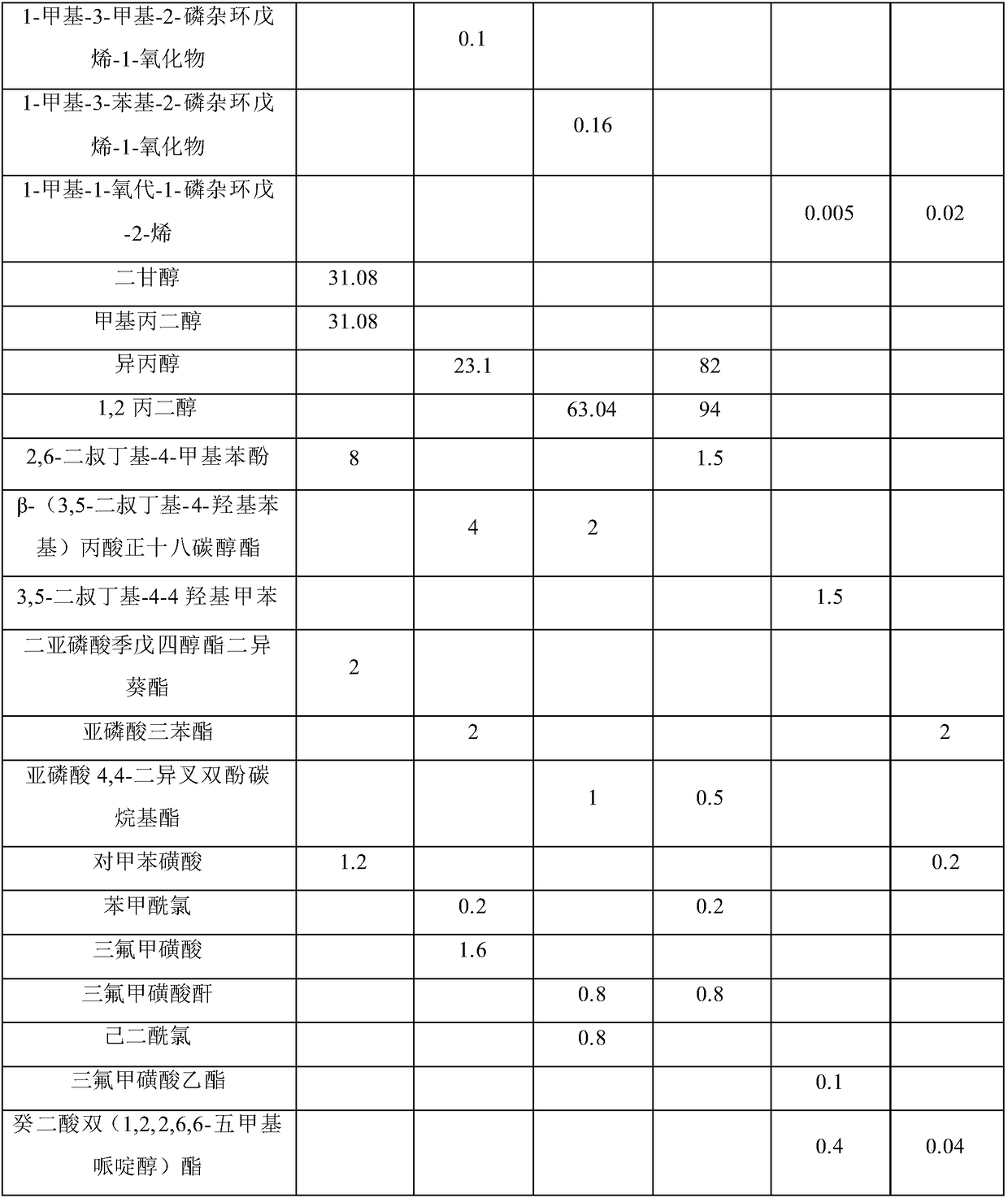

Embodiment 1

[0059] Nitrogen is passed into the reactor, and 20kg of MDI-30, heated to 90°C; 31.08g of diethylene glycol and 31.08g of methyl propylene glycol were evenly mixed to obtain a small molecule alcohol; 0.04g of 1-phenyl-3-methyl-2-phospholane Add ene-1-oxide to 0.16g of small molecule alcohol, mix evenly and add to the reactor;

[0060] Add 8 g of 2,6-di-tert-butyl-4-methylphenol and 2 g of pentaerythritol di-isodecyl diphosphite into 50 g of small molecule alcohol, mix evenly and add to the reactor;

[0061] Raise the temperature of the mixture in the reactor to 120°C and react for 2 hours; add 1.2g of p-toluenesulfonic acid to 12g of small molecule alcohol, mix well and add to the reactor to deactivate the catalyst in the mixture by "poisoning";

[0062] The temperature of the mixture in the reactor was lowered to 45° C. and stirred for 3.5 hours to obtain a sample.

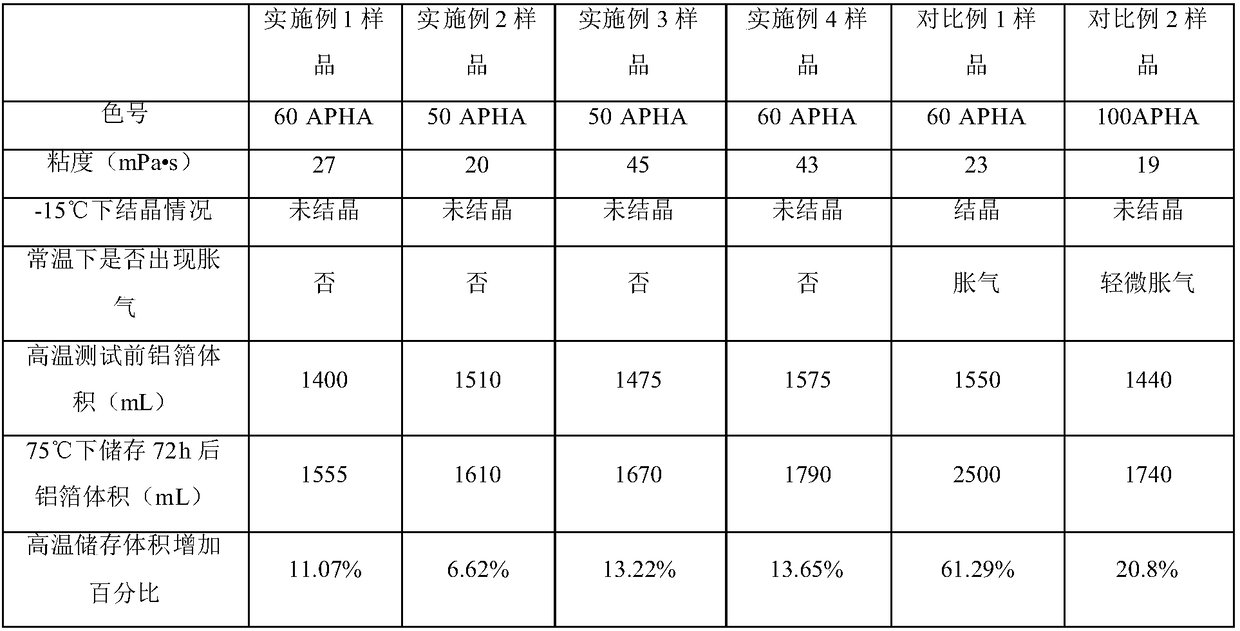

[0063] The color number of the obtained sample is 60APHA, and the isocyanate group content is 29.3%; the to...

Embodiment 2

[0065] Nitrogen is passed into the reactor, and 20kg of MDI-50, heated to 90°C;

[0066] Add 0.1 g of 1-methyl-3-methyl-2-phosphole-1-oxide into 0.4 g of isopropanol, mix well and add to the reactor;

[0067] Add 4g of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and 2g of triphenyl phosphite into 20g of isopropanol, mix well and add to the reaction device;

[0068] The temperature of the mixture in the reactor was raised to 110° C., and reacted for 2.5 hours; 1.6 g of trifluoromethanesulfonic acid and 0.2 g of benzoyl chloride were added to 2.7 g of isopropanol, mixed uniformly and added to the reactor to make The catalyst in the mixture is "poisoned" and deactivated;

[0069] The temperature of the mixture in the reactor was lowered to 40°C and stirred for 4 hours to obtain a sample.

[0070] The color number of the obtained sample is 50APHA, and the isocyanate group content is 31.7%; the total mass of the modified isocyanate containing carbodiimide grou...

Embodiment 3

[0072] Nitrogen is passed into the reactor, and 20kg of MDI-100, heated to 90°C;

[0073] Add 0.16g of 1-methyl-3-phenyl-2-phosphole-1-oxide into 0.64g of 1,2-propanediol, mix well and add to the reactor;

[0074] Add 2g of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and 1g of phosphite 4,4-diisoylidene bisphenol carbon alkyl ester to 60g of 1,2-propanediol, mixed evenly and added to the reactor;

[0075] Raise the temperature of the mixture in the reactor to 95°C and react for 4 hours; add 0.8g of trifluoromethanesulfonic anhydride and 0.8g of adipoyl chloride to 2.4g of 1,2-propanediol, mix well and add to the reactor , to deactivate the catalyst in the mixture by "poisoning";

[0076] The temperature of the mixture in the reactor was lowered to 35°C and stirred for 4 hours to obtain a sample.

[0077] The color number of the obtained sample is 50APHA, and the isocyanate group content is 27.3%; the total mass of modified isocyanate containing carbodiimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com