Heat-conductive oil composition having high temperature oxidation resistance

A high-temperature anti-oxidation and high-temperature anti-oxidant technology, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problem that high-temperature thermal stability and heat transfer characteristics cannot meet the processing temperature and heat transfer, and affect the normal and safe operation of the system. Short service life and other problems, to achieve the effect of excellent high anti-oxidation stability, excellent high anti-oxidation stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

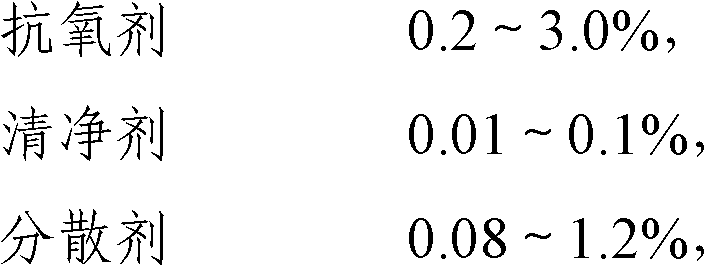

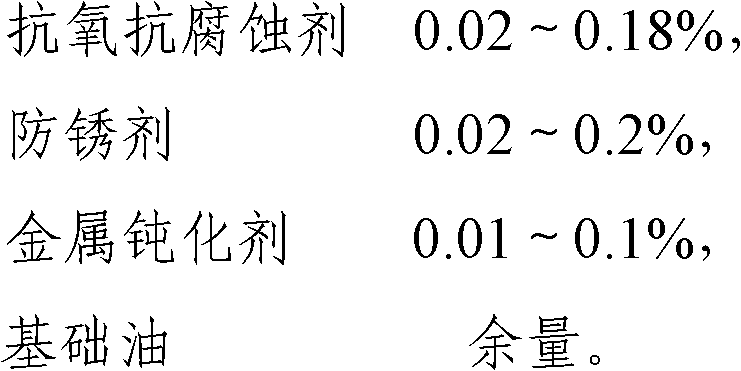

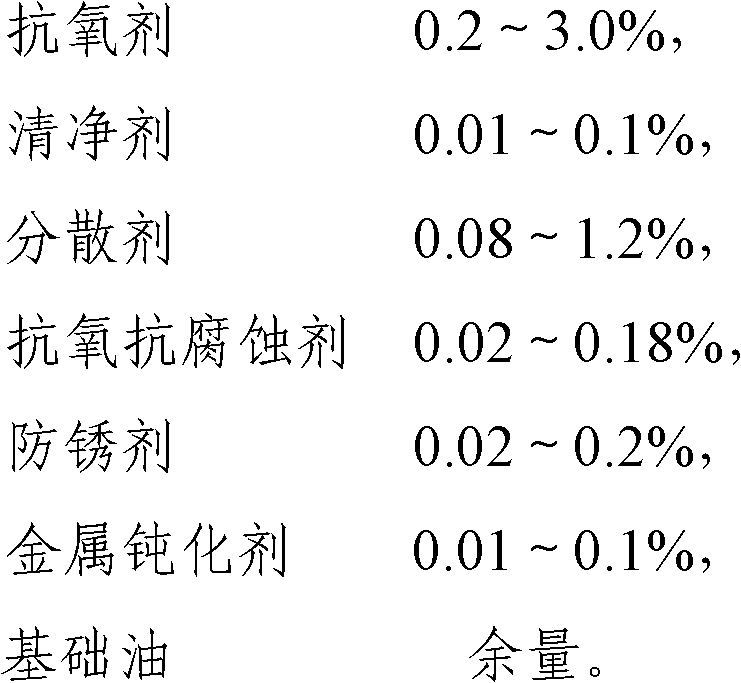

Method used

Image

Examples

Embodiment 1

[0024] Take 2.2kg of high-efficiency composite high-temperature antioxidant (T506), 0.05kg of high alkali value sulfurized alkylphenate calcium (T122), 0.3kg of borated polyisobutylene succinimide (T154B), 0.3kg of sulfur phosphorus secondary alcohol base zinc salt ( T205) 0.05kg, benzotriazole (T706) 0.08kg, thiadiazole derivative metal deactivator (T561) 0.06kg, and then added to 97.26kg of 40 ℃ kinematic viscosity of 40mm 2 / s base oil, mixed and stirred at 75°C for 1 hour to make the product of the present invention.

[0025] The thermal oxidation stability test (175°C, 72h) of this product adopts the method of Appendix C of GB 23971, and the evaluation results are "viscosity increase (40°C) is 21.1%", "acid value increase is 0.58mg KOH / g", "sediment 19.6mg / 100g"; the thermal stability test adopts the GB / T 23800 method to evaluate the results as "yellow and transparent in appearance" and "deterioration rate 5.6%".

Embodiment 2

[0027] Take 1.2kg of high-efficiency composite high-temperature antioxidant (T506), 0.1kg of high-basic value alkyl salicylate calcium (LZL109B), 0.6kg of high-molecular-weight succinimide (T161), 0.6kg of sulfur phosphorus secondary alcohol base zinc salt (T205 ) 0.08kg, heptadecenyl imidazolidinyl succinate (T703) 0.16kg, thiadiazole derivative metal deactivator (T561) 0.04kg, triazole derivative (Ciba IRGAMET30) 0.02kg, and then The kinematic viscosity at 40°C added to 97.8kg is 30mm 2 / s base oil, mixed and stirred at 55°C for 2 hours to make the product of the present invention.

[0028] The thermal oxidation stability test (175°C, 72h) of this product adopts the method of Appendix C of GB 23971, and the evaluation results are "viscosity increase (40°C) is 12.74%", "acid value increase is 0.32mgKOH / g", "sediment 4.2mg / g 100g"; the thermal stability test adopts the GB / T 23800 method to evaluate the results as "yellow and transparent in appearance" and "6.1% deterioration ...

Embodiment 3

[0030] Take 0.4kg of high-efficiency composite high-temperature antioxidant (T506), 0.6kg of dinonyl diphenylamine (T558), 0.04kg of high alkali value sulfurized alkylphenate calcium (T122), and borated polyisobutylene succinimide (T154B) 0.06kg, 0.02kg of high molecular weight succinimide (T161), 0.02kg of sulfur phosphorus secondary alcohol zinc salt (T205), 0.04kg of benzotriazole (T706), thiadiazole derivative metal deactivator ( T561) 0.04kg, triazole derivatives (Ciba IRGAMET 30) 0.04kg, and then sequentially added to 98.74kg of 40 ° C kinematic viscosity of 35mm 2 / s base oil, mixed and stirred at 65°C for 3 hours to make the product of the present invention.

[0031]The thermal oxidation stability test (175°C, 72h) of this product adopts the method in Appendix C of GB 23971, and the evaluation results are "viscosity increase (40°C) is 11.34%", "acid value increase is 0.40mgKOH / g", "sediment 2.8mg / g 100g"; the thermal stability test adopts the GB / T 23800 method to eval...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com