Antiwear energy-saving environment-friendly diesel engine oil

An energy-saving and environmental-friendly diesel engine technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., to achieve the effects of light color, fuel saving, and inhibition of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Component A: Measure base oil M8 34.5% and 5CS 50% into the blending kettle, raise the temperature to 65°C±5°C, and add viscosity enhancer HIVI9618 8.5% and pour point depressant T803B 0.60 in sequence under constant stirring %, anti-oxidant and anti-corrosion agent T202 0.5%, compound agent LZ3699C 5.9%, stir for 30-40 minutes, let it settle for 1 hour to get CF-4 15W / 40 (1#).

Embodiment 2

[0035]Component A: Measure base oil M8 36.0% and 5CS 49.0% into the blending kettle, raise the temperature to 65°C±5°C, and add viscosity enhancer HIVI9618 8.4% and pour point depressant T803B 0.6 in sequence under constant stirring %Antioxidant and anticorrosion agent T202 0.5%, compound agent LZ3699C 5.5%, stir for 30~40 minutes, let it settle for 1 hour to get CF-4 15W / 40 (2#).

Embodiment 3

[0037] Configuration component A: Measure base oil M8 36.0%, 5CS 50.0% and add it to the blending kettle, raise the temperature to 65°C±5°C, add viscosity enhancer HIVI9618 8.0% and pour point depressant T803B 0.5 in sequence under constant stirring %Antioxidant and anticorrosion agent T202 0.5%, compound agent LZ3699C 5.0%, stir for 30~40 minutes, let it settle for 1 hour to get CF-4 15W / 40 (3#).

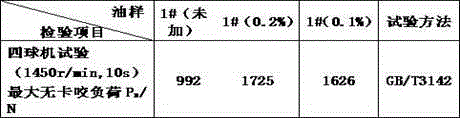

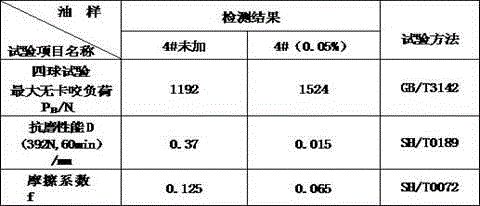

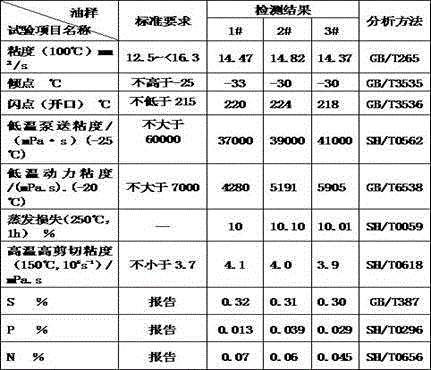

[0038] The main physical and chemical indicators of the energy-saving and anti-wear diesel engine oil (CF-4) obtained in the above examples are analyzed as follows:

[0039] Table 1 Analysis report of main physical and chemical indicators of micro-fluorine series anti-wear and energy-saving diesel engine oil CF-4 15W / 40

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com