Special lubricating oil for engines and preparation method of special lubricating oil

An engine and lubricating oil technology, applied in the field of lubricating oil, can solve the problems of large lubrication resistance, increased fuel consumption, burning engine oil, etc., and achieve the effects of low evaporation loss, sufficient performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of engine special lubricating oil, comprising:

[0044] a) After heating a part of the composite base oil, pre-mix it with a composite anti-oxidant and anticorrosion agent, a composite detergent, a dispersant, a metal deactivator, an antirust agent and polymethacrylate to obtain a semi-finished product;

[0045] b), the semi-finished product obtained in the above steps is mixed again with another part of the composite base oil, and after spraying the antifoaming agent simultaneously, the mixed semi-finished product is obtained;

[0046] c), continue mixing the mixed semi-finished product obtained in step b), and obtain the special lubricating oil for the engine after filtering.

[0047] In the above-mentioned preparation method of the present invention, the preferred principle and the added amount of the raw materials used are consistent with the preferred principles and added amount in the above-mentioned engine ...

Embodiment 1

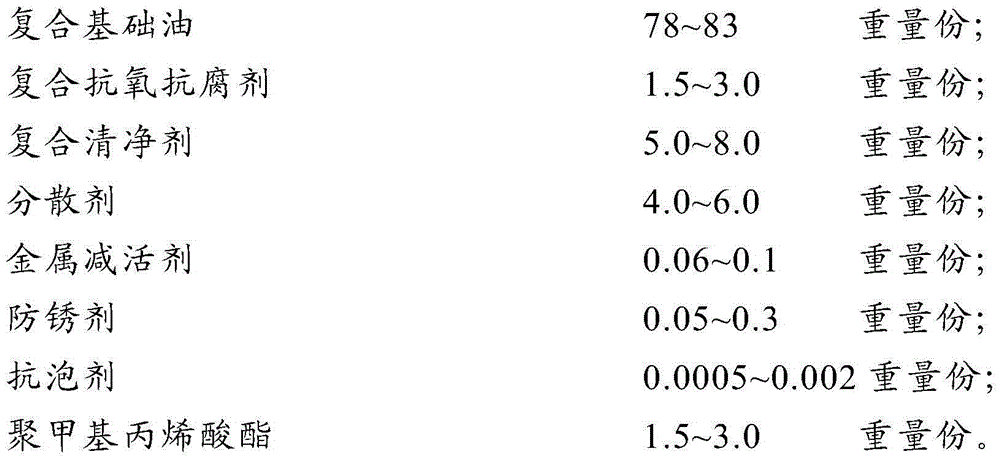

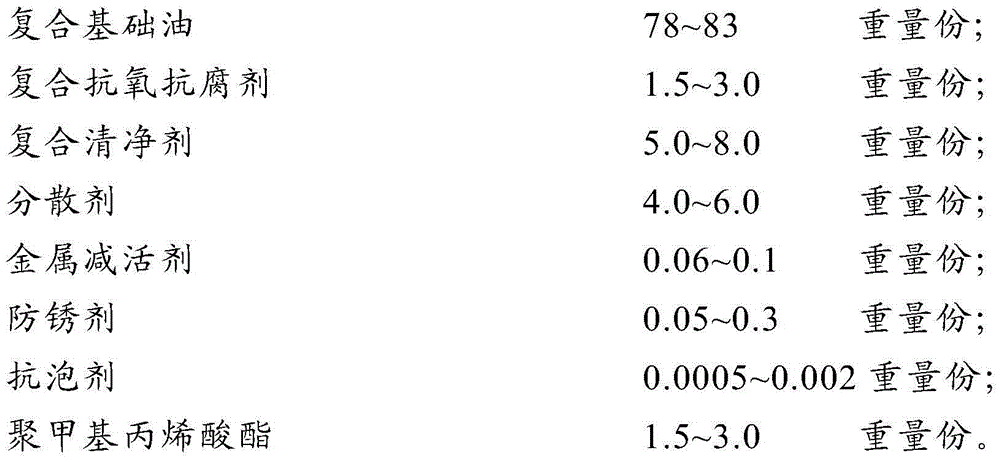

[0057] According to the mass percentage in Table 1, take the raw material of engine special lubricating oil.

[0058] Table 1 The mass percent composition of the raw materials used in Example 1

[0059]

[0060]

[0061] First, pump the alkylnaphthalene and hydrogenated base oil into the blending tank according to the above ratio, stir and mix to obtain the composite base oil, and heat to 50°C at the same time.

[0062] Then put a part of the composite base oil into the ground pond, and while putting it into the ground pond, add compound anti-oxidant and anti-corrosion agent, compound detergent, compound ashless dispersant, metal deactivator, high-performance anti-corrosion agent according to the above ratio Rust agent and polymethacrylate, fully and evenly stirred and pre-mixed to obtain a semi-finished product.

[0063] Then pump the above-mentioned semi-finished product into the blending kettle, mix it with another part of composite base oil, and spray anti-foaming a...

Embodiment 2

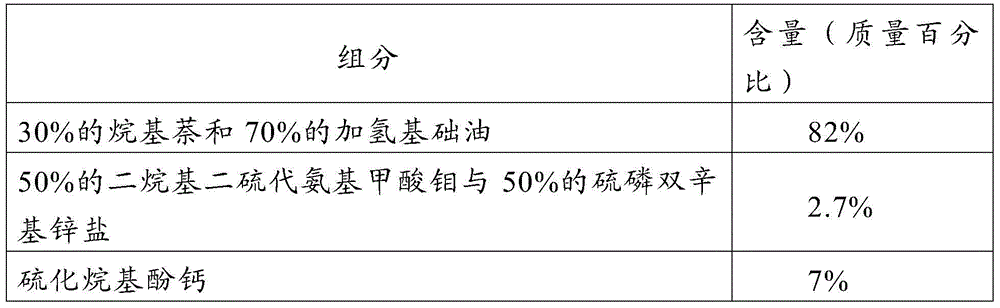

[0089] According to the mass percentage in Table 7, take the raw material of engine special lubricating oil.

[0090] Table 7 The mass percent composition of raw materials used in embodiment 2

[0091]

[0092] First, pump the alkylnaphthalene and hydrogenated base oil into the blending tank according to the above ratio, stir and mix to obtain the composite base oil, and heat it to 55°C at the same time.

[0093] Then put a part of the composite base oil into the ground pond, and while putting it into the ground pond, add compound anti-oxidant and anti-corrosion agent, compound detergent, compound ashless dispersant, metal deactivator, high-performance anti-corrosion agent according to the above ratio Rust agent and polymethacrylate, fully and evenly stirred and pre-mixed to obtain a semi-finished product.

[0094] Then pump the above-mentioned semi-finished product into the blending kettle, mix it with another part of composite base oil, and spray anti-foaming agent at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Total base number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com