Composite screw type air compressor oil

An air compressor oil and screw type technology, which is applied in the field of lubricating oil, can solve the problems of ashless screw air compressor head gelling, thermal oxidation stability, poor fluidity at low temperature, insurmountable asphalt and colloid, etc. Achieve excellent anti-oxidation stability, excellent viscosity-temperature performance, good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

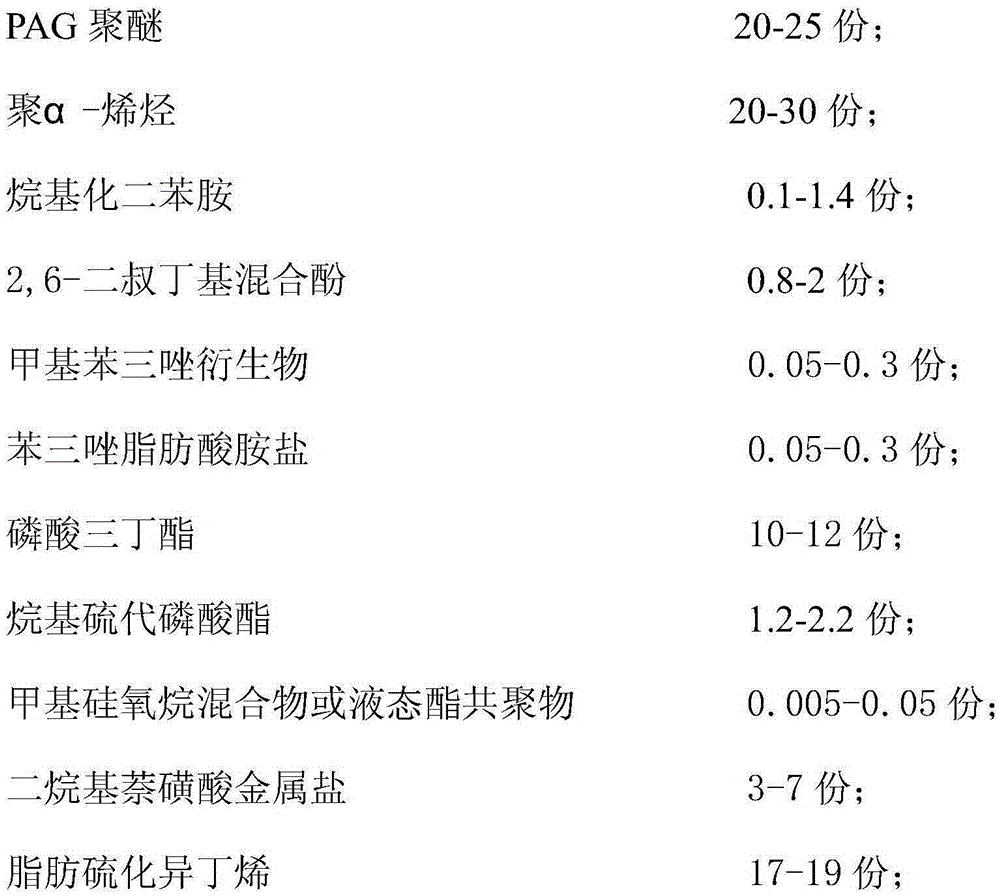

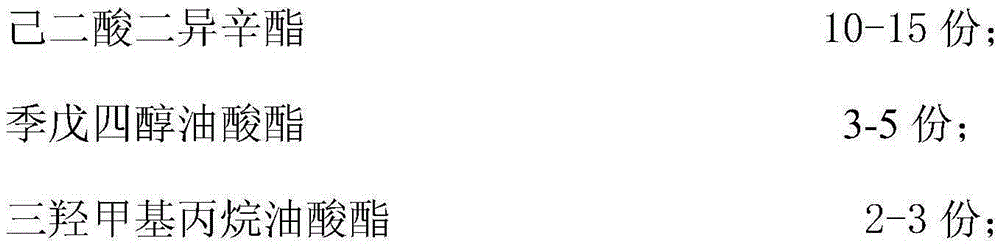

Examples

Embodiment 1

[0019] Synthetic base oil A: Vegetable rapeseed oil with isopropanol chloroformate, in Et 2 Al 2 Cl 3 In the presence of base oil A, react at 50-65°C for 4-6 hours;

[0020] Synthetic base oil B: in parts by mass, react 75Kg of vegetable rapeseed oil with 20Kg of methanol and 1.2Kg of NaOH at 65-70°C for 3-4 hours to obtain vegetable methyl oleate; then mix 3Kg of vegetable methyl oleate with Et 2 Al 2 Cl 3 , 36Kg of isopropanol chloroformate was reacted at 50-65°C and Friedel-Crafts for 4-6 hours to obtain base oil B.

[0021]

[0022]

Embodiment 2

[0024]

[0025]

Embodiment 3

[0027]

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com