Composite calcium-based lubricating grease and preparation method thereof

A calcium-composite, lubricating grease technology, applied in lubricating compositions, the petroleum industry, etc., can solve the problems that the market price of lithium-based lubricating grease cannot rise synchronously, squeeze the profit margin of production enterprises, and increase the cost of lithium-based lubricating grease, etc. Achieve the effects of improving storage hardening, improving friction and wear resistance and oxidation stability, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

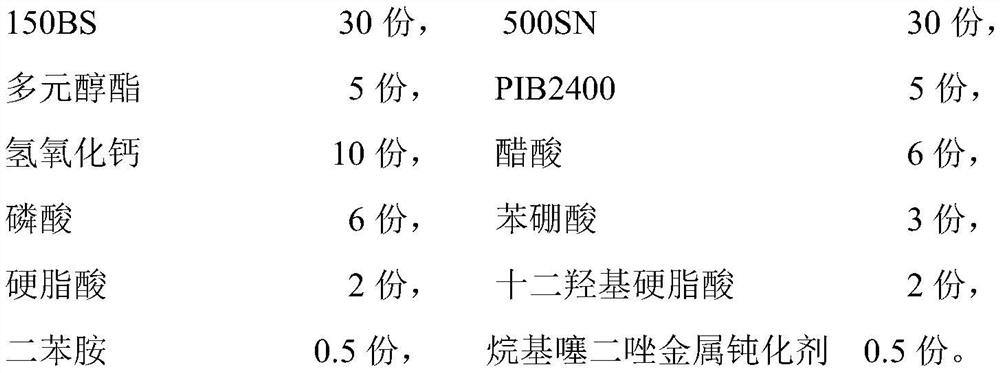

[0072] It is formulated by weight from the following components and contents of raw materials:

[0073]

[0074] Preparation:

[0075] Add 30 parts of 150BS, 30 parts of 500SN and 9 parts of calcium hydroxide to the reaction kettle according to metering, and stir evenly. Below 60°C, add 6 parts of glacial acetic acid and 6 parts of phosphoric acid, and stir for 40 minutes; then add 3 parts of phenylboronic acid, and stir for 20 minutes; when the temperature rises to 90°C, add 2 parts of dodecyl hydroxy Stearic acid and 2 parts of stearic acid were stirred and reacted for 10 min, and heated again. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 1 part of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 5 parts of polyol ester and 5 parts of PIB2400. When the temperature continues to rise to 220-240°C, heat-preserve and refine for 5-15 minutes. After refining, cool down to 80-120...

Embodiment 2

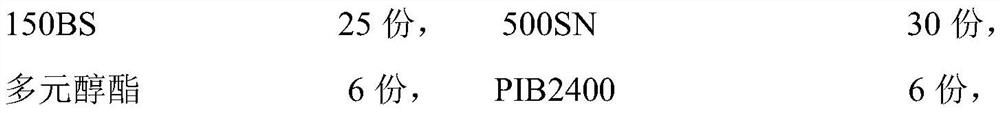

[0078] It is formulated by weight from the following components and contents of raw materials:

[0079]

[0080]

[0081] Preparation:

[0082] Add 25 parts of 150BS, 30 parts of 500SN and 10.8 parts of calcium hydroxide to the reactor according to the metering, and stir evenly. Below 60°C, add 7 parts of glacial acetic acid and 7 parts of phosphoric acid, and stir for 40 minutes; then add 3 parts of phenylboronic acid, and stir for 20 minutes; when the temperature rises to 90°C, add 1.5 parts of dodecyl hydroxy Stearic acid and 1.5 parts of stearic acid were stirred and reacted for 10 min, and heated again. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 1.2 parts of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 6 parts of polyol ester and 6 parts of PIB2400. When the temperature continues to rise to 220-240°C, heat-preserve and refine for 5-15 minutes. After refining, c...

Embodiment 3

[0085] It is formulated by weight from the following components and contents of raw materials:

[0086]

[0087] Preparation:

[0088] Add 35 parts of 150BS, 30 parts of 500SN and 7.2 parts of calcium hydroxide to the reactor according to the metering, and stir evenly. Below 60°C, add 5 parts of glacial acetic acid and 5 parts of phosphoric acid, and stir for 40 minutes; then add 3 parts of phenylboronic acid, and stir for 20 minutes; when the temperature rises to 90°C, add 2.5 parts of dodecyl hydroxy Stearic acid and 2.5 parts of stearic acid were stirred and reacted for 10 minutes, and heated again. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 0.8 parts of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 4 parts of polyol ester and 4 parts of PIB2400. When the temperature continues to rise to 220-240°C, heat-preserve and refine for 5-15 minutes. After refining, cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com