Anti-wear hydraulic oil and preparation method thereof

An anti-wear hydraulic oil and base oil technology, which is applied in the field of lubricating oil, can solve the problems of easy oxidation and deterioration, poor quality of hydraulic oil, and no improvement in base oil, etc., to achieve complete removal of impurities, excellent thermal stability, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

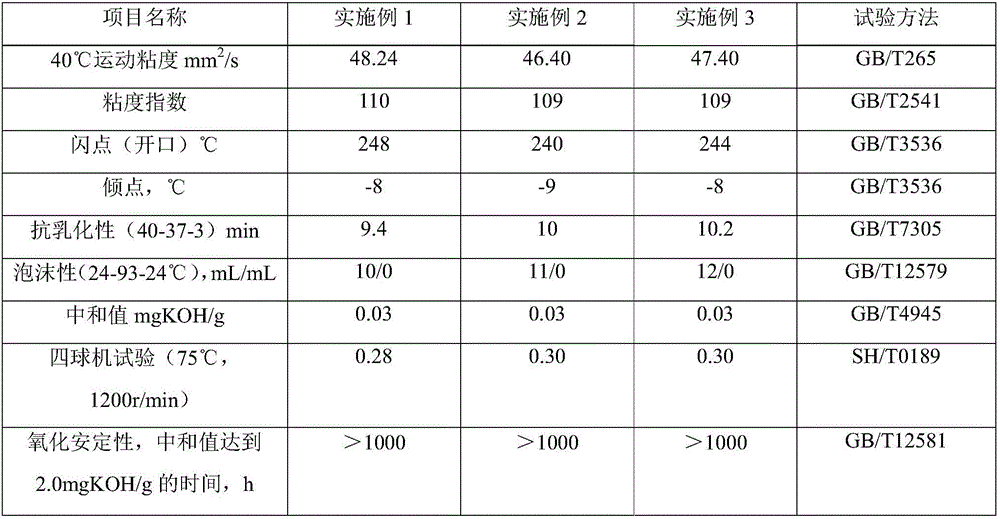

Examples

Embodiment 1

[0027] The anti-wear hydraulic oil in this example is prepared from the following raw materials: 95g of Group I base oil, 3g of tricresyl phosphate, 7g of zinc dialkyldithiophosphate, 0.8g of thiadiazole derivatives, polymethacrylic acid 6g of ester, 3g of barium dinonylnaphthalenesulfonate, 0.4g of methyl silicone oil, and 4g of adsorbent, which is a mixture of bentonite and halloysite with a mass ratio of 1:0.5.

[0028] The preparation method is as follows: (1) Heating Group I base oil to 90°C, then adding adsorbent, stirring for 20 minutes and then filtering;

[0029] (2) Heat the filtered Group I base oil to 60°C, then add tricresyl phosphate, zinc dialkyl dithiophosphate, thiadiazole derivatives, polymethacrylate, dinonyl naphthalene sulfonic acid Barium and methyl silicone oil, stir well to get anti-wear hydraulic oil.

[0030] Wherein, the preparation method of adsorbent in the present embodiment is as follows:

[0031] (1) bentonite is crushed through 80 mesh sieve,...

Embodiment 2

[0035] The anti-wear hydraulic oil in this example is prepared from the following raw materials: 90g of Group I base oil, 2g of tricresyl phosphate, 6g of zinc dialkyl dithiophosphate, 0.5g of thiadiazole derivatives, polymethacrylic acid 5 g of ester, 2 g of barium dinonylnaphthalene sulfonate, 0.3 g of methyl silicone oil, and 3 g of adsorbent, which is a mixture of bentonite and halloysite with a mass ratio of 1:0.4.

[0036] The preparation method is as follows: (1) Heating Group I base oil to 80°C, then adding adsorbent, stirring for 15 minutes and then filtering;

[0037] (2) Heat the filtered Group I base oil to 60°C, then add tricresyl phosphate, zinc dialkyl dithiophosphate, thiadiazole derivatives, polymethacrylate, dinonyl naphthalene sulfonic acid Barium and methyl silicone oil, stir well to get anti-wear hydraulic oil.

[0038] Wherein, the preparation method of adsorbent in the present embodiment is as follows:

[0039] (1) Bentonite is pulverized through 80 me...

Embodiment 3

[0043]The anti-wear hydraulic oil in this example is prepared from the following raw materials: 100 g of Class I base oil, 4 g of tricresyl phosphate, 8 g of zinc dialkyl dithiophosphate, 1 g of thiadiazole derivatives, polymethacrylate 7g, 4g of barium dinonylnaphthalene sulfonate, 0.5g of methyl silicone oil, and 5g of adsorbent, which is a mixture of bentonite and halloysite with a mass ratio of 1:0.6.

[0044] The preparation method is as follows: (1) Heat Group I base oil to 100°C, then add adsorbent, stir for 25 minutes and filter;

[0045] (2) Heat the filtered Group I base oil to 60°C, then add tricresyl phosphate, zinc dialkyl dithiophosphate, thiadiazole derivatives, polymethacrylate, dinonyl naphthalene sulfonic acid Barium and methyl silicone oil, stir well to get anti-wear hydraulic oil.

[0046] Wherein, the preparation method of adsorbent in the present embodiment is as follows:

[0047] (1) Bentonite is pulverized through 80 mesh sieve, halloysite is pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com