Hair clipper

A technology of barber scissors and scissors, which is applied in metal processing and other directions, and can solve problems such as not easy to wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

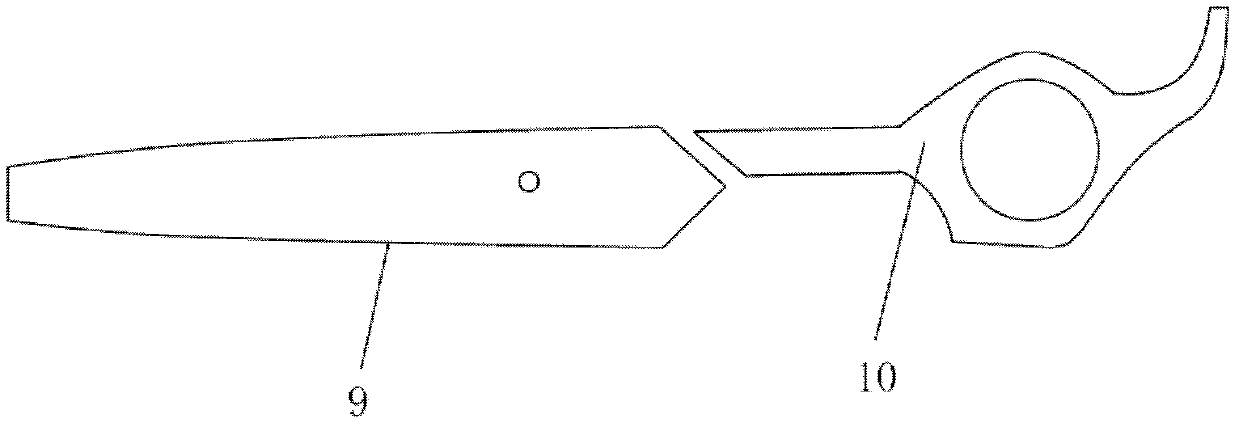

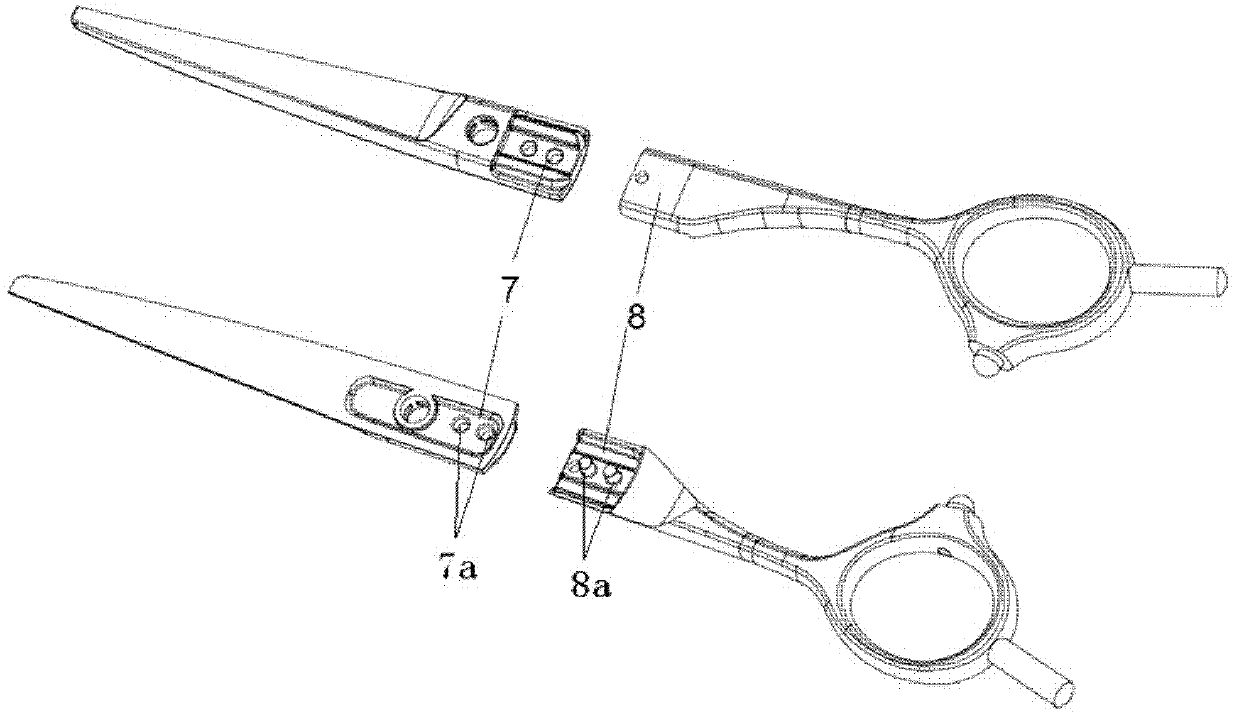

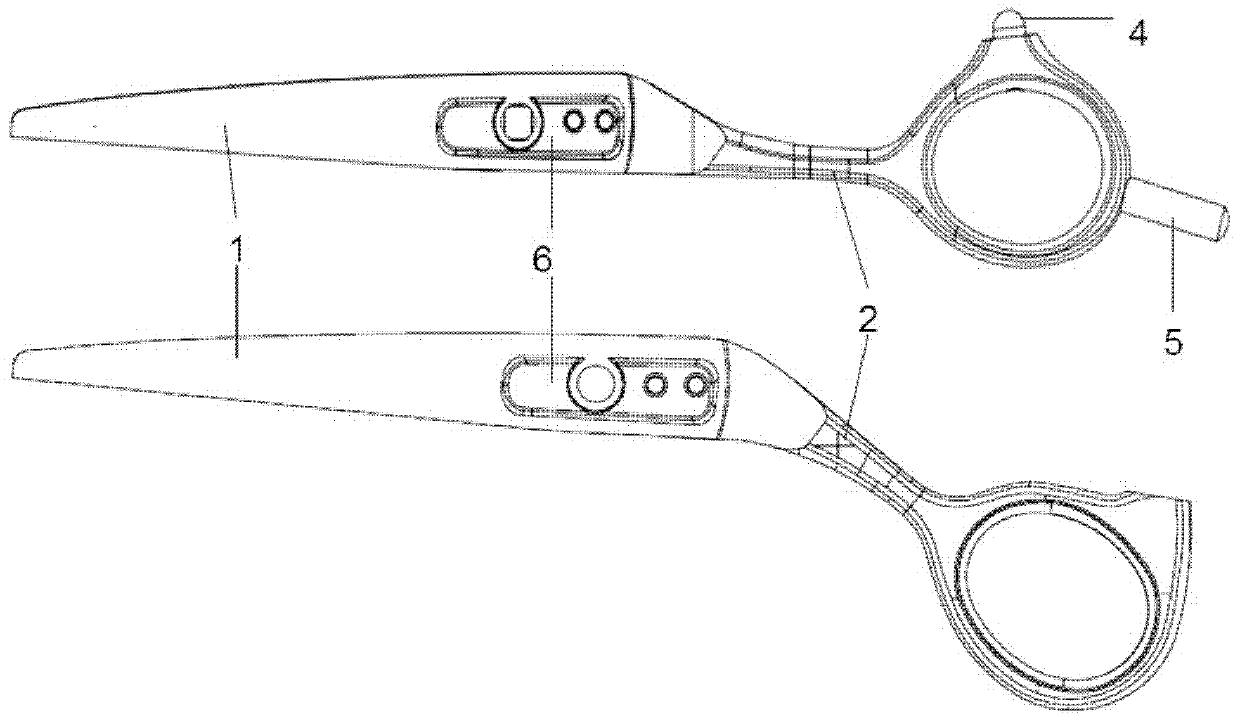

[0023] combine Figure 2 to Figure 6 , the hairdressing scissors of the present invention, which includes a pair of knife body, each knife body includes a scissors blade 1 and a scissors handle 2. The blades of the scissors can be straight blades used as hair clippers, or the blades can be comb-shaped and used as hair scissors. The shape of the scissors blade 1 can be made into different styles according to different requirements, which will not be described in detail here. The scissor handle 2 is made of stainless steel and titanium through powder metallurgy injection molding. The shape and size of the handle can also be changed according to user requirements. The middle parts of the two cutter bodies are provided with through holes and are connected by a pivot 3 . Described scissors blade 1 end portion has first boss 7, and this first boss 7 forms opening plane i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com