Electromagnetic induction dryer

A technology of electromagnetic induction and electromagnetic induction coils, which is applied in drying, drying machines, heating devices, etc., can solve the problem of heavy maintenance of steam drying cylinders or oil drying cylinders, heavy maintenance workload of equipment failures, complex steam and water Separation device and other issues to achieve the effect of reducing equipment update cost, convenient self-plastic update, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

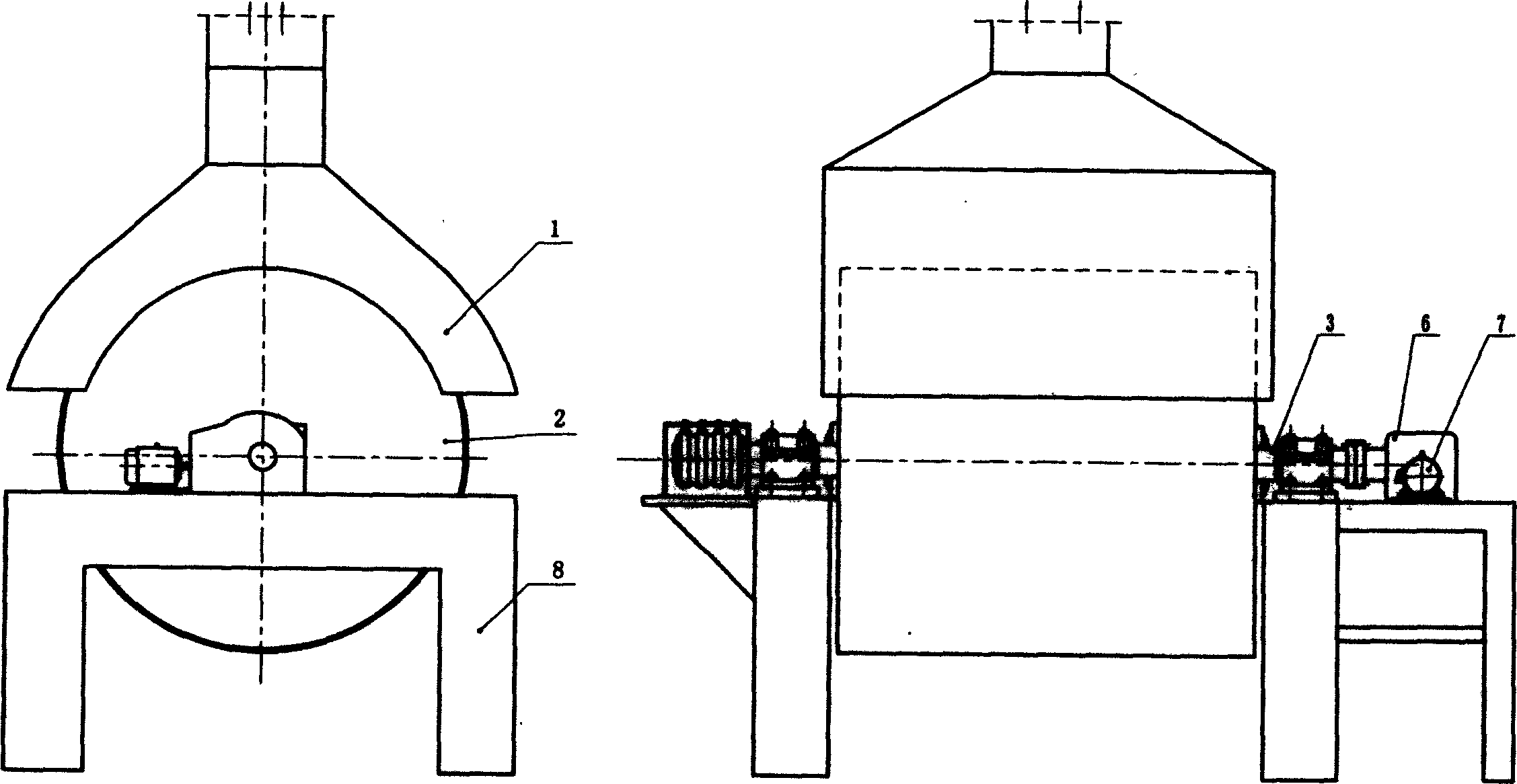

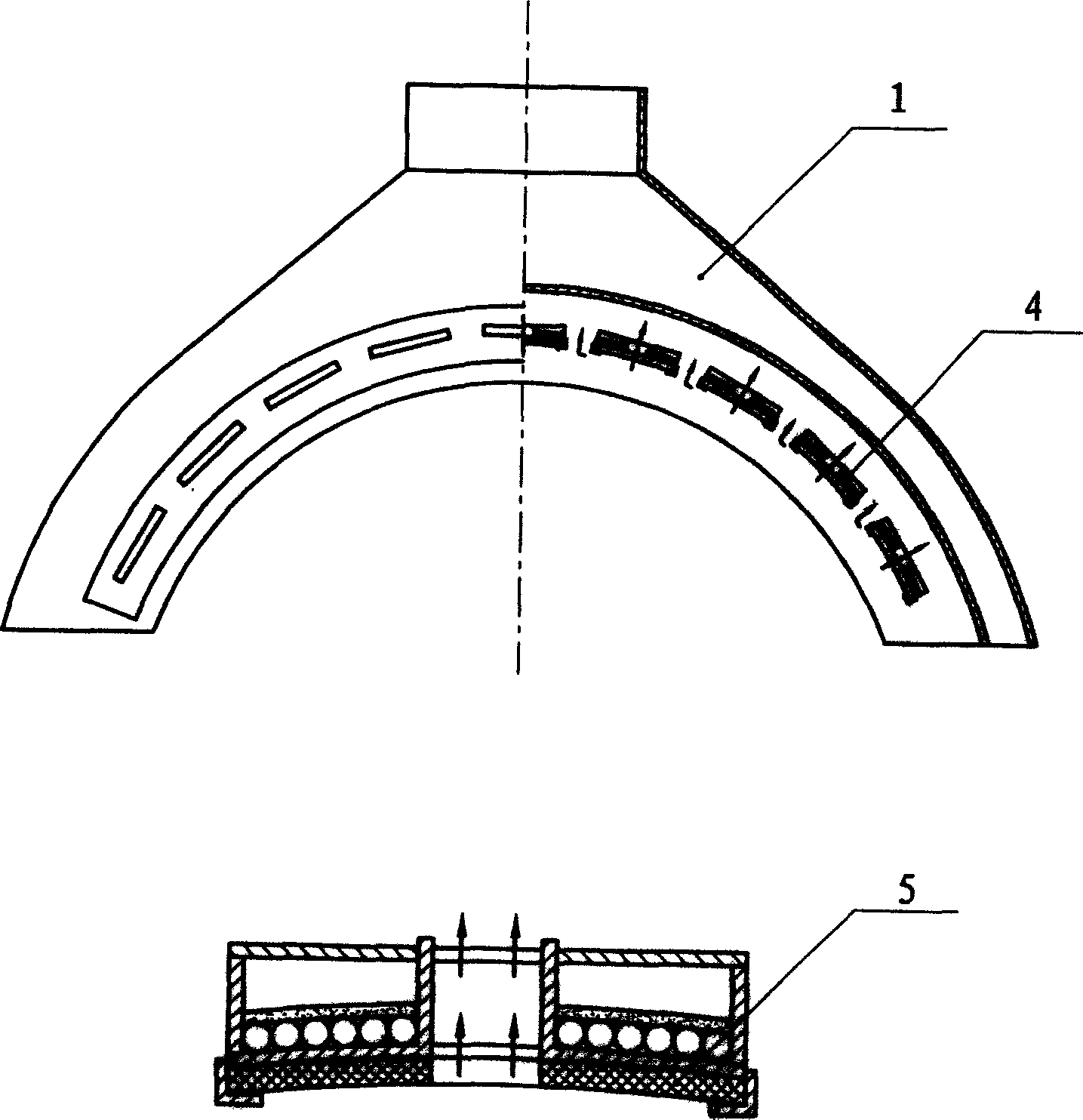

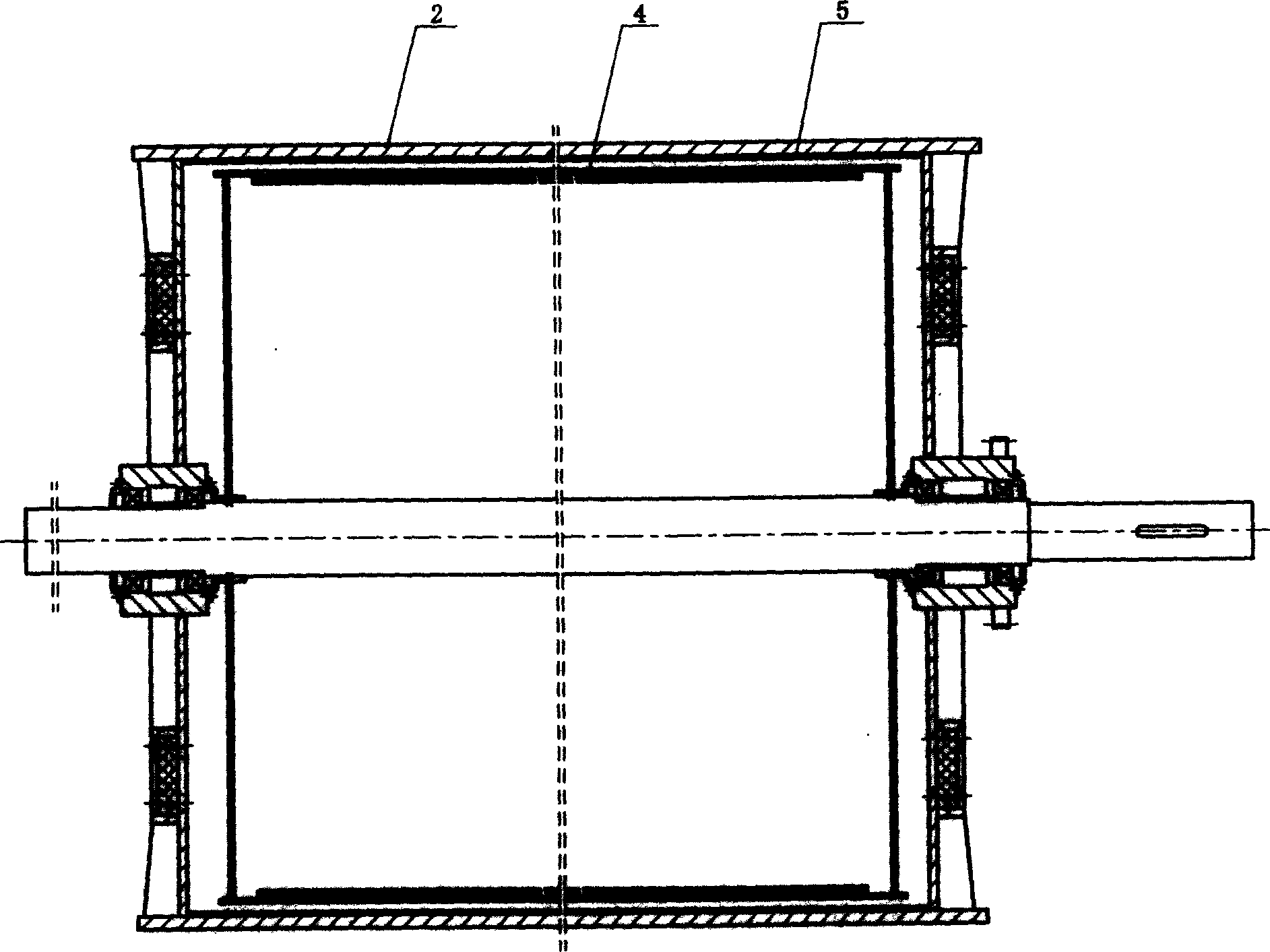

[0013] An electromagnetic induction drying cylinder includes a frame 8, on which a transmission shaft 3 and a reduction box 6 are arranged, a drying cylinder body 2 is connected to the transmission shaft 3, and a drying cylinder cover is arranged on the drying cylinder body 2 1. An electromagnetic induction coil 4 and a crystalline ceramic glass protective layer 5 are installed inside the dryer cover 1, and the electromagnetic induction coil 4 is connected with a collector ring, a high-frequency power supply and an automatic control system.

[0014] Another electromagnetic induction drying cylinder includes a frame 8, on which a transmission shaft 3 and a reduction box 6 are arranged, a drying cylinder cylinder 2 is connected to the transmission shaft 3, and a drying cylinder The cover 1 is equipped with an electromagnetic induction coil 4 and a crystalline ceramic glass protective layer 5 inside the cylinder body 2 of the drying cylinder. The electromagnetic induction coil 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com