Filtration cloth bag for pressure filtration machine filtration, and molding method

A filter cloth bag and filter press technology, which is applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of cumbersome installation, easy to loosen the rope, increase the after-sales cost of the supplier, and solve the cumbersome installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

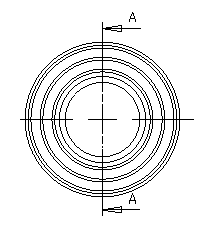

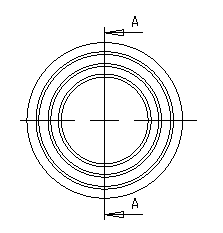

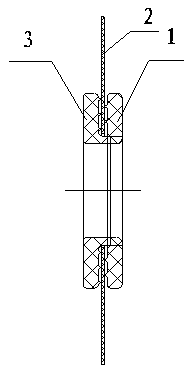

[0015] Embodiment 1: with reference to attached Figure 1-5 . A filter cloth bag used for filtering a filter press, the upper edge of the filter cloth bag is a plastic buckle with a hole on the pile, the upper buckle 1 and the lower buckle 3 of the plastic buckle are filter cloth 2 and the upper buckle 1, filter cloth 2 and the lower buckle are The three buckles are bonded together by hot-melt bonding. The lower buckle 3 of the plastic buckle has a round shoulder structure with holes, and the upper buckle 1 has a circular flat pad structure with holes, and the upper and lower buckles are inlaid with filter cloth for pressure bonding. The upper buckle 1 and the lower buckle 3 of the plastic buckle are provided with protruding cusps 4 on the opposite surfaces.

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, a method for forming a filter cloth bag for filter press filtration, the lower button 3 of the plastic button with a protruding shoulder is positioned through the mold, and the filter cloth bag with small holes is opened Put it on the lower button 3 of the plastic buckle with protruding shoulders and expose the lifting shoulder, then put the upper button 2 of the plastic buckle on the lifting shoulder and press the filter cloth flatly, pressurize and heat-melt through the pressurized heating equipment to make the upper and lower circles The shaped plastic buckle is bonded and fixed to the filter cloth. It is used for hanging buckle of filter cloth bag for filter press, it includes filter cloth bag made of various chemical fiber materials, round plastic buckle with protruding shoulder and plastic flat pad with opening in the middle, plastic buckle and flat pad are made of PE, PO and ABS and other raw materials; a row of small h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com