Patents

Literature

33 results about "Metal swarf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

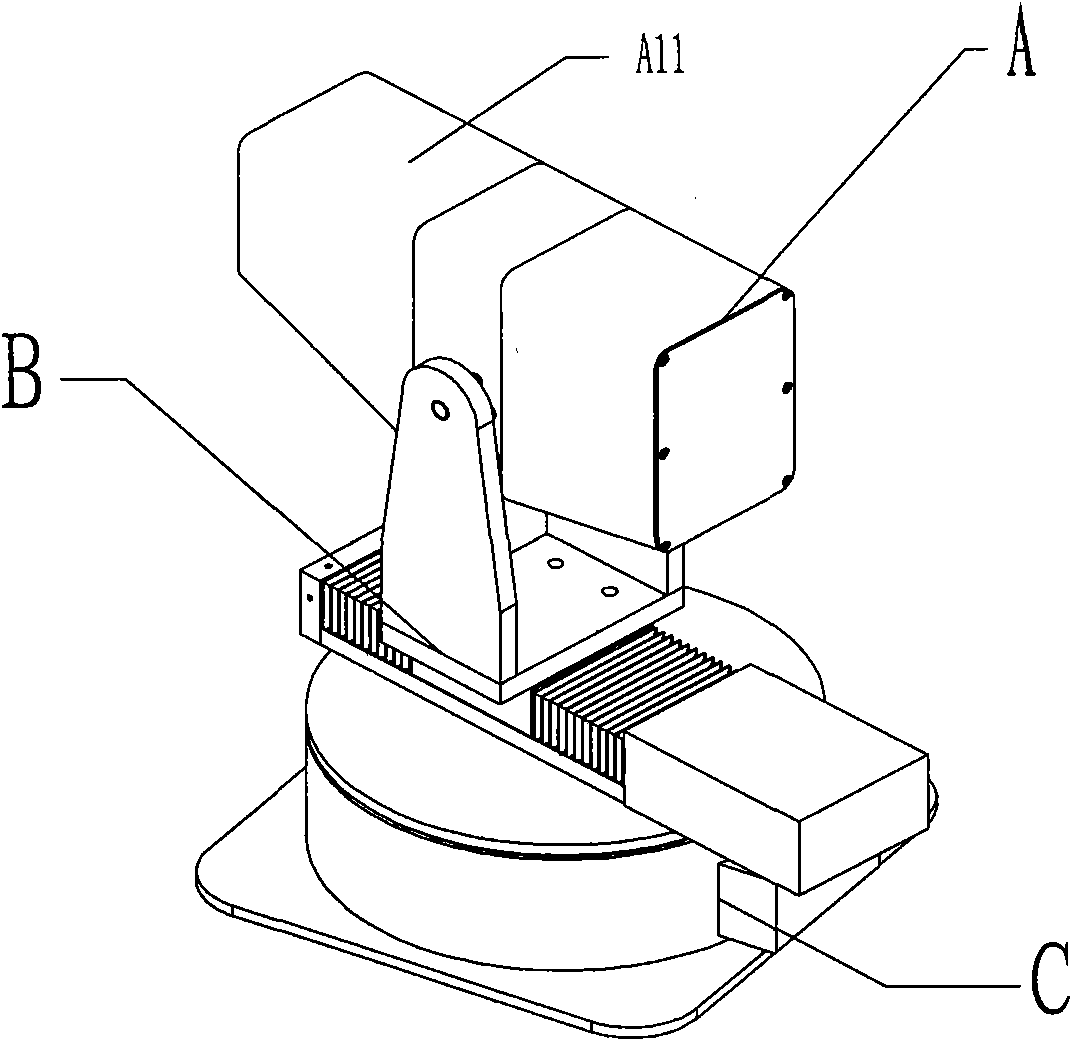

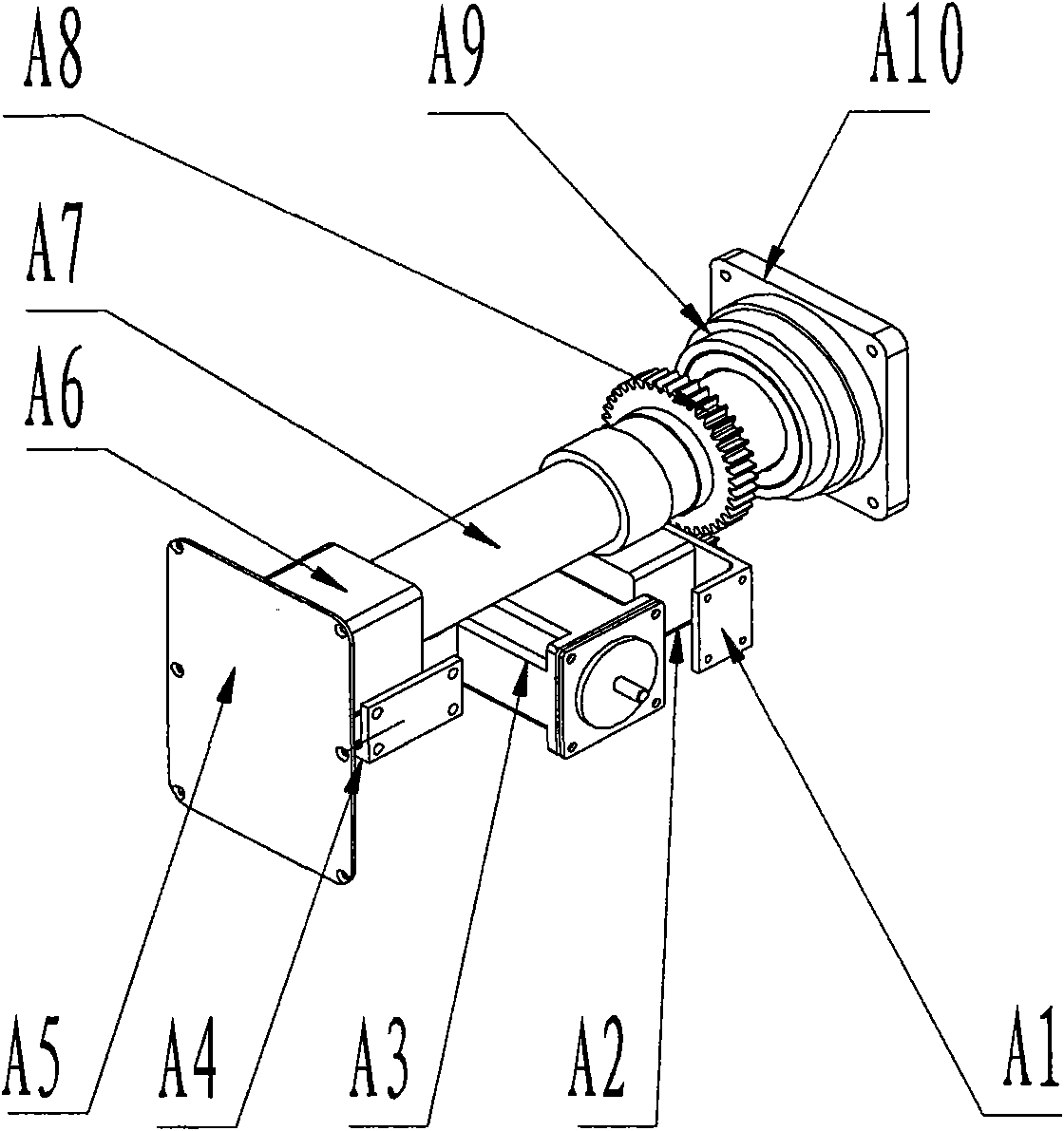

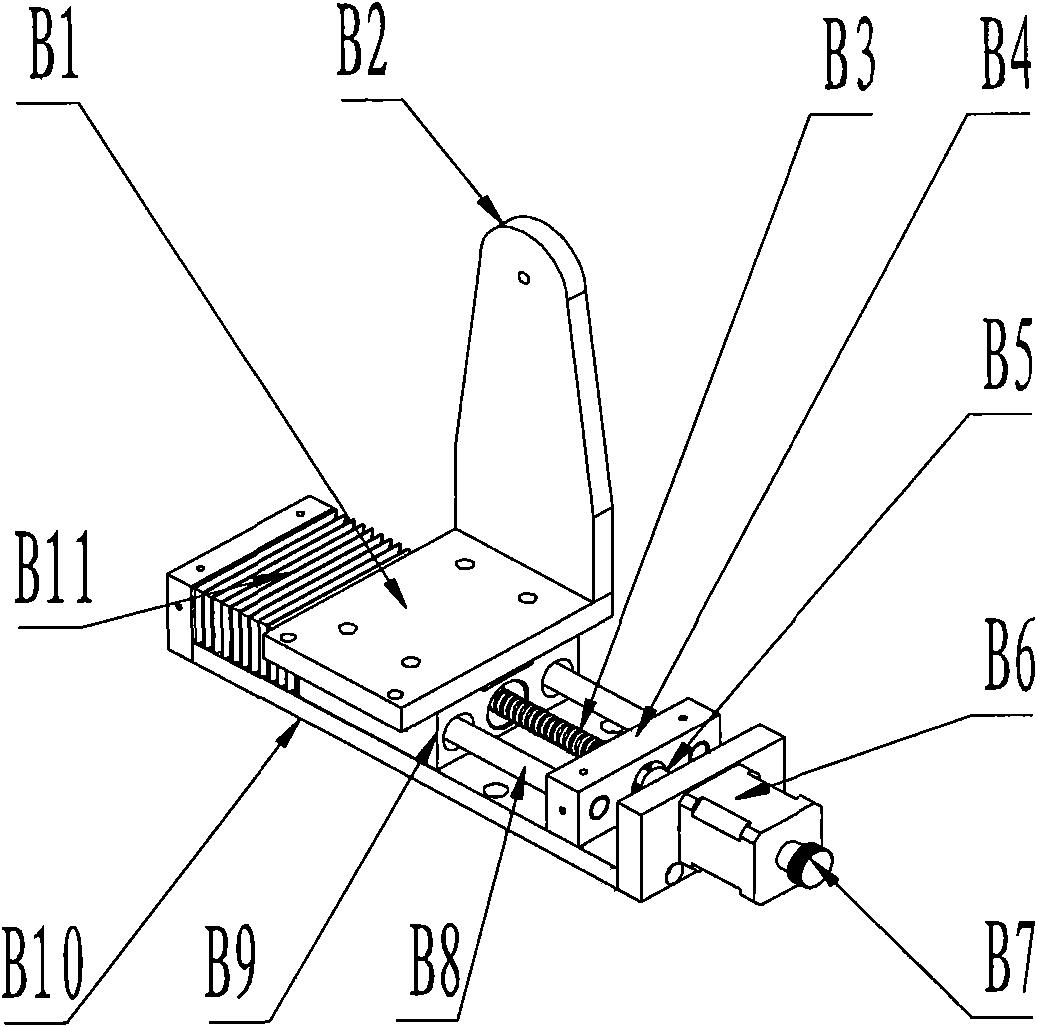

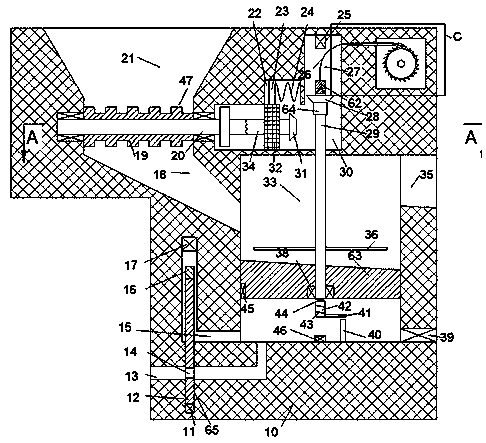

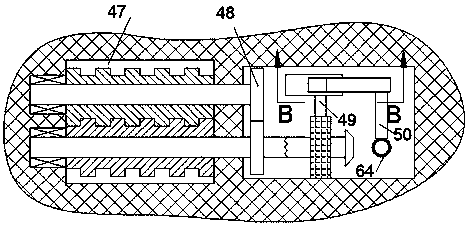

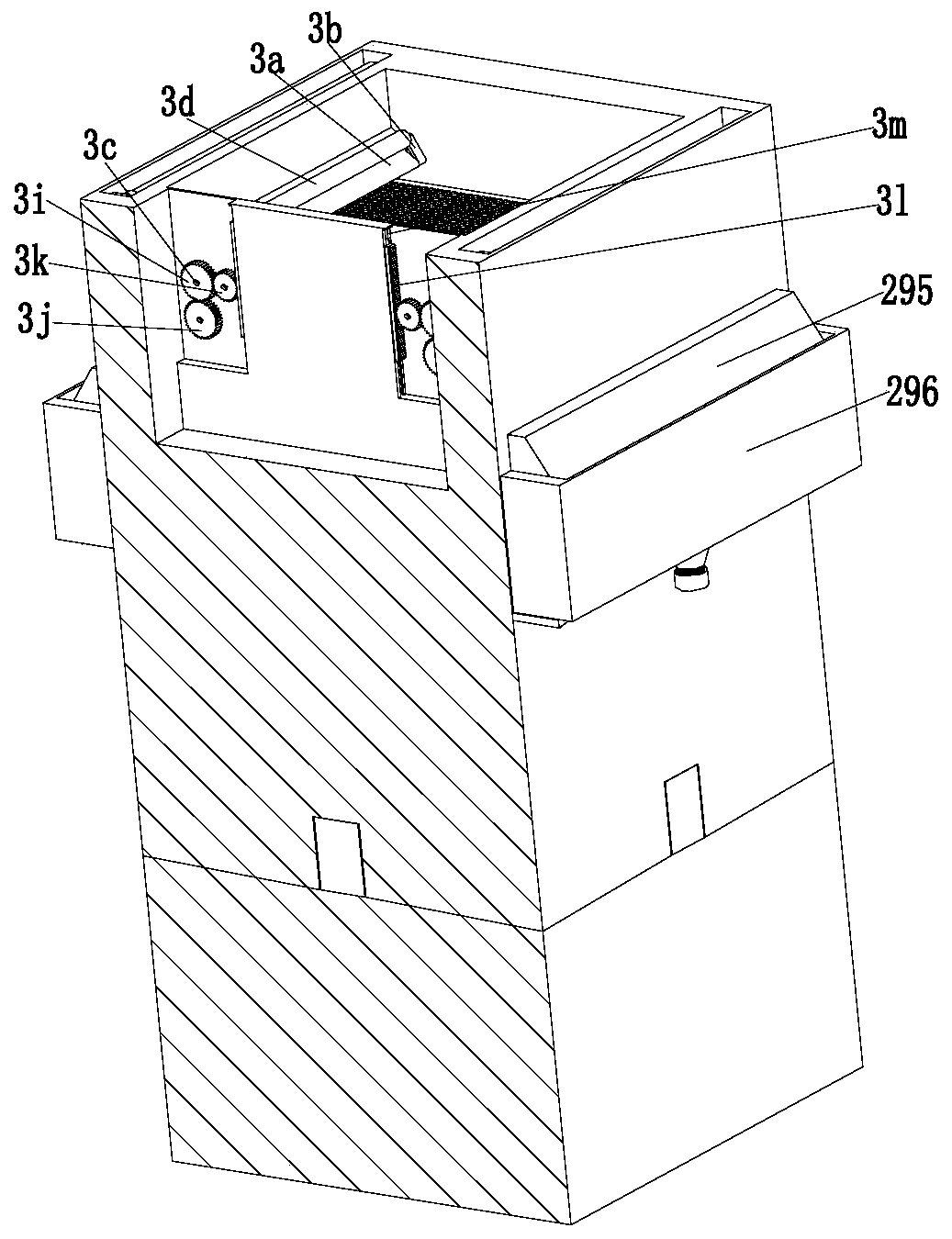

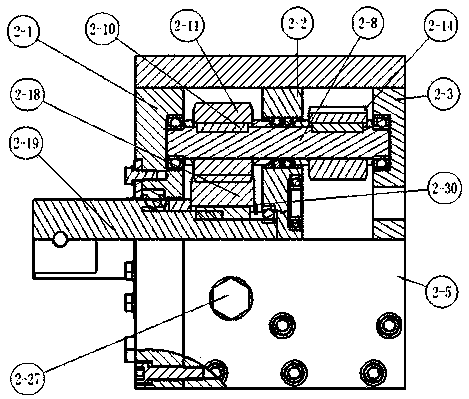

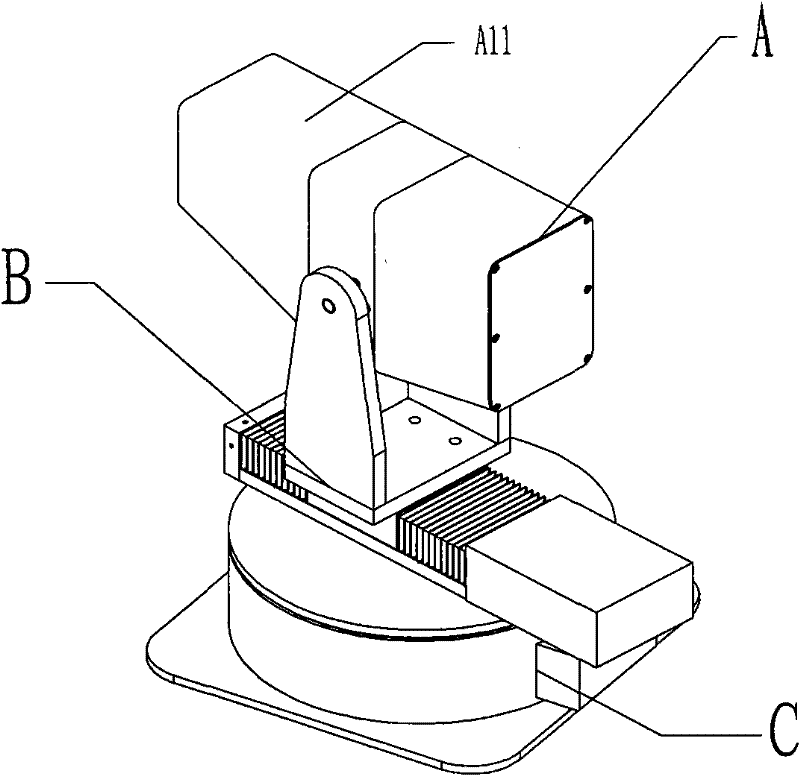

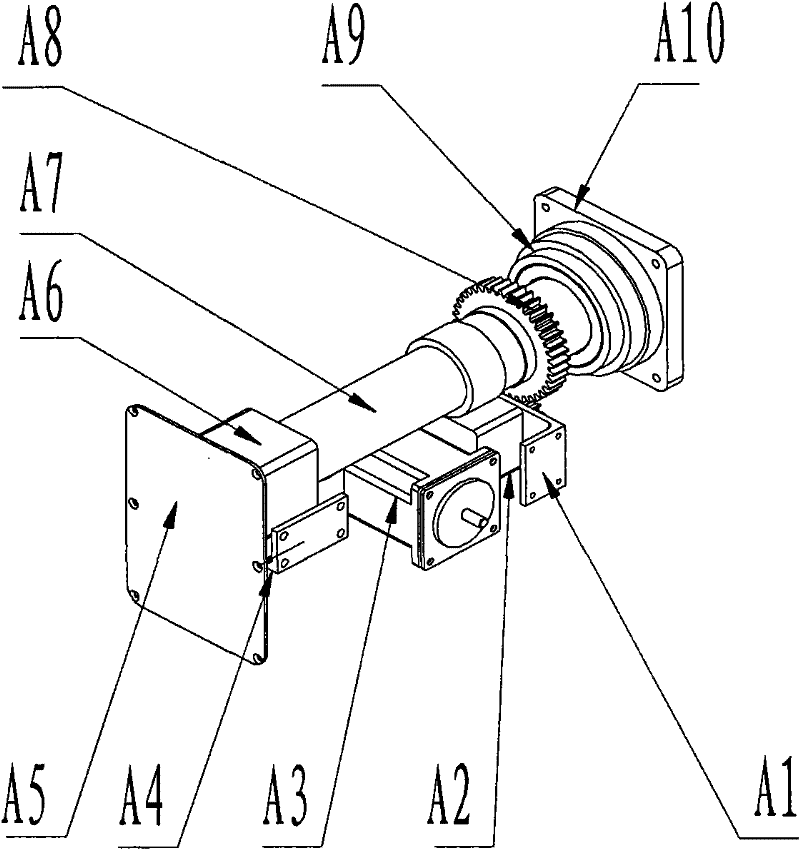

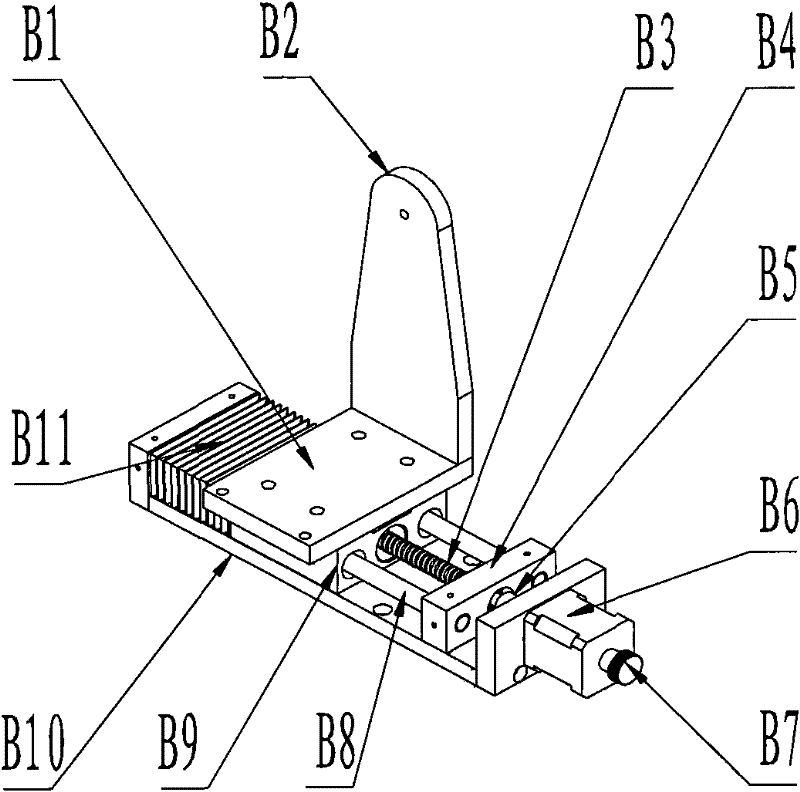

Abrasion detection device of mixed type rotary cutter

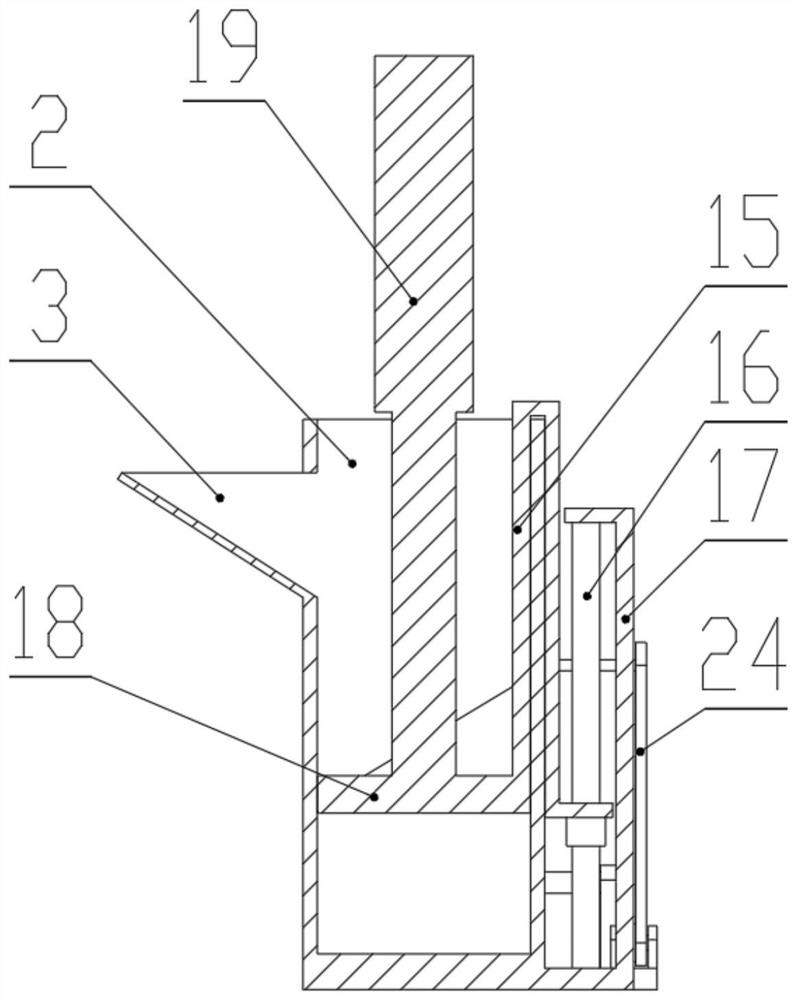

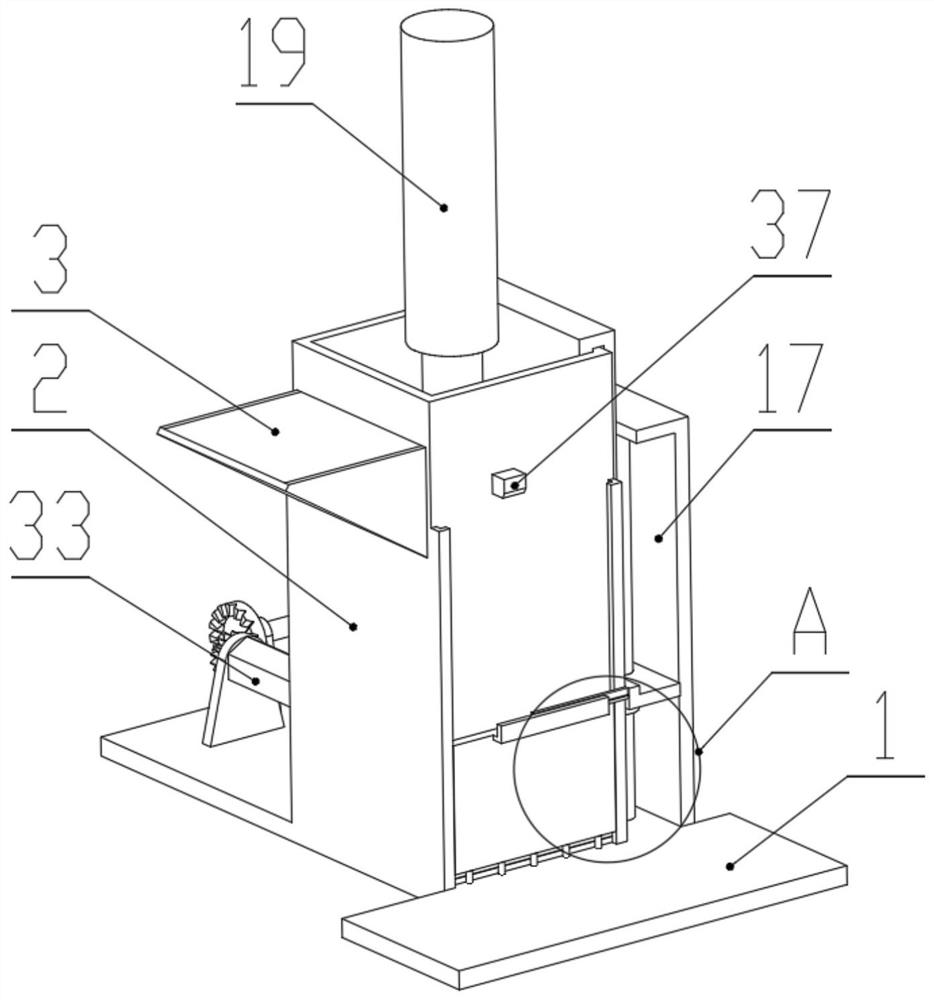

The invention relates to an abrasion detection device of a mixed type rotary cutter, which belongs to the field of mechanical processing. In the invention, the abrasion image of the cutter is obtained by utilizing an area array type CCD industrial camera and is transmitted to an upper computer by a USB. In order to realize the multi-angle shooting of the cutter, the camera has three degrees of freedom aggregately: a translation platform realizes the focusing function of the camera to the cutter to be detected, a horizontal rotation platform realizes the multi-direction shooting of the camera to the cutter, and a pitching rotation platform realizes the shooting of the camera to a plurality of angles of the cutter. In order to realize the measurement of the abrasion of the cutter in a processing process, the design has the function of water prevention and can prevent cutting fluid and metal swarfs from entering the inside of the device.

Owner:BEIHANG UNIV

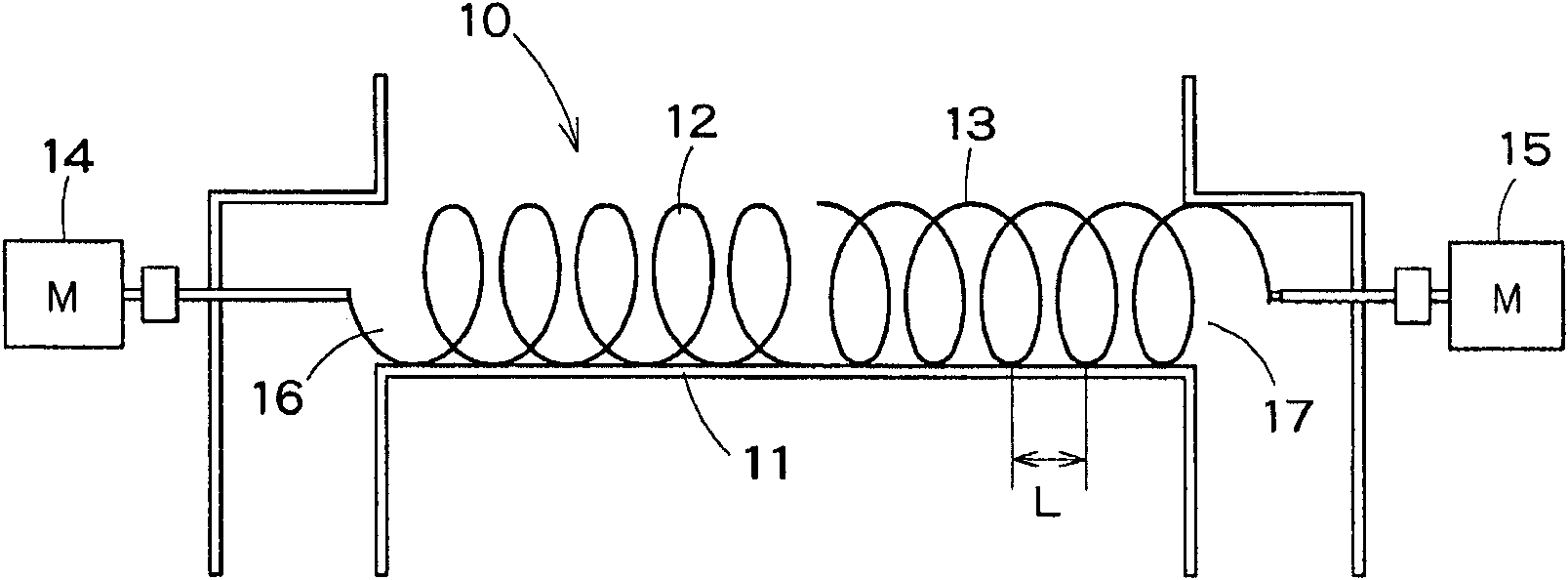

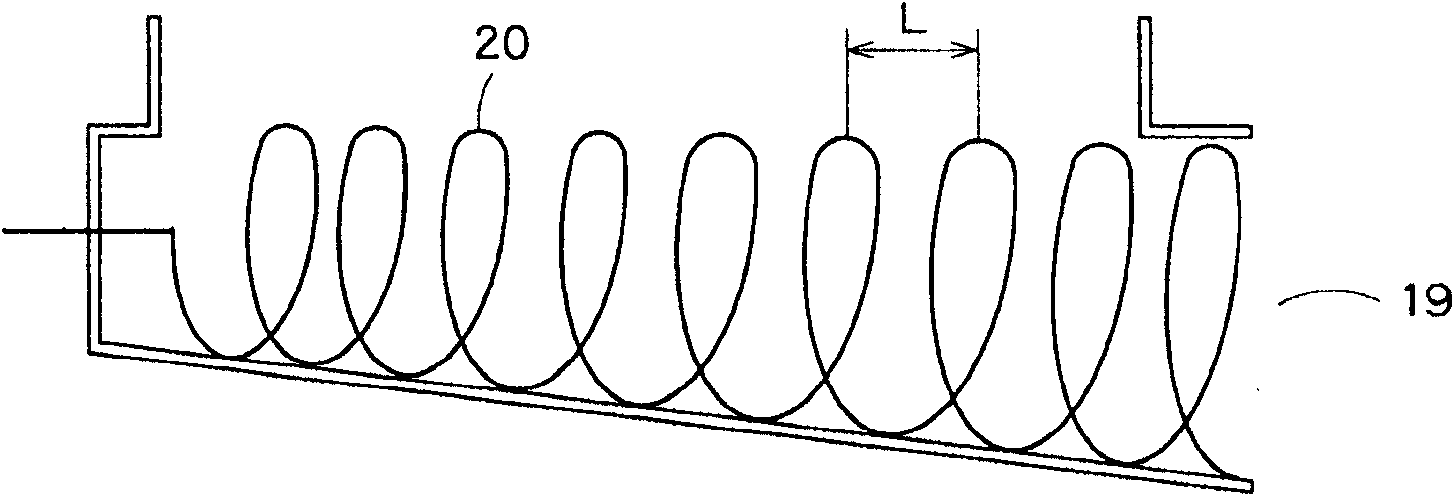

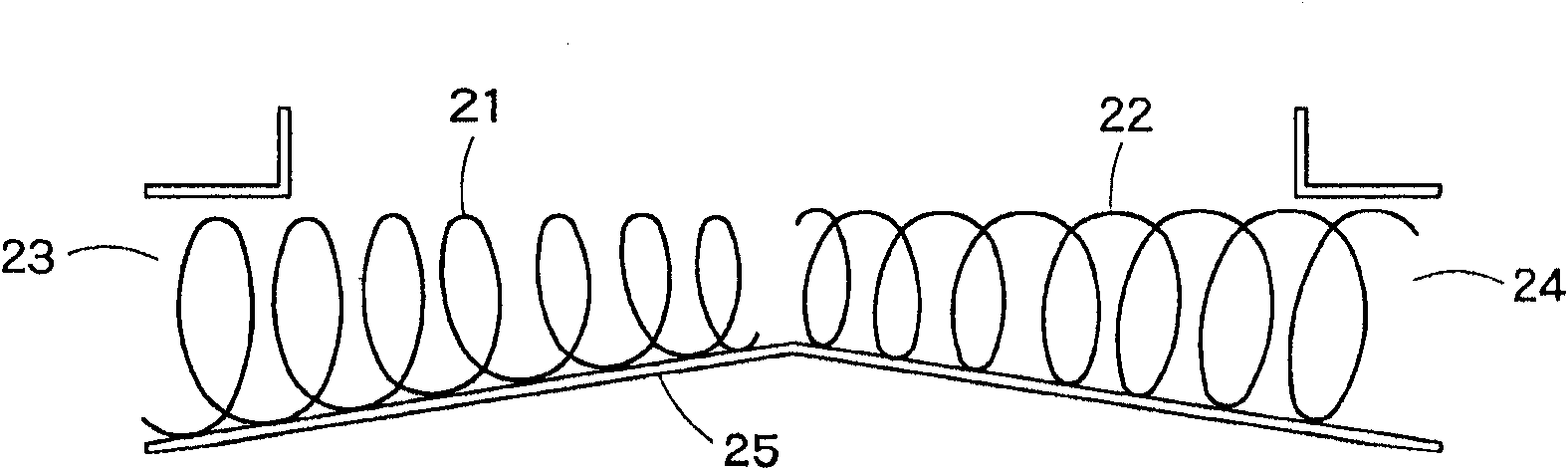

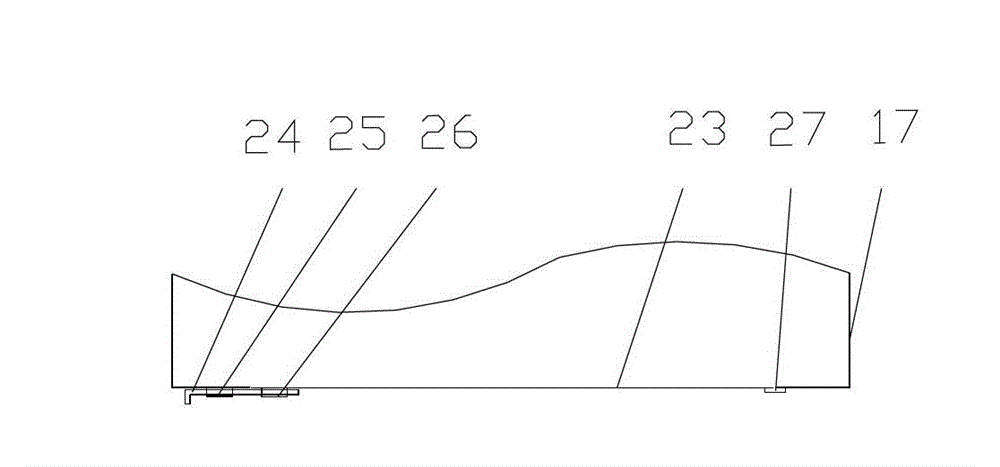

Conveyor apparatus of metal cutting chip

InactiveCN101927894AAvoid cloggingPackagingMaintainance and safety accessoriesEngineeringMetal swarf

The invention provides a coil conveyor apparatus, which can prevent blockage of a discharge port and stably discharge the metal cutting chip. The coil conveyor apparatus comprises a receiving component and a coil part arranged in the receiving component, wherein the receiving component is used for receiving the metal cutting chip from a machine tool and drives the coil part to rotate, so as to send the metal cutting chip to the outside of the receiving component. The coil conveyor apparatus is characterized in that the receiving component is provided with discharge ports at two areas, the coil part is provided with an integrated coil with twisting direction on one side being different from that of the other side, one side of the integrated coil is arranged at one side of a discharge port, while the other side thereof is arranged at the other side of the other discharge port.

Owner:TOSHIBA MASCH CO LTD

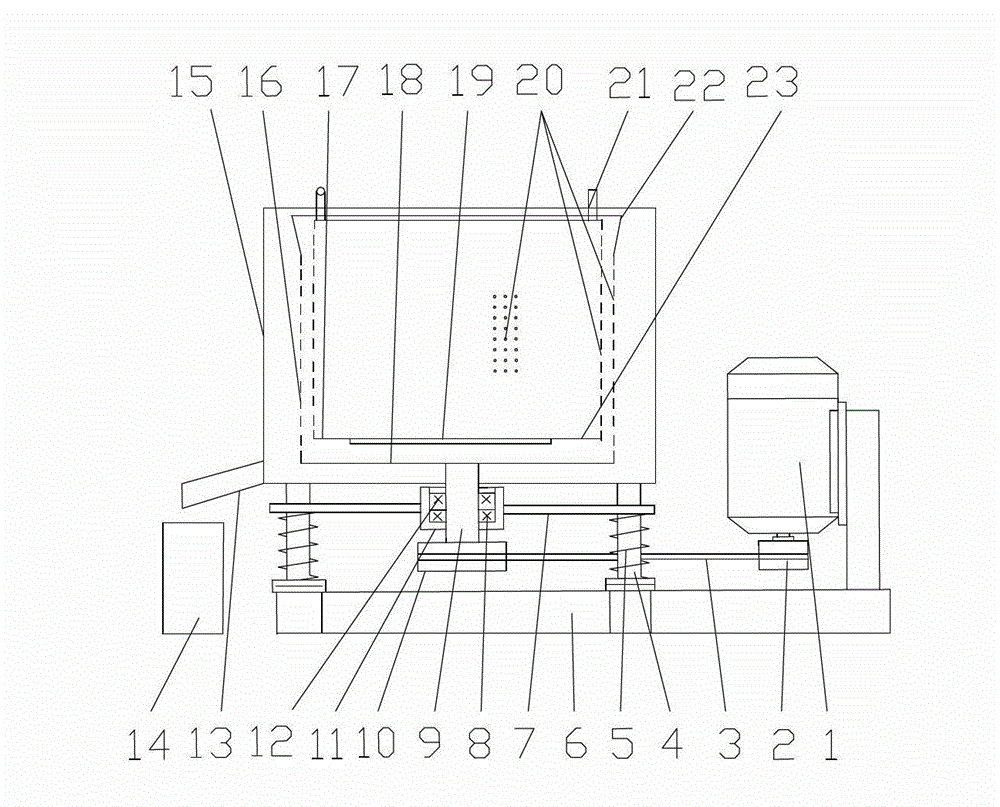

Crushing and oil-removing device of lathe metal cutting chips

ActiveCN111389500AEfficient storageEfficient transportCleaning using liquidsGrain treatmentsProcess engineeringMetal swarf

The invention discloses a crushing and oil-removing device of lathe metal cutting chips. The crushing and oil-removing device of lathe metal cutting chips comprises a machining box. A feeding hopper is arranged in the left side on the upper surface of the machining box. The lower side of the feeding hopper communicates with a crushing cavity. A first rotating shaft is rotationally connected into the left wall and the right wall of the crushing cavity in a front-back symmetry manner. A shearing cylinder used for shearing and crushing the cutting chips is fixedly connected to the first rotatingshaft. The cutting chips are crushed, so that the cutting chips can be effectively stored and transported, and the cutting chip storage amount of a unit area can be increased. By removing oil of the cutting chips, cooling liquid and other oil type matter attached to the cutting chips can be recycled and reutilized, so that better economical efficiency and environmental friendliness can be achieved. The cutting chips obtained after oil removal can have a higher price during recycling, and the quality of the cutting chips is better when used as a metal raw material.

Owner:高唐融知融智科技服务有限公司

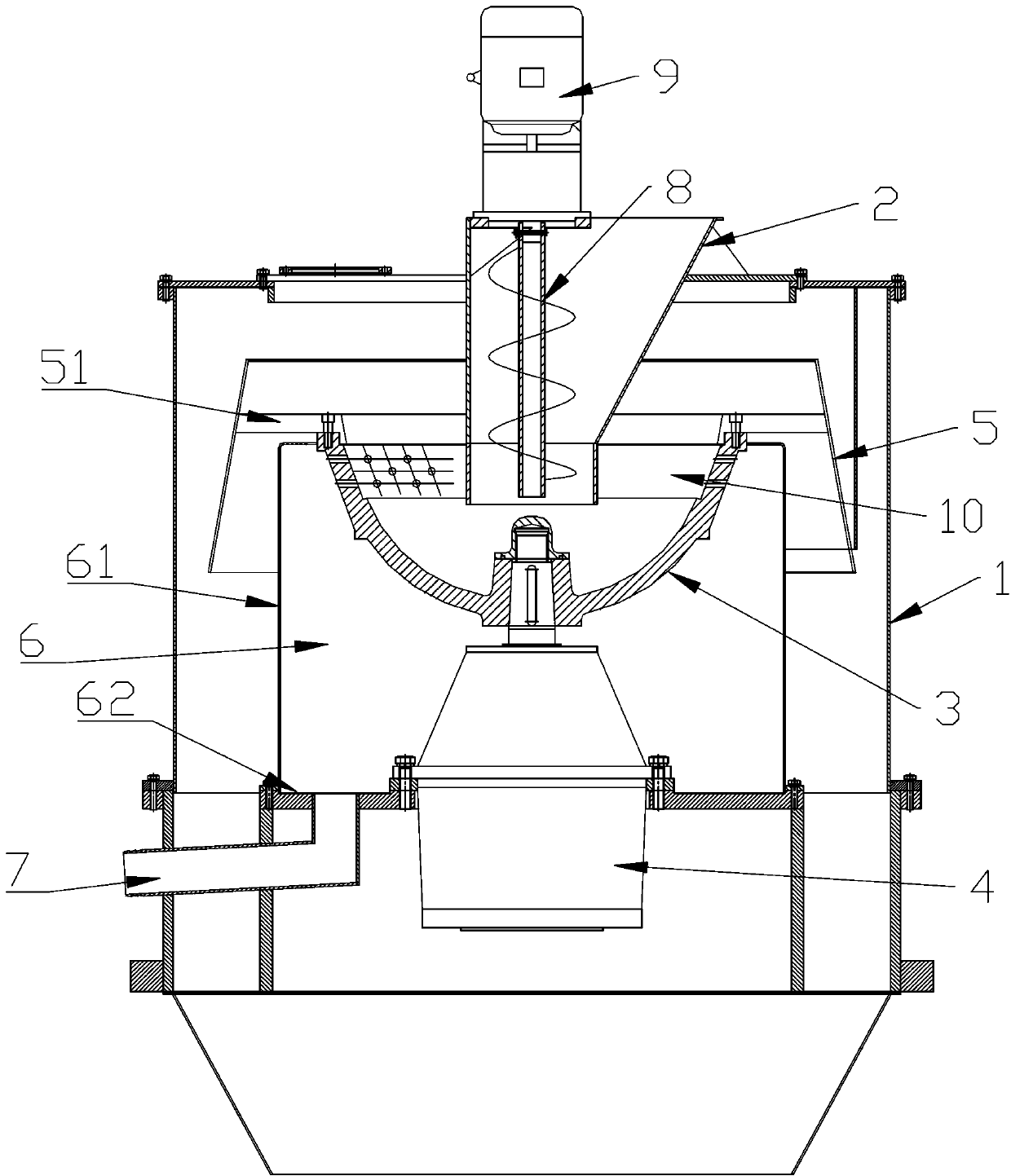

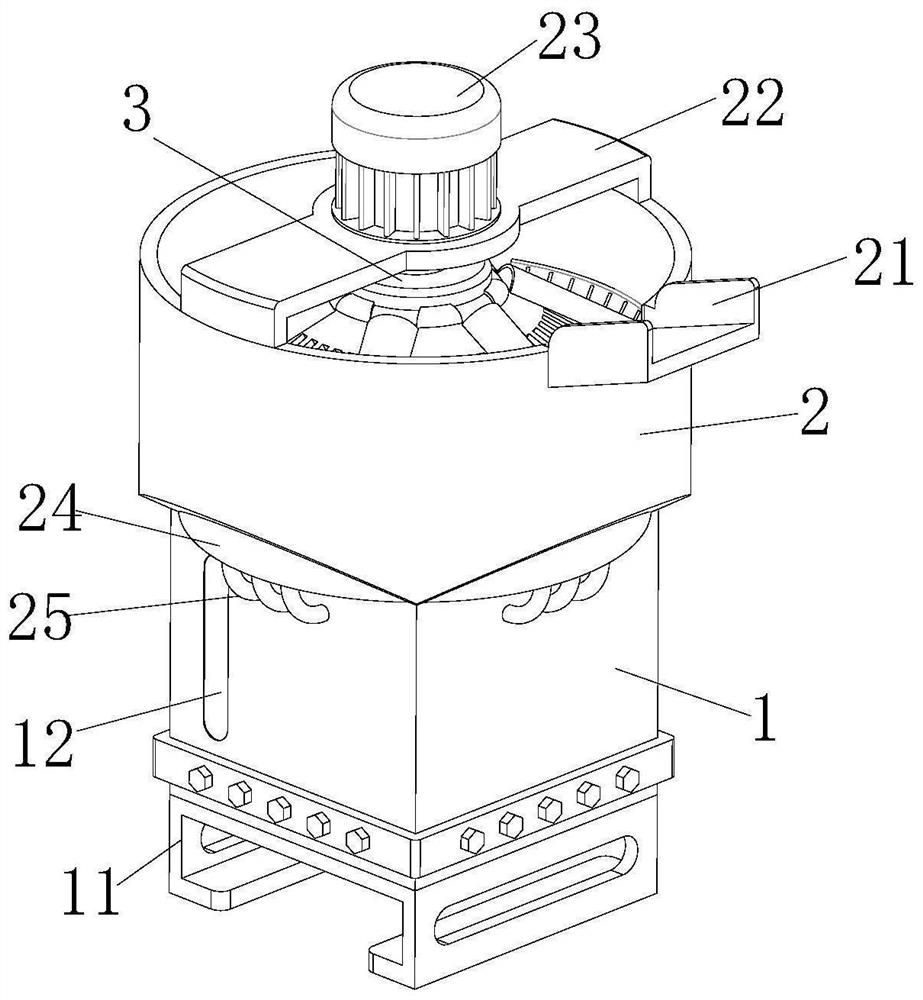

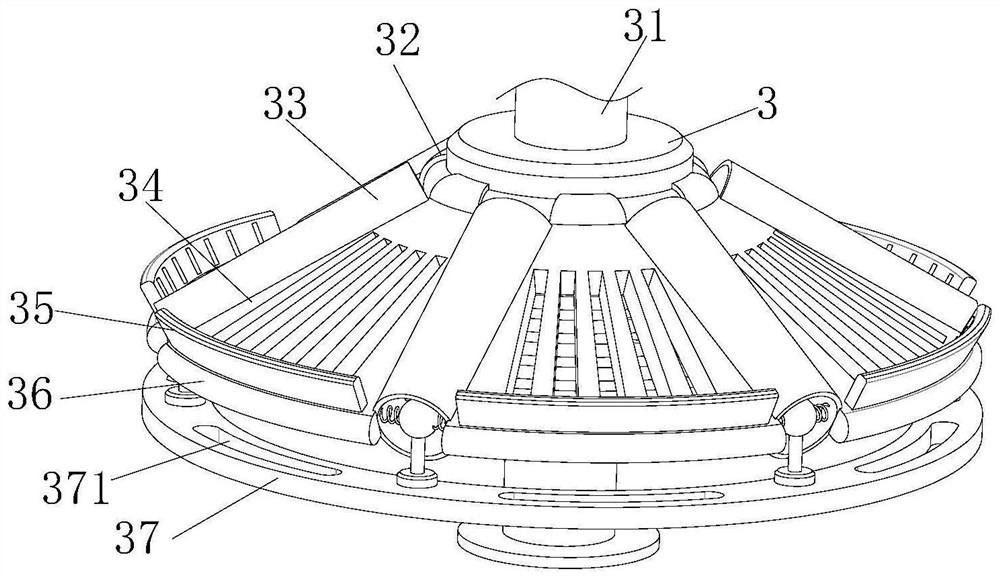

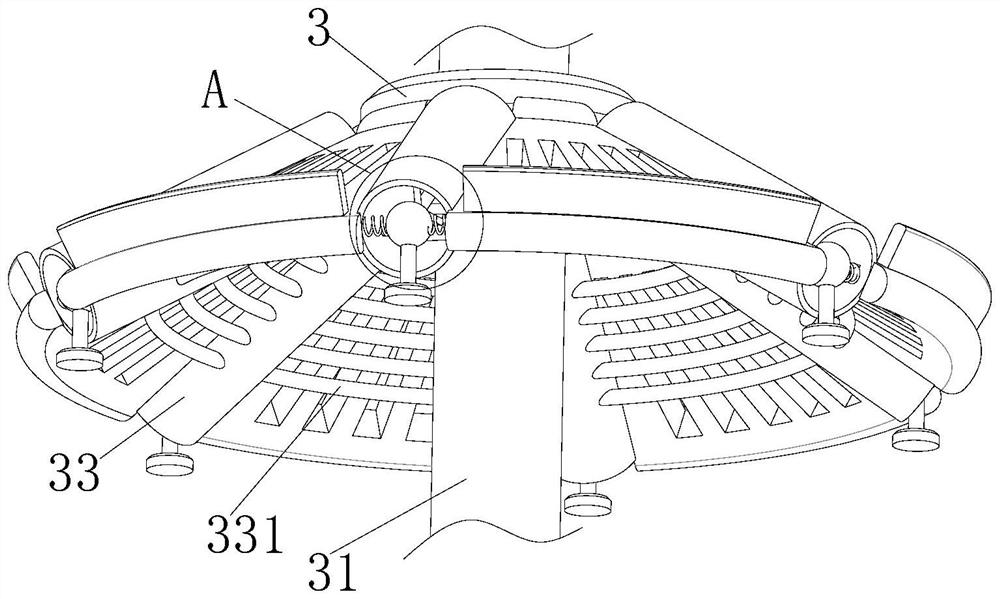

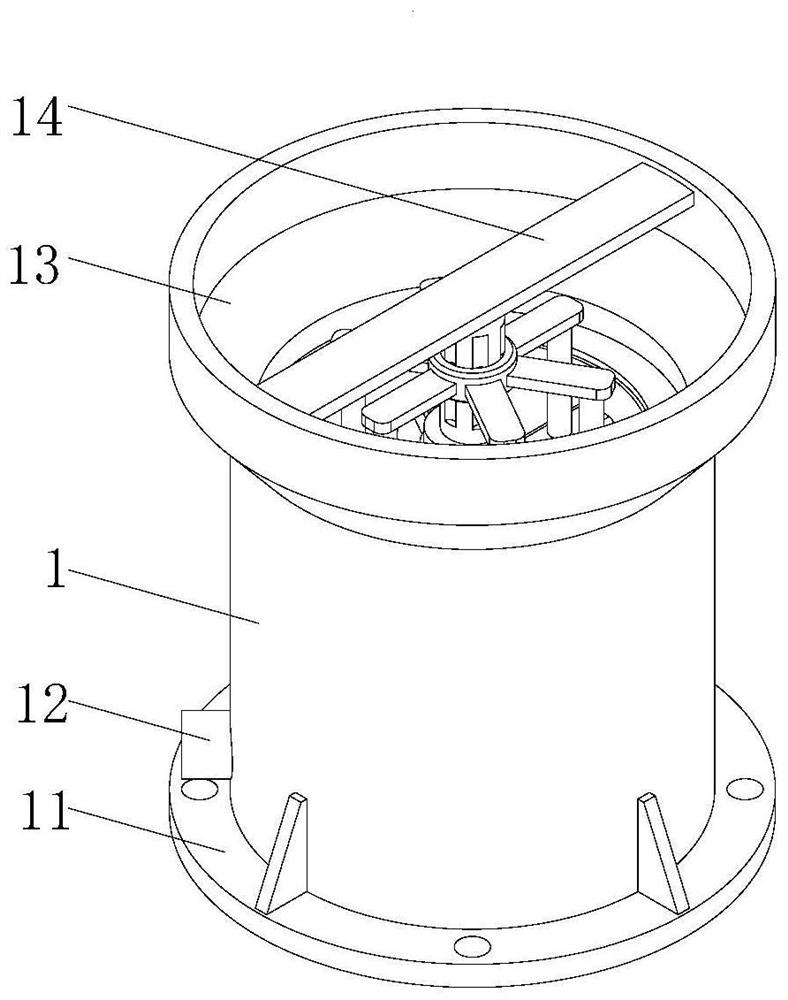

Metal chip centrifugal machine

The invention relates to centrifugal machines, in particular to a metal chip centrifugal machine. The centrifugal machine comprises a shell body, a hopper is arranged on the upper portion of the shell body, an inward-turning basket used for containing metal chips to be cleared is arranged below the hopper, a motor is connected on the bottom portion of the inward-turning basket, an outward-turning basket is arranged outside the inward-turning basket, and the outward-turning basket is fixed with the inward-turning basket and moves along with the inward- turning basket. According to the metal chip centrifugal machine, the metal chip is thrown into the outward-turning basket to carry out a secondary separation after being separated in the inward-turning basket, and after the secondary separation, the metal chip is discharged. The cleaning effect of the cutting oil on the surface of the metal chip is improved, and a residual quantity is greatly reduced.

Owner:JIANGSU HUJIANG CENTRIFUGE MFR

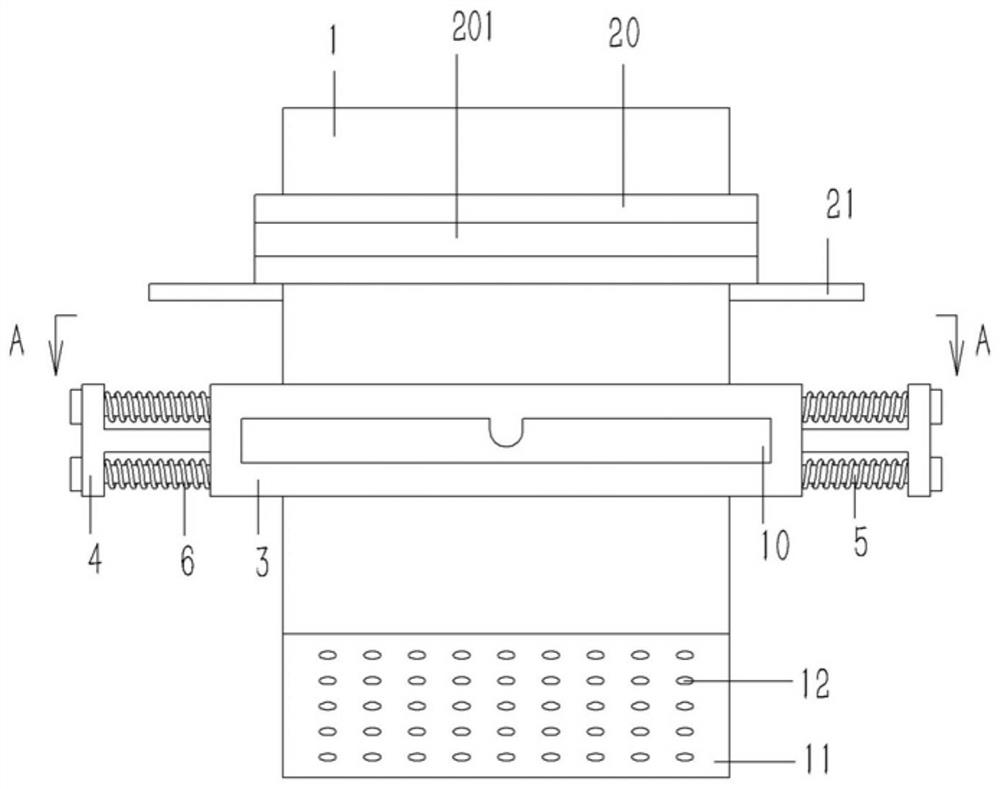

Metal cutting fluid recovery processing system

InactiveCN111036399AIncrease costImprove cleanlinessMagnetic separationStationary filtering element filtersProcess engineeringMetal swarf

The invention relates to a metal cutting fluid recovery processing system. The system comprises a hollow rectangular pipe, a first-stage filtering device, a closing device and a second-stage filteringdevice. The first-stage filtering device is mounted at an upper end of the hollow rectangular pipe; the closing device is mounted on the first-stage filtering device; and the second-stage filtering device is mounted at a lower end of the hollow rectangular pipe. During filtering of a recycled metal cutting fluid, there are the following problems that firstly, in most of existing filtering modes,filter paper is used to filter the recycled metal cutting fluid; as the filtering goes on, impurities are continuously accumulated on the filter paper, the filter paper is easily blocked, a filteringeffect is influenced, weight of the filter paper is continuously increased, and the filter paper easily sinks or cracks so that the filtered impurities enter a recycling box, and filtering failure iscaused; and secondly, metal cutting fluid recovery equipment on a market at present is low in recovery rate and insufficient in recovery cleanliness, and the recovered metal cutting fluid cannot be filtered well. The system of the invention can solve the above problems.

Owner:张汀仁

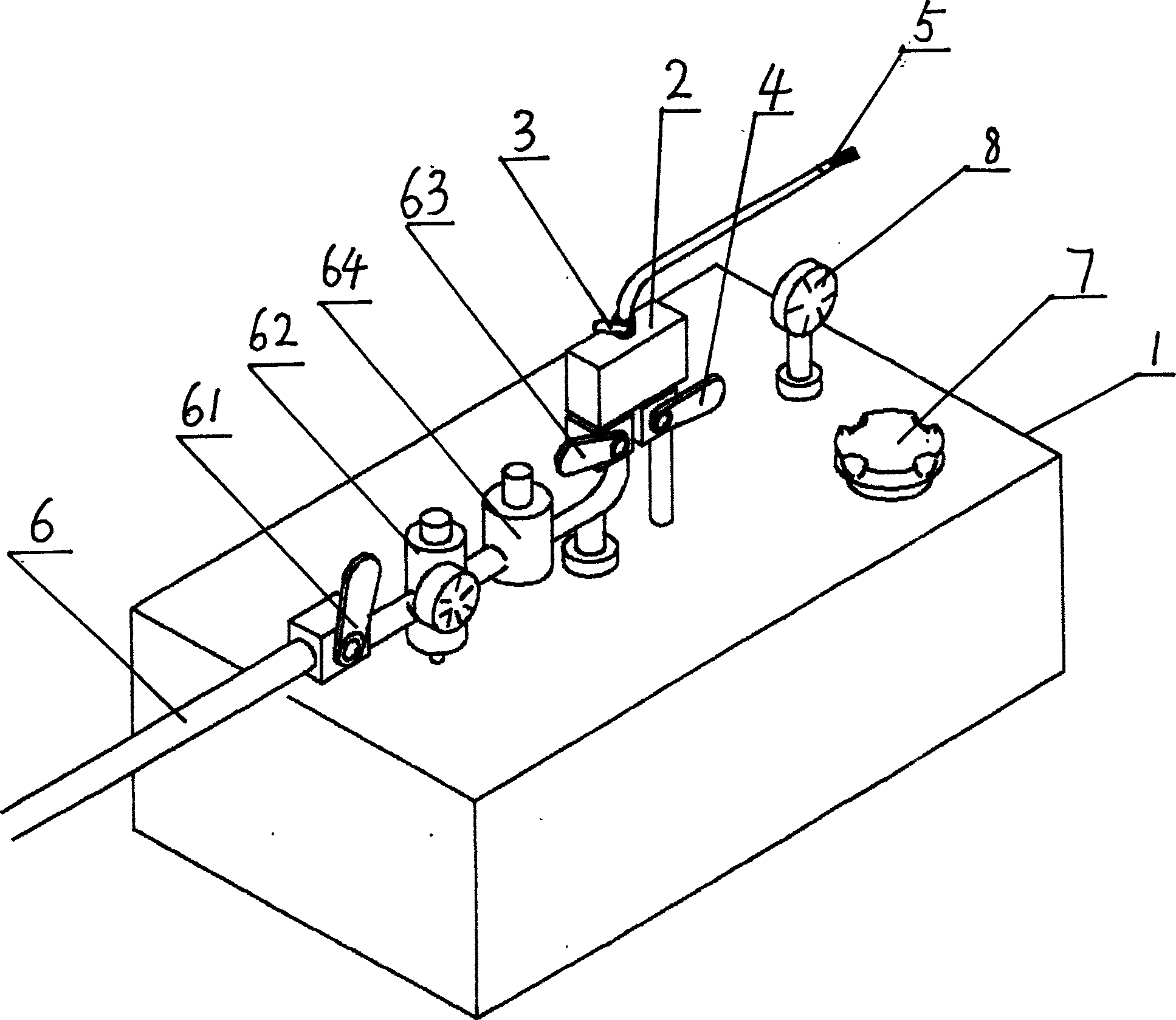

Roller atomized cutting technique and device thereof

InactiveCN1730238AReduce the temperatureIncreased durabilityTurning machinesMaintainance and safety accessoriesMetal swarfEngineering

The invention discloses a roller atomization cutting processing manufacture technique. Wherein, it uses a special atomization device to mix the cutting solution in compressed air and form spray jet with some pressure; when turning, the jet sprays on cutting zone to cool cutting tool, lubricate the friction, increase the durable property and cutting efficiency and avoid the dust. This invention is environmental friend.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

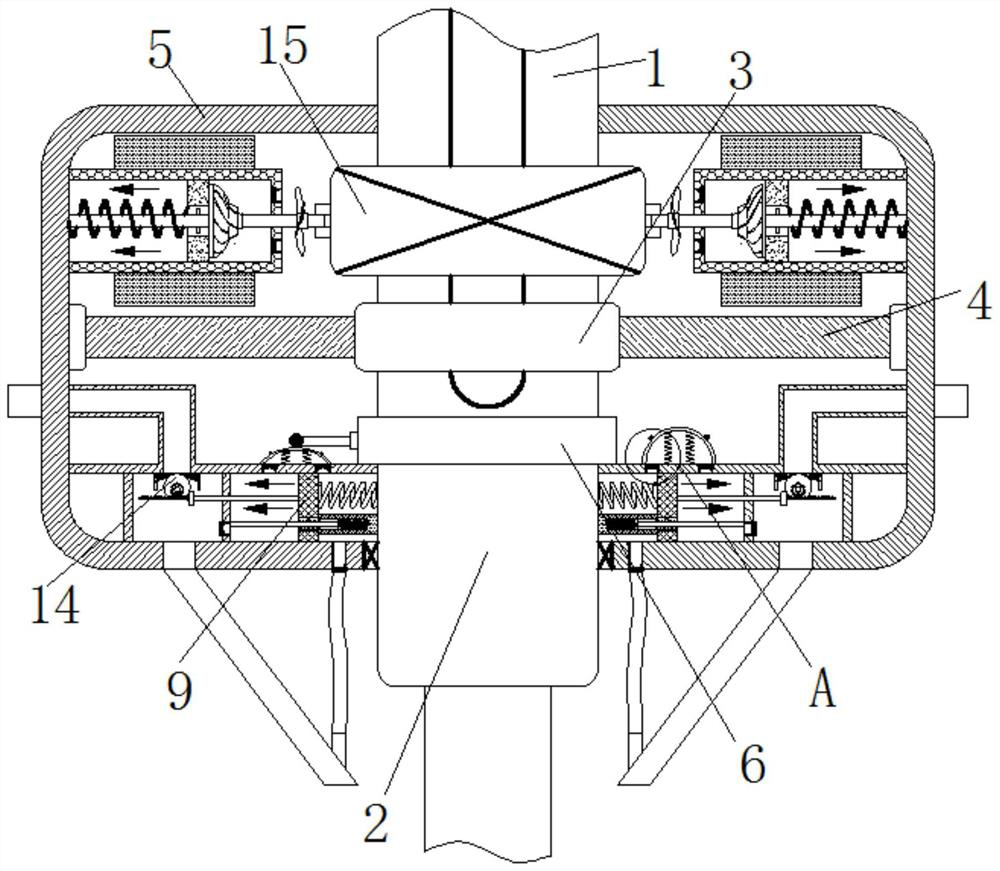

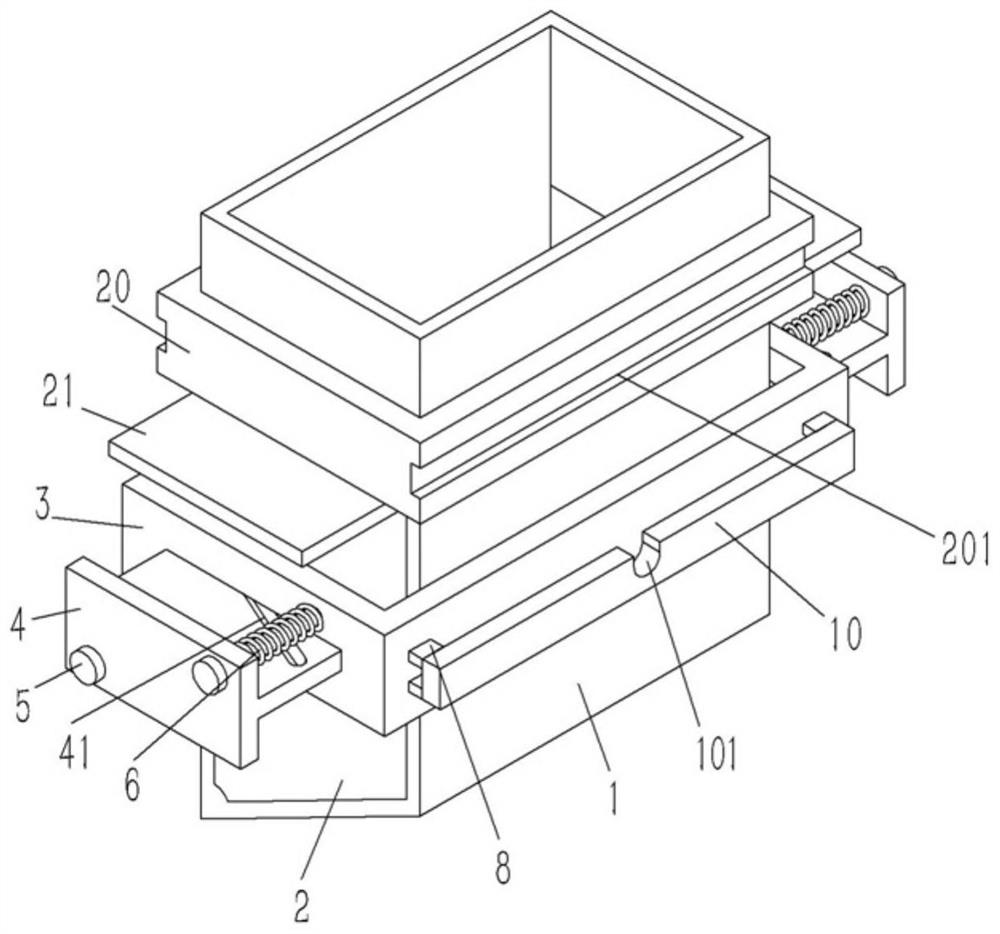

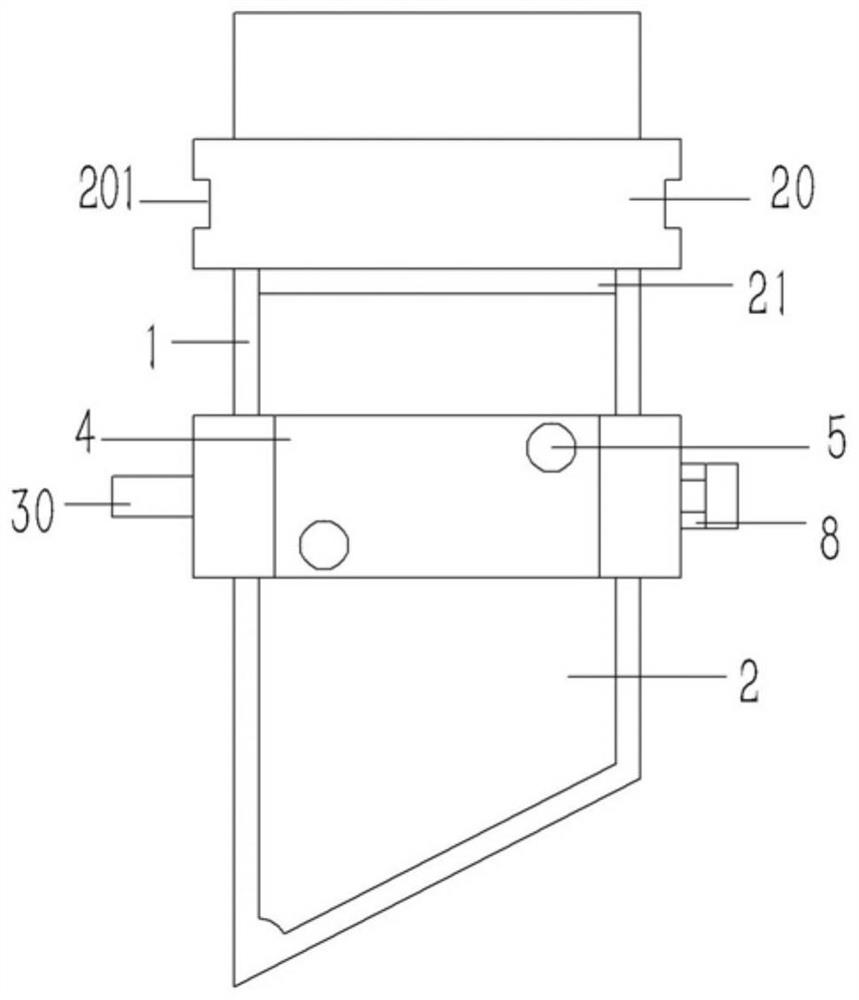

Machine tool cutting chip two-way compression device

PendingCN111645355AImprove stabilityPrevent leakageMaintainance and safety accessoriesPressesEngineeringMetal swarf

The invention relates to the technical field of machine tools, in particular to a machine tool cutting chip two-way compression device comprising a compression box, a transverse compression mechanismand a longitudinal compression mechanism. The transverse compression mechanism comprises a transverse power device and a transverse pressing plate. The longitudinal compression mechanism comprises a longitudinal power device, a longitudinal pressing plate, a movable plate and a first spring. The movable plate is horizontally arranged on the longitudinal pressing plate in a sliding manner. According to the machine tool cutting chip two-way compression device, the movable plate and the first spring are arranged on the longitudinal pressing plate; when metal cutting chips in a compression cavityare compressed leftwards through the transverse pressing plate, the movable plate of the longitudinal pressing plate keeps making contact with the transverse pressing plate all the time, it is avoidedthat the metal cutting chips leak from the portion between the transverse pressing plate and the longitudinal pressing plate, the longitudinal pressing plate and the transverse pressing plate can conduct compression at the same time, and the compression efficiency can be improved; and the strip-shaped metal cutting chips in the compression cavity can be compressed into regular integral cutting chip block structures, and therefore the stacking volume of the strip-shaped metal cutting chips is reduced, and cost of transporting and warehousing is reduced.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Clamp for machining inner wall of motor shell of new energy automobile

PendingCN114012467AAvoid vibrationImprove machining accuracyWork clamping meansPositioning apparatusNew energyElectric machinery

The invention relates to the technical field of motor shell machining clamps, and provides a clamp for machining the inner wall of a motor shell of a new energy automobile. The clamp comprises: a rotating table used for connecting a tool; a main body assembly arranged below the rotating table, wherein a plurality of fixing sleeves movably arranged in the axis direction of the main body assembly; and a driving part arranged on the main body assembly, wherein the inner diameter of each fixing sleeve is larger than the outer diameter of a workpiece to be machined, and the driving part can drive the fixing sleeves to be switched between a first position and a second position on the main body assembly. Compared with the prior art, the clamp has the advantages that the clamp is connected to the tool in the vertical direction through the rotating table, and when a workpiece is cut by a cutter, metal chips stripped from the inner wall of the workpiece are separated from the workpiece under the action of self gravity, so that the influence of the metal chips on the inner wall of the workpiece is reduced, and the machining precision of the inner wall of the workpiece is improved.

Owner:宁波旭升集团股份有限公司

Cutting fluid recovery equipment for numerical control machine tool

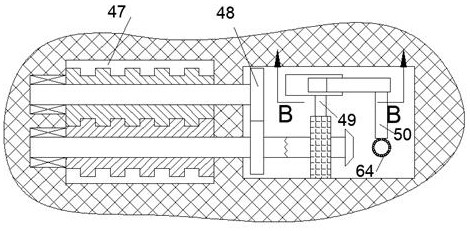

InactiveCN114770211AReduce the situation of mixing togetherEasy to separateSievingScreeningNumerical controlDrive shaft

The invention discloses numerical control machine tool cutting fluid recovery equipment which comprises a storage box, the bottom of the storage box is fixedly connected with a pair of mounting frames, the mounting frames are L-shaped, a transparent plate is fixedly mounted on the surface of the storage box, a separation hopper is fixedly mounted on the surface of the storage box, and a plurality of storage cavities are fixedly connected to the side wall of the separation hopper; a plurality of conveying pipes are fixedly connected to the bottom of the containing cavity and fixedly connected with the surface of the storage box, a feeding port is fixedly connected to the surface of the separating hopper, a supporting frame is fixedly connected to the surface of the separating hopper, a driving motor is fixedly installed on the surface of the supporting frame, and a transmission shaft is fixedly installed at the output end of the driving motor. A mounting disc is fixedly mounted on the surface of the transmission shaft; compared with the prior art, through circular motion of the arc-shaped sieve plate seat, cuttings accumulated on the surface of the arc-shaped sieve plate can be separated, the situation that the cuttings are mixed together due to mixing of different kinds of metal cuttings in the cutting fluid is reduced, and the separation effect on the cutting fluid can be enhanced.

Owner:舒洁

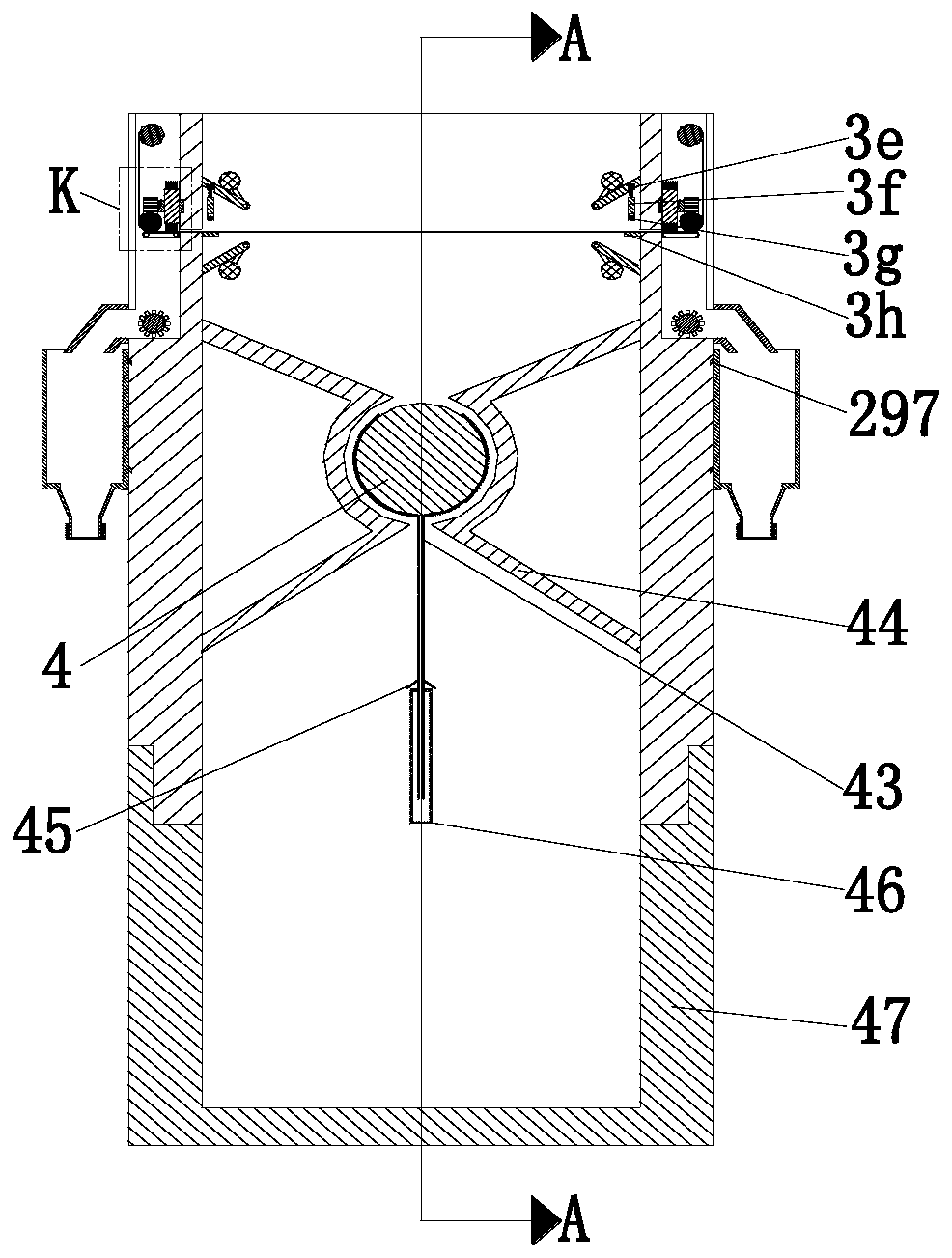

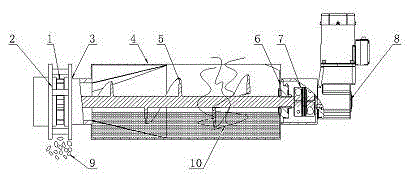

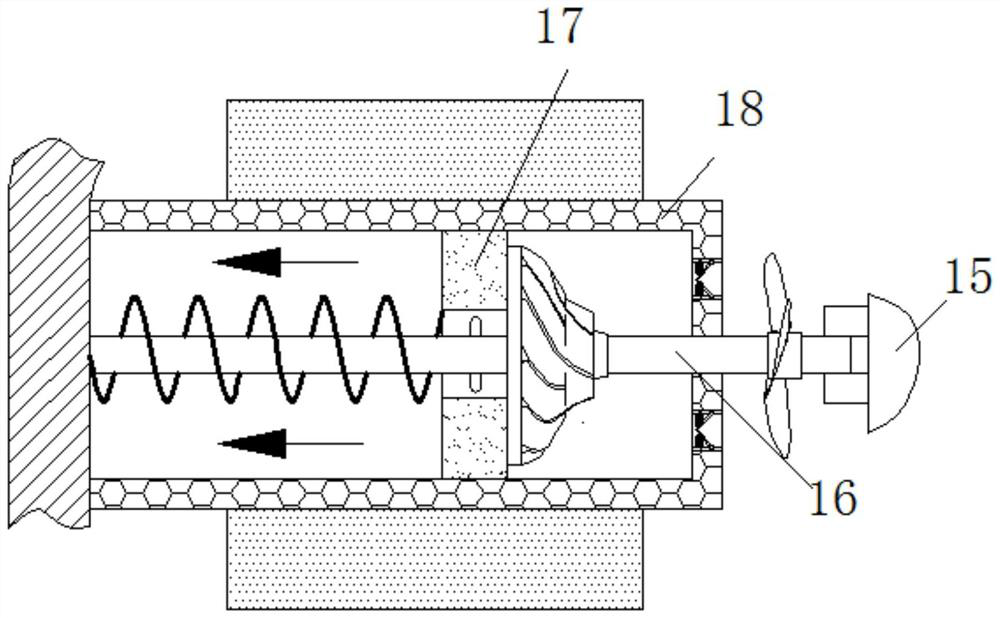

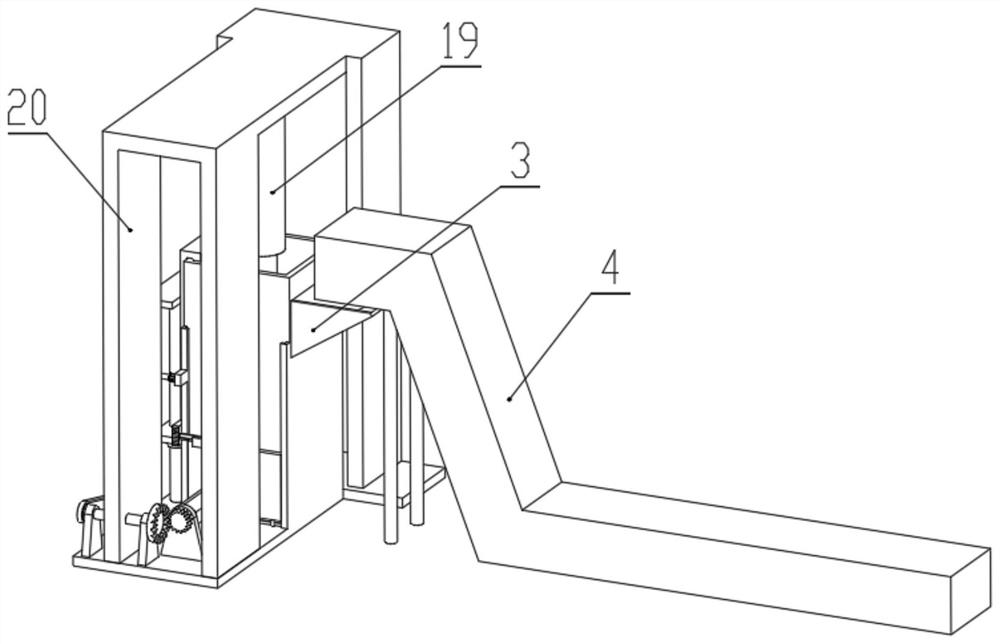

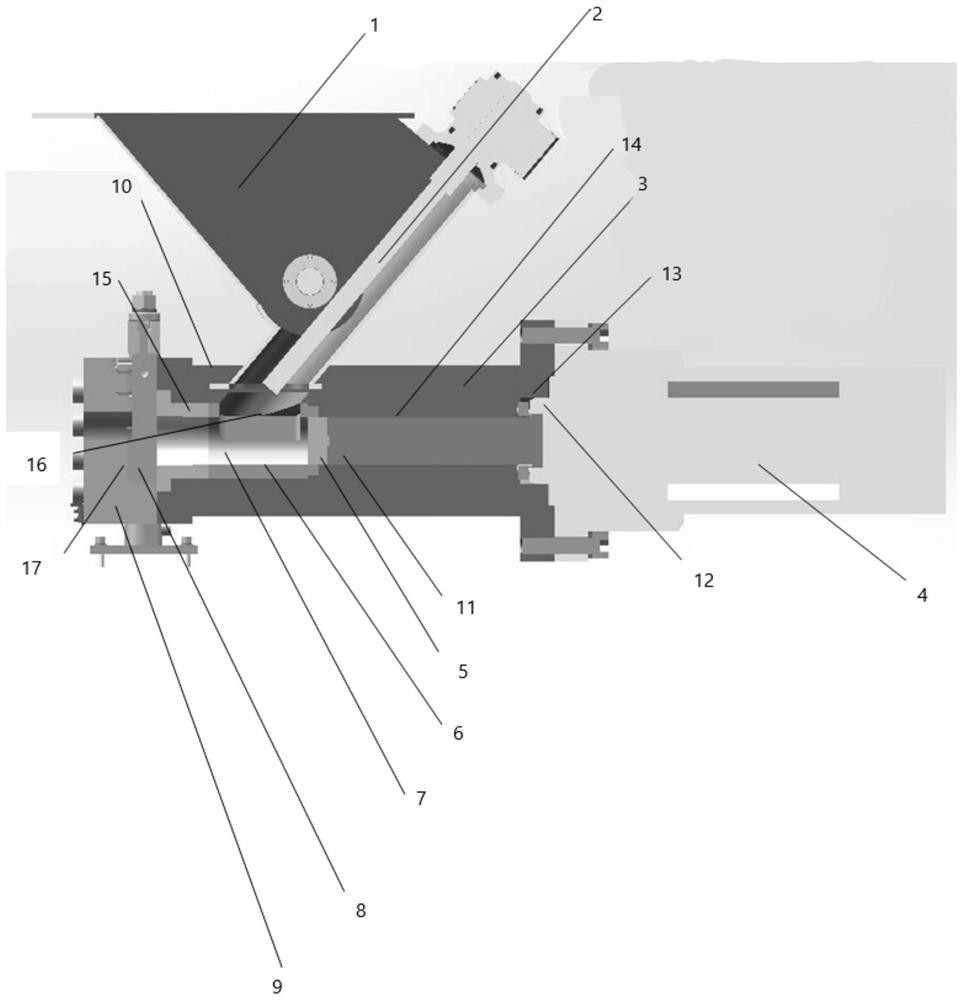

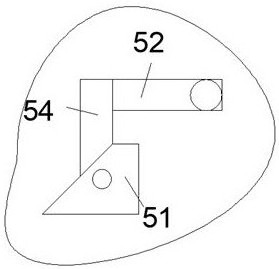

Shear type metal chip crushing machine

InactiveCN105127830ANovel structureReduce the overall heightGrain treatmentsMaintainance and safety accessoriesCouplingDrive motor

A shear type metal chip crushing machine is characterized in that a right cutter head (3) is connected with the left end of a body (4) through a bolt; a left cutter head (2) is connected to the left end of the right cutter head (3) through a bolt, the left cutter head (2) and the right cutter head (3) are fixed to the left end and the right end of a shear type cutter disc (1) and connected with a spiral feeding device (5) through bearings, and the shear type cutter disc (1) is arranged on the bearings; a waterproof sealing structure (6) is connected with the right end of the body (4), a driving motor (8) is connected with the spiral feeding device (5) through a coupler, the driving motor (8) provides driving force to drive the spiral feeding device (5) to rotate through the coupler (7), the shear type cutter disc (1) rotates along with the spiral feeding device (5), and the body (4), the left cutter head (2) and the right cutter head (3) are fixed. The shear type metal chip crushing machine has the advantages of being novel in structure, small in height of the feeding port, compact in structure, small in occupied space, small in smashing particle size and the like.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

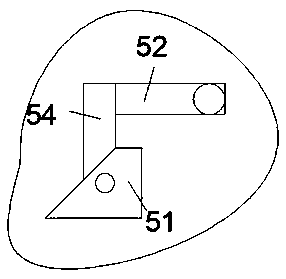

Abrasion-preventing centrifugal protection device for main shaft of vertical machining center

PendingCN113601199AAvoid wear and tearAvoid enteringLarge fixed membersMaintainance and safety accessoriesMetal swarfCentrifugal force

The invention relates to the technical field of vertical machining center equipment, and discloses an abrasion-preventing centrifugal protection device for a main shaft of a vertical machining center. The device comprises a first connecting shaft, a shaft key is fixedly connected to the outer side of the first connecting shaft, a first connecting block is clamped in the middle of the shaft key, a first connecting rod is fixedly connected to the outer side of the first connecting block, one end of the first connecting rod is fixedly connected with a first shell, and the bottom end of the first connecting shaft is rotationally connected with a second connecting block. According to the abrasion-preventing centrifugal protection device for the main shaft of the vertical machining center, through connection of the first connecting shaft and the second connecting block, the problem that a bearing in a main shaft in the prior art is prone to rusting is solved, centrifugal force is utilized, the flow speed of cooling liquid can be controlled, the cost is reduced, meanwhile, metal cuttings, dust and the like can be prevented from entering the main shaft, the purpose of prolonging the service life is achieved, the dead weight of the equipment is effectively reduced, and the reliability is greatly improved.

Owner:蒋涛

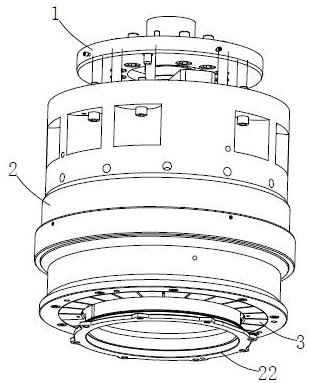

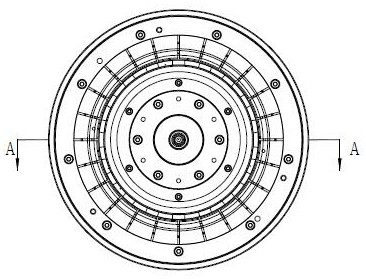

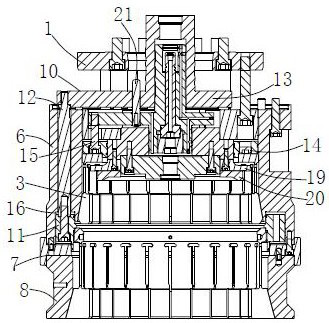

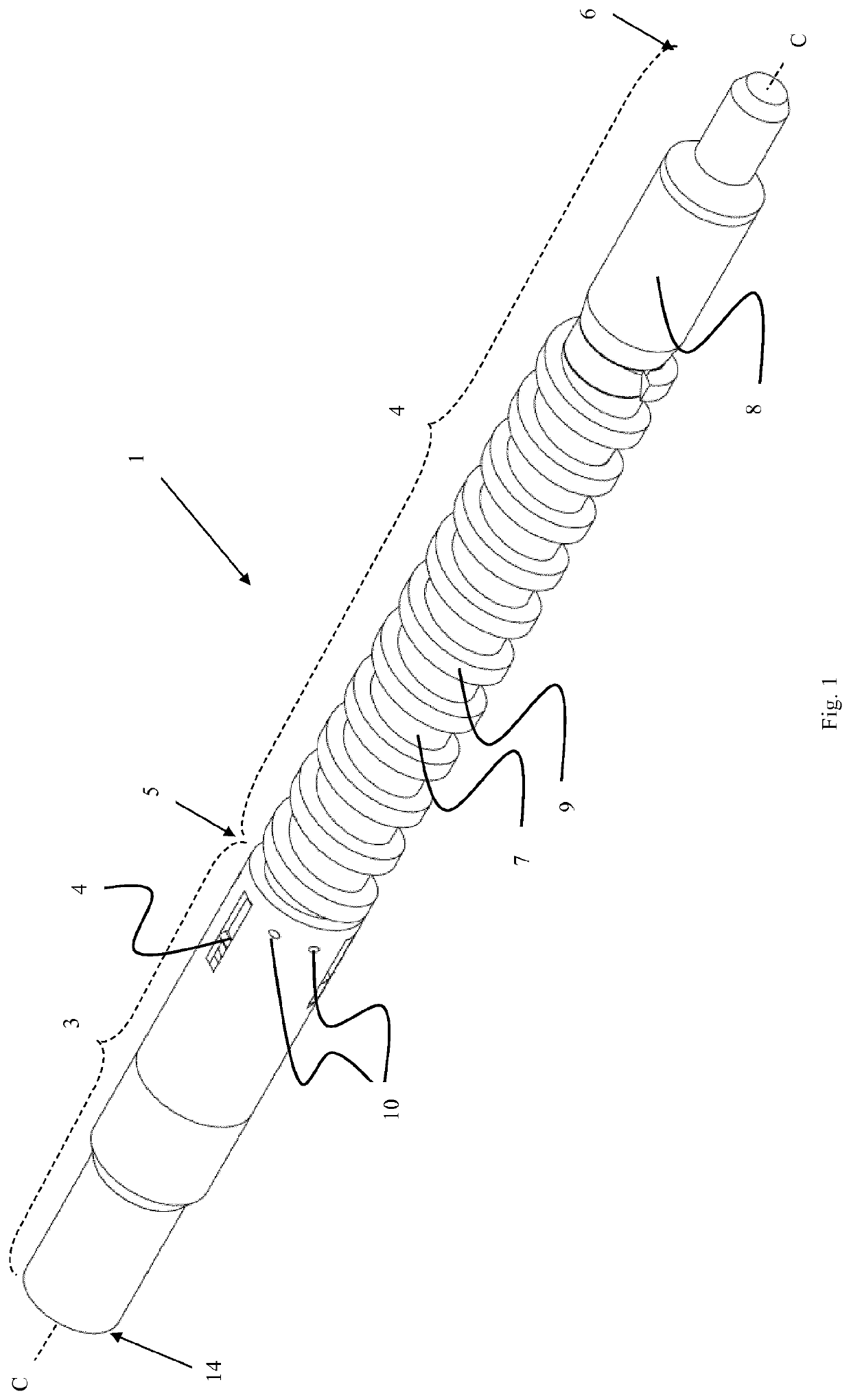

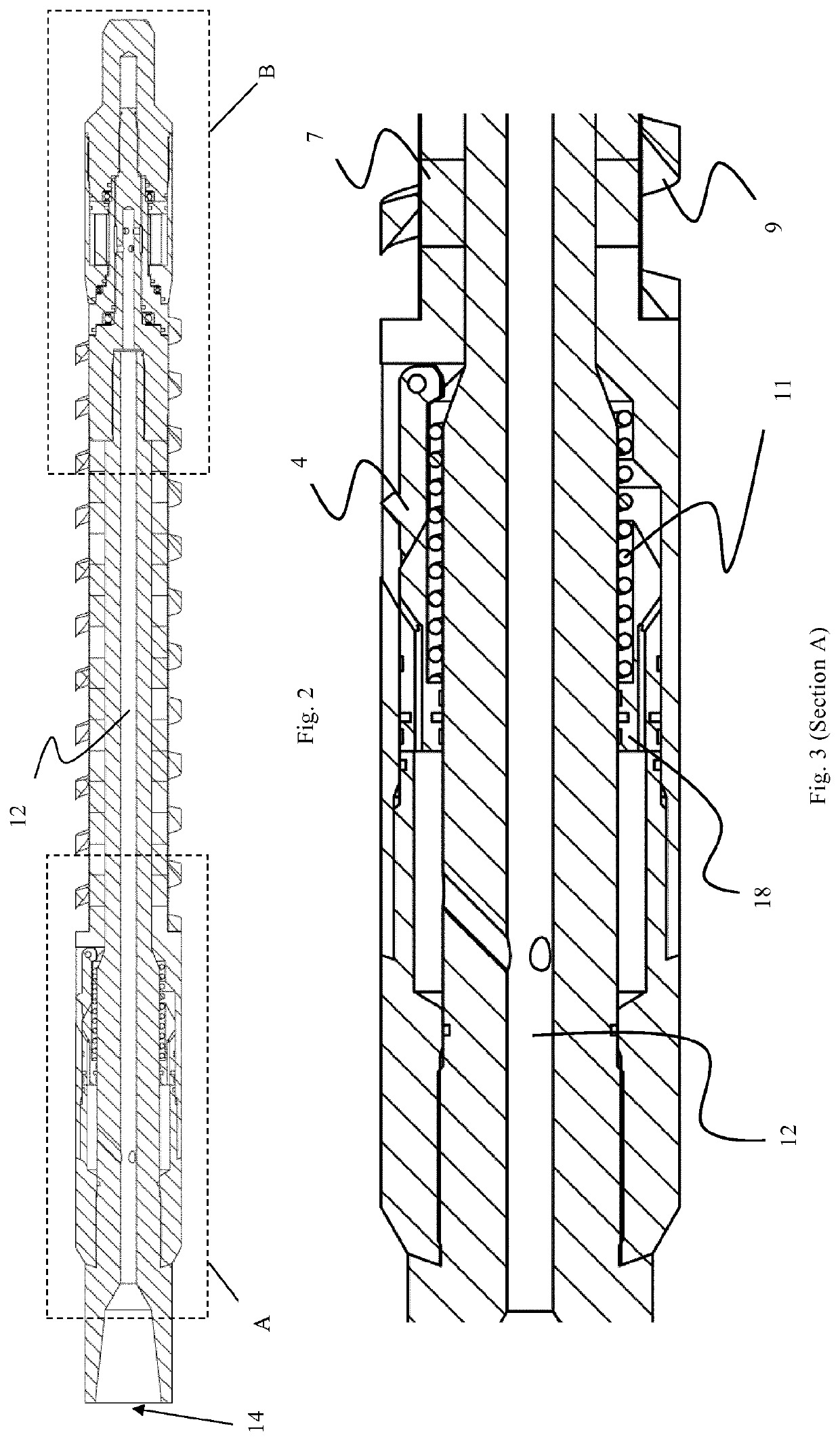

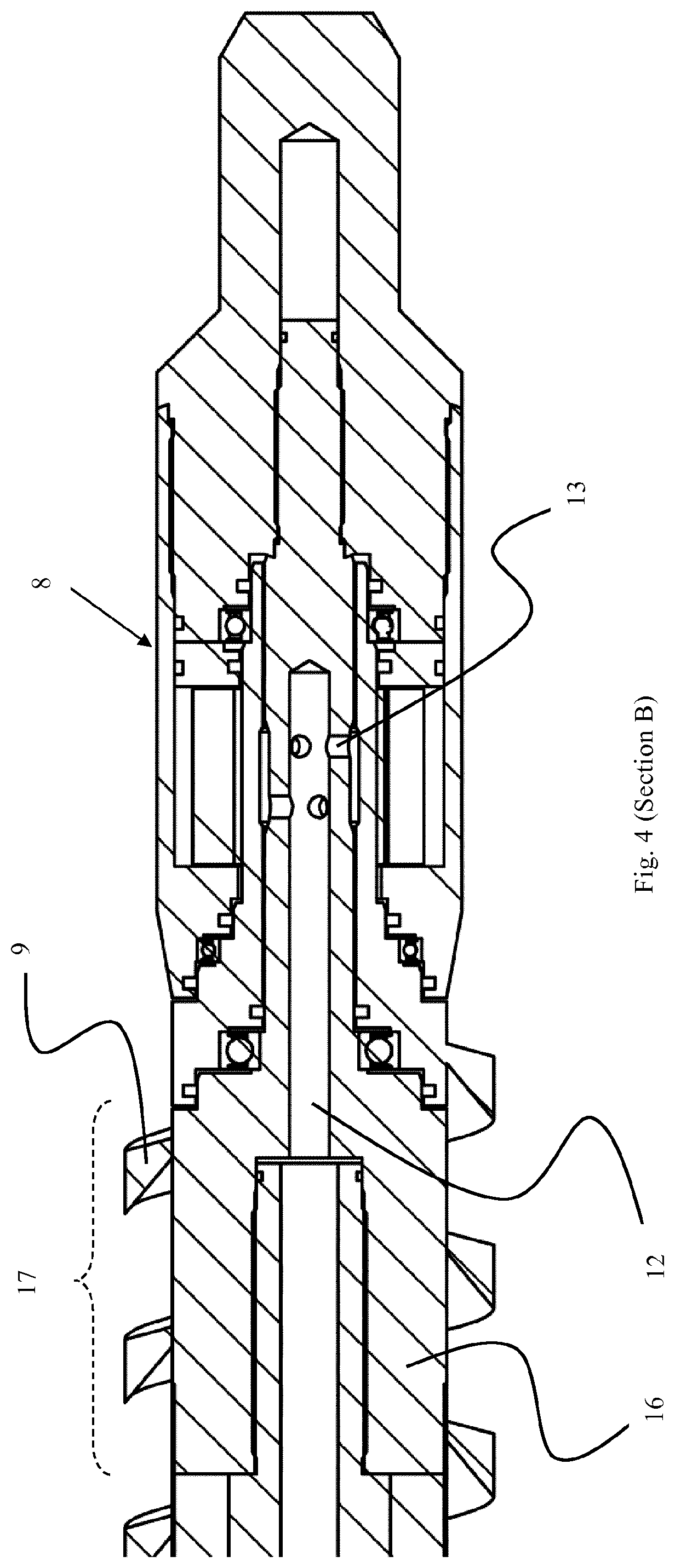

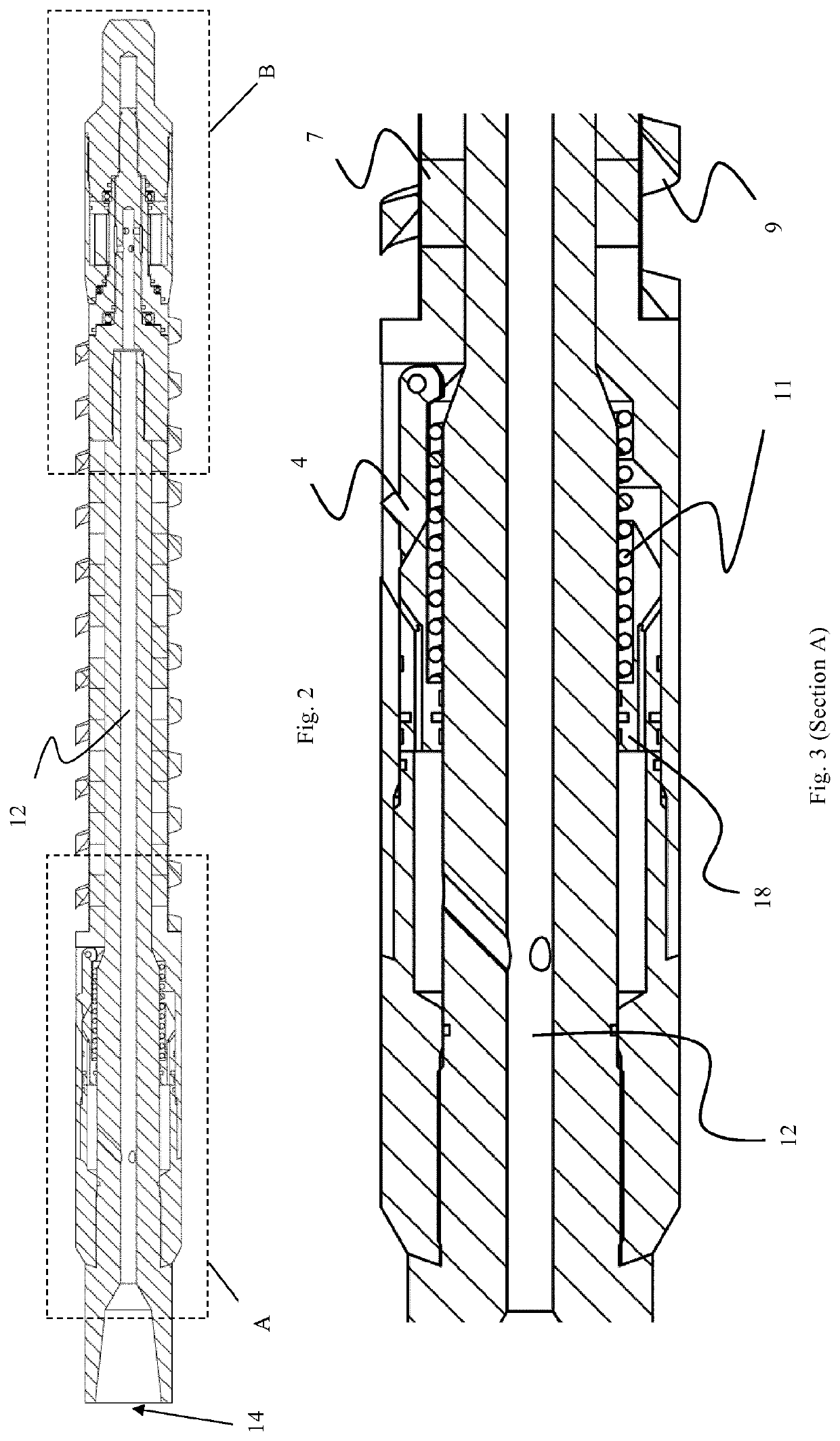

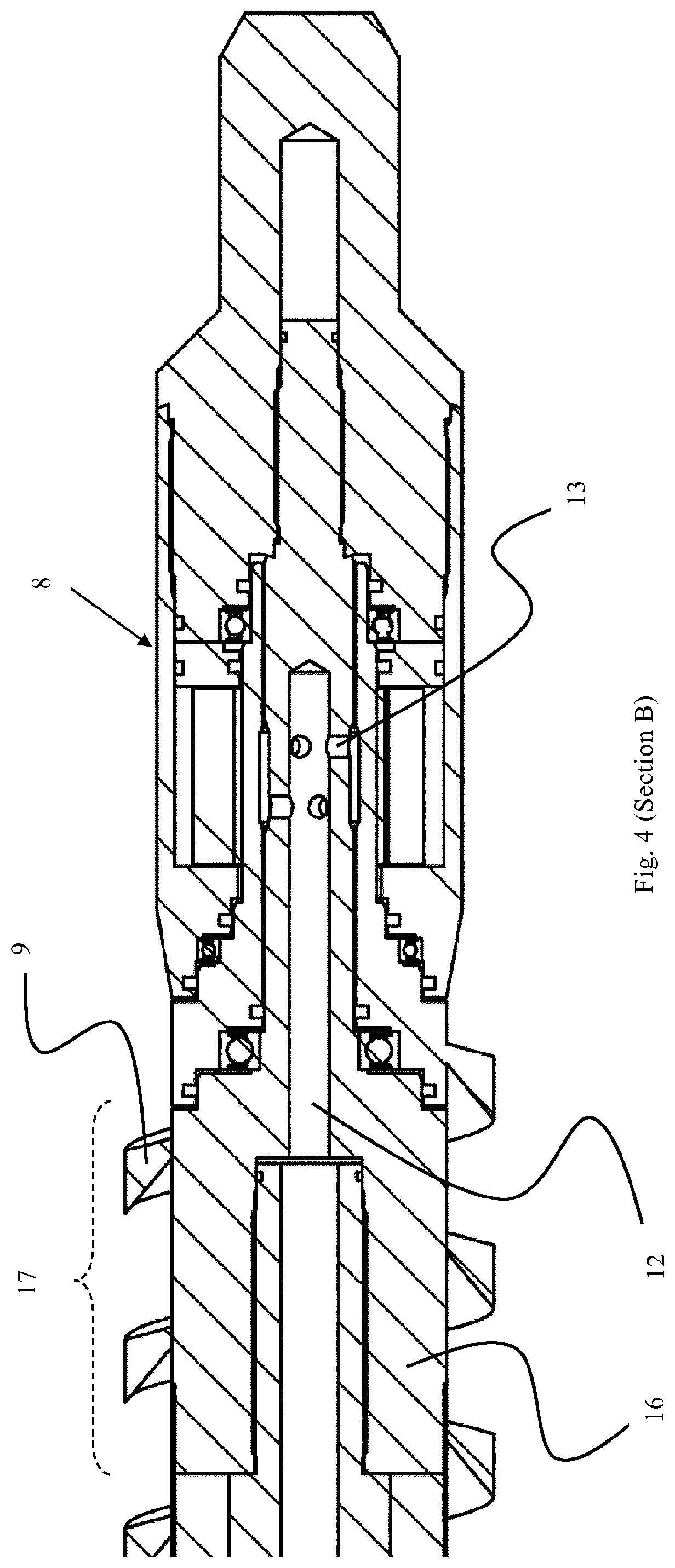

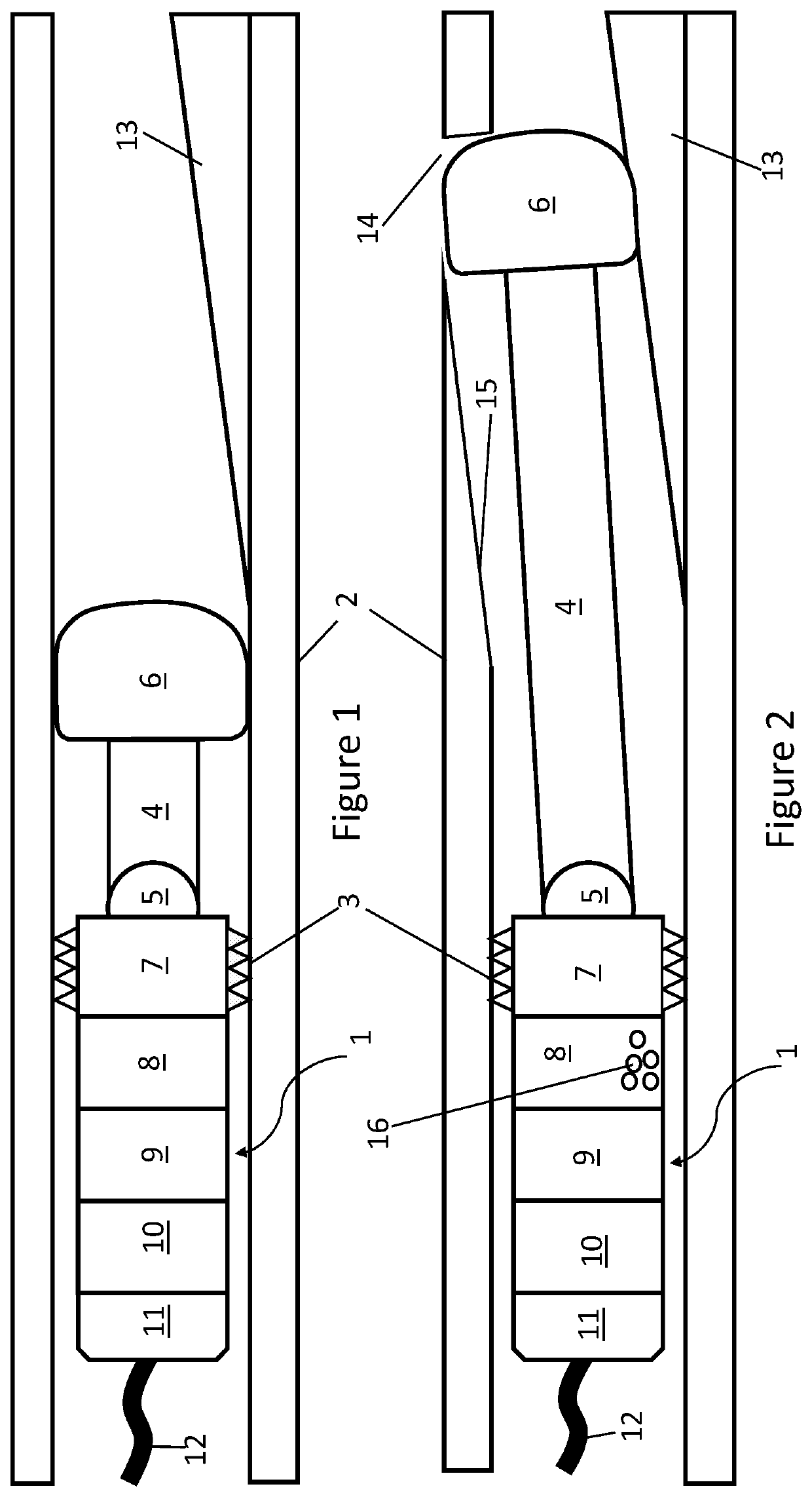

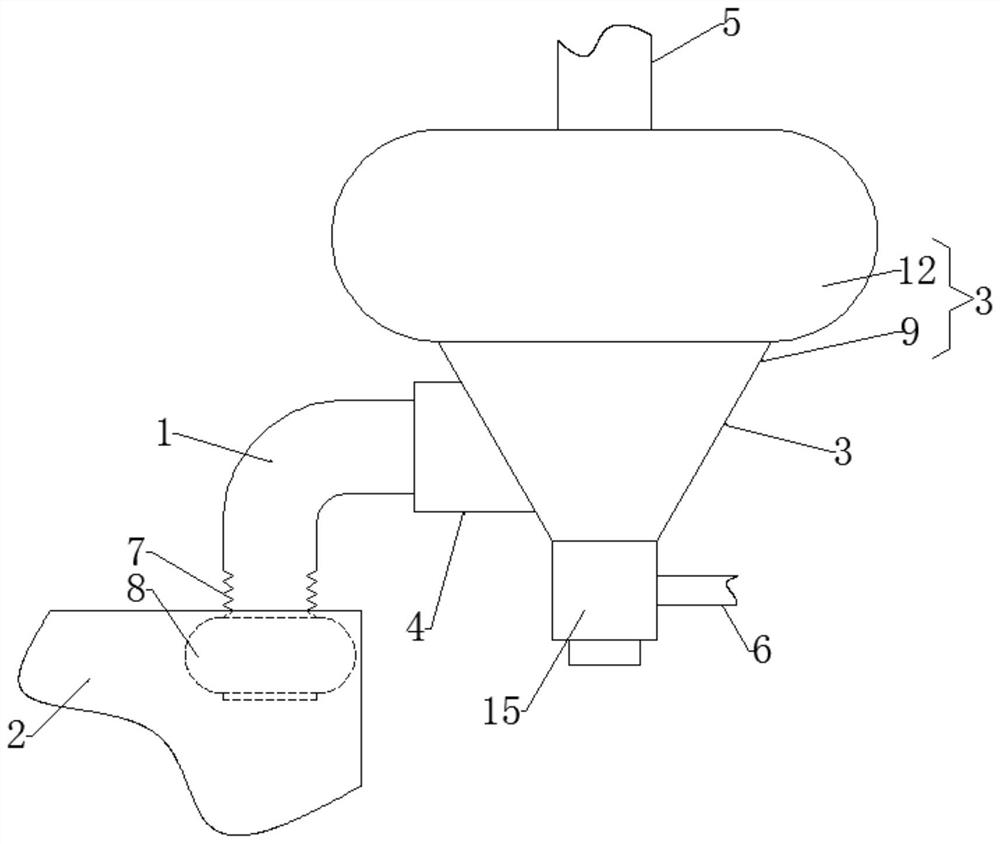

Milling tool

ActiveUS20210148189A1Eliminate magnetic attractionCleaning apparatusSealing/packingMilling cutterEngineering

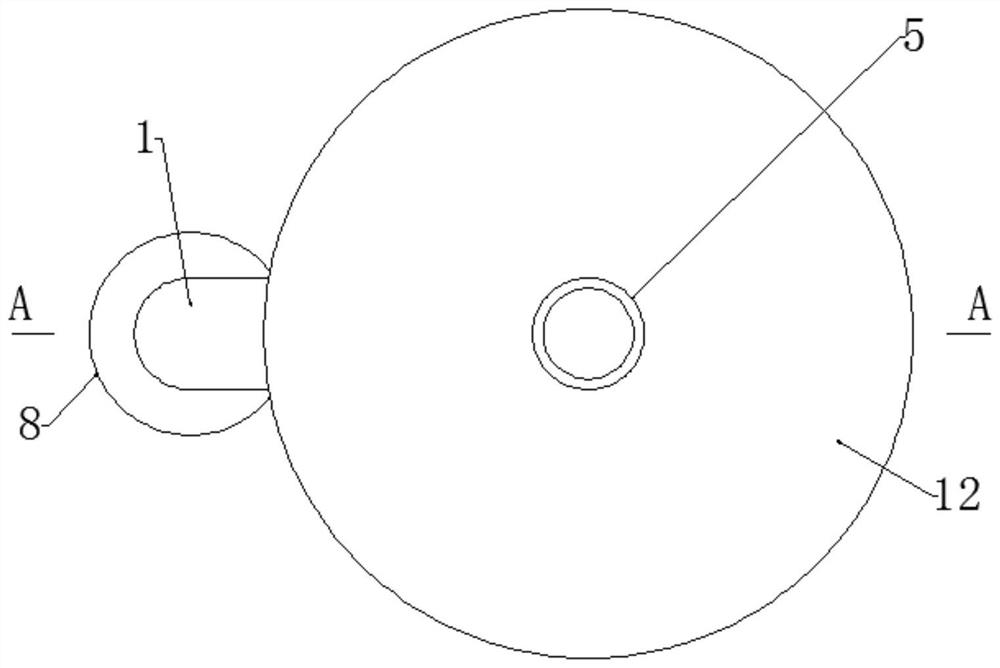

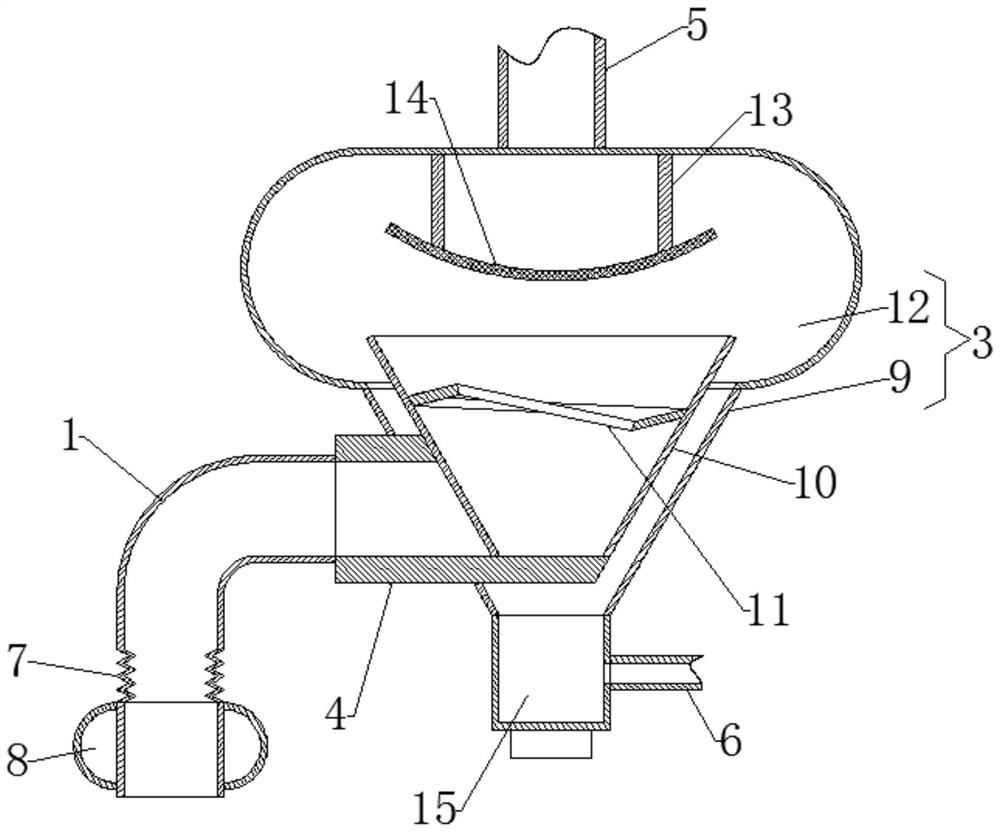

The present invention provides a milling tool (1) for a wellbore, comprising a milling section (2) and a metal cuttings removal section (3), the milling section (2) comprises radially arranged milling elements (4); and the metal cuttings removal section (3) has a first end (5) and a second end (6) and comprises a cylinder-shaped magnetic element (7), a rotation generating device (8) and a helix-shaped longitudinal guide element (9), wherein the first end (5) is connected to the milling section; the helix-shaped longitudinal guide element (9) is arranged around the cylinder-shaped magnetic element (7); the rotation generating device (8) is operably connected to the cylinder-shaped magnetic element (7) or the helix-shaped longitudinal guide element (9); wherein the cylinder-shaped magnetic element and the helix-shaped longitudinal guide element (9) are rotatable relative to each other around a common centreline (C), and configured such that metal cuttings accumulating on the cylinder-shaped magnetic element during use is guided by the helix-shaped longitudinal guide element towards the second end (6) of the metal cuttings removal section when the rotation generating device is operated.

Owner:SWARFIX AS

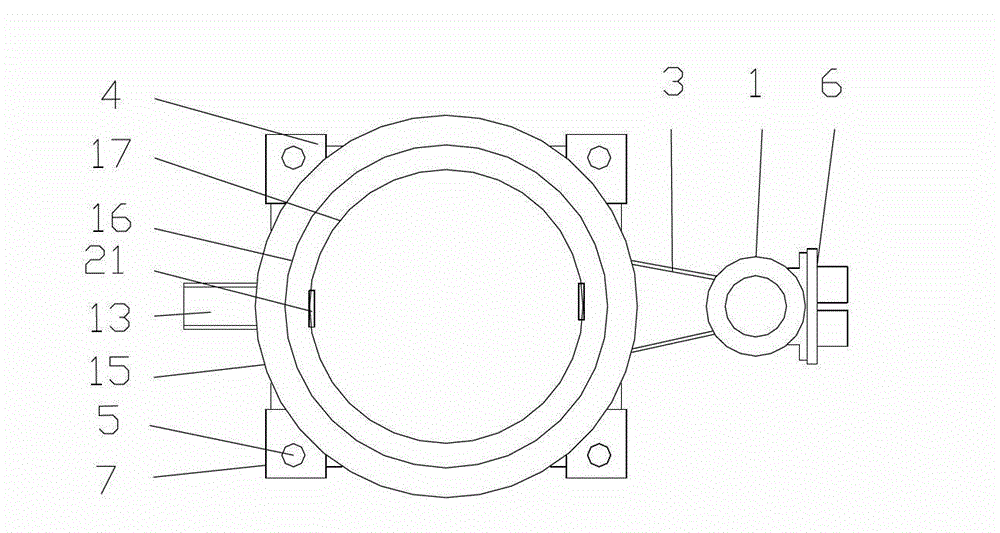

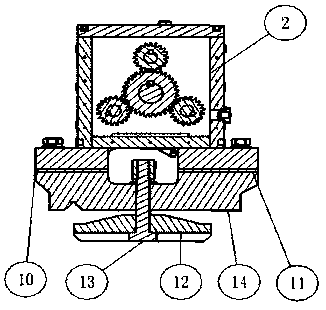

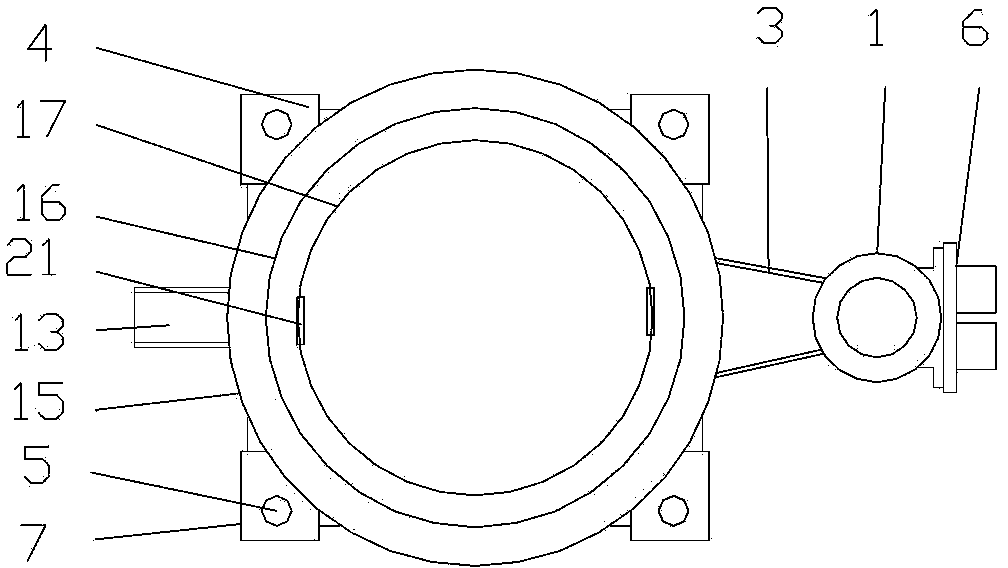

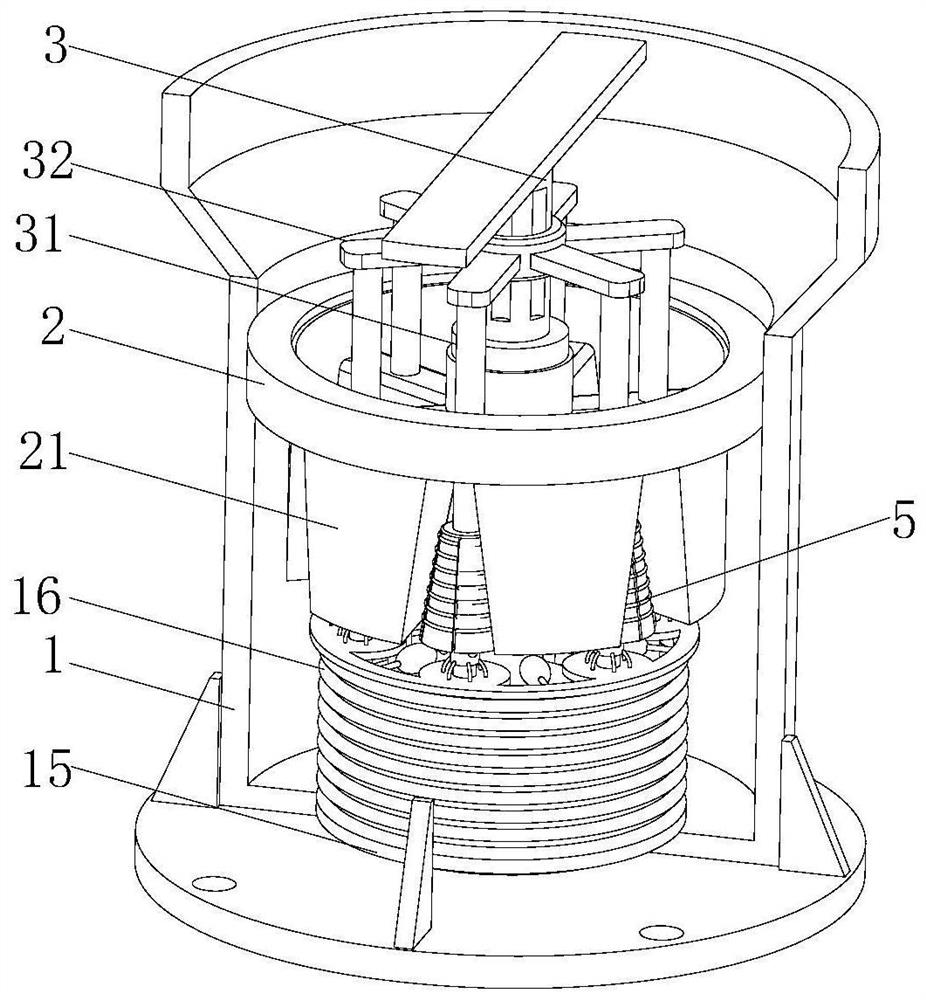

Liquid separating device capable of separating liquid from metal chip materials

ActiveCN102721268AWon't wasteWill not polluteDrying machines with non-progressive movementsAdhesive beltHydrocotyle bowlesioides

The invention relates to a liquid separating device capable of separating liquid from metal chip materials. Four positioning guide columns and a motor are installed on a base. A spring respectively sleeves each positioning guide column. The upper end of each positioning guide column is sequentially provided with a stander and a circular outer barrel. A bearing seat with a bearing A and a bearing B in the middle part is installed in the middle part of the stander, and a main shaft is installed between the bearing A and the bearing B. The lower part of the main shaft is connected with the motor through a triangular adhesive tape. A porous circular barrel is fixedly installed on the main shaft. A porous movable suspension barrel is movably installed in the middle of the porous circular barrel, and the bottom of the porous movable suspension barrel is provided with a movable soleplate. A suspension ring is installed on the porous movable suspension barrel. Both the porous circular barrel and the porous movable suspension barrel are provided with a plurality of liquid holes. A liquid holding barrel is arranged below a liquid flow-out pipe of the circular outer barrel. When the liquid separating device is used for separating the liquid from the metal chip materials, less vapor and less smoke, which are mixed with hydrocarbon, are produced, the heat energy is not wasted, the environment is not polluted, and the body health of the operation personnel is not damaged. The liquid separating device can be used for recycling the mixed liquid of cutting liquid and lubricating oil and for further processing and utilizing the metal chip materials.

Owner:KEHUA HLDG

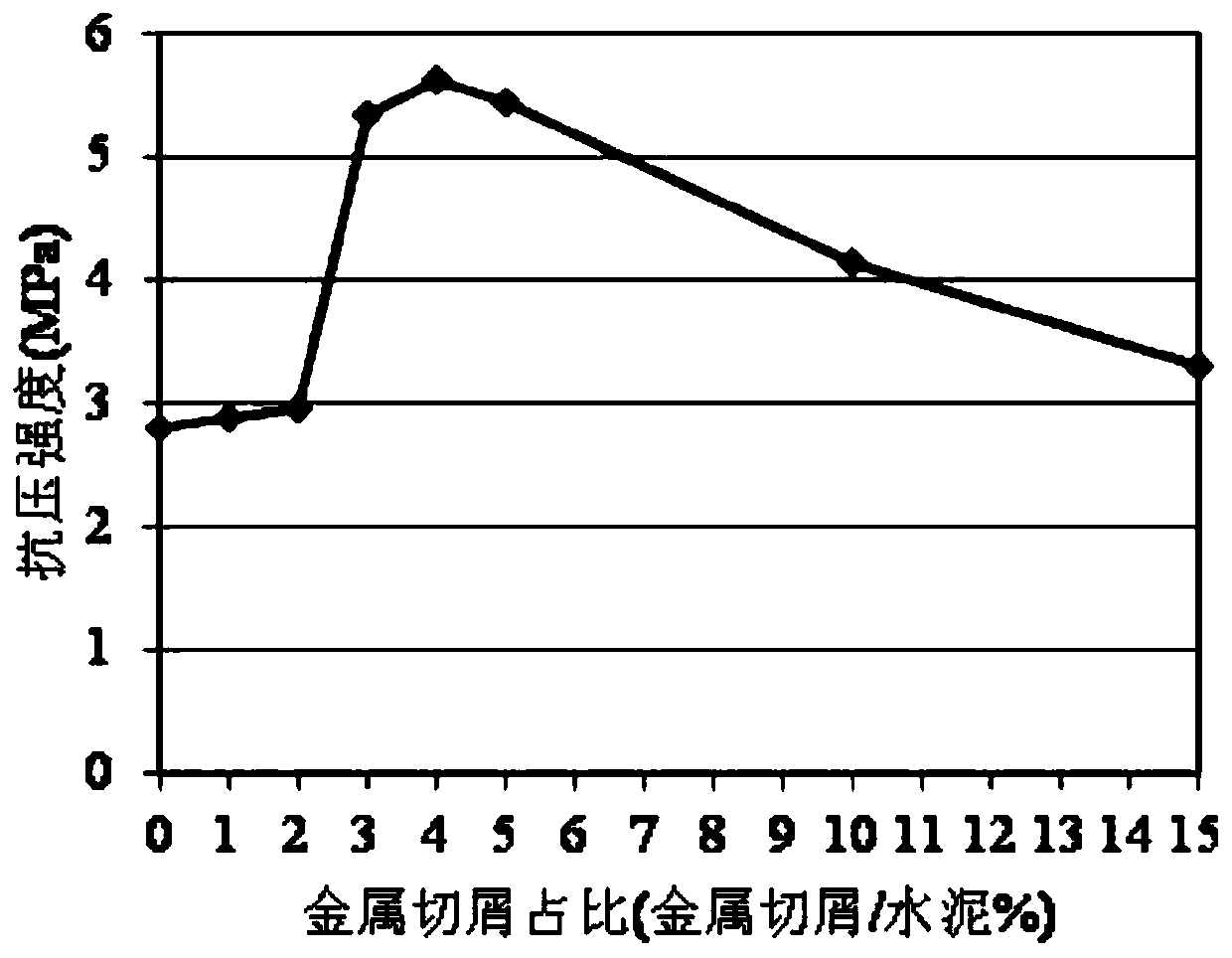

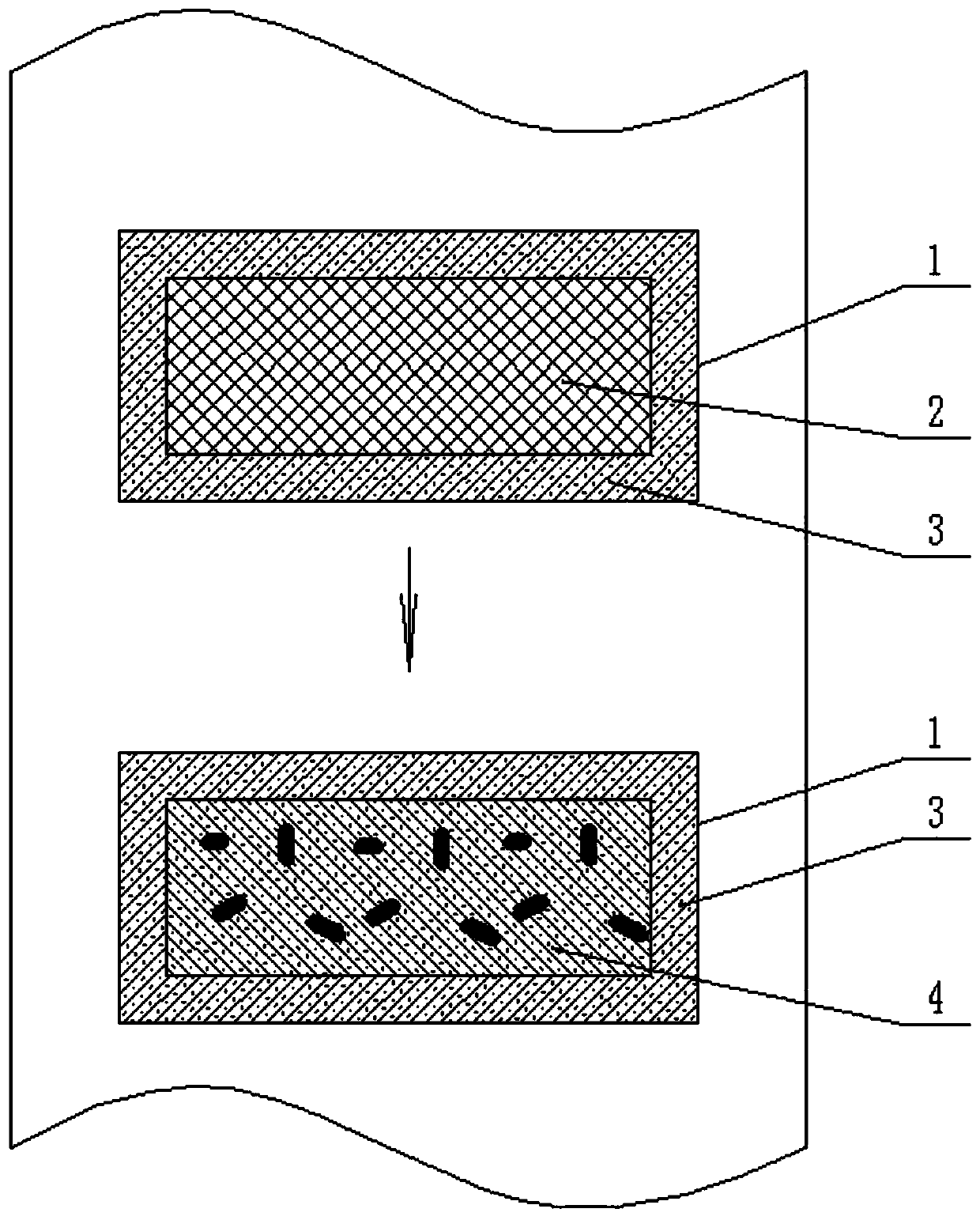

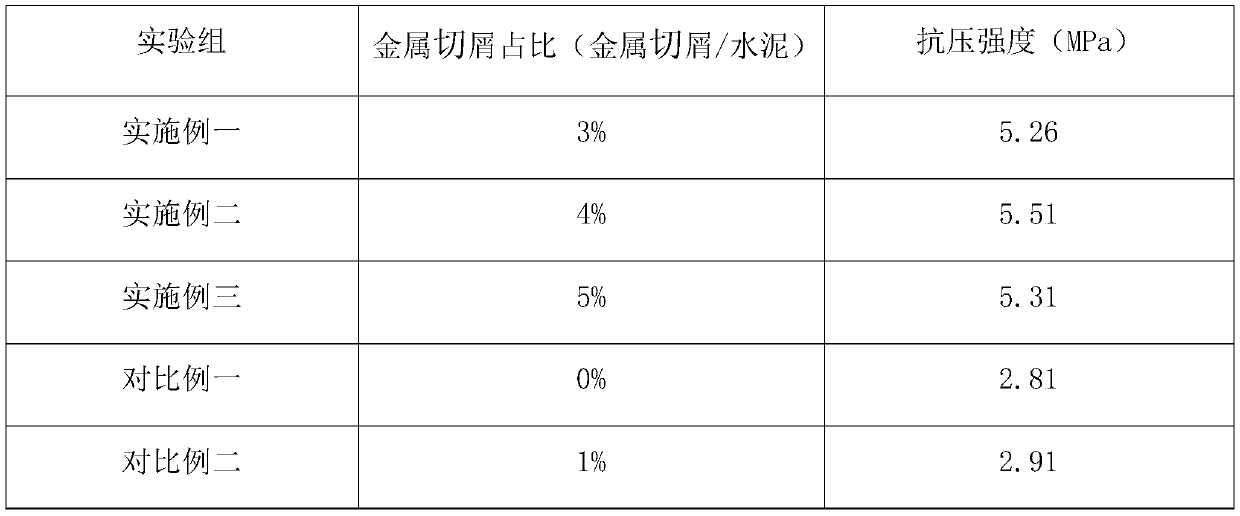

Reinforced concrete hollow brick and preparation method thereof

InactiveCN110845186AHigh compressive strengthReduce pollutionConstruction materialSolid waste managementReinforced concreteBrick

The invention discloses a reinforced concrete hollow brick. The reinforced concrete hollow brick comprises the following raw materials in parts by mass: 20-30 parts of cement; 120 to 180 parts of sand; 10 to 30 parts of water; and 0.8 to 1.2 parts of metal chips. The invention also relates to a preparation method of the reinforced concrete hollow brick. The method comprises the following steps: S1, the following raw material in parts by mass: the 20-30 parts of cement; 120 to 180 parts of sand; 10 to 30 parts of water and 0.8 to 1.2 parts of metal chips are prepared; s2, the metal cuttings aresubjected to breaking treatment, so that the length range of the metal cuttings is within 5-20 mm; s3, the metal chips are subjected to degreasing treatment; and S4, the cement, sand, the metal chipsand water are fully stirred and then conveyed into a mold, and the mixture is compacted and fired into bricks. According to the concrete hollow brick, the metal chips are added, the metal chips are uniformly distributed in the concrete hollow brick in a physical form, and a compressive strength test shows that the compressive strength of the concrete hollow brick added with the metal chips is obviously improved.

Owner:QILU UNIV OF TECH

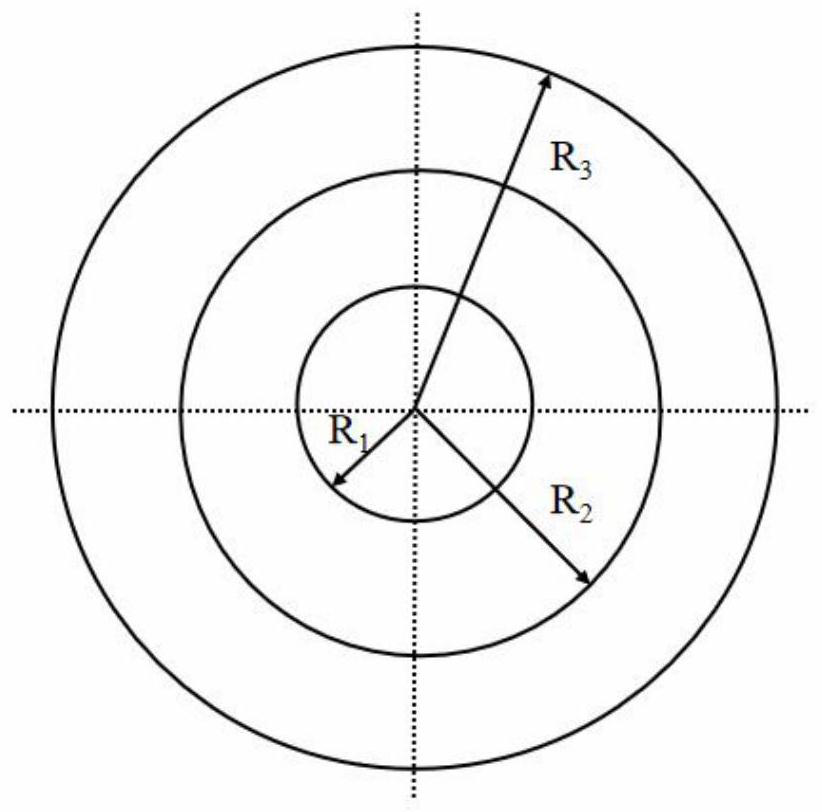

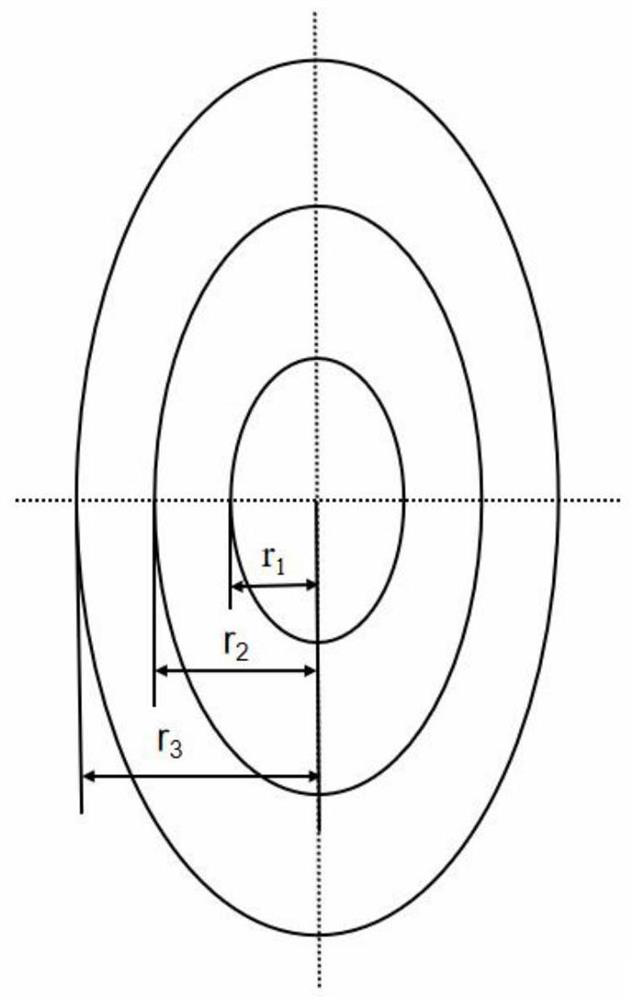

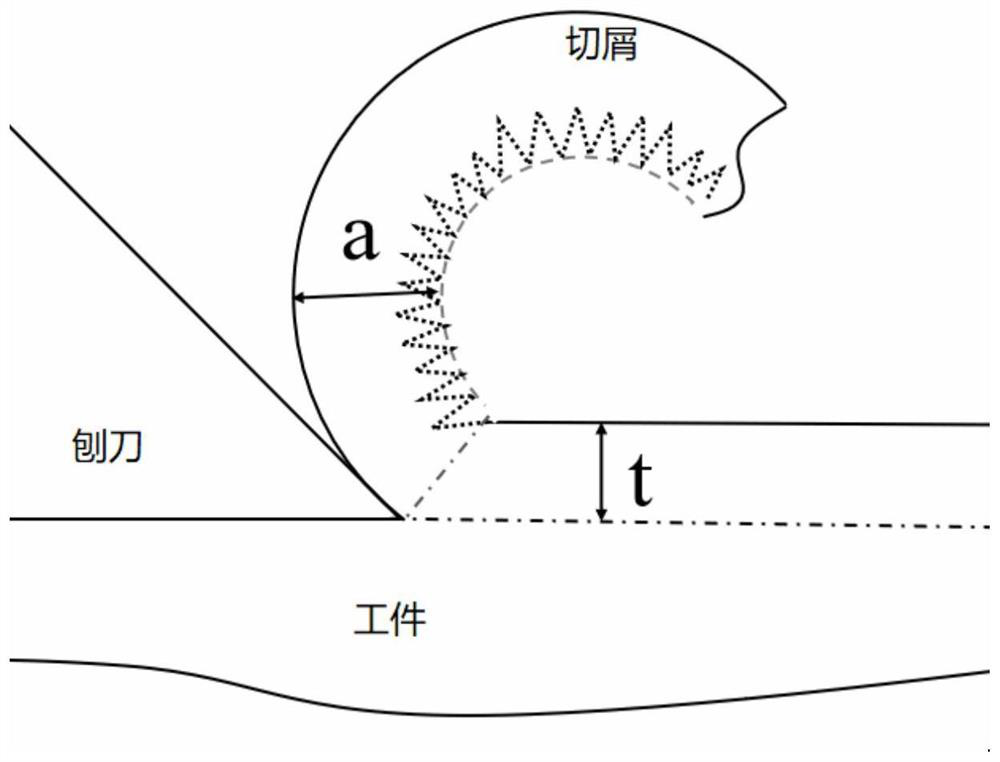

Method for measuring chip deformation

ActiveCN113587853ASimple structureEasy to observeMechanical thickness measurementsUsing optical meansMetallic materialsEngineering

Owner:HANGZHOU DIANZI UNIV +1

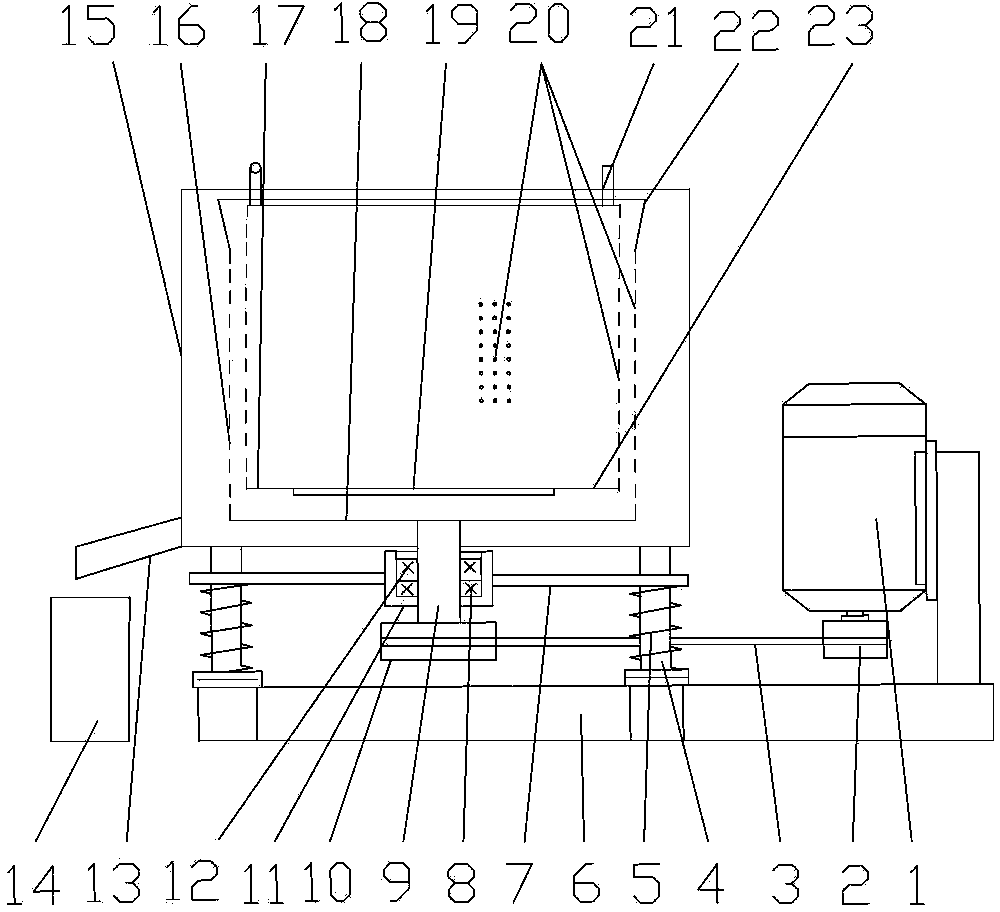

Machine tool chip removal and cleaning device for numerical control machine tool

ActiveCN112792607AEasy to handleEasy to storeMaintainance and safety accessoriesPressesNumerical controlMetal swarf

The invention discloses a machine tool chip removal and cleaning device for a numerical control machine tool. The device comprises a base plate, wherein a main body shell is fixedly arranged at the upper end of the base plate; a feeding port is arranged in the upper end of the right side of the main body shell; a chip remover is arranged at the upper side of the feeding port; the chip remover is arranged at the right side of the main body shell; discharging openings are arranged in the front side and the rear side of the lower end of the main body shell correspondingly; guide rails are integrally arranged at the left side and the right side of each discharging opening correspondingly; blocking columns are arranged at the lower sides of the discharging openings correspondingly; baffles are arranged at the outer sides of the discharging openings correspondingly; the baffles and the guide rails form sliding connection structures correspondingly; and lifting plates are integrally arranged at the upper ends of the baffles. According to the machine tool chip removal and cleaning device for the numerical control machine tool, chips can be conveniently, safely and efficiently treated, metal chips are prevented from scratching workers, the space can be greatly saved, the chips can be conveniently stored, transported and recycled, and the economic benefits are improved.

Owner:广东铨冠智能科技有限公司

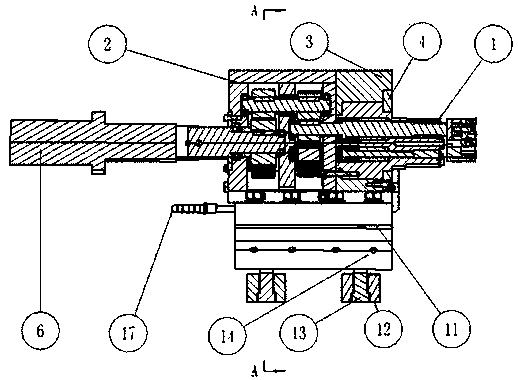

Special device for machining non-circular holes by utilizing common lathe through improvement

PendingCN107824891AImprove processing efficiencyReduce the cost of the whole machineMaintainance and safety accessoriesEngineeringUltimate tensile strength

The invention relates to the technical field of machining, and particularly to a special device for machining non-circular holes by utilizing a common lathe through improvement. The special device ischaracterized in that the main shaft of the lathe serves as the power input part, the rotating speed is adjusted through a speed regulating mechanism of the lathe, the power of the device is from themain shaft of the common lathe, the power and torque are transmitted out through a gear box assembly and a tool holder assembly of the device, three tool bits in the tool holder assembly are driven torotate synchronously, so as to perform cutting machining on workpieces, and non-circular hoes required by parts can be obtained through one-time cutting of cutting tools; and besides, during the cutting machining process, a cooling liquid nozzle of the lathe is connected onto the device through a pipe, so that the machined workpieces and tools can be cooled, and metal filings are taken away. According to the special device for machining non-circular holes by utilizing the common lathe through improvement, the internal non-circular holes in the parts needing to be machined can be obtained by one-time machining, the operative difficulty and labor intensity of workers and the production cost are greatly reduced, and meanwhile the production efficiency and product quality are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

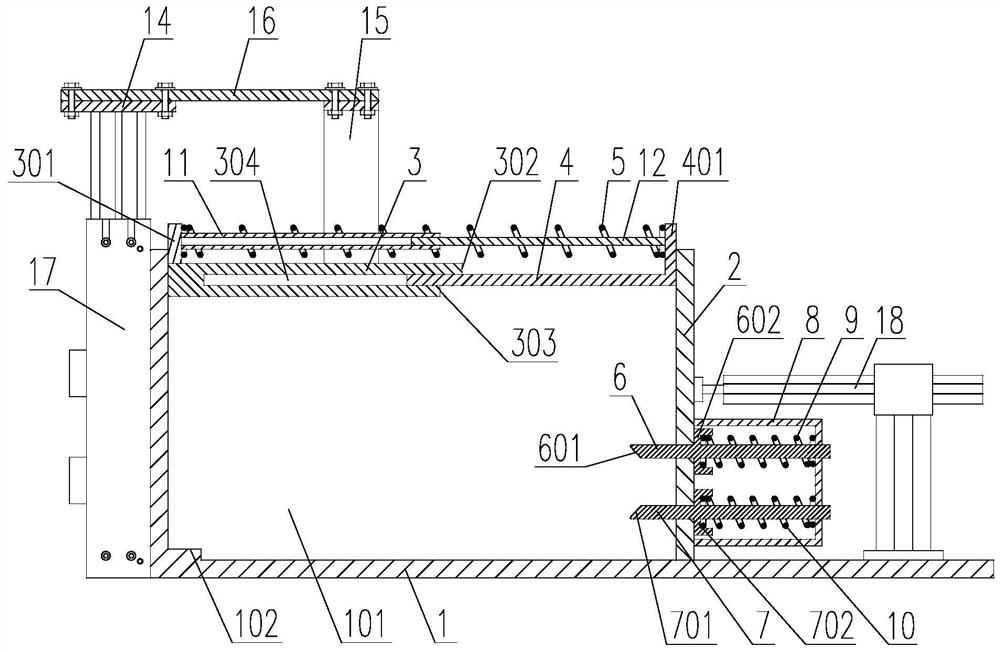

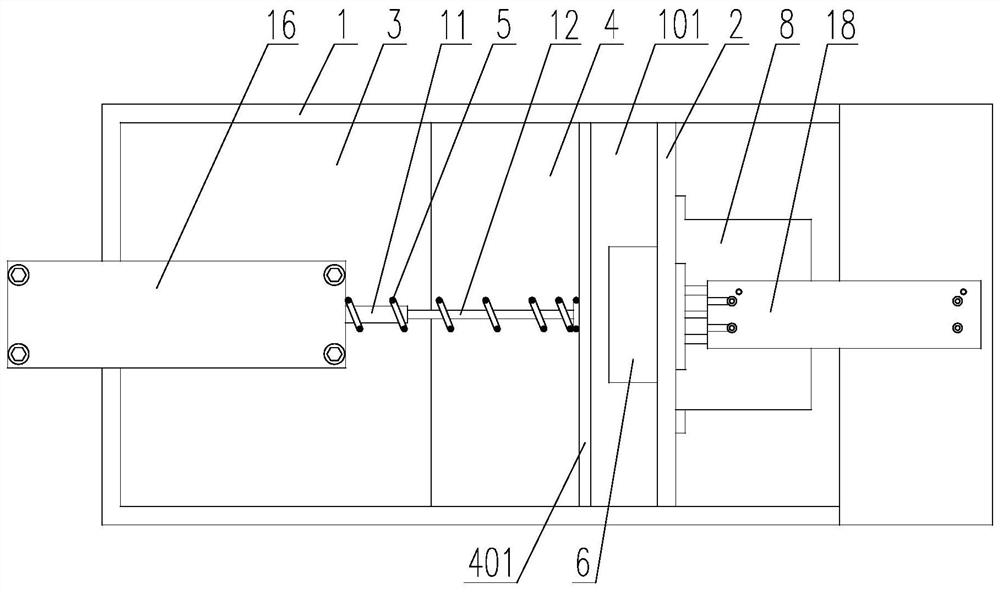

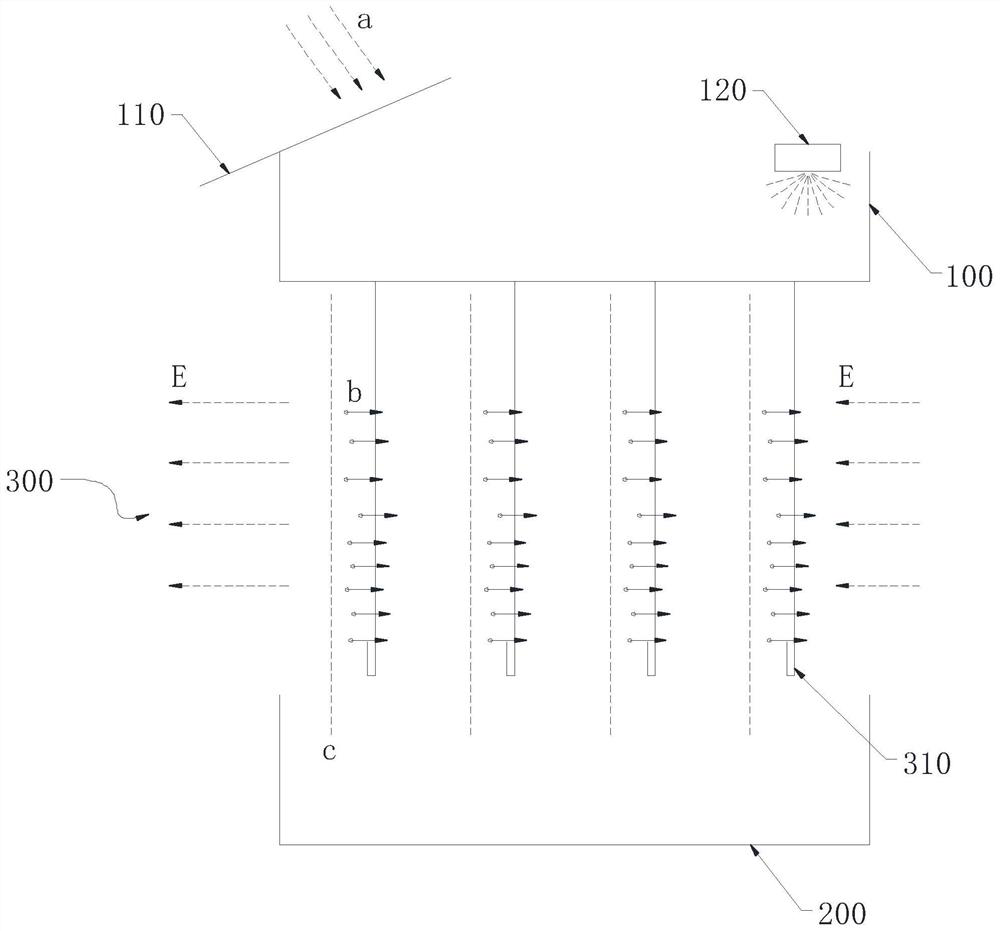

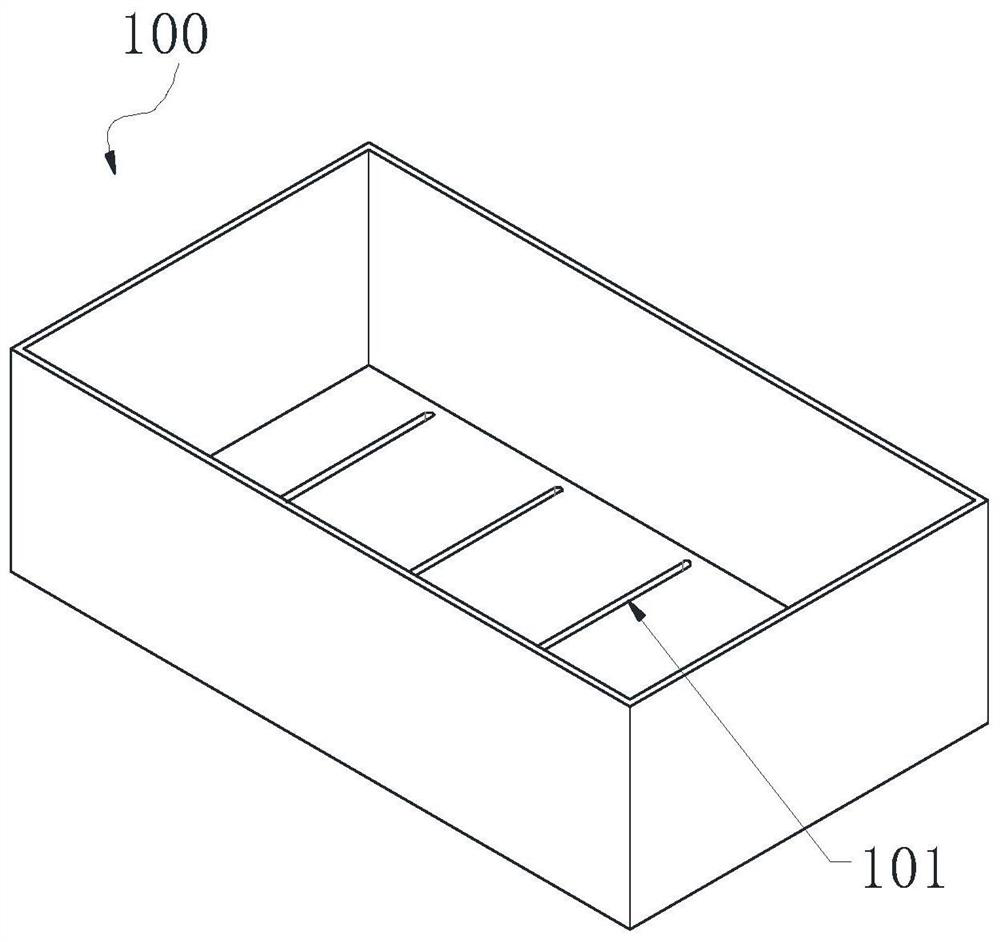

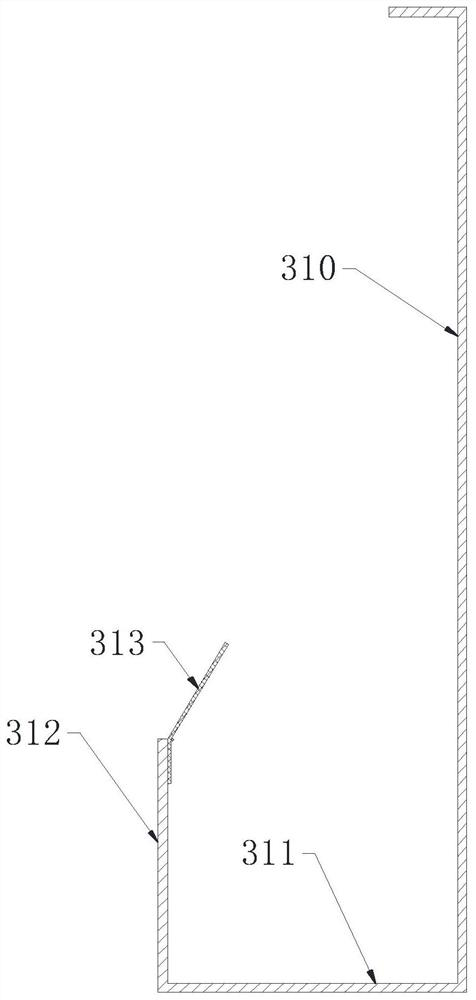

Chip liquid cooling and separating device and five-axis machining center

PendingCN113649852ALower requirementAvoid prone to cloggingTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsMetal swarfMechanical engineering

The invention discloses a chip liquid cooling and separating device and a five-axis machining center comprising the same. The chip liquid cooling and separating device sequentially comprises a primary screen, a first liquid collecting box, an electric field area and a second liquid collecting box from top to bottom; the primary screen is used for primarily screening out chips, with large particle sizes, carried in chip liquid; the first liquid collecting box is an insulator, the first liquid collecting box is used for collecting the chip liquid screened by the primary screen, an electron gun for emitting electrons to the chip liquid to enable the metal chips to form charged particles is arranged in the first liquid collecting box, and liquid leakage holes are further formed in the bottom of the first liquid collecting box; the electric field area provides any electric field which is not parallel to a water curtain. According to the chip liquid cooling and separating device and the five-axis machining center, the requirement on the screen can be greatly reduced, and meanwhile, the conditions of blockage and low efficiency caused by the fact that the screen is used only can be avoided; the separation efficiency and the separation rate of the metal chips in the chip liquid can be improved through the electric field; and the heat dissipation area of the cutting fluid is multiplied by the water curtain formed during electric field separation, so that the heat dissipation efficiency is greatly improved.

Owner:安徽省安达兴智能装备有限公司

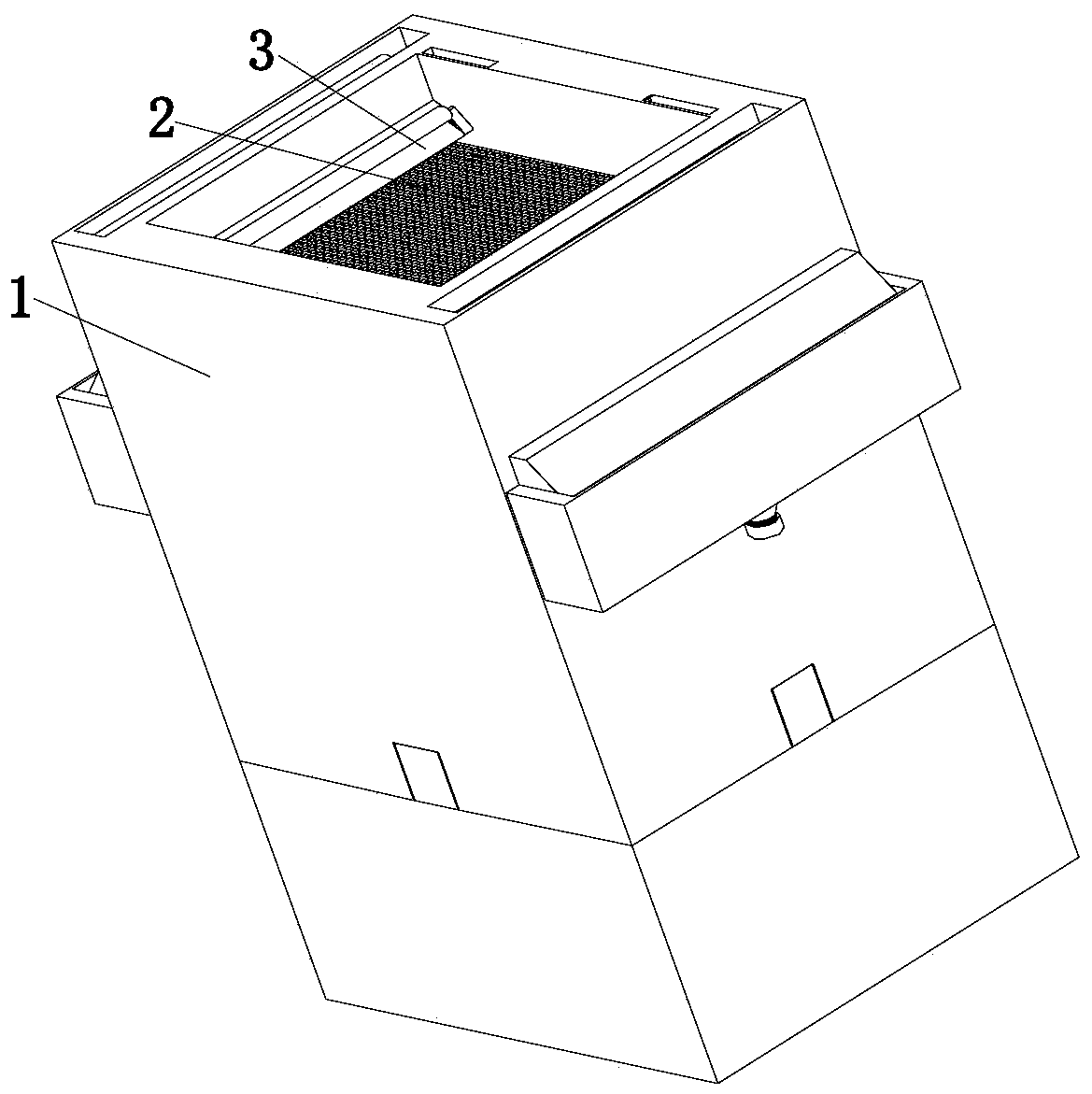

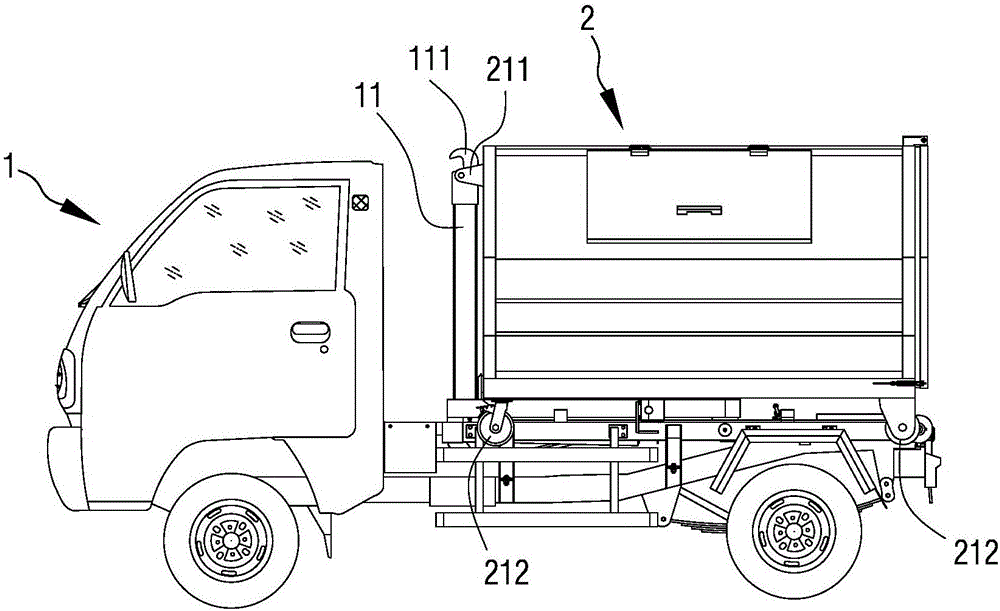

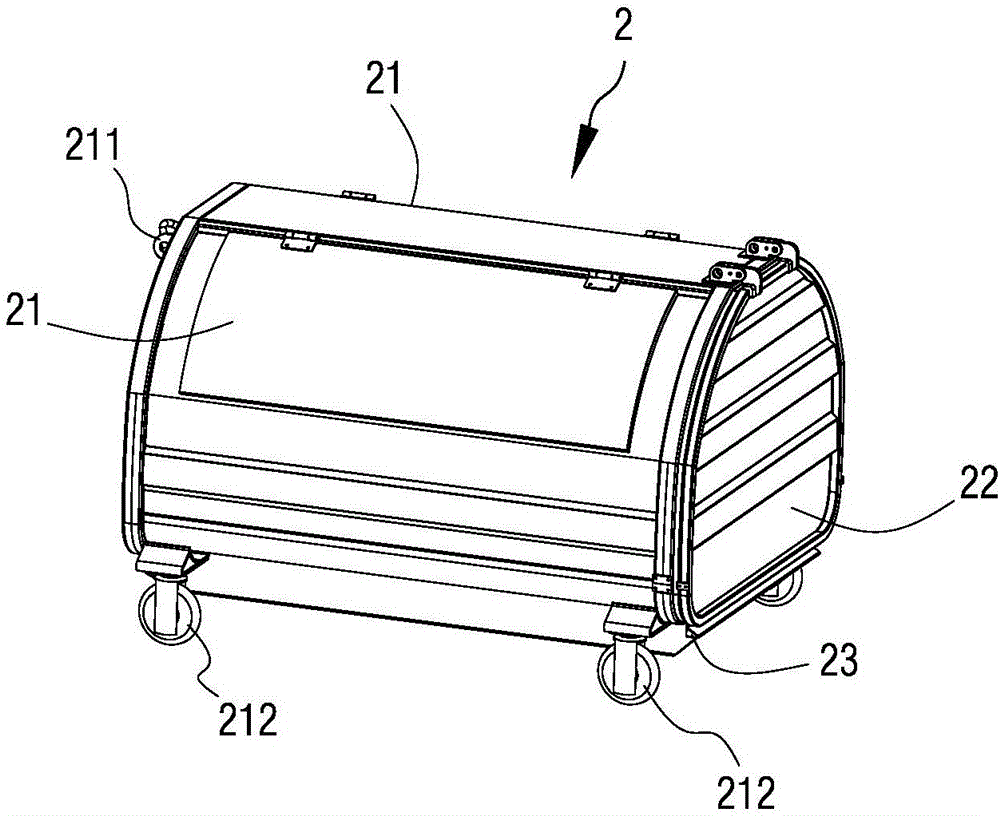

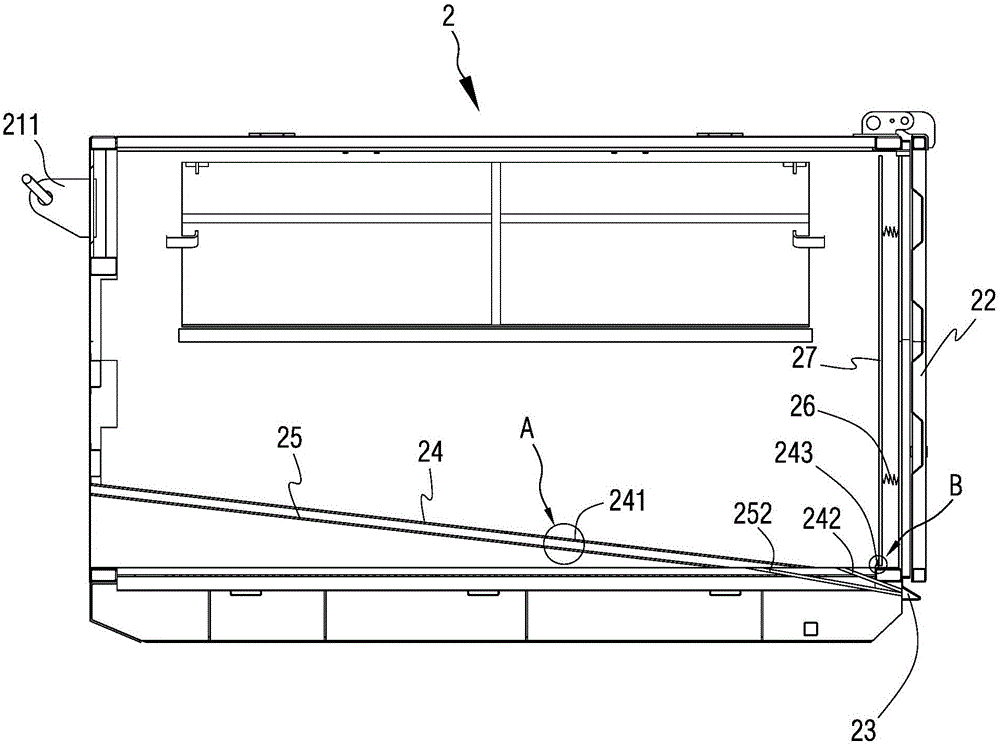

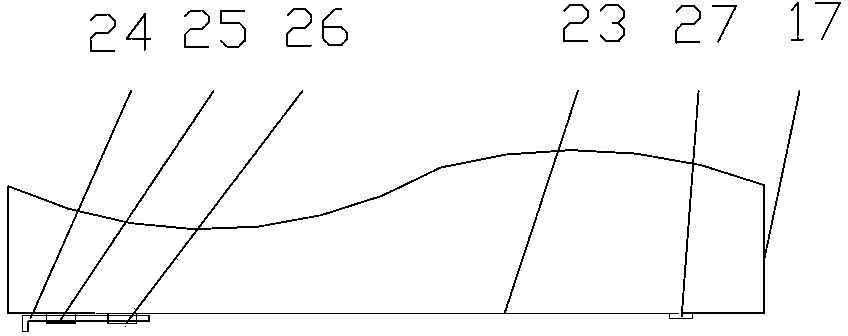

Metal boring collecting box for collecting and transporting metal borings

ActiveCN106275985AEasy to collectAvoid pollutionLarge containersRefuse receptaclesEngineeringMetal swarf

The invention provides a metal boring collecting box for collecting and transporting metal borings. The metal boring collecting box can be used for collecting metal borings. The collecting box (2) is of a closed box structure, two overturning covers (21) are hinged to the two sides of the top of the collecting box (2), a tail door (22) is arranged at the back portion of the collecting box (2), a cutting liquid collecting box (23) is arranged at the portion, close to the tail door (22), of the bottom of the collecting box (2), and the upper portion of the tail door (22) is hinged to the top of the collecting box. According to the metal boring collecting box for collecting and transporting metal borings, collecting of metal borings is improved, the environment pollution in the collecting and transferring processes is avoided, working efficiency is improved, and the investment in the aspect of infrastructure construction at a boring piling place is reduced.

Owner:SHAN DONG DA YUN HE TOU ZI YUN YING YOU XIAN GONG SI

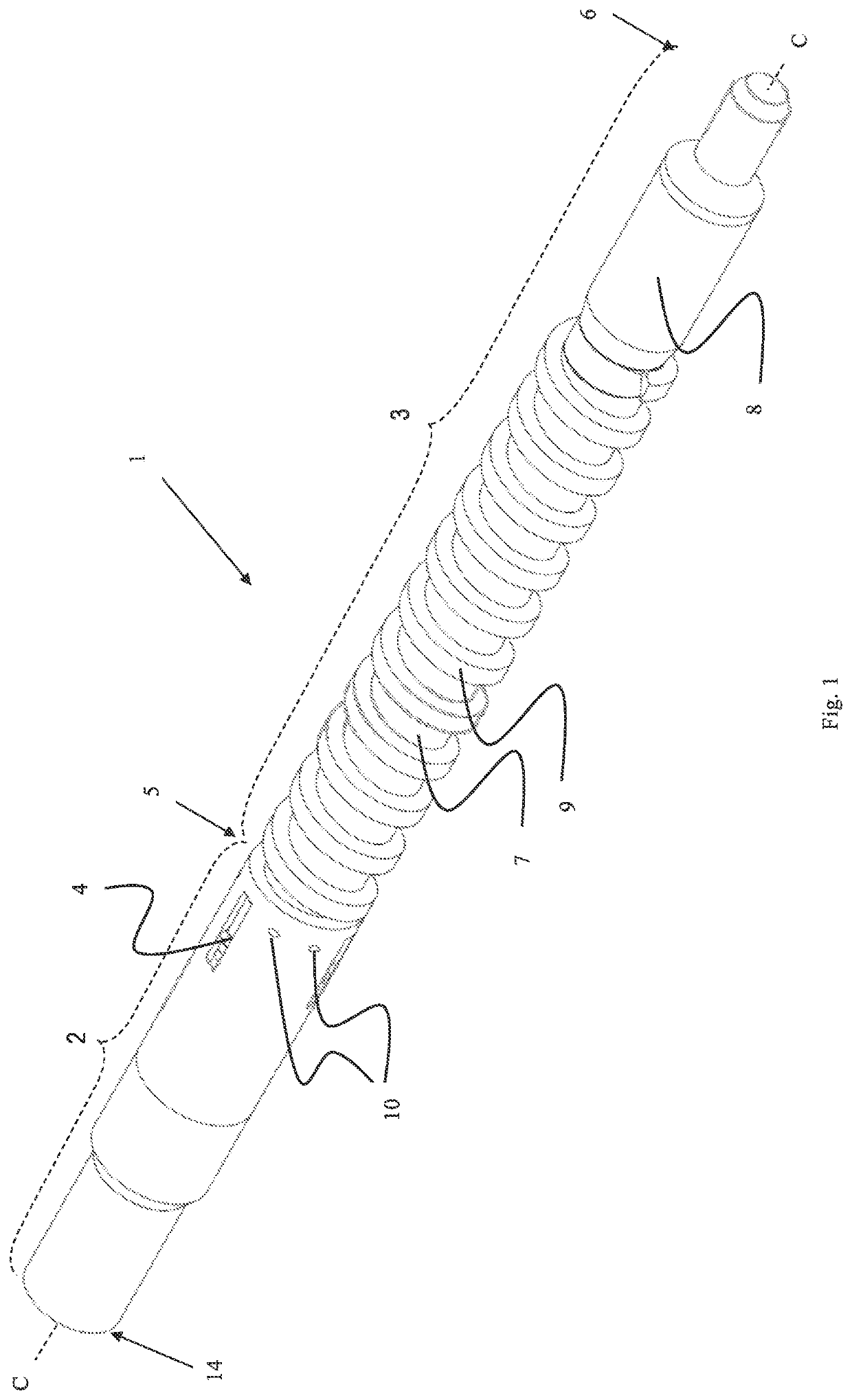

Milling tool

ActiveUS11371315B2Eliminate magnetic attractionIncrease distanceCleaning apparatusSealing/packingMilling cutterEngineering

The present invention provides a milling tool (1) for a wellbore, comprising a milling section (2) and a metal cuttings removal section (3), the milling section (2) comprises radially arranged milling elements (4); and the metal cuttings removal section (3) has a first end (5) and a second end (6) and comprises a cylinder-shaped magnetic element (7), a rotation generating device (8) and a helix-shaped longitudinal guide element (9), wherein the first end (5) is connected to the milling section; the helix-shaped longitudinal guide element (9) is arranged around the cylinder-shaped magnetic element (7); the rotation generating device (8) is operably connected to the cylinder-shaped magnetic element (7) or the helix-shaped longitudinal guide element (9); wherein the cylinder-shaped magnetic element and the helix-shaped longitudinal guide element (9) are rotatable relative to each other around a common centreline (C), and configured such that metal cuttings accumulating on the cylinder-shaped magnetic element during use is guided by the helix-shaped longitudinal guide element towards the second end (6) of the metal cuttings removal section when the rotation generating device is operated.

Owner:SWARFIX AS

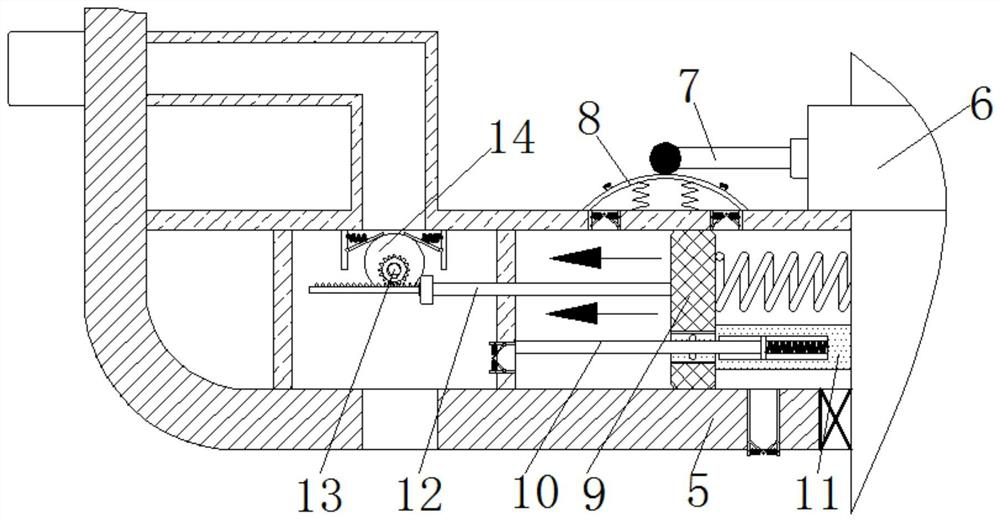

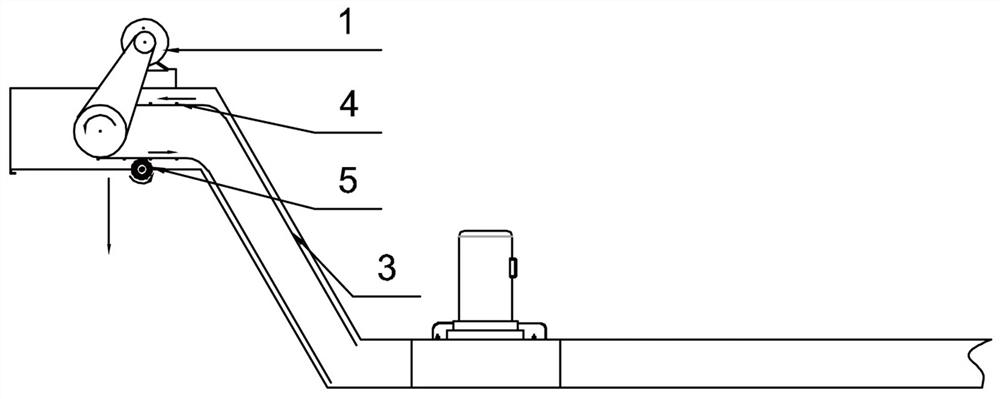

Intelligent chip removal device for metal chip cutting machine tool and control method thereof

PendingCN113909988AReduced risk of cloggingReduce risk of damageMaintainance and safety accessoriesComputer hardwareMetal swarf

The invention relates to an intelligent chip removal device for a metal chip cutting machine tool. The intelligent chip removal device is characterized in that a chip removal channel is internally connected with a cut chip conveying belt through a conveying driving device, one end of the chip removal channel is positioned at a horizontal low position and is provided with a cut chip inlet, and the other end of the chip removal channel is positioned at a high position and is provided with a cut chip outlet; an opening is formed in the outer wall, located at the horizontal low position, of the chip removal channel, a flow box with a flow guide channel is arranged at the opening, the height of the flow box is consistent with that of the opening, and the upper edge of the opening is higher than that of cut chip mixed liquid in the chip removal channel; and a first-stage filter screen and a second-stage filter screen are sequentially arranged in the flow guide channel of the flow box, a circulating pump is arranged at the top of the flow box, and a working part at the bottom of the circulating pump is inserted into the flow guide channel. The chip removal device has the characteristics of automatically, efficiently and timely cleaning chips in the cutting fluid and avoiding blockage of the chip removal device, and is a novel intelligent chip removal device for the machine tool.

Owner:SHENYANG MASCH TOOL CO LTD

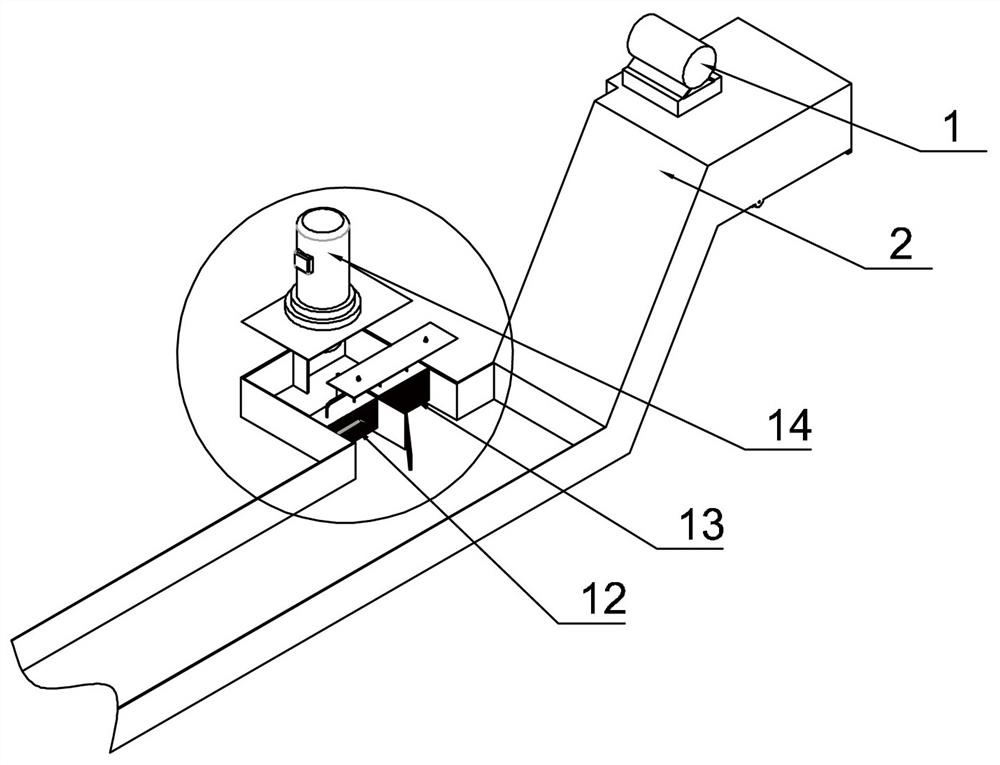

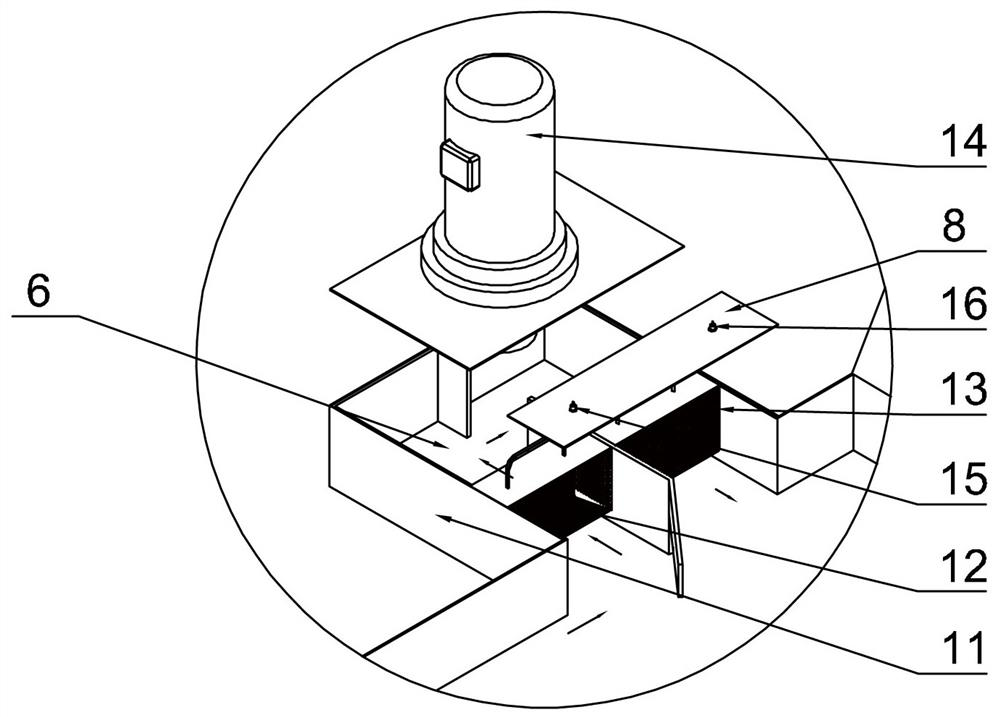

Method and apparatus for milling a window in casing

PendingUS20220170336A1Strength is not impairedAvoid many problemsBorehole/well accessoriesThermodynamicsCoiled tubing

A process is described for milling a window in the casing (2) of an oil or gas producing well, for example in order to drill a lateral well branching off from the main well. A wireline milling tool is first used, in a relatively low cost operation, to create a small window (14) or notch in the casing (2). Provided a small window (14) or notch can be created successfully, an expensive heavy duty coil tubing milling operation can then be conducted to create the full window, some 4-6 feet in length. Previous attempts to create a full window using wireline tools have encountered difficulties due to there being no circulating drilling fluid to remove metal swarf and due to the need for the tool to be supported by casing during the milling operation, when the integrity of the casing is being compromised by drilling the window. The proposed wireline tool has an actuator (4) with relatively small stroke length and a relatively small container (8) to manage the swarf produced by the milling process. (FIG. 2).

Owner:CONOCOPHILLIPS CO

Waste box for collecting metal chips

InactiveCN112496851AAchieve extrusionMeet emission standardsMaintainance and safety accessoriesStructural engineeringMetal swarf

The invention discloses a waste box for collecting metal chips. The waste box comprises a rectangular box body, wherein clamping plates are inserted into the two side walls of the box body, the upperends of the clamping plates are each bent to form a horizontal baffle plate, a rectangular lower supporting frame is inserted and fixed on the box body, and gaps are formed between left and right frames of the lower supporting frame and the side walls of the box body. T-shaped driving plates are inserted into the left and right frames of the lower supporting frame, the inner side edges of the driving plates are fixed to the clamping plates, each driving plate is composed of a horizontal part and a vertical part, inclined guide grooves are formed in the horizontal parts of the driving plates, vertical guide shafts are inserted into the guide grooves, the two ends of each guide shaft penetrate through driving rods and are hinged to guide wheels through bearings, the guide wheels abut againstthe inner walls of the left side and the right side of the lower supporting frame, and the driving rods are parallel to the left side wall and the right side wall of the box body and penetrate through the lower supporting frame to be fixed with pull rods.

Owner:咸宁新创工业设计有限公司

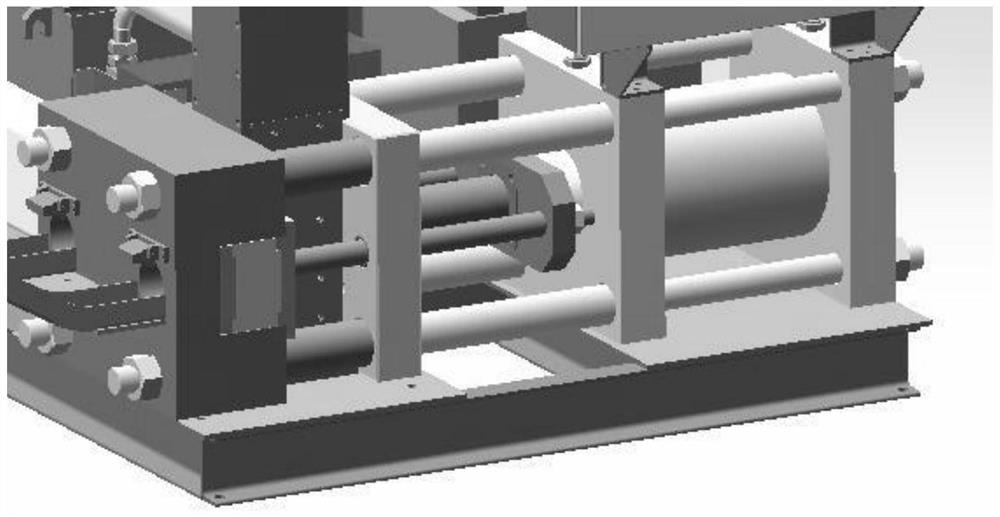

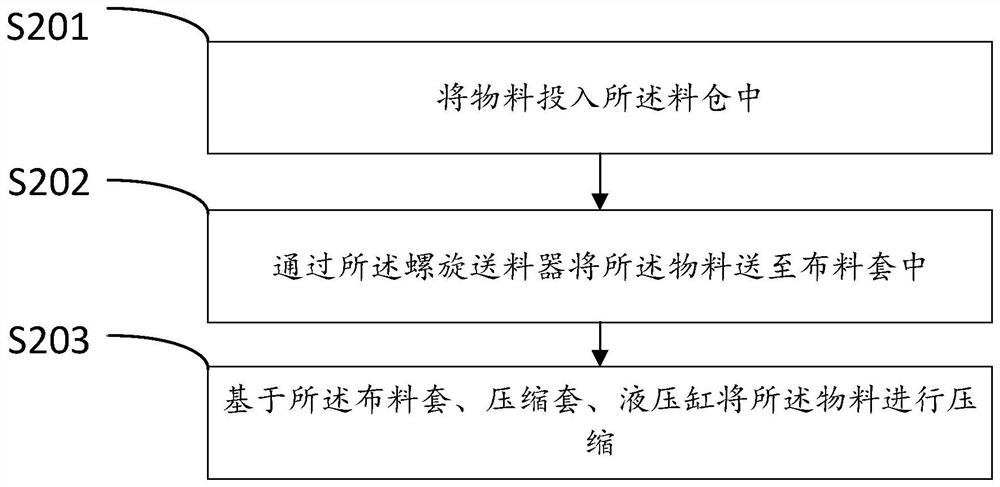

Compression molding method and device for metal chip briquetting machine

InactiveCN112477253ASo as not to damageExtended service lifePressesCompression moldingHydraulic cylinder

The invention discloses a compression molding method and device for a metal chip briquetting machine. The method is applied to a compression molding device comprising a stock bin, a spiral feeder, a material distribution sleeve, a compression sleeve and a hydraulic cylinder, and comprises the following steps: putting materials into the stock bin, conveying the materials into the material distribution sleeve through the spiral feeder, and compressing the materials based on the material distribution sleeve, the compression sleeve and the hydraulic cylinder. The stable compression of the materials is achieved, the service life of the device is prolonged, and the user experience is improved.

Owner:廊坊市泽田依诺机械设备有限公司

Liquid separating device capable of separating liquid from metal chip materials

ActiveCN102721268BWon't wasteWill not polluteDrying machines with non-progressive movementsAdhesive beltHydrocotyle bowlesioides

The invention relates to a liquid separating device capable of separating liquid from metal chip materials. Four positioning guide columns and a motor are installed on a base. A spring respectively sleeves each positioning guide column. The upper end of each positioning guide column is sequentially provided with a stander and a circular outer barrel. A bearing seat with a bearing A and a bearing B in the middle part is installed in the middle part of the stander, and a main shaft is installed between the bearing A and the bearing B. The lower part of the main shaft is connected with the motor through a triangular adhesive tape. A porous circular barrel is fixedly installed on the main shaft. A porous movable suspension barrel is movably installed in the middle of the porous circular barrel, and the bottom of the porous movable suspension barrel is provided with a movable soleplate. A suspension ring is installed on the porous movable suspension barrel. Both the porous circular barrel and the porous movable suspension barrel are provided with a plurality of liquid holes. A liquid holding barrel is arranged below a liquid flow-out pipe of the circular outer barrel. When the liquid separating device is used for separating the liquid from the metal chip materials, less vapor and less smoke, which are mixed with hydrocarbon, are produced, the heat energy is not wasted, the environment is not polluted, and the body health of the operation personnel is not damaged. The liquid separating device can be used for recycling the mixed liquid of cutting liquid and lubricating oil and for further processing and utilizing the metal chip materials.

Owner:KEHUA HLDG

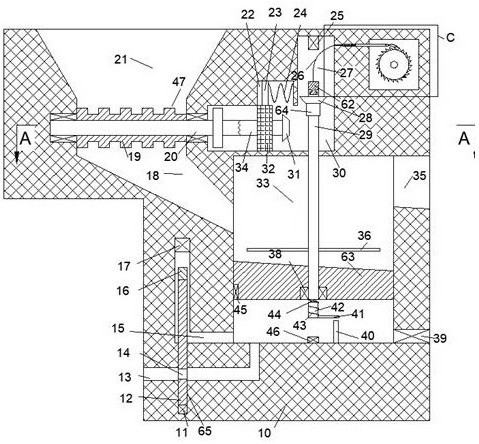

A device for crushing and removing oil from lathe metal chips

ActiveCN111389500BEfficient storageEfficient transportCleaning using liquidsGrain treatmentsProcess engineeringMetal swarf

The invention discloses a crushing and oil-removing device of lathe metal cutting chips. The crushing and oil-removing device of lathe metal cutting chips comprises a machining box. A feeding hopper is arranged in the left side on the upper surface of the machining box. The lower side of the feeding hopper communicates with a crushing cavity. A first rotating shaft is rotationally connected into the left wall and the right wall of the crushing cavity in a front-back symmetry manner. A shearing cylinder used for shearing and crushing the cutting chips is fixedly connected to the first rotatingshaft. The cutting chips are crushed, so that the cutting chips can be effectively stored and transported, and the cutting chip storage amount of a unit area can be increased. By removing oil of the cutting chips, cooling liquid and other oil type matter attached to the cutting chips can be recycled and reutilized, so that better economical efficiency and environmental friendliness can be achieved. The cutting chips obtained after oil removal can have a higher price during recycling, and the quality of the cutting chips is better when used as a metal raw material.

Owner:高唐融知融智科技服务有限公司

Cutting fluid separation equipment for numerical control machine tool

PendingCN114632634AExtended service lifeEasy to separateCentrifugesMaintainance and safety accessoriesNumerical controlDrive shaft

The invention discloses numerical control machine tool cutting fluid separation equipment which comprises a separation barrel, a connecting base fixedly connected to the bottom of the separation barrel, a plurality of reinforcing ribs fixedly connected to the surface of the connecting base, a drainage pipe fixedly connected to the surface of the separation barrel, a feeding hopper fixedly connected to the surface of the separation barrel, and a supporting plate fixedly connected to the feeding hopper. A transmission shaft is rotatably arranged at the bottom of the supporting plate, a limiting ring is fixedly connected to the inner wall of the separation cylinder, a separation funnel is rotatably arranged in the limiting ring, and a plurality of drainage holes are formed in the separation funnel; compared with the prior art, the welding ring can be driven to rotate through the transmission shaft, so that the separation funnel does circular motion, cutting fluid and metal cuttings can be rapidly separated, the situation that rust is caused due to the fact that part of the cutting fluid remains on the surfaces of the metal cuttings is reduced, and the service life of the cutting fluid can be prolonged; and good economic benefits are achieved.

Owner:方卫国

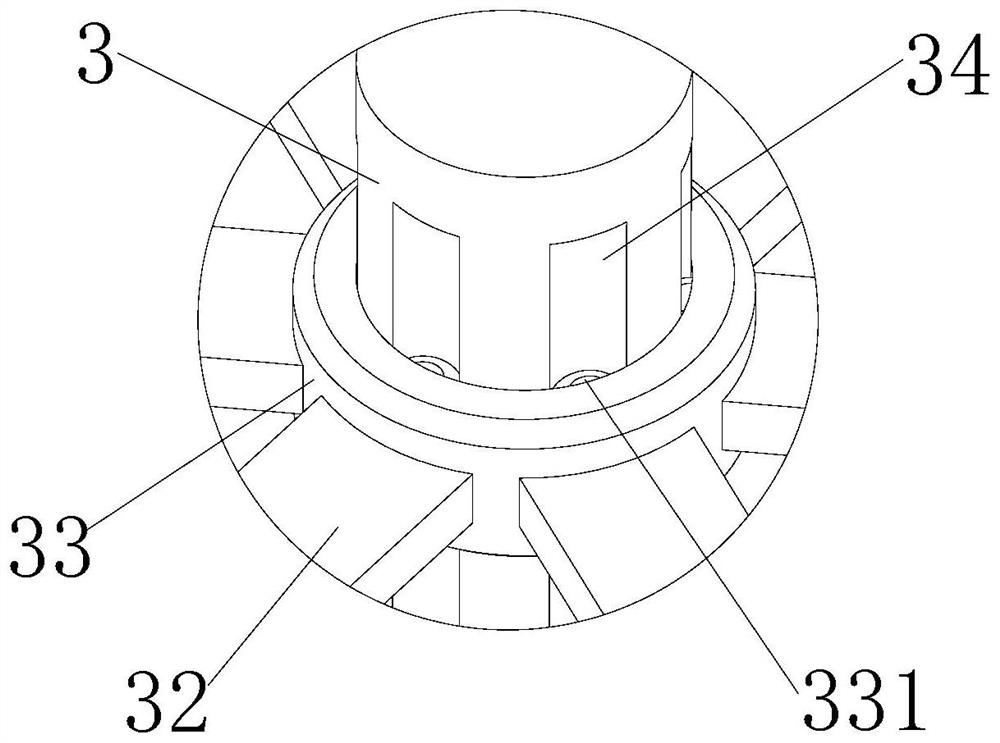

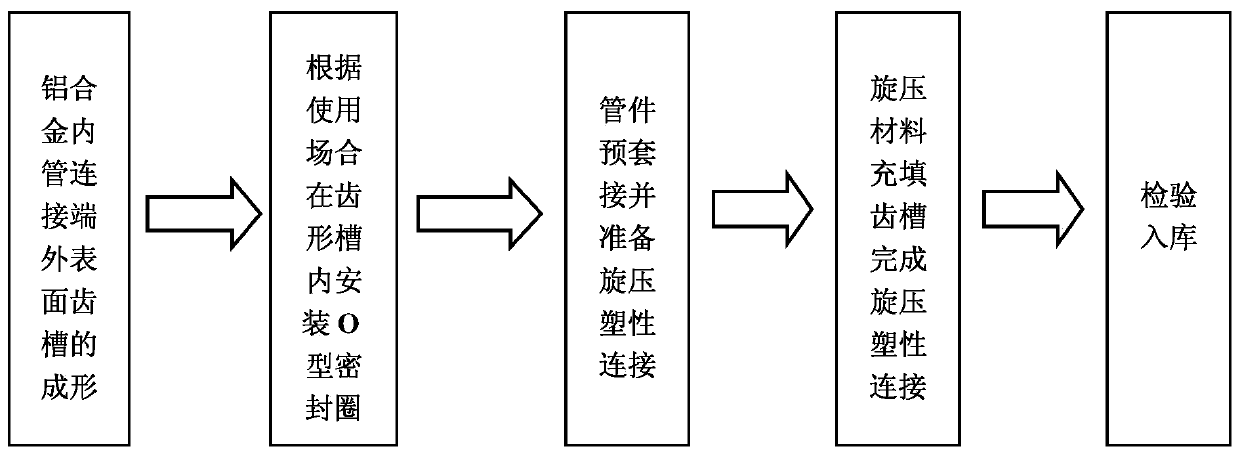

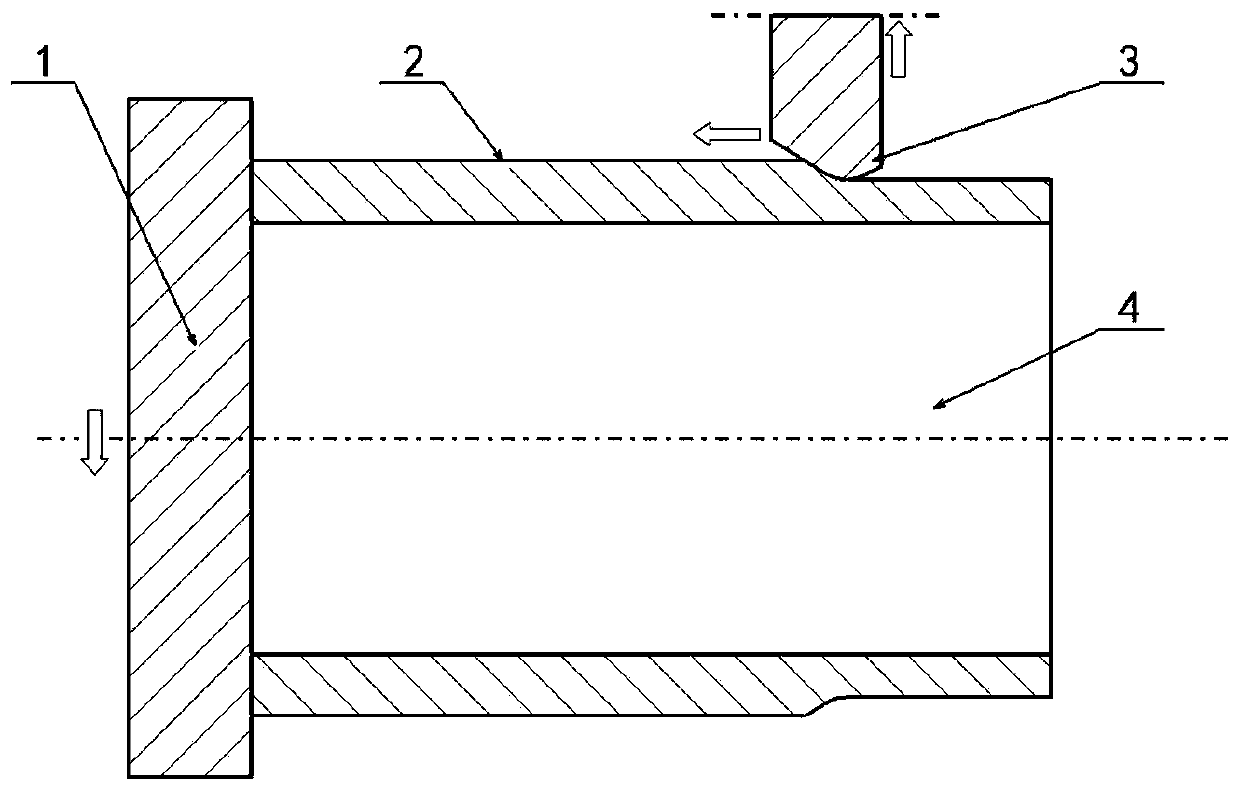

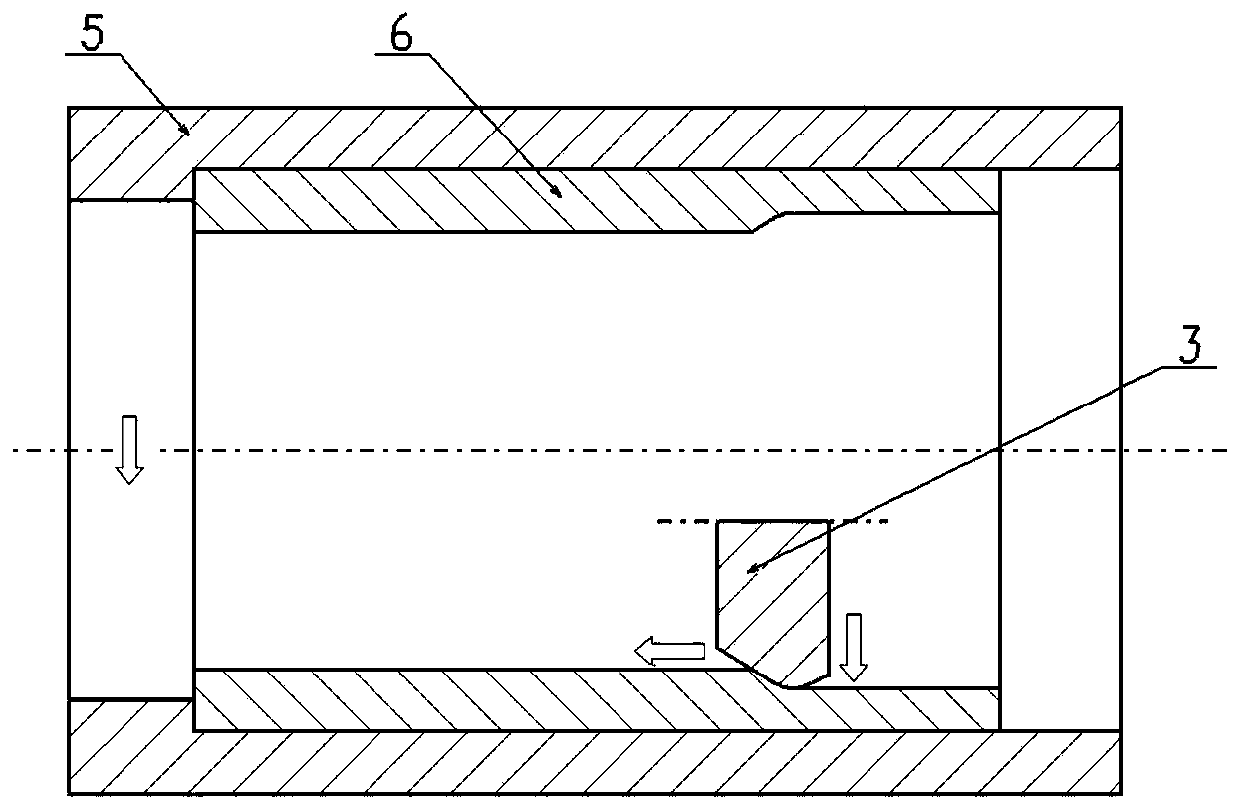

A plastic connection method of aluminum alloy pipe fittings based on spinning

ActiveCN108480970BAchieve destructionReliable connection of chip-free green fittingsMetal working apparatusNon-disconnectible pipe-jointsPipe fittingMetal swarf

The invention discloses an aluminium alloy pipe fitting plastic connection method based on rotary extrusion. According to the method, tooth form grooves are formed in the outer surface, for outward rotation connection, of the connection end of a small-diameter pipe fitting by an inward rotation technology; O-shaped seal rings are mounted in the grooves; an aluminium alloy inner pipe and an aluminium alloy outer pipe are mounted on a rotary extrusion machine tool in a pre-sleeving manner; metal plastic flow deformation is carried out on the aluminium alloy outer pipe by an outward rotation technology to fill the tooth form grooves and the O-shaped seal rings are pressed to realize sealing connection of the pipe fittings. Compared with the traditional aluminium alloy pipe fitting connectionmethod, the aluminium alloy pipe fitting plastic connection method based on rotary extrusion has the advantages that since the rotary extrusion technology belongs to local point loading, no metal cuttings are generated and metal flow line is not destroyed, the connection process saves labor and reduces damage, and equipment, tooling and molds are simple; and during connection, the plasticity of metal is fully utilized to fill the tooth form grooves and the O-shaped seal rings are pressed, thus achieving environment-friendly and reliable pipe fitting connection with no cuttings and small damage.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Abrasion detection device of mixed type rotary cutter

Owner:BEIHANG UNIV

A front-end high-efficiency slag removal protection device for the coolant circulation pump of a CNC machine tool

ActiveCN110653660BSlow down the flowAchieve separationMeasurement/indication equipmentsMaintainance and safety accessoriesNumerical controlSlag

The invention relates to the field of numerical control machine tools, and discloses a front-end high-efficiency slag removal protection device for a coolant circulation pump of a numerical control machine tool, which includes a first water inlet pipe, and the water inlet end of the first water inlet pipe is located at the bottom of the coolant water storage tank Above, the water outlet end of the first water inlet pipe communicates with the lower part of the slag removal box, and the first water inlet pipe communicates with the lower part of the slag removal box through a one-way valve, and one end of the one-way valve extends to the slag removal box internal. A liquid outlet hopper with a spiral structure guide plate is installed inside the slag removal box, so that the cooling liquid flowing out of the liquid outlet hopper flows into the centrifugal cavity in a rotating state. Due to the large inner diameter of the centrifugal cavity, the cooling liquid is here The flow velocity at the center decreases, and the heavy metal chips are gradually brought to the inner wall side of the centrifugal chamber, and fall into the bottom of the slag removal box along the gap between the inner wall of the cone and the outer wall of the liquid outlet hopper under the action of its own weight. , so as to realize the separation of metal chips.

Owner:大连元坤机械设备有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com