Conveyor apparatus of metal cutting chip

A technology for metal chips and conveyors, which is applied in the direction of metal processing machinery parts, metal processing equipment, packaging, etc., and can solve problems such as blockage of the discharge port and failure of the coil conveyor device, and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

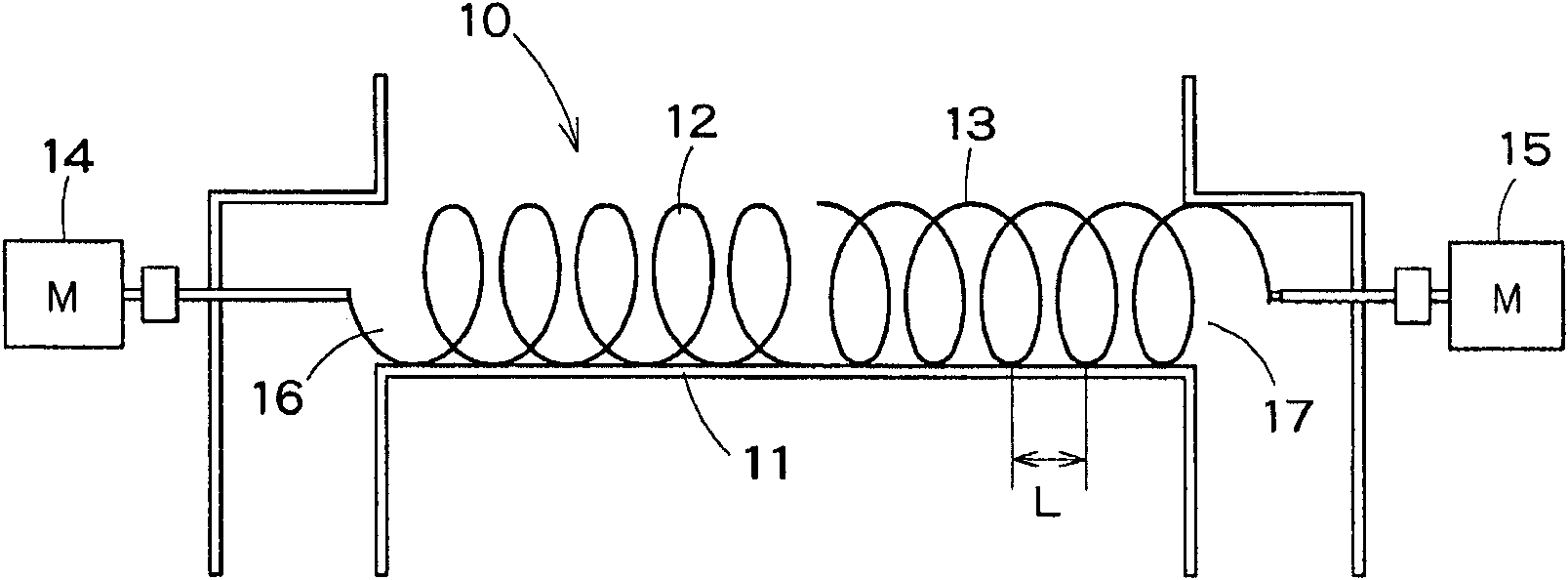

[0025] Next, preferred embodiments of the coil conveyor device of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram of the coil conveyor apparatus which concerns on one Embodiment of this invention. according to figure 1 The coil conveyor device, the metal chips are discharged to the left and right discharge ports. As the coil section, a method of separating the coil on one side and the coil on the other side in which the twist directions are different from each other is adopted.

[0026] More specifically, the coil conveyor device 10 includes a receiving member 11 capable of receiving metal chips from a machine tool or the like, and coil portions 12 and 13 provided inside the receiving member 11 and driven to rotate. The coil section has one side coil 12 and the other side coil 13 whose twist directions are different from each other. One side coil 12 is driven to rotate by a motor 14 , and the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com