Liquid separating device capable of separating liquid from metal chip materials

A metal cutting and deliquoring technology, applied in non-progressive dryers, dryers, lighting and heating equipment, etc., can solve problems such as damage to the health of operators, consumption of heat energy, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

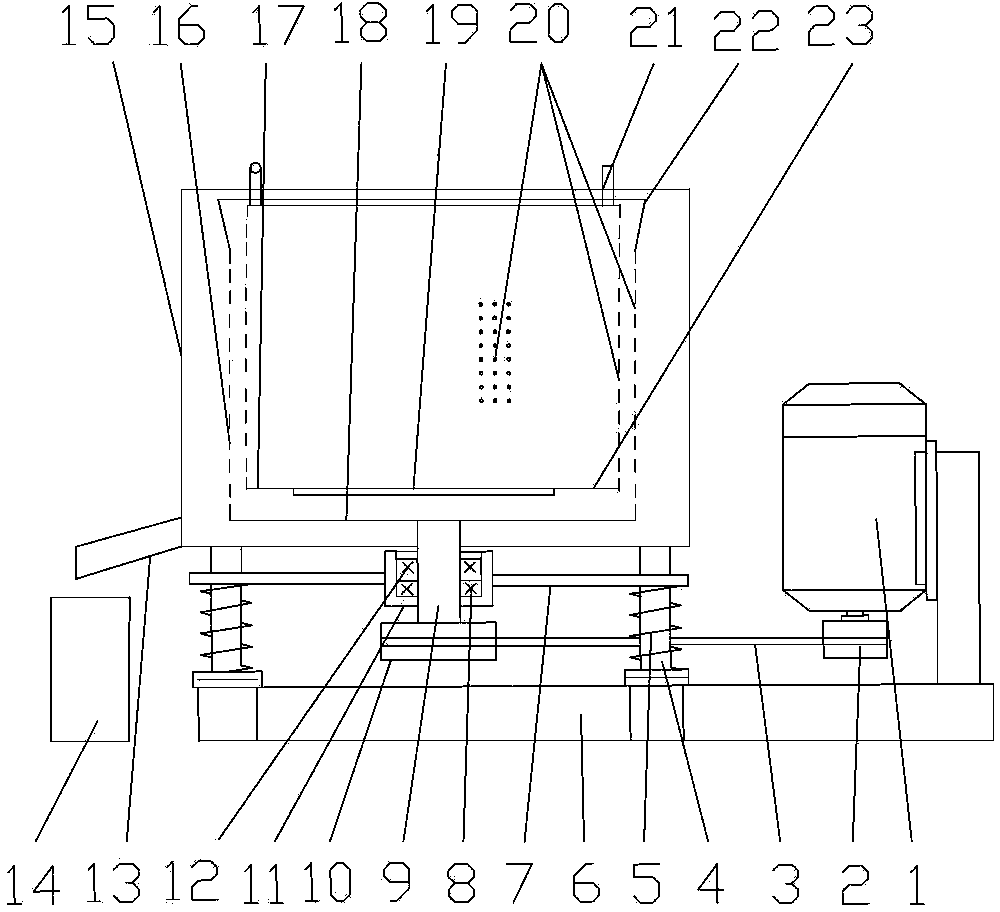

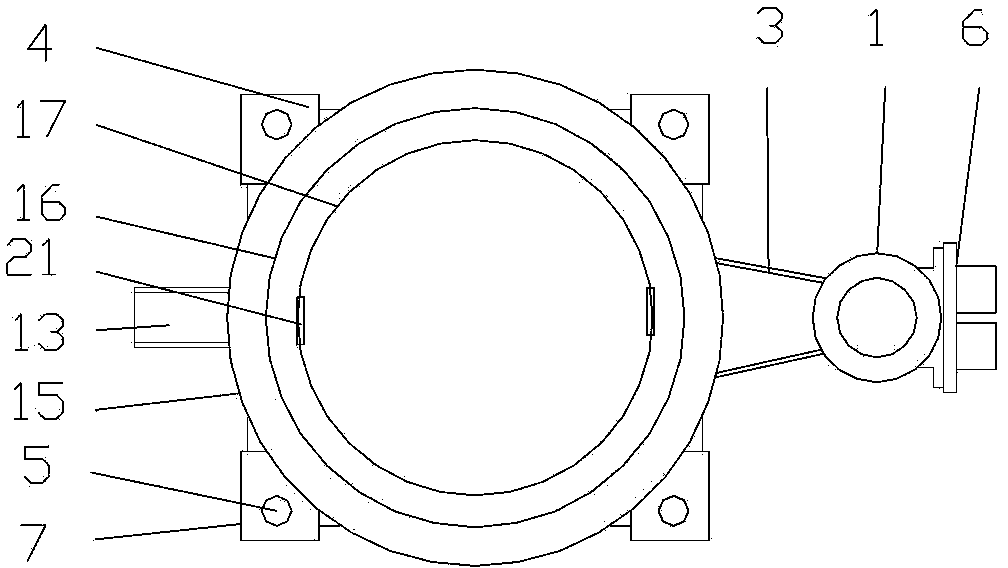

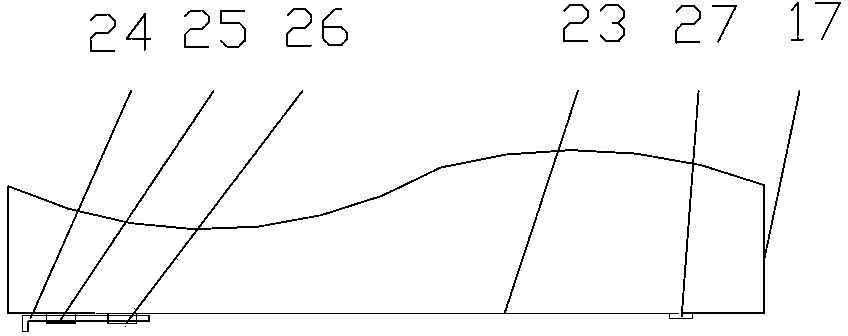

[0013] The embodiment shown in each figure is as follows: a dehydration device capable of dehydrating metal swarf. Four positioning guide posts 4 and the motor 1 are installed on the base 6 . Springs 5 are all sleeved on the four positioning guide posts 4 . Four positioning guide pillars 4 upper ends are equipped with frame 7 and circular outer bucket 15 successively. Frame 7 is contained in spring 5 tops. The liquid outflow pipe 13 is equipped with in the lower part of the circular outer barrel 15 side walls. The bearing block 11 that bearing A8 and bearing B12 are housed in the middle is contained in the middle part of frame 7, and main shaft 9 is contained in the middle of bearing A8 and bearing B12. Main shaft V-belt pulley 10 is equipped with in main shaft 9 bottoms, and motor shaft V-belt pulley 2 is housed on the motor shaft of motor 1 bottom, is connected by V-belt 3 between main shaft V-belt pulley 10 and motor shaft V-belt pulley 2. A perforated cylinder 16 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com