Method for measuring chip deformation

A chip deformation and chipping technology, applied in measuring devices, mechanical thickness measurement, instruments, etc., can solve the problems of no chip curvature measurement, limited application range, large error, etc., to achieve easy measurement and calculation, easy to observe, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

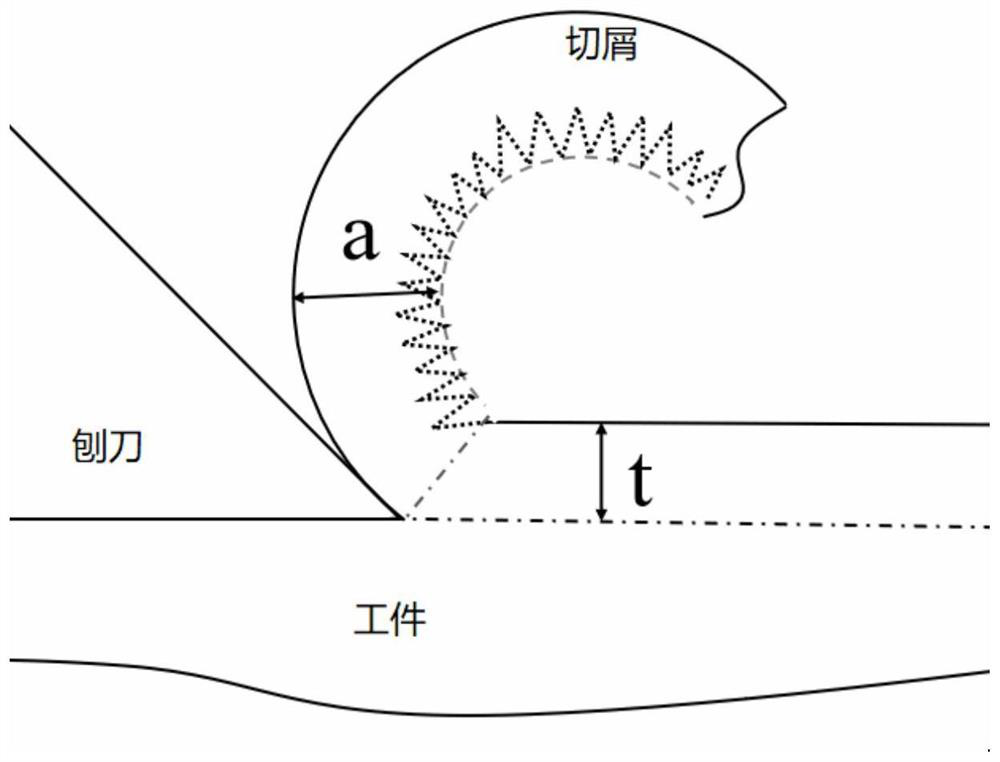

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] The method for measuring chip deformation of the invention has wide application range, and the chip deformation of easy-cut metal materials such as metal aluminum, copper and steel can be measured by the method of the invention. For the shape of the metal material below, select a rectangular plate.

[0035] A method of measuring chip deformation as follows:

[0036] Step 1: In order to facilitate marking on the metal plate and to clearly observe the shape and characteristics of chips, the machined surface of the metal plate is ground and polished in sequence. When grinding, select a plurality of sandpapers with particles ranging from coarse to fine (the particle size number of the sandpaper is selected from 80 to 600 mesh) and repeat it several times in turn; polishing uses a variety of polishing fluids with abrasive particle sizes from large to small (this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com