Clamp for machining inner wall of motor shell of new energy automobile

A new energy vehicle, motor housing technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve the problem of affecting the machining accuracy of the workpiece, reducing the machining accuracy of the workpiece, scratching the inner wall of the workpiece, etc., to increase the processing accuracy. Accuracy, impact reduction, vibration avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

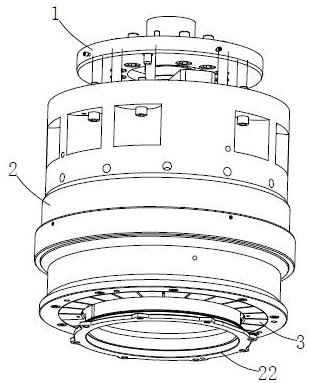

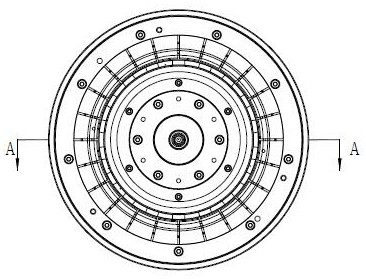

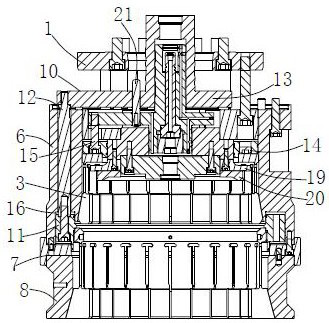

[0031] Such as Figure 1 to Figure 3 As shown, a fixture for processing the inner wall of a new energy vehicle motor housing according to the present invention includes: a turntable 1, which is used to connect a machine tool; a main body assembly 2, which is arranged under the turntable 1, and the main body assembly 2 There are several fixed sleeves 3 movable along the axial direction of the main body assembly 2, and the driving parts arranged on the main body assembly 2. The inner diameter of each fixed sleeve 3 is larger than the outer diameter of the workpiece 22 to be processed, and the driving parts can drive The fixed sleeve 3 is switched between the first position and the second position on the main body assembly 2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com