Shear type metal chip crushing machine

A metal chip and crusher technology, used in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problem that the chip crusher is difficult to meet the demand, and achieve the effect of novel structure, low speed and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

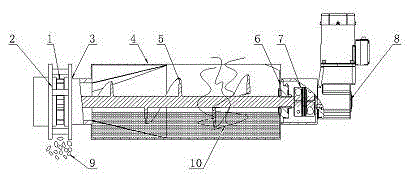

[0016] A scissor-type metal chip crusher, comprising a scissor-type cutter head 1, a left cutter head 2, a right cutter head 3, a main body 4, a screw feeding device 5, a waterproof sealing structure 6, a coupling 7, a driving motor 8, and after crushing Chips 9, chips 10 before crushing, the screw feeding device 5 is set in the main body 4, the left end of the main body 4 is connected to the right cutter head 3 by bolts; the left end of the right cutter head 3 is bolted to the left cutter head 2, the left cutter head 2 and the right cutter head 3 Fixed on the left and right ends of the scissor cutter head 1, the left cutter head 2 and the right cutter head 3 are connected to the screw feeding device 5 through bearings, and the scissor cutter head 1 is set on the bearing; the right end of the main body 4 is connected to the waterproof sealing structure 6 Connection, the drive motor 8 is connected with the screw feeding device 5 through a coupling, and is arranged at the rightmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com