Special device for machining non-circular holes by utilizing common lathe through improvement

A common lathe, non-circular hole technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high processing cost, low production efficiency, and high requirements for workers to operate, save machining costs, improve Machining efficiency and the effect of reducing tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

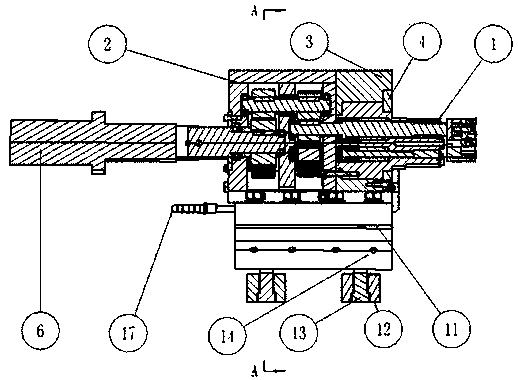

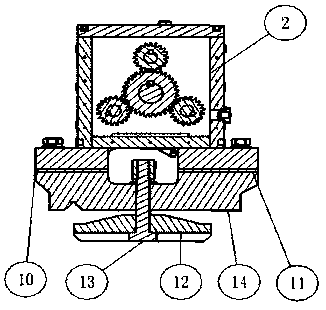

[0031] like figure 1 and figure 2 As shown, the present invention provides a device specially used for processing non-circular holes through transformation of ordinary lathes. Using waste ordinary lathes, the device is fixed on the guide rail of the lathe through the pressing block 12, the fixing screw 13, and the base 14. The sheet group 11 adjusts the center of the central shaft transmission shaft 6 to be coaxial with the center of the lathe main shaft, and then connects the lathe main shaft and the central shaft transmission shaft 6 through the cross shaft and the coupling, as the power input of the device, and the device passes through the gear box part 2. The tool rest part 1 transmits the input power for machining.

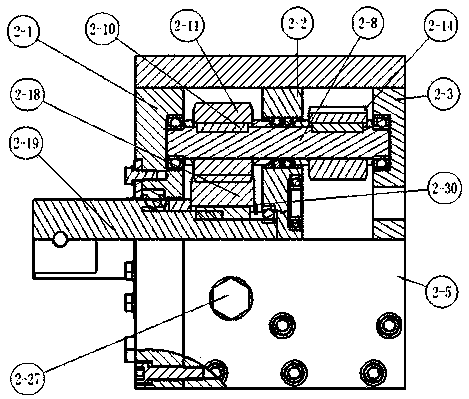

[0032] like image 3 As shown, in the gear box part 2, the power and torque are transmitted from the central shaft 2-19 to the large gear 2-18, and the large gear 2-18 is fixed on the central shaft by the flat key 2-10 and the shaft end retaining ring 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com