Metal chip centrifugal machine

A metal cutting and centrifuge technology, applied in the field of centrifuges, can solve the problems of oil pollution on the ground, residues, adverse effects on the factory environment, etc., and achieve the effect of improving the cleaning effect and reducing the residual amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

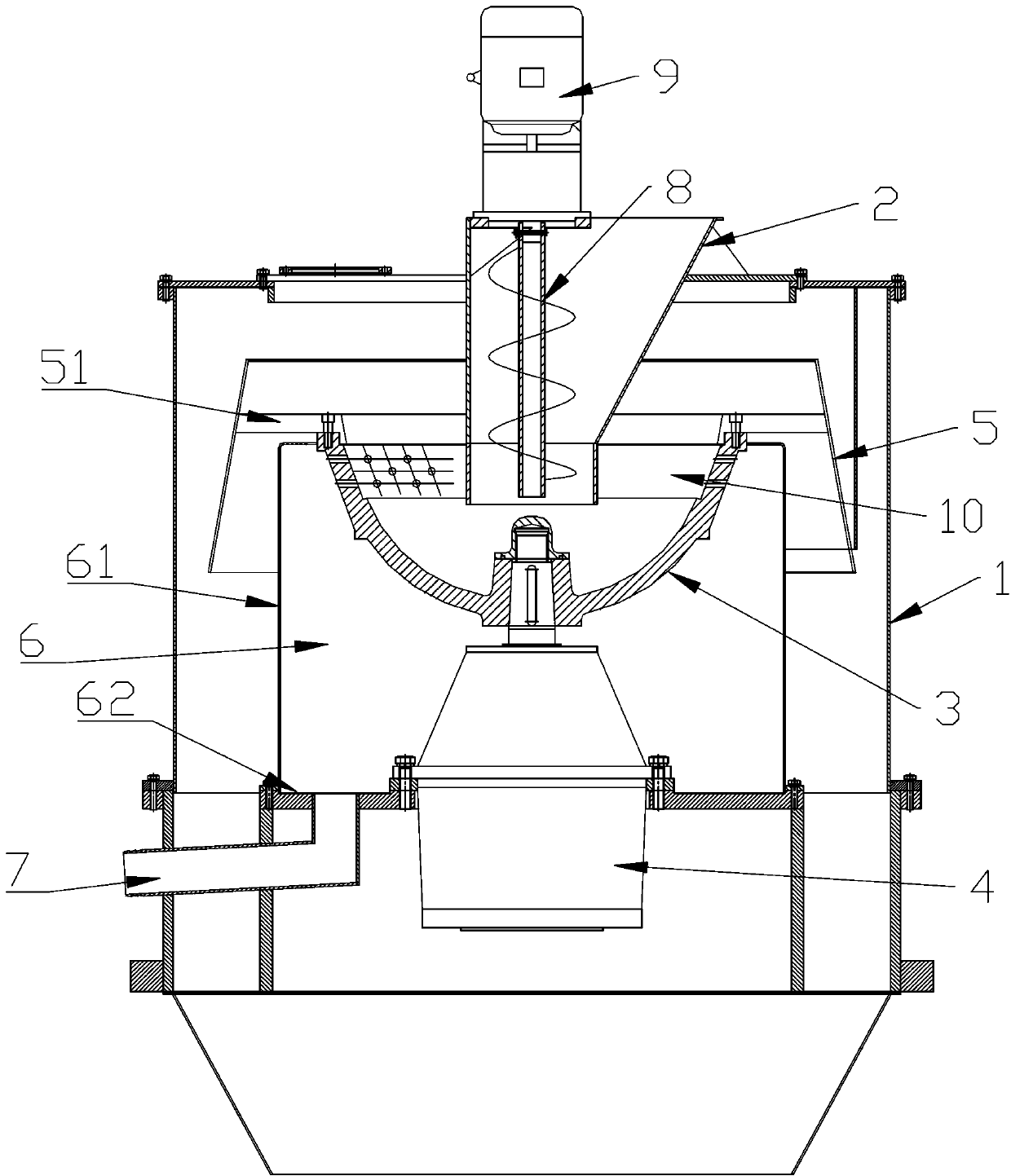

[0021] Such as figure 1 As shown, the metal swarf centrifuge of this embodiment includes a housing 1, the upper part of the housing 1 is provided with a hopper 2, and the lower part of the hopper 2 is provided with an inner basket 3 containing metal swarf to be cleaned. A motor 4 is connected to the bottom of the rotating basket 3 , and an outer rotating basket 5 is arranged on the outside of the inner rotating basket 3 , and the outer rotating basket 5 is fixed to the inner rotating basket 3 and moves with the inner rotating basket 3 .

[0022] In order to facilitate waste oil collection, in this embodiment, the inner basket 3 is provided with a closed cavity 6 outside, and the closed cavity 6 is connected to the outside of the housing 1 through an oil outlet pipe 7 .

[0023] In this embodiment, the inner basket 3 is a bowl-shaped opening upwards; the outer basket 5 is upside down on the inner basket 3; the outer basket 5 is provided with a horizontal annular partition 51, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com