Intelligent chip removal device for metal chip cutting machine tool and control method thereof

A metal chip and chip conveyor technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as damage, shutdown to clean the chip conveyor, blockage of the chip conveyor, etc., to avoid blockage or damage, The effect of reducing the residual probability and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

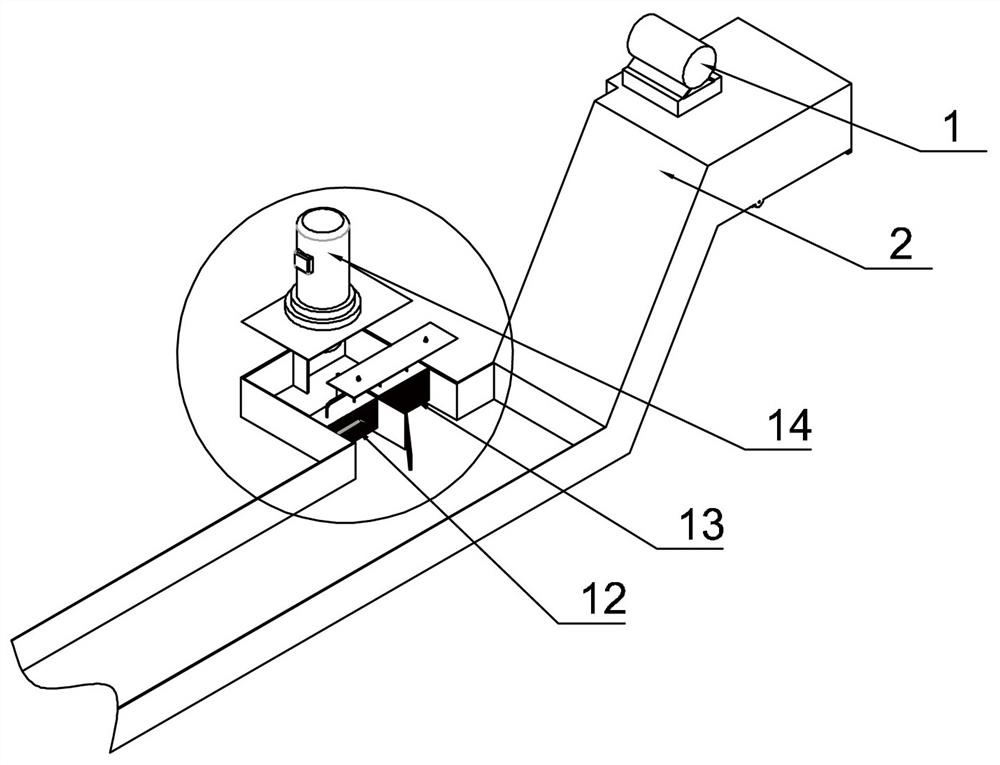

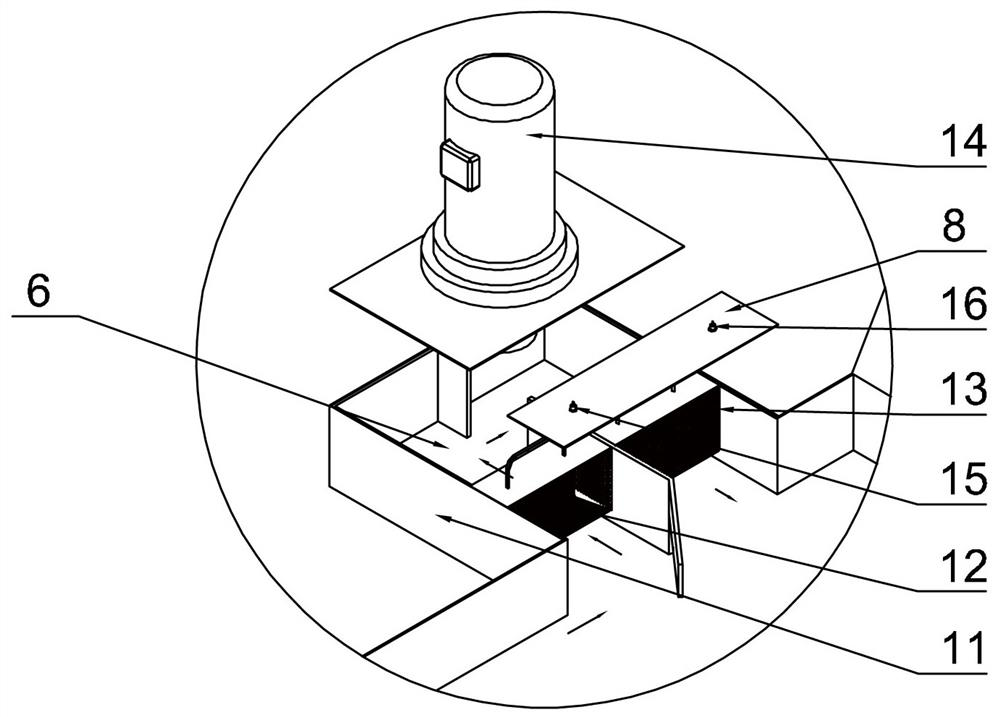

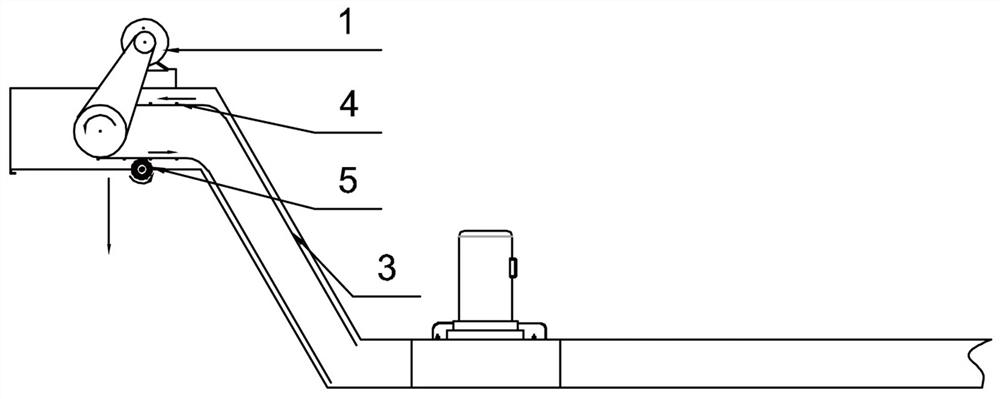

[0026] Such as Figure 1 to Figure 3 As shown, an intelligent chip conveyor for metal chip machine tools includes a chip conveyor belt 3 connected to a chip conveyor 1 through a transmission drive device 1 in a chip discharge channel 2. The transmission drive device 1 uses a servo motor to drive the chip conveyor belt 3. Adjust the chip removal speed; one end of the chip removal channel 2 is at a low horizontal position, with a chip inlet, and the other end is at a high position, with a chip outlet, and the outer wall of the chip removal channel 2 is at a low horizontal position. The flow box 11 of the guide channel 6, the height of the flow box 11 is consistent with the height of the opening, and the upper edge of the opening is higher than the height of the chip mixture in the chip removal channel 2; in the flow guide channel 6 of the flow box 11, I A circulation pump 14 is provided on the top of the flow box 11 for the first-stage filter screen 12 and the second-stage filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com