Chip liquid cooling and separating device and five-axis machining center

A five-axis machining center, cooling and separation technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of small particle size of metal powder, blockage of screen holes, low screening efficiency, etc., to reduce requirements, avoid clogging and inefficiencies, facilitate cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

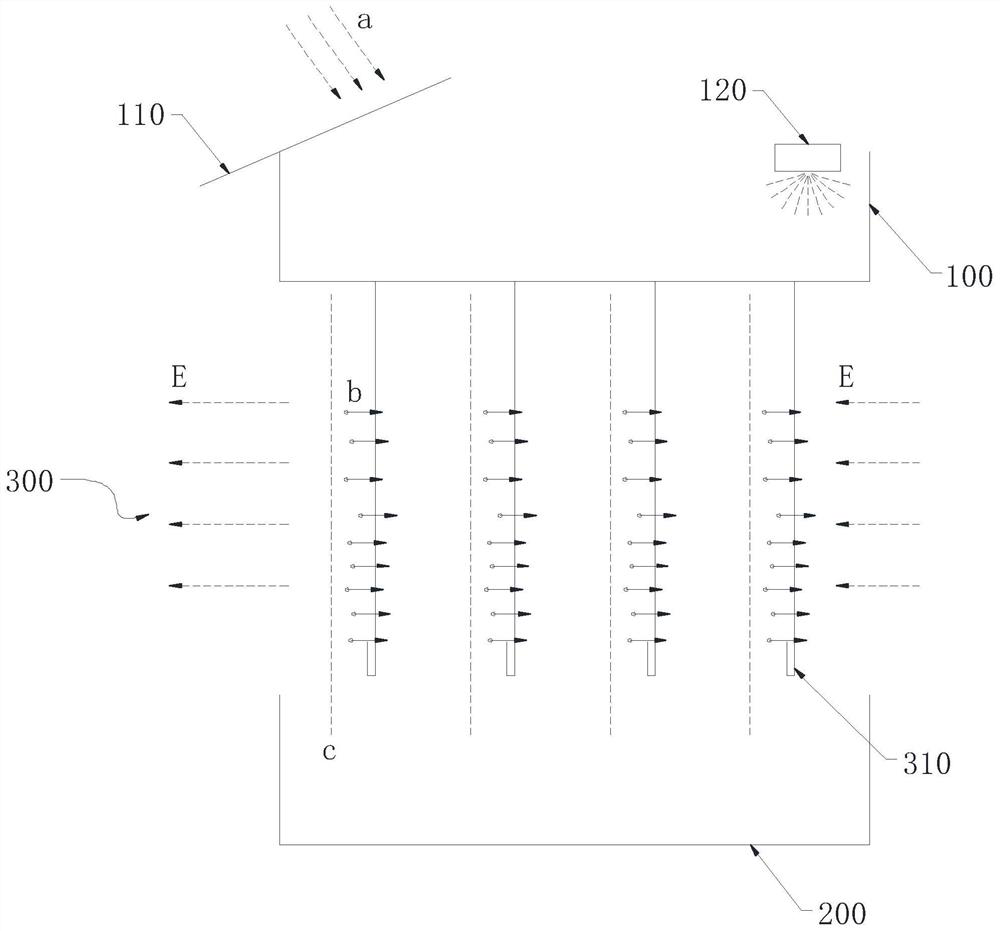

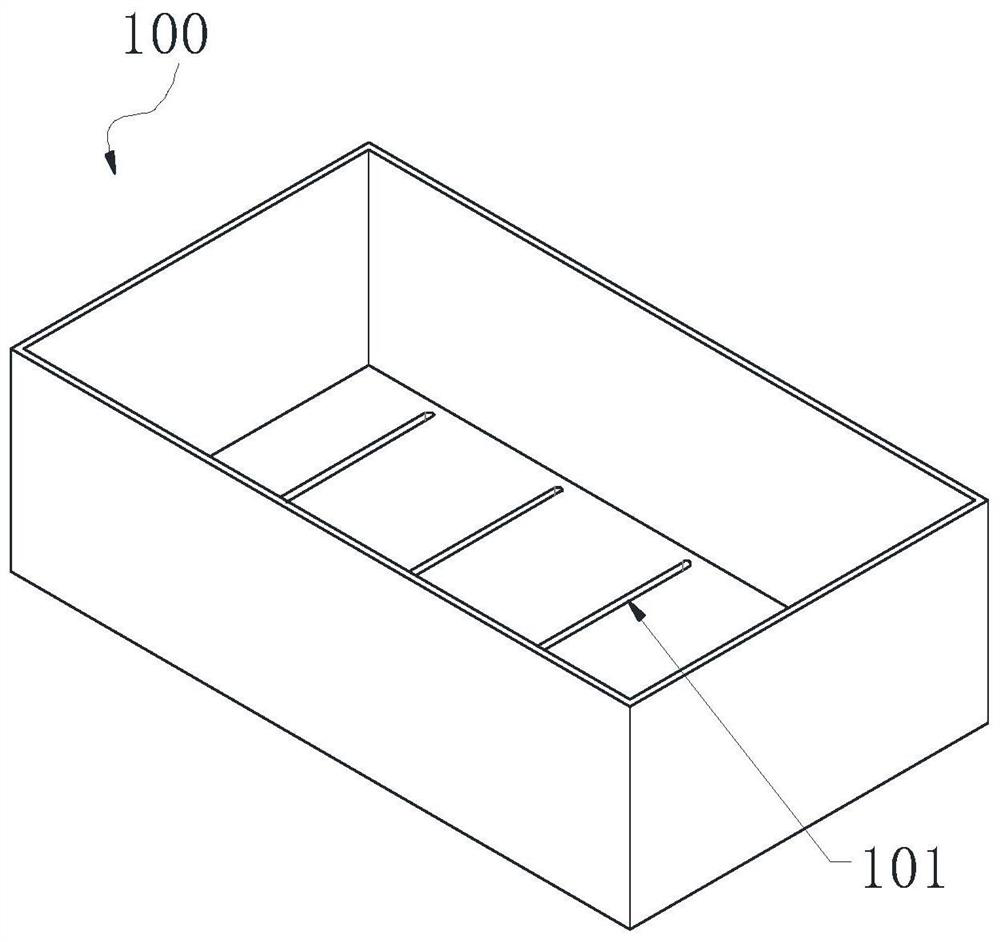

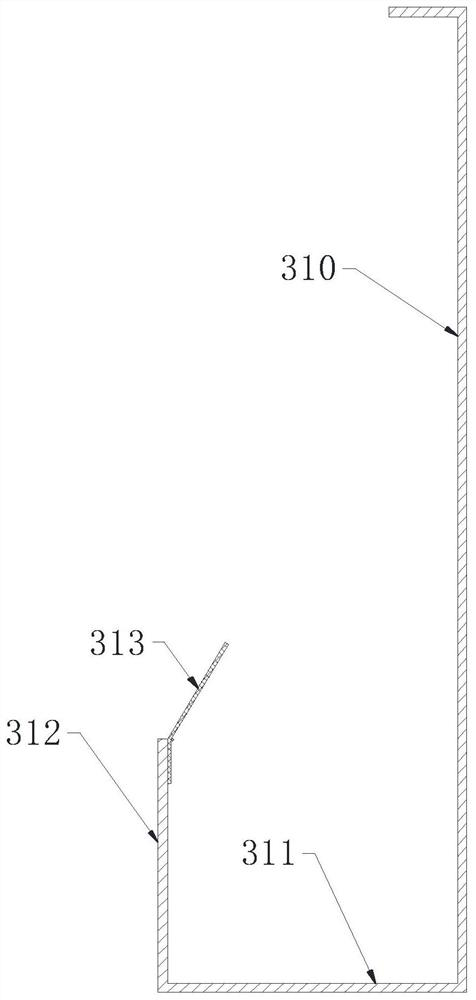

[0026] Such as figure 1 Shown is the chip liquid cooling and separating device of the present invention, the chip liquid cooling and separating device includes a No. 1 liquid collection tank 100 and a No. 2 liquid collection tank 200, wherein the No. Above, the top of the No. 1 liquid collecting tank 100 is also provided with a preliminary screen 110, and an electron gun 120 is installed in the No. 1 liquid collecting tank 100, and an interval is set between the No. 1 liquid collecting tank 100 and the No. 2 liquid collecting tank 200, and An electric field area 300 is provided between the No. 1 liquid collection tank 100 and the No. 2 liquid collection tank 200 , and the bottom of the No. 1 liquid collection tank 100 has a liquid leakage hole 101 .

[0027] The collected cutting fluid is screened through the primary screen 110, such as figure 1 As shown by the arrow a in the middle, the primary screen 110 mainly screens out granular and filamentous metal waste, and the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com