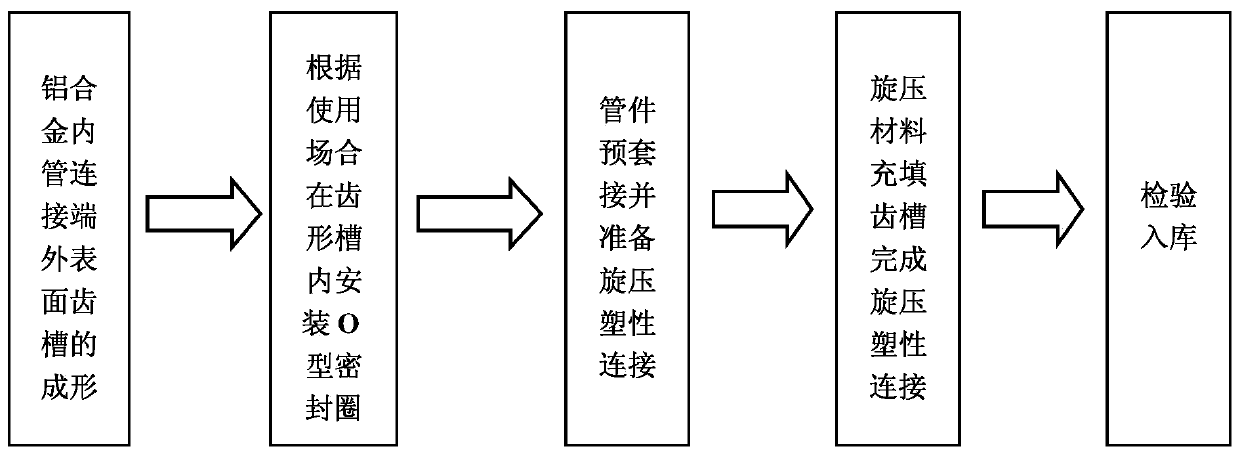

A plastic connection method of aluminum alloy pipe fittings based on spinning

A connection method and aluminum alloy technology, which is applied in non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as pipe crushing and deformation, and achieve reliable connection, simple mold, and less damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] This embodiment is a socket connection between an aluminum alloy outer tube and an aluminum alloy inner tube using a spinning process; the outer diameter×length×wall thickness of the aluminum alloy outer tube is Φ300×500×15mm, and the The outer diameter × length × wall thickness of the aluminum alloy inner tube is Φ280 × 500 × 15mm.

[0055] The concrete process of this embodiment is:

[0056] Step 1. Forming the alveolar grooves on the outer surface of the connecting end of the aluminum alloy inner tube.

[0057] According to the design requirements, a tooth groove is processed on the outer surface of the connecting end of the aluminum alloy inner tube, and the specific operation is as follows:

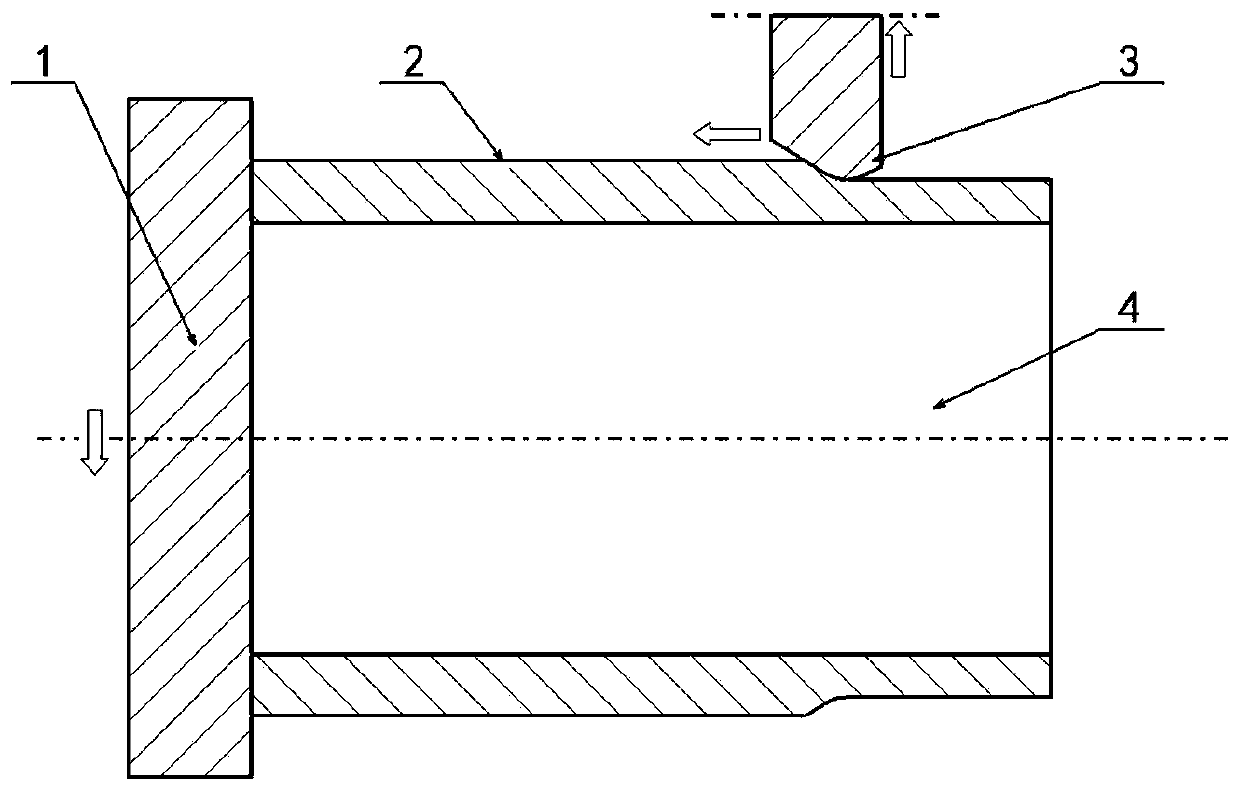

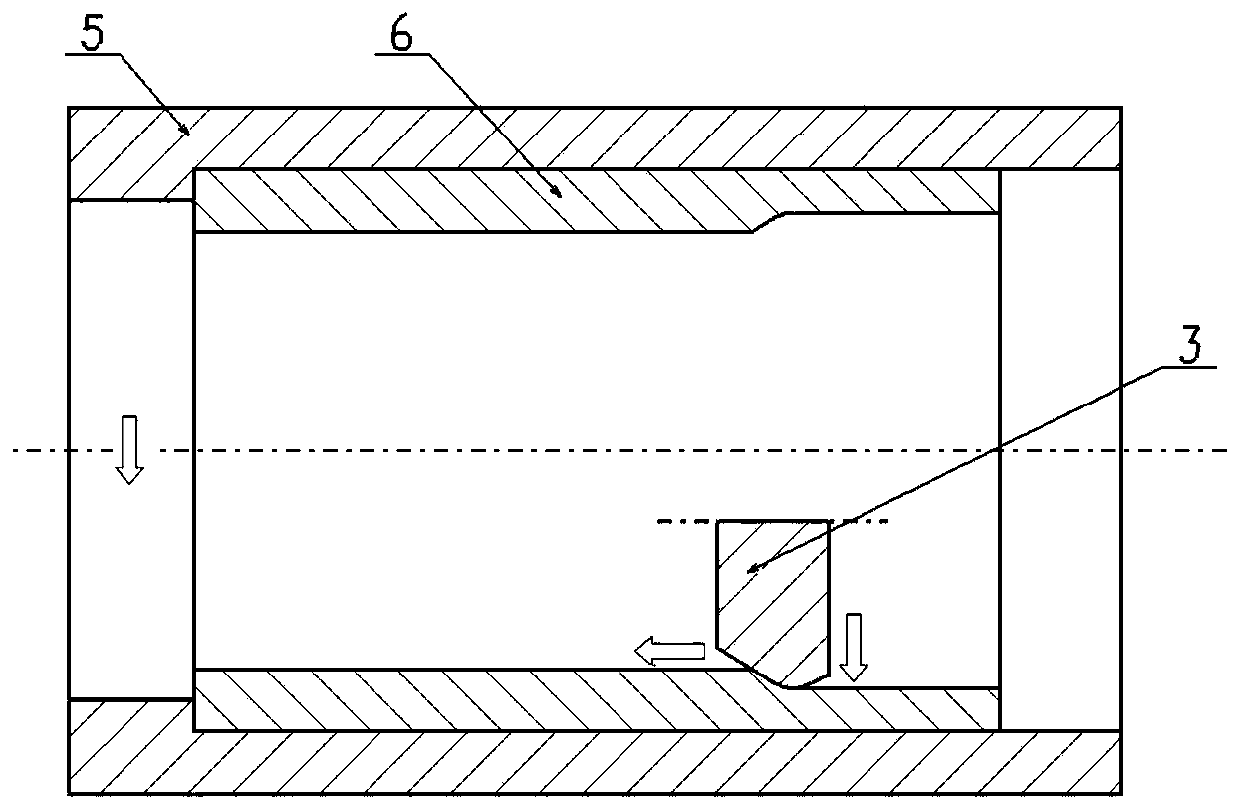

[0058] Ⅰ Install the internal rotation mandrel 5 on the connecting flange 1 of the spindle of the spinning machine tool, put the aluminum alloy inner tube into the inner rotation mandrel, and make the connection end of the aluminum alloy inner tube on the inner rotation mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com